Transcription

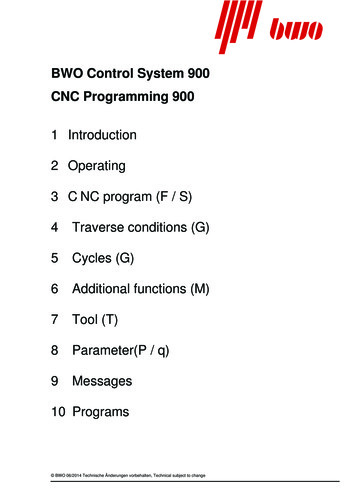

BWO Control System 900CNC Programming 9001 Introduction2 Operating3 C NC program (F / S)4Traverse conditions (G)5Cycles (G)6Additional functions (M)7Tool (T)8Parameter(P / q)9Messages10 Programs BWO 06/2014 Technische Änderungen vorbehalten, Technical subject to change

CNC 900INTRODUCTION1.Introduction1.1Hardware construction1-21.1.1Modules1-21.1.2Examples of CNC controllers1-41.1.3Operating panels1-61.2Software construction1-91.2.1Overall view1-91.2.2Software input with operating panel CNC 910 / CNC 920 / RC 9101 -101.2.3Software programs CNC 910 / CNC 920 / RC 9101 -121.2.4Software input with operating panel CNC 9001 -141.2.5Software input with operating panel CNC 900 C1 -151.2.6Software programs CNC 900 / CNC 900 C1 -161.3Software - components / - version check / - update1 -181.3.1Operating panels1 -181.3.2CNC CPU1 -191.3.3PLC CPU1 -241.4Notes for the line-up1 -251.5CNC funktions1 -30Edition 03.20041-1

CNC 9001.1INTRODUCTIONHardware constructionThe control system 900 consists of two components:- chassis with slots for the plug-in modules- operating panel in the housing or with planner front for the cabinet installation1.1.1ModulesEnvironment conditionsOperating temperatureStorage temperatureDampness0 to 50 c-10 to 60 c10 to 90 %, non-condensingChassiswith 1, 2, 4 and 8 slots for the accommodation of the modules.The individual chassis can by plugging together to be line up.Back-up battery PBBus termination BABuffering the RAM Memory ( 3,6V)Termination of the internal bus systemPower packs 5V / 4A 5V / 8A 5V / 16A 5V / 24ANG 4NG 8NG 16NG 24and 15V / 0,2Aand 15V / 0,5Aand 15V / 1Aand 15V / 1,5AChassis with 1 slotChassis with 1 slotChassis with 2 slotsChassis with 2 slotsCentral processing unitsCNC 32Bit / 64Bit ETHfor all CNC and PLC Functions,user memories 1,5MB / 3MB for NC programs and parameters,flag memory 60kB.CNC 32Bit / 64Bitfor all CNC Functionsas well as alternatively for integrated / all PLC functions,user memories 1,5MB / 3MB for NC programs and parameters,flag memory 60kB.PLC 16k / 64kHigh performance RISC processor for all PLC Functions as well asNC functions with POS modules,Flag memory 60kB, Program memory for 16k / 64k of instruction.1-2Edition 03.2004

CNC 9001.1.1INTRODUCTIONModules (continuation)Axis modulesAxis moduleAxis moduleAxis moduleAAZ1AAZ2AAZ4passively, for 1 analog triggered axis, incrementalpassively, for 2 analog triggered axes, incrementalpassively, for 4 analog triggered axes, incrementalAxis moduleAxis moduleAZA2AZA4passively, for 2 analog triggered axes, absolutelypassively, for 4 analog triggered axes, absolutelyAxis moduleASMpassively, for 3 stepping motorsAxis moduleSERCaktiv, for 8 digitally triggered axeswith SERCOS LWL InterfaceDigital I/O modulesmax. ones 1024 in and outputsInput moduleIn / output moduleEKAEK32 inputs16 inputs, 16 outputs (0.5A)Output moduleOutput moduleRelay moduleAKAK2AKR32 outputs (0,5A)16 outputs (2A)16 outputsDAW2DAW4ADW4two-wayfourfoldfourfoldCOMETHAS ICANprogramming processor module for special applicationsconnection of the system PLC 900 to the Ethernetperipheral connection of peripheral deviceconnection to the CAN bus for drives and I/OKOPto couple of two groups of chassis (PLC CPU)Analog I/O modulsDigital-analog converterDigital-analog converterAnalog-digital converterCommunication modulesLogsEthernet connectionConnection of peripheralCAN bus connectionAddition modulesKoppelmodulEdition 03.20041-3

CNC 9001.1.2INTRODUCTIONExamples of CNC controllersExample of a CNC controller of 4 axesExample of a CNC Controller of mediumperformance of 8 axesChassis with:Chassis with:4 slots for Power pack NG4,1 slot forPower pack NG8,Central processing unit CNC (32bit),1 slot forcentral processing unit CNC (32bit),Axis module AAZ andAEK module.8 slots for Axis modules AAZ andI/O modules.1 Back-up battery(left at the chassis beside the power pack)1 Back-up battery(left at the chassis beside the power pack)1 Bus termination(on the right attached at the chassis)1 Bus termination(on the right attached at the chassis)1-4Edition 03.2004

CNC 9001.1.2INTRODUCTIONExamples of CNC controllers (continuation)Example of a CNC Controller of high performance of 16 axesChassis with:2 slots forPower pack NG16,2 slots forCentral processing unit CNC (64bit),4 slots forAxis modules AAZ,8 slots forI/O modules.1 Back-up battery (left attached at the chassis beside the power pack)1 Bus termination (on the right attached at the chassis)Edition 03.20041-5

CNC 9001.1.3INTRODUCTIONOperating panelsOperating panel CNC910CNC 910- LCD-Bildschirm TFT- Resolution- Colours of 4096- Touch screen with resolution- Run-time memory DRAM- Flash disk memory6.5 “640 x 4802561024 x102416MB8MBT1 T2 T3 T4 T5 T6 T7 T8F%iS%N!I0I?0- 42 function keys, of it 15 freely shapableXYZABC. -- PLC Keys with display on the LCD Display- connections1 Ethernet RJ451 serial interface- machine operating panel(integrated)1 emergency stop1 key-operated switsch2 potentiometersOperating panel CNC920- LCD-Bildschirm TFT10.4“- Resolution640 x 480- Colours of 4096256- Touch screen1024 x1024- Run-time memory DRAM 16MB- Flash disk memory8MB- 42 function keys,of it 15 freely shapable- PLC keys with displayon the LCD display- Connections1 Ethernet RJ451 serial interface- Machine operating panel(separately)1-61 emergency stop1 key-operated switsch2 potentiometers1 illuminated push buttonEdition 03.2004

CNC 9001.1.3INTRODUCTIONOperating panelsOperating panels RC910for the mobile applicationin the versions (from above):Standard,with handwheel,with joystick- LCD LCD-Bildschirm TFT- Resolution- Colours of 4096- Touch screen with resolution- Run-time memory DRAM- Flash disk memory6.5 “640 x 4802561024 x102416MB8MB- 42 function keys, of it 15 freely shapable- PLC Keys with display on the LCD Display- connections1 Ethernet RJ451 serial interface- machine operating panel(integrated)1 emergency stop1 key-operated switsch2 potentiometersEdition 03.20041-7

CNC 9001.1.3INTRODUCTIONOperating panelsOperating panel CNC 900Operating panel CNC 900CWide Color LCD TFT,VGA diagram (640 x 480),Wide Color LCD TFT,VGA diagram (640 x 480),512kB EEPROM for user specificmasks and 256k flash drive,Integrated function keys, cursor keys,numeric key block,CPU Pentium compatibly, 200MHz,RAM Memory 16MB,Hard disk 3,2GB,Floppy disk drive 3.5" 1.44MB,ASCII foil keyboard (optional),Separate keys for axis selection,keys for machine functions,Peripheral device interface,1 serial interface,Integrated function keys, cursor keys,numeric key block,Separate keys for axis selection,keys for machine functions,emergency-stop key,2 potentiometers and key switches,2 control elements (optional)Peripheral device interface,1 parallel and 2 serial interfaces,2 free slots,Emergency-stop key and2 potentiometers1-8Edition 03.2004

CNC 900INTRODUCTION1.2Software construction1.2.1Overall viewThe required software consists of several components:- PLC900 for the programming of the adaptation program(manual for the machine manufacturer)- PROMA to the programming of the graphic control surface and display(manual for the machine manufacturer)- CNC900, the CNC Core- WINBV for operating system administration with CNC910 / CNC920 / RC910 / CNC ETH (10.1)- BV.EXE for operating system administration with CNC 900 / CNC 900 C(10.2)- DLL for operating system extension- NCARC for the archiving of the NC programs(10.3)in this manual operation and NC programming for the CNC userEdition 03.20041-9

CNC 9001.2.2INTRODUCTIONSoftware input with operating panels CNC910 / CNC920 / RC910Configuration with PCThe graphic control surface is chargedover the CNC CPU into the EEPROMmemory of the control panel.NC programs, parameter lists and axesmachine data comes into the RAMmemory of the CNC CPU. BACKUP intothe EEPROM memory of the CNC CPUis possible.Also the PLC interface is situated in theEEPROM memory of the CNC CPU.Hybrid cableswith data lineand lines forEmergency-stop key,Release button,24 V supplyConnectioncable RJ45Connectioncable RJ45PLCPC programming software PLC1 - 10Edition 03.2004

CNC 9001.2.2INTRODUCTIONSoftware input with operating panels CNC910 / CNC920 / RC910Configuration with networksThe graphic control surface is chargedover the CNC CPU into the EEPROMmemory of the control panel.NC programs, parameter lists and axesmachine data comes into the RAMmemory of the CNC CPU.BACKUP into the EEPROM memory ofthe CNC CPU is possible.Also the PLC interface is situated in theEEPROM memory of the CNC CPU.Hub /RouterConnectioncable Rj45Connectioncable Rj45Hub /RouterServerCompany-ownedIntranet upEthernet baseLANEdition 03.2004Internet WAN1 - 11

CNC 9001.2.3INTRODUCTIONSoftware for data tansfer between CNC Operating panel and PCWINBVSoftware on a PC to controlling of the CNC.Display of the CNCon PC shownCNC becomes ofPC servesThe display of the CNC is illustrated on a PC. The control can be served then from the PC.Thus can be implemented: Diagnosis locally On-line remote diagnostics Operating system care Data adminstration Data protection NC archivingDetails in addition in this manual paragraph 10.1.SERVERSoftware on a PC for data transfer with the CNC.NC dataload /saveBy the CNC can be accessed the drive assemblies of a server. Several controls can be connectedat a server and load NC data from the server or save on the server.1 - 12Edition 03.2004

CNC 9001.2.3INTRODUCTIONSoftware for data tansfer between CNC Operating panel and PCWINTERMSoftware on the CNC Operating panel to the control PCDisplay of the PCon CNC shownCNC administer/startsprograms on PCOn the CNC Operating panel the display PC is illustrated.From the CNC Operating panel programs on the PC can be started and managed.Edition 03.20041 - 13

CNC 9001.2.4INTRODUCTIONSoftware input with operating panel CNC 900The graphic control surface is charged with PROMAinto the EEPROM memory.NC programs, parameter lists and axis machine dataare charged into the RAM memory of the CPU.Backup into the EEPROM memory of the CPU ispossible.Update of the CNC system software is possible withthe operating system management program BV.EXE.For this a transducer set (P-LINK and cableconnection) is necessary.Also the PLC interface program is charged withPLC900 into the EEPROM memory of the CNC CPU.Cableconnection' operatingpanel 'Cableconnection' peripheral ‘V24 interfaceTransducer set P-LINK 900and cable connections' service '0PLC90 AMOPRCNCAR00PLC9APROMCNCARCable connections' prog. device '20mA interfacePC programming and data protection softwarePLC900PROMANCARC1 - 14PLC programGraphic control surfaceNC archive programEdition 03.2004

CNC 9001.2.5INTRODUCTIONSoftware input with operating panel CNC 900 CThe graphic control surface is charged onthe hard disk.NC programs, parameter lists and axis machinedata are charged into the RAM memory of theCPU. Backup into the EEPROM memory of theCPU is possible.Update of the CNC system software is possible:- with operating system management programBV.EXE. For this is a transducerSet (P-LINK and cable connection) necessarily.- over I/O traffic.Also the PLC interface program is charged withPLC900 into the EEPROM memory of the CNCCPU.Cable connections' operating panel 'Transducer set P-LINK 900and cable connections' service '0PLC90Cable connection' prog. device 'PC program software PLC900Edition 03.20041 - 15

CNC 9001.2.6INTRODUCTIONSoftware programsBootstrap loader (Boot software or Booter)The bootstrap loader for the CNC900 is on the boat PROM (purchase number 084076) of the CNCmodule. The CNC module is delivered with the topical status of the bootstrap loader.Operating system often commodity consisting of the files- ‘ BS900 ‘- ‘ DLL ‘BWO standard operating system for CNC900BWO library software for customized operating system extensions.The operating system software for the CNC900 is on the FLASH EPROM of the CNC module. TheCNC module is delivered with the topical status of the operating system often commodity.NC programIn the buffered SRAM memory of the CNC module the following data are stored:- NC programs- parameter P- machine data q or PThese data can be read in or output with I/O traffic over the operating panel (V.24 peripheraldevice interface). In addition the archiving program „ NCARC „ can be used.Operating system management program BV.EXEWith BV.EXE valid operating system and library files can be burned in the Flash EPROM of theCNC module. Furthermore BV.EXE offers different auxiliary functions for the administration andarchiving of operating systems, libraries as well as NC programs and CNC parameters.Programming software PLC900With the programming software PLC900 can be created on a PC a machine-specific interfaceprogram.Programming software PROMAWith the programming software PROMA can be created on an IBM-compatible PC(with VGA 640 x 480) a machine-specific graphic control surface. A control surface consists ofseveral frames, which are summarized in a project.1 - 16Edition 03.2004

CNC 9001.2.6INTRODUCTIONSoftware programs (continuation)BootCNC CPUCNC kernelPLC taskCNC DLL (optional)NetworkingProgrammerServiceFlash memorycan alsoBV.EXEread,describedbecomePLC programcan alsoPLC900.EXEchargedbecomeMachinedata fileTool data,Points of zero.via I/O trafficFlash memory(EEPROM)RAM memoryPLC programmPLC flagmemoryParametermemoryChannel 1Channel 1P .Channel 1P .P .q0q1q2q3:to max 30 000orto max 60 000Opanel eratingNC memoryNCprogram,NC programsand cyclesCyclesvia I/O trafficZ6:P4711P.Edition 03.2004PLC900store withSAVEEEPROMCNCcntrol system(BS900.SYS)CNC-DLL(optional)PLC program(PLCOBJ)with q10 : 170save theparameterwith EEPROMidentifierparameter(PARAM)with q10 : 175save theprogramsand cyclesNC programsand cycles(NCZYK)with q10 : 176save onlythe cycles1 - 17

CNC 9001.3INTRODUCTIONSoftware - components / - version check / - updateNote: in the following text xxx the 3 digit version number always means1.3.1operating panelsSoftware components

in this manual operation and NC programming for the CNC user. CNC 900 INTRODUCTION 1 - 10 Edition 03.2004 1.2.2 Software input with operating panels CNC910 / CNC920 / RC910 Configuration with PC PLC The graphic control surface is charged over the CNC CPU into the EEPROM memory of the control panel. NC programs, parameter lists and axes machine data comes into the RAM memory of the CNC