Transcription

VERIFICATION & TESTING STRATEGIESFOR COMPLIANCE WITH ISO13485:2016, IEC 62304 / 60601-1 /82304-1AUGUST 6TH, 2020WEBINAR

MEDICAL DEVICE QUALITY IS ALL WE DO,AND WE’RE ALWAYS AHEAD OF THE GAME

Rook Quality Systems is a consulting firm dedicated to helping startup to midsized medical device companies develop and maintain effective and efficientquality systems.Rook QualitySystemsWe provide specialized and custom consulting services for all classes ofmedical devices, including medical software and combination devices.Quality SystemDesignDHF/ TFCreationAudit SupportSoftwareValidationDesign ControlRiskManagementRegulatorySubmissionSupport (Int’l)Quality SystemTraining

KYLE ROSE, PRESIDENTMedical Device expert specializing in development of efficient Quality Systems for smalland startup medical device companiesIntro toKyle RoseWorks as the contract Quality Manager for multiple medical device companiesoverseeing overall quality strategy and ensuring compliance through documentationand auditing servicesCertified quality auditor with regulatory and audit experience for a variety of marketsincluding FDA, CE Mark, MDSAP, and CFDAServes as a quality mentor to many medical device incubators around the worldRook Quality encourages the simplification of Quality Systems to reduce the qualityburden and improve compliance through training and efficient QS designGreenlight GuruVerification and ValidationPost Market Surveillance &PMCFComplaint HandlingProduct DevelopmentMedical Device SoftwareValidationQuality System DevelopmentISO 13485:2016, 21 CFR 820, MDDand MDR, ISO 14971Design ControlRisk ManagementCorrective andPreventative ActionsInternal and Supplier Audits

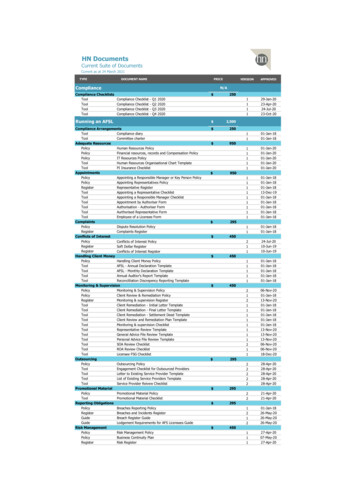

1. Overview of Medical Device Testing2. How to Identify TestingWebinarOutline3. External Testing Laboratories4. IEC 60601 / 610105. Software Testing IEC 620346. Internal Bench Testing7. What to do if you fail8. Ongoing Testing / Questions

Design and development verification Design and development verification shall be performed inaccordance with planned and documentedOverview ofMedicalDeviceTesting arrangements to ensure that the design and developmentoutputs have met the design and development input requirements. The organization shall document verification plans that includemethods, acceptance criteria and, as appropriate, statistical techniques with rationale for samplesize. If the intended use requires that the medical device beconnected to, or have an interface with, other medical device(s), verification shall include confirmation thatthe design outputs meet design inputs when so connected or interfaced.

Overview ofMedicalDeviceTesting FDA 21 CFR 820.30 Design verification Each manufacturer shall establish andmaintain procedures for verifying the devicedesign. Design verification shall confirm thatthe design output meets the design inputrequirements. The results of the designverification, including identification of thedesign, method(s), the date, and theindividual(s) performing the verification,shall be documented in the DHF.

Design ControlUser Needsare met21 CFR 820.30ISO 13485:2016 section 7.3Clinical EvidenceSpecificationsHow your inputs are metDesign OutputsProof of Specificationeet InputsValidationDesign InputVerificationBench testingOutputsmDesignValidationGeneric NeedsHow your needs are metsutnptIeeUser NeedssmuttpOuDesignPlanning

Overview of Medical Device TestingTest ProtocolExecuteProtocol Designed to showhow Design Outputsmeet Design Inputs Define testingprocess Define sample sizeand acceptancecriteriaReport Summarizetesting data Capture testresults Results of test Capture anydeviations

How toIdentifyTesting Design Traceability Matrix - Verify Inputs meetOutputs Determine regulatory requirements for specificdevice Identify if the regulatory testing applies to yourdevice Discuss with testing lab Confirm testing plan if unsure (pre-submissionmeeting)

How to Identify TestingDesign Traceability Matrix - Verify Inputs meet OutputsCreate designinputs/softwarerequirements for yourdeviceIf you are unsure of thespecifications or tolerancescreate testing protocols todetermine specificationsEnsure theinputs/requirements canbe tested or verified

How toIdentifyTesting Regulatory Requirements Identify the product code for your device Search product code on the FDA websiteand identify consensus standards. Purchase Standards – Review thestandards in detail Review FDA website to identify any FDAGuidance documents related to yourdevice Review Predicate Devices

How toIdentifyTesting Regulatory Requirements Review Consensus Standards, GuidanceDocs, and Predicates to determine if thestandard applies to your device There may be situations where you canjustify not doing testing using variousmethods Risk Review Materials/components already tested tostandard

Discuss with Testing Lab Determine if any of the testing willrequire external laboratories to completeExternalTesting 60601/61010 FCC/Wireless Co-existence testing Biocompatibility Discuss strategies and requirements oftesting with the test lab Confirm sample size

ExternalTesting Get multiple quotes from testing labs Compare quotes and discuss timelines Confirm if possible that all testing will becompleted at the same facility Determine timelines for testing and documentreview Implement testing

IEC 60601Testing Requirement for electrical medicaldevices Multiple components of the 60601standard that need to be reviewed Testing is just part of the certification Risk Management File reviewed in detail IFU and Label reviewed in detail

IEC 60601Testing Requirement for electrical medicaldevices Multiple components of the 60601standard that need to be reviewed Testing is just part of thecertification Risk Management File reviewed indetail IFU and Label reviewed in detail

Review to see if additionalsections of the standard arerequired for your deviceIEC 60601Testing 60601-1-11 Home Use Device 60601-1-3 X-Ray Systems 60101-1,2 Electrical LabEquipment (Diagnostic Devices) 80601-2-56 Clinical Thermometer

IEC 60601TestingProcess Review quotes and agree to tests tobe completed Ship devices for testing (multiple,may be destructive) Submit RMF, IFU, Label Submit documentation for devicecomponents, data sheets, materialspecifications, antenna

Complete required paperworkto begin testingIEC 60601TestingProcess insulation diagramessential performanceclassificationrisk checklists Begin testing Review Report

Software V&V: How it fits into theSoftware LifecycleRisk-basedQualification andClassificationRequirementDefinitions (URS,SRS, SDS)ImplementationVerification andValidationRelease andDeploymentMaintenanceand UpdateCreate Requirement Specifications User Requirement Specifications Describe how software integrateswith clinical workflow Software Requirement Specifications Frontend Backend Risk control measures Non-functional Algorithm performance Data requirements Software design Specifications Architecture design decisions basedon URS, SRS, and risks.

Software V&V: Verification PlanningRisk-basedQualification andClassificationRequirementDefinitions (URS,SRS, SDS)ImplementationVerification andValidationRelease andDeploymentMaintenanceand Updatev Structured such that the developed softwaremeets the defined requirementsv Verification should be considered whenrequirements are being developed (high-level) IEC 62304 Testing Identify Risk Classification per IEC 62304 Test coverage driven by risk profile Unit, integration & system level Verification Planning Primary purpose to look into defects Defect tracking method needs to beidentified up front Acceptance criteria clearly laid out for eachtest case planned

Software V&V ExecutionRisk-basedQualification andClassificationRequirementDefinitions (URS,SRS, SDS)ImplementationVerification andValidationRelease andDeploymentMaintenanceand Update Ideally, requirements should be implementedbefore beginning software verification Test Cases Establish entry and exit criteria to definewhen test execution can begin and end Test Environment should be detailed tocapture intended use scenario Test assumptions should outline anypreparation steps needed to produce theexpected results in the test case Validation Scenarios cover the clinical user andenvironment Acceptable failure behavior

InternalBenchTesting Perform all identified testing on a finished device design, or anaccurate prototype of the device, not on a device that is still underdevelopment and subject to design changes Determine Master Testing Plan Testing of your device's design outputs/specifications Such as: Mechanical and Bioengineering performance Example: Fatigue, wear, tensile strength, compression, andburst pressure; bench tests using ex vivo, in vitro, and in situanimal or human tissue; and animal carcass or humancadaveric testing Testing identified through Risk Assessments Testing per applicable device specific regulatorystandards/guidance doc Testing Documentation Test Protocols & Test Report Templates to be used during testing Final Test Reports & Summaries to be included in yourpremarket submission

Define your Test Objectives (specifications or compliance to aregulatory standard/guidance) Determine Sampling ParametersInternalBenchTestingElements Sample: Entire device/a part or component/attribute of the device Is it the final/finished device subjected to all manufacturing processes? If not, justify why this approach is appropriate given any differences thatmay impact performance of the tested device Sample Size: Based on Test Objectives, Risk Analysis, Sampling Plan or asdescribed in the standard/guidance Describe sample configuration, how samples represent a clinicallyrelevant scenario and how inter and intra lot variability are accountedfor Determine Pass/Fail Criteria (when applicable) Should be Pre-Defined: Based on performance needs & intended use ofthe device For characterization tests without an acceptance criteria, determineassessment criteria

Determine Data Analysis Plan Planned Qualitative and/or Quantitative Assessments Test ResultsInternalBenchTesting Present data collected for all samples (including outlying results) in datasheets or tables Accompanied by summaries, statistical information, additional images,rounding methods Data Analysis Conclude with if acceptance criteria were met and describe potentialreasons of failure Determine if re-testing is required, describe test protocol deviations andassess impact on test results Discussion/Conclusions Discuss conclusions drawn from test results with respect to statedobjectives Whether pre-specified acceptance criteria were met

oSummarize failure in the test reportoDetermine the root cause of the failureWhat to do ifyou Fail?oIdentify how to edit device or software for abetter resultoCapture changes in design file (DesignInput/Output changes)oConduct re-testingoRepeat as necessary

OngoingDesignChanges andTestingoCapture changes in design file (DesignInput/Output changes)oUtilized design traceability matrix anda risk assessment to determine ifadditional verification testing is neededoJustify reasons for not testingoUpdate DHF with new outputs andtestingoTrack changes in ECO, Software ChangeprocessoRelease new design

Questions?www.RookQS.comContact info@rookqs.com for more questions,comments, or to set up a meeting. One of ourconsultants will be sure to reach out to assist!kyle.rose@rookqs.com

13485:2016, IEC 62304 / 60601-1 / 82304-1 AUGUST 6TH, 2020 WEBINAR. MEDICAL DEVICE QUALITY IS ALL WE DO, ANDWE’REALWAYSAHEADOFTHEGAME. Rook Quality Systems Rook Quality Systems is a consulting firm dedicated to helping startup to mid-sized medical devi