Transcription

Hydraulic FittingThread Identification ManualU.S.A. 2014www.contitech.us

Hydraulics Table of Contents1Introduction3Using the ToolsMeasuring ThreadsMeasuring Thread PitchMeasuring Seat AngleCompare Measurements to Tables4556North American Thread TypesNPTFNPSMJIC 37 Flare (SAE J514)SAE 45 Flare (SAE J512)O-Ring Boss Straight Thread (SAE J514)O-Ring Face Seal (SAE J1453 ORS/ORFS)SAE J514 Flareless Tube FittingCode 61/Code 62/Caterpillar Flange (SAE J518)SAE 45 Inverted Flare (SAE J512)SAE J1467 Clip Fastener79101113151718202324British Thread TypesBSPT (British Standard Pipe Tapered)BSPP (British Standard Pipe Parallel)2526

Hydraulics Table of Contents2French Thread TypesMillimetrique and GAZ 24GAZ Poclain 24 Flange2831German Thread TypesDIN 2353 24 ConeDIN 3863 60 ConeDIN 3852 Types A & BDIN 3852 Type CStandpipe AssemblyDIN 20066 4-Bolt Flange323436445052Japanese Thread TypesJIS 30 (Parallel Pipe Threads)JIS 30 Male Inverted Seat (Parallel Pipe Threads)JIS Tapered Pipe (JIS B 0203)Japanese Komatsu 30 Flare with Metric Threads (JIS B 0207)Komatsu Flange FittingJIS B 8363 4-Bolt Flange545657585960O-Rings62Thread Reference Guide69

Hydraulics Introduction3It is important to properly identify a fitting so that an assembly canbe connected correctly within the hydraulic system. This manualcan be used as a guide in the identification of major thread types,including North American threads, British Threads, French Threads,German Threads and Japanese Threads. The Continental ContiTechThread Identification Kit includes calipers, a North American/Metricthread pitch gauge and seat gauges.To identify a fitting, 1) first select country of origin for the fitting;2) identify the fitting visually, using illustrations in the proper section ofthis manual; 3) measure ID, OD, thread pitch and seat angles using theproper tools; 4) compare measurements to the tables in this manual.Information in this manual supersedes all previously printed material and is current as ofAugust 2014. Due to continual improvements, Continental ContiTech reserves the right to alterproducts and procedures without prior notice. For the most current i nformation, visit us online atwww.contitech.us.

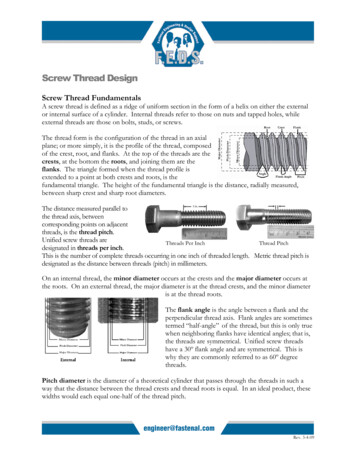

Hydraulics Using the Tools4Measuring Threads and Seat AnglesTools required: ID/OD Calipers, Seat Angle Gauge (English and Metric),Thread Pitch GaugeMeasuring ThreadsA caliper is used to measure the OD of male threads and the ID offemale threads. Measure at the largest point. In some cases, threadsmay be worn, and the exact measurement taken may not matchexactly to the thread charts. For accuracy, it is recommended themale thread be measured.One Source. One System. One Solution.www.contitech.us

Hydraulics Using the ToolsMeasuring Thread PitchA Thread Pitch Gauge is used to determine the number of threadsper inch or the distance between threads in a metric connection.To assure an accurate reading, make sure the fit of the threadgauge is snug.Measuring Seat AngleA Seat Angle Gauge is used to measure the angle of the sealingsurface. For either male or female fittings, place the gauge on thesealing surface. An accurate reading is taken when the gauge isparallel to the centerline of the coupling.5

Hydraulics Using the Tools6Compare Measurements to TablesID/OD measurements, thread pitch and seat angle will be used to identify the fitting. Measurements taken can be used to compare withthe dimensions found on charts in the following pages.As an example, a fitting will be defined as:Continental ContiTech EP B2-NPMX-0606 with 3/8-18 threads.From the hydraulic catalog, the fitting can be identified as a NPTF/MALE/SWIVEL.The -6 fitting has 3/8-18 threads, which can be identified using thecalipers, thread gauge and the following tables.

Hydraulics North American Thread TypesFitting StandardsThere are five basic fitting standards. They are identified as NorthAmerican, British, French, German and Japanese.North American Thread TypesAlso known as American Dryseal Pipe Threads, the thread typesinclude NPTF, NPSF and NPSM.N – NationalF – FuelsT – Tapered ThreadS – Straight ThreadP – PipeM – Mechanical JointPipe threads can be either straight or tapered. The first step inidentifying this fitting is to determine if the thread is parallel (straight)or tapered.Parallel ThreadsTapered ThreadsParallel ThreadsA straight thread is not used for sealing fluids. In this type of fitting, aseal is achieved with an O-Ring, a metal seal or a seat machined into7

Hydraulics North American Thread Types8the end of the fitting. A straight thread can be determined by layinga straightedge against the threads. If all the threads are parallel to the centerline of the fitting, then it is a straight thread.Tapered ThreadsA tapered thread seals by the interference in the engagement ofthe male and female threads. These threads deform when they aretightened, causing metal deformation and a pressure-tight joint.Thread sealants are commonly used in this connection. A taperedthread can be determined by laying a straightedge against the threads.A fitting may also be referred to by its Dash number. The Dash numberis a universal abbreviation for sizing pipe systems. The following chartswill show a Dash number for each fitting. The Dash number comesfrom the dimension of the port of the fitting. It is the dimension in 1/16of an inch. A 3/8” port would be 6/16” or a Dash 6 (-6).in.1/16Dash Sizein.1/16Dash 1f24/16-241/28/16-8232/16-323/412/16-12

Hydraulics North American Thread Types9NPTFMaleFemaleIdentificationNational pipe taperedmechanical, tapered threadSealThe thread is tapered andsealing takes place with thedeformation of the threads. TheNPTF male has a 30-degree seatand will mate with the NPTFfemale, also with tapered threads,but no seat. A thread sealant iscommonly used. A NPTF malewith 30-degree seat will matewith a NPSM female, which hasstraight threads and a 30-degree inverted seat. The sealing takesplace on the 30-degree seat.ApplicationThe NPTF fitting is a drysealthread, commonly used influid power systems but notrecommended by the NationalFluid Power Association forhydraulic applications.

Hydraulics North American Thread Types10NPSMMaleFemaleIdentificationNational pipe taperedmechanical, tapered threadSealBoth male and female have astraight thread and 30-degreeseat and chamfer. The seal takesplace by compression of the30-degree seat on the chamfer.The threads hold the connectionmechanically.ApplicationUsed in fluid power systems.Thread Identification TableNPTF/NPSF/NPSMDash SizeNominalSize (in.)# of Threadsper in.FemaleThread ID (in.)Male ThreadOD 1e11f1x1:-241f11f1113-32211f2e2b

Hydraulics North American Thread Types11SAE Thread TypesJIC 37 Flare (SAE J514)ApplicationSAE specifies use with highpressure hydraulic tubing.MaleFemaleIdentificationStraight threads. Both male andfemale have 37-degree seat.SealThe seal is made on the37-degree flare seat. Thethreads hold the connectionmechanically. Only connect maleSAE 37 with female SAE 37.CommentsCommonly known as JICfittings and found in fluid powersystems. Use caution whenidentifying this fitting, as thethreads are the same as SAEJ512 45-degree in -2, -3, -4, -5,-8 and -10 sizes. The sealingsurface angles are different,however.Thread Identification TableJIC 37 Flare

Hydraulics North American Thread Types12Dash SizeNominalSize (in.)Thread SizeFemale ThreadID (in.)Male ThreadOD 2191c-241f1d-121;1d-3222f-12282f

Hydraulics North American Thread Types13SAE 45 Flare (SAE J512)MaleFemaleIdentificationStraight threads. Both male andfemale have 45-degree seat.SealThe seal is made on the 45-degreeflare seat. The threads hold theconnection mechanically. Onlyconnect male SAE 45 with femaleSAE 45.ApplicationCommonly used in low-pressure,refrigeration and automotivepiping systems, and arefrequently constructed of brassand connected to copper tubing.CommentsUse caution when identifyingthis fitting as the threads are thesame as SAE J512 37-degree(JIC), in -2, -3, -4, -5, -8 and -10sizes. The sealing surface anglesare different, however.Thread Identification TableSAE 45 Flare

Hydraulics North American Thread Types14Dash SizeNominalSize (in.)Thread SizeFemale ThreadID (in.)Male ThreadOD /87/8-1413/167/8-123/41h-1463/641h

Hydraulics North American Thread Types15O-Ring Boss Straight Thread (SAE J514)connection mechanically. Onlyconnect O-Ring boss male withO-Ring boss female.MaleFemaleIdentificationMale fitting hasa straight thread and an O-Ring.The female port has a straightthread and a chamfer to acceptthe O-Ring.SealThe seal takes place bycompressing the O-Ring into thechamfer. The threads hold theApplicationRecommended by the NationalFluid Power Association foroptional leakage control inmedium- and high-pressurehydraulic systems.Thread Identification TableStraight Thread O-Ring Boss

Hydraulics North American Thread Types16DashSizeTubeSize (in.)NominalSize (in.)ThreadSizeFemale Thread Male ThreadID (in.)OD ;1d-3222f2f-12282f

Hydraulics North American Thread Types17O-Ring Face Seal (SAE J1453 ORS/ORFS)the flat face of the female. Thethreads hold the connectionmechanically.MaleFemale SwivelIdentificationMale fitting has a straight threadand an O-Ring. Female has astraight thread and a machinedflat face.SealThe seal takes place bycompressing the O-Ring ontoApplicationFittings are intended for hydraulicsystems where elastomericseals are accepted to overcomeleakage and leak resistance. Thisconnection offers the very bestleakage control.Thread Identification TableO-Ring Face Seal (ORFS)Dash SizeNominalSize (in.)Thread SizeFemale ThreadID (in.)Male ThreadOD 11k-121u1k-201e1m-121y1m-241f2-12132

Hydraulics North American Thread Types18SAE J514 Flareless Tube FittingMaleFemaleIdentificationMale and female have straightthreads. Male has 24-degree seat.SealFemale includes a compressionsleeve for the sealing surface.A seal is formed with thecompression sleeve as thefemale nut is tightened onto themale thread. A seal is formedbetween the compression sleeve,the male 24-degree seat andtubing.ApplicationUsed to adapt steel tubing to ahydraulic hose assembly.Thread Identification TableFlareless Tube Fitting(see table on next page)

Hydraulics North American Thread Types19(SAE J514 Flareless Tube Fitting continued)DashSizeTubeSize (in.)NominalSize (in.)ThreadSizeFemale Thread Male ThreadID (in.)OD ;1d-3222f2f-12282f

Hydraulics North American Thread Types20Code 61/Code 62/Caterpillar Flange (SAE J518)SAE Code 61 and Code 62Male4-Bolt Split FlangeIdentificationThe female port is an unthreadedhole surrounded with 4 boltholes in a rectangular pattern.The male consists of a flangedhead, grooved for an O-Ring, anda flange with holes to match theport.SealThe seal takes place on theO-Ring, which is compressedbetween the flanged head andthe flat surface surrounding theport. The threaded bolts hold theconnection mechanically.ApplicationCommonly used in fluid powersystems, worldwide, and usuallyin connection on pumps andmotors. The fitting is available intwo pressure ratings. Code 61,Form R, PN 35/350 bar, Type I isreferred to as the “standard” seriesand can withstand an operatingpressure of 3000–5000 psidepending on size. Code 62,Form S, PN 415 bar Type II isthe heavy-duty, 6000 psi series.While the design is the same,bolt hole spacing and flangedhead diameters are larger for thehigher pressure Code 62 fitting.CommentsSAE J518, DIN 20066, ISO/DIS 6162 and JIS B 8363 areinterchangeable, except forthe bolt sizes. The -10 is notavailable as an SAE standard size.Caterpillar flanges, which havethe same flange OD as SAE(continued on next page)

Hydraulics North American Thread Types21(Continued)Code 62, have a thicker flangehead, which is the “C” dimensionin the table.How to MeasureMeasure port hole diameterusing calipers. The port holediameter is the Nominal FlangeSize. Measure the longest boltNominal FlangeSize (in.)hole spacing from center tocenter, which is Dimension “B,”or the Flange OD for furtheridentification.Thread Identification TablesCode 61/Code62/CAT Code 61Flange 420.265

Hydraulics North American Thread TypesNominal FlangeSize (in.)22Code 62Flange 01.4373.1250.49523.1251.7503.8120.495Nominal FlangeSize (in.)Caterpillar Code 62Flange .7503.8120.560

Hydraulics North American Thread Types23SAE 45 Inverted Flare (SAE J512)The female has a straight threadand a 42-degree inverted flare.MaleFemaleIdentificationMale fitting, with a straight thread,can either be a 45-degree flare asa tube fitting or a 42-degree seatas a machined adapter.SealThe seal takes place on the flaredsurfaces. The threads hold theconnection in place mechanically.ApplicationFitting is frequently used inautomotive systems.Thread Identification TableSAE 45 Inverted FlareDash SizeNominalSize (in.)Thread SizeFemale ThreadID (in.)Male ThreadOD /87/8-1813/167/8-123/41h-1611h

Hydraulics North American Thread Types24SAE J1467 Clip Fastenerinserted through the two holes,locking the connection together.MaleFemaleIdentificationThe male has an external O-Ringwith a groove to accept a clip. Thefemale has a smooth bore withtwo holes to accept a “U”-shapedclip. With the male fitting insertedinto the female fitting, a clip isSealThe seal is formed between theO-Ring on the male fitting and thesmooth bore of the female fitting.ApplicationCommonly used for hydraulicapplication in undergroundmines.Thread Identification TableSAE J1467 Clip FastenerDash SizeNominal Size (in.) Female Thread ID (in.) Male Thread OD -123/41 9/641 9/64-1611 25/641x-201e1n1n-241f2 11/642r-3222x2 33/64

Hydraulics British Thread Types25British Thread TypesBSPT (British Standard Pipe Tapered)MaleFemaleIdentificationThe British Standard PipeTapered is very similar to theNPTF fitting. Male fitting hasa tapered thread. BSP threadsare also known as Whitworththreads.SealThe BSPT male can beconnected with a BSPT femaleor BSPP female. In eithercase, the seal is made withinthe threads through threaddistortion. A thread sealant isrecommended.CommentsThe BSPT fitting, althoughsimilar to the NPTF fitting, is notinterchangeable. The threadpitch is different in most casesand the thread angle is 55degrees for the BSPT, versusthe 60 degrees found on NPTFthreads.(see table on page 27)

Hydraulics British Thread Types26BSPP (British Standard Pipe Parallel)by compression of the 30-degreeseat on the chamfer. The threadshold the connection mechanically.MaleFemaleFemale PortIdentificationThe British Standard Pipe Parallelwould be similar to the NPSMfitting. BSP threads are also knownas Whitworth threads.SealThe BSPP male will connect withthe BSPP female or female port.Both male and female have astraight thread and 30-degree seatand chamfer. The seal takes placeCommentsThe BSPP fitting, althoughsimilar to the NPSM fitting, is notinterchangeable. The thread pitchis different in most cases and thethread angle is 55 degrees forthe BSPP, versus the 60 degreesfound on NPSM threads.Thread Identification TableBSPT and BSPP(see table on next page)

Hydraulics British Thread Types27(BSPT and BSPP continued)Dash SizeNominalSize (in.)Thread SizeFemale ThreadID (in.)Male ThreadOD 1z-241f1f-11111d-3222-112s2u

Hydraulics French Thread Types28French Thread TypesMillimetrique and GAZ 24 Male 24 ConeFemale 24 ConeFemale Tube FittingIdentificationGAZ fittings have a 24-degreeseat and straight, metric threads.While similar to DIN fittings, theFrench use fine threads on allsizes while the DIN fitting mayhave a coarse thread on thelarger sizes.SealThe French Metric (GAZ) malewith 24-degree seat will matewith the female, 24-degree coneor the female tube fitting.CommentsThe Millimetrique Series is usedwith whole number metric ODtubing and the GAZ Series isused with fractional numbermetric OD pipe size tubing.Thread Identification TableFrench Metric Millimetrique(see table on next page)

Hydraulics French Thread Types29(French Metric Millimetrique Continued)Metric ThreadFemale Thread ID Male Thread ODTube OD(Dia. x Pitch)mmin.mmin.mmin.M 12 x 1.011.00.4312.00.4760.24M 14 x 1.512.50.4914.00.5580.31M 16 x 1.514.50.5716.00.63100.39M 18 x 1.516.50.6518.00.71120.47M 20 x 1.518.50.7320.00.79140.55M 22 x 1.520.50.8122.00.87150.59M 24 x 1.522.50.8924.00.94160.63M 27 x 1.525.51.0027.01.06180.71M 30 x 1.528.51.1230.01.18220.87M 33 x 1.531.51.2433.01.30250.98M 36 x 1.534.51.3636.01.42281.10M 39 x 1.537.51.4839.01.54301.18M 42 x 1.540.51.5942.01.65321.26M 45 x 1.543.51.7145.01.77351.38M 48 x 1.546.51.8348.01.89381.50M 52 x 1.550.51.9952.02.05401.57M 54 x 2.051.92.0454.02.13451.77

Hydraulics French Thread Types30Thread Identification TableFrench Metric GAZ 24 ConeMetricDash Size Thread(Dash)Female Thread Male ThreadIDOD(Dia. x Pitch) mmTube ODin.mmin.mmin.-6M 20 x 1.518.50.7320.00.7813.250.52-8M 24 x 1.522.50.8924.00.9416.750.66-10M 30 x 1.528.51.1230.01.1821.250.83-12M 36 x 1.534.51.3636.01.4126.751.05-16M 45 x 1.543.51.7145.01.7733.501.32-20M 52 x 1.550.51.9952.02.0442.251.66

Hydraulics French Thread Types31GAZ Poclain 24 Flangewith a 24-degree seat is differentfrom an SAE flange in that thereis a lip that protrudes from theflange face.MaleSealThe male flange will connectwith a female flange or port. Theseal is made on the 24-degreeseat.Flange ClampFemaleIdentificationUsually found on Poclainequipment. The Poclain flangeThread Identification TableGAZ Poclain 24 FlangeNominal Size 0.43

Hydraulics German Thread Types32German Thread TypesDIN 2353 24 Coneto measure seat angle as thedimension is taken from thefitting centerline.Male 24 ConeFemale 24 Cone withO-RingFemaleMetric TubeFemaleUniversal24 or 60 ConeIdentificationBoth male and female havestraight metric threads. Themale has a 24-degree seatand a recessed counter borewhich matches the tube ODused with it. The female can beany of three styles includinga 24-degree cone with anO-Ring, a metric tube fitting, ora universal 24- or 60-degreecone. Use a 12-degree gaugeSealSealing takes place between the24-degree seat in the male endand the respective sealing area inthe female end.CommentsThere is a light and heavyversion of this coupling. Properidentification is made bymeasuring the thread size andtube OD. The heavy-duty versionhas a smaller tube OD than thelight-duty version, but has a thickerwall section.Thread Identification TableDIN 2353 24 Cone(see table on next page)

Hydraulics German Thread Types33(DIN 2353 24 Cone continued)Metric ThreadFemaleThread IDMale ThreadODTube ODTube ODLight Series Heavy Series(Dia. x Pitch)mmin.mmin.mmin.M 12 x 1.510.50.41120.4760.24M 14 x 1.512.50.49140.558M 16 x 1.514.50.57160.6310M 18 x 1.516.50.65180.7112M 20 x 1.518.50.73200.79M 22 x 1.520.50.81220.87M 24 x 1.522.50.89240.94M 26 x 1.524.50.96261.02180.71M 30 x 2.028.51.12301.1822M 36 x 2.033.91.33361.4228M 42 x 2.039.91.57421.65M 45 x 2.042.91.69451.77351.38M 52 x 18381.500.59

Hydraulics German Thread Types34DIN 3863 60 ConeMale 60 ConeFemale 24 or60 ConeIdentificationBoth male and female havestraight metric threads. Use a30-degree gauge to measureseat angle as this dimension istaken from the fitting centerline.SealThe male has a 60-degreeseat. The female has a 24- or60-degree seat. The seal takesplace by contact between the60-degree seat in the male endand the respective sealing area inthe female end.Thread Identification TableDIN 3863 60 Cone(see table on next page)

Hydraulics German Thread Types35(DIN 3863 60 Cone continued)Metric ThreadFemale Thread ID Male Thread ODTube OD 60 Cone(Dia. x Pitch)mmin.mmin.mmin.M 12 x 1.510.50.41120.4760.21M 14 x 1.512.50.49140.5580.41M 16 x 1.514.50.57160.63100.39M 18 x 1.516.50.65180.71120.47M 22 x 1.520.50.81220.87150.59M 26 x 1.524.50.96261.02180.71M 30 x 2.028.51.12301.18220.87M 38 x 2.036.51.44381.50281.10M 45 x 2.043.51.71451.77351.38M 52 x 2.050.51.99522.05421.65

Hydraulics German Thread Types36DIN 3852 Types A & BMale TypeAMale TypeBFemale TypesA&BIdentificationBoth male and female, type A(light-duty) and type B (heavyduty) have straight threads.SealThe seal occurs when the ringseal in type A or the face seal intype B connects with the face ofthe female port.Thread Identification TablesDIN 3852 Types A & BL LightMale Metric Thread ParallelTube OD(Dia. x Pitch)Metric ThreadSize (mm)ThreadOD (in.)A (mm) B (mm)C (mm)610 x 1.010141.58812 x 1.512172.0121014 x 1.514192.0121216 x 1.516212.5121518 x 1.518232.5121822 x 1.522273.0142226 x 1.526313.0162833 x 2.033393.0183542 x 2.042493.0204248 x 2.048553.022(continued on next page)

Hydraulics German Thread Types37(DIN 3852 Types A & B continued)S HeavyMale Metric Thread ParallelTube OD(Dia. x Pitch)Metric ThreadSize (mm)ThreadOD (in.)A (mm) B (mm)C (mm)612 x 1.512172.012814 x 1.514192.0121016 x 1.516212.5121218 x 1.518232.5121420 x 1.520353.0141622 x 1.522273.0142027 x 2.027323.0162533 x 2.033393.0183042 x 2.042493.0203848 x 2.048553.022

Hydraulics German Thread Types38Thread Identification TablesDIN 3852 Types A & BL LightTube OD(Dia. x Pitch)Female Metric Thread ParallelMetric Thread Size (mm) Thread ID (in.)A (mm) B (mm)610 x 1.08.5151.0812 x 1.510.5181.51014 x 1.512.5201.51216 x 1.514.5221.51518 x 1.516.5242.01822 x 1.520.5282.52226 x 1.524.5322.52833 x 2.031.5402.53542 x 2.040.5502.54248 x 2.046.5562.5(continued on next page)

Hydraulics German Thread Types39(DIN 3852 Types A & B continued)S HeavyTube OD(Dia. x Pitch)Female Metric Thread ParallelMetric Thread Size (mm) Thread ID (in.)A (mm) B (mm)612 x 1.510.5181.5814 x 1.512.5201.51016 x 1.514.5221.51218 x 1.516.5242.01420 x 1.518.5262.01622 x 1.520.5282.52027 x 2.025.5332.52533 x 2.031.5402.53042 x 2.040.5502.53848 x 2.046.5562.5

Hydraulics German Thread Types40(DIN 3852 Types A & B continued)L LightMale Whitworth Thread Parallel (BSPP)Tube OD(Dia. x Pitch)Metric ThreadSize (mm)ThreadOD (in.)A (mm) B (mm)C e-111z493.020421f-111d553.022(continued on next page)

Hydraulics German Thread Types41(DIN 3852 Types A & B continued)S HeavyMale Whitworth Thread Parallel (BSPP)Tube OD(Dia. x Pitch)Metric ThreadSize (mm)ThreadOD (in.)A (mm) B (mm)C 301e-111z493.020381f-111d553.022

Hydraulics German Thread Types42(DIN 3852 Types A & B continued)L LightTube OD(Dia. x Pitch)Female Whitworth Thread Parallel (BSPOR)Metric Thread Size (mm) Thread ID (in.)A (mm) B 5421f-1111562.5(continued on next page)

Hydraulics German Thread Types43(DIN 3852 Types A & B continued)S HeavyTube OD(Dia. x Pitch)Female Whitworth Thread Parallel (BSPOR)Metric Thread Size (mm) Thread ID (in.)A (mm) B 5381f-1111562.5

Hydraulics German Thread Types44DIN 3852 Type CSealThe male will only connect withthe female as shown. The sealtakes place on the threads.MaleFemaleIdentificationBoth male and female havetapered threads and are availablein metric and Whitworth threads.CommentsType C couplings are availablein extra light (LL), light (L) andheavy (S).Thread Identification TablesDIN 3852 Type CLL Extra LightTube OD(Dia. x Pitch)Male Metric Tapered ThreadsMetric Thread Size (mm)A (mm) B (mm)Thread OD (in.)48 x 1.08.408858 x 1.08.4088610 x 1.010.40810810 x 1.010.40810(continued on next page)

Hydraulics German Thread Types45(DIN 3852 Type C continued)L LightTube OD(Dia. x Pitch)Male Metric Tapered ThreadsMetric Thread Size (mm)A (mm) B (mm)Thread OD (in.)610 x 1.010.40810812 x 1.512.5312121014 x 1.514.5312141216 x 1.516.5312161518 x 1.518.5312181822 x 1.522.651422S HeavyTube OD(Dia. x Pitch)Male Metric Tapered ThreadsMetric Thread Size (mm)A (mm) B (mm)Thread OD (in.)612 x 1.512.531212814 x 1.514.5312141016 x 1.516.5312161218 x 1.518.5312181420 x 1.520.6514201622 x 1.522.651422

Hydraulics German Thread Types46(DIN 3852 Type C continued)LL Extra LightTube OD(Dia. x Pitch)Female Metric Tapered ThreadsMetric Thread Size (mm)Thread ID (in.)A (mm)48 x 1.06.55.558 x 1.06.55.5610 x 1.08.55.5810 x 1.08.55.5L LightTube OD(Dia. x Pitch)Female Metric Tapered ThreadsMetric Thread Size (mm)Thread ID (in.)A (mm)610 x 1.08.55.5812 x 1.510.58.51014 x 1.512.58.51216 x 1.514.58.51518 x 1.516.58.51822 x 1.520.510.5(continued on next page)

Hydraulics German Thread Types47(DIN 3852 Type C continued)S HeavyFemale Metric Tapered ThreadsTube OD(Dia. x Pitch)Metric Thread Size (mm)Thread ID (in.)A (mm)612 x 1.510.58.5814 x 1.512.58.51016 x 1.514.58.51218 x 1.516.58.51420 x 1.518.510.51622 x 1.520.510.5LL Extra LightTube OD(Dia. x Pitch)Male Whitworth Tapered ThreadsMetric Thread Size (mm)A (mm) B (mm)Thread OD 1/881/8-280.39281/8

Hydraulics German Thread Types48(DIN 3852 Type C continued)L LightTube OD(Dia. x Pitch)Male Whitworth Tapered ThreadsMetric Thread Size (mm)A (mm) B (mm)Thread OD 0.839141/2S HeavyTube OD(Dia. x Pitch)Male Whitworth Tapered ThreadsMetric Thread Size (mm)A (mm) B (mm)Thread OD 40.839141/2(continued on next page)

Hydraulics German Thread Types49(DIN 3852 Type C continued)LL Extra LightTube OD(Dia. x Pitch)Female Whitworth Tapered ThreadsMetric Thread Size (mm)Thread ID (in.)A 1/8-2811/325.5L LightTube OD(Dia. x Pitch)Female Whitworth Tapered ThreadsMetric Thread Size (mm)Thread ID (in.)A 123/8-1919/328.5151/2-143/48.5181/2-143/410.5

Hydraulics German Thread Types50(DIN 3852 Type C continued)S HeavyTube OD(Dia. x Pitch)Female Whitworth Tapered ThreadsMetric Thread Size (mm)Thread ID (in.)A dpipe tionA metric standpipe is comprisedof three components attached toa male fitting. The componentsare a standpipe, a bite sleeve anda metric nut.CommentsThe bite sleeve and standpipeare selected on the basis of tubeOD. A DIN light metric nut orheavy metric nut can also be selected.(see table on next page)

Hydraulics German Thread Types51Thread Identification TableMetric Standpipe AssemblyMetric Nut ThreadMetric DIN TubeOD (mm)Bite Sleeve DINTube OD (mm)66M 12 x 1.588M 14 x 1.5M 16 x 1.51010M 16 x 1.5M 18 x 1.51212M 18 x 1.5M 20 x 1.51515M 22 x avyM 24 x 1.5M 26 x 1.5M 30 x 2.0M 30 x 2.0M 36 x 2.0M 36 x 2.0M 42 x 2.0M 45 x 2.0M 52 x 2.0M 52 x 2.0

Hydraulics German Thread Types52DIN 20066 4-Bolt FlangeFlange Head4-Bolt Split FlangeIdentificationThe female port is an unthreadedhole surrounded with 4 boltholes in a rectangular pattern.The male consists of a flangedhead, grooved for an O-Ring,and a flange with holes to matchthe port.SealThe seal takes place on theO-Ring, which is compressedbetween the flanged head andthe flat surface surrounding theport. The threaded bolts hold theconnection mechanically.CommentsThere are two pressure ratings.Form R is similar to SAE Code61 and is referred to as the“standard” series. Form S issimilar to SAE Code 62 and isreferred to as the “heavy-duty”series. The design concept isthe same, but bolt diametersand flange head diam

O-Ring Boss Straight Thread (SAE J514) Identification Male fitting has a straight thread and an O-Ring. The female port has a straight thread and a chamfer to accept the O-Ring. Seal The seal takes place by compressing the O-Ring into the chamfer. The threads hold the connection mechanicall