Transcription

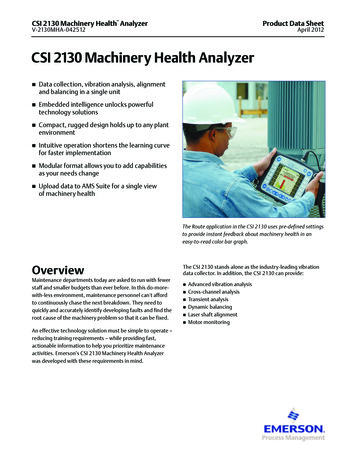

CSI 2130 Machinery Health AnalyzerProduct Data Sheet V-2130MHA-042512April 2012CSI 2130 Machinery Health AnalyzernData collection, vibration analysis, alignmentand balancing in a single unitnEmbedded intelligence unlocks powerfultechnology solutionsnCompact, rugged design holds up to any plantenvironmentnIntuitive operation shortens the learning curvefor faster implementationnModular format allows you to add capabilitiesas your needs changenUpload data to AMS Suite for a single viewof machinery healthThe Route application in the CSI 2130 uses pre-defined settingsto provide instant feedback about machinery health in aneasy-to-read color bar graph.OverviewMaintenance departments today are asked to run with fewerstaff and smaller budgets than ever before. In this do-morewith-less environment, maintenance personnel can't affordto continuously chase the next breakdown. They need toquickly and accurately identify developing faults and find theroot cause of the machinery problem so that it can be fixed.An effective technology solution must be simple to operate –reducing training requirements – while providing fast,actionable information to help you prioritize maintenanceactivities. Emerson’s CSI 2130 Machinery Health Analyzerwas developed with these requirements in mind.The CSI 2130 stands alone as the industry-leading vibrationdata collector. In addition, the CSI 2130 can provide:nnnnnnAdvanced vibration analysisCross-channel analysisTransient analysisDynamic balancingLaser shaft alignmentMotor monitoring

CSI 2130 Machinery Health Analyzer April 2012Increase Productivity with theDual-Channel OptionComplex data from vibration signals is condensed intomachinery health information and presented in an easy-tounderstand bar graph format. Details are available at thepush of a button.Routine data and corrective maintenance jobs can beuploaded to AMS Suite: Machinery Health Manager foranalysis and reporting. AMS Machinery Manager integratesdata from multiple technologies, including vibration andoil analysis, thermography, and alignment and balancinginto a singe database. Alerts generated by AMS MachineryManager can be exported automatically to AMS Suite: AssetPerformance Management where they are combined withalerts from other plant assets to provide a unified view ofyour plant's health. These predictive diagnostics powerPlantWeb by enabling plant personnel to improve plantavailability and reliability. Monitor More Machines in Less TimeAs shown below, data collection time is reduced by as muchas 60% compared to the CSI 2120, and even more whencompared to other instruments. Faster data collectiontranslates into more machines monitored and more timededicated to machinery analysis.Portable and DurableThe durability of this unit makes it ideal for field work in awide variety of industrial applications.nnnn2The CSI 2130 is available with either one or two channelsfor vibration analysis. The dual-channel option not onlyenables advanced analysis options, but also brings significantefficiency improvements. Emerson's patented dual-channeldata collection technique slashes measurement time byan additional 20% to 45%. This increase in productivitytranslates into a complete return on investment within thefirst year.Easy OperationThe CSI 2130 requires only minimal training for effectiveoperation. In addition to collecting data, the CSI 2130converts data into actionable information about machineryhealth. For example, it can automatically distinguish betweenan imbalance and a bearing fault. The user is instantlynotified about the nature of developing faults at the timeof measurement, so that you can focus your attention oncritical machine issues immediately.Embedded IntelligenceThe ability to perform additional diagnostic tests at themachine site transforms simple data collection into aneffective machinery health program. In today’s demandingwork environment, it is difficult to find the time to acquireadvanced analysis skills. Embedded diagnostics enable evena novice user to conduct sophisticated tests with the touchof a button. The bottom line impact is that users can quicklyharness the full power of the CSI 2130 in the field,immediately impacting your bottom line.Large Color Display: backlit VGA display for use anywhere.Small and Lightweight: easily carried on long routesIn-Field Reports: color-coded alarm report for each point.Industrial Design: IP 65 rated with optional safety rating.www.assetweb.com/mhm

CSI 2130 Machinery Health Analyzer April 2012Detect the Earliest Sign of Bearingand Gear WearDetecting imbalance or misalignment is simple with mostdata collectors, but the CSI 2130 can also detect developingfaults on bearings and gears.Emerson's patented PeakVue processing applies digitaltechnology to detect stress waves – the earliest sign ofbearing and gear wear. Demodulation and other analogtechnologies typically can not detect such faults untilmuch later – after the machine is already damaged. PeakVue processing not only offers the earliest warning ofdeveloping faults, it also provides an indication of severity.Measurements can be translated into reliable trends todetermine the optimal timing for maintenance.With PeakVue, machinery faults are clearly visible in thewaveform, opening up new options for fault detection anddiagnosis.The full VGA screen displays standard and PeakVue data atthe same time. The PeakVue plot (bottom right) provides clearindication of a rolling element bearing fault that is not visiblein the standard reading (bottom left).Full Spectrum of MeasurementAnother unique feature of the CSI 2130 is its exceptionalfrequency range. Using Emerson's patented Slow SpeedTechnology (SST), the CSI 2130 can accurately measuresignals on critical low speed equipment that would be outof range for other vibration analyzers. The CSI 2130 alsoboasts the highest frequency range in the market. It canmeasure signals up to 80,000 Hz, which is important foraccurate diagnosis of centrifugal compressors and otherhigh speed machinery.In-field AnalysisThere are many route vibration data collectors availablefor simply getting the normal periodic vibration spectrumand waveform. But when your needs call for an advancedvibration analyzer with analysis tools beyond normalperiodic route vibration measurements, then the CSI 2130is unmatched. The CSI 2130 has advanced in-field analysistools, including:nnn3waveform autocorrelation for identifying periodic-versusrandom impacting waveform energy.fault frequency overlays to match and identify the sourceof peaks in the vibration spectrumtrending of up to 12 narrow band parameters for as longas two years, allowing you to see where on the trend yourimmediate measurement acquisition appearsnnFourteen predefined analysis experts (such as coastdown, bump tests, time synchronous averaging, ordertracking, MCSA, high resolution, high frequency, etc.) fortroubleshooting difficult machine problemsQuad plotting for comparisons of multiple measurementsVariable Speed AnalysisVariable speed analysis is essential to any effective machineryhealth program because most critical pieces of equipmentmust be operated at varying speeds to accommodate thechanging production demands. While most vibrationsystems do not take variable speed into account duringdata collection, the CSI 2130 automatically adapts all of itsdiagnostic tools to variabl turning speeds during routinedata collection. This provides an accurate evaluation ofdeveloping problems in the field.Predict Catastrophic FailureMany online monitoring systems installed in plantstoday serve as nothing more than a shutdown switch inthe case of a catastrophic condition. By collecting thesignals from these systems with the CSI 2130, you canadd predictive capabilities by identifying faults before acatastrophe occurs. Orbit plots can be generated toidentify problems such as misalignment and shaft rubs.Trending data also helps to uncover developing cracksand other types of structural faults.www.assetweb.com/mhm

CSI 2130 Machinery Health Analyzer Monitoring Trouble SpotsThe CSI 2130 can also serve as a temporary online monitor.With line power, it is possible to monitor machine healthfor longer spans up to a month. It can automatically acquireand store data such as the overall vibration, fault frequenciesassociated with specific fault types, or even the completespectrum over an extended period of time. You can capturethe break-in period for new equipment or to ensure that amachine with a known fault can make it to the next outage.April 2012As a further enhancement, the ODS/Modal application(Operational Deflection Shapes) makes structural analysissimple by automatically configuring the required series ofcross-channel tests.Cross-channel data can also be analyzed in the VibPromodule of AMS Machinery Manager, or exported tospecialized ODS/Modal analysis software.Capture Machine ShutdownsFor analysis of transient events, the CSI 2130 collects a seriesof machine vibration snapshots during startup, coastdownor process changes. These spectra can then be viewedindividually or in a Cascade plot.Correlate Vibration and ProcessVariables to Identify MachineProblemsUse the dual-channel feature of the CSI 2130 to correlatemachinery vibration with process variables. This isaccomplished by inputting the process information asa volt signal into one channel, while monitoring vibrationon the other.Unsurpassed VersatilityThe CSI 2130 incorporates a modular design so that it can beconfigured to specifically address your current needs. As yourneeds evolve, the CSI 2130 can be easily and affordablyexpanded to enhance your capabilities while protectingyour initial investment. This versatile unit can be purchasedas a single- or dual-channel analyzer – with or without routemeasurement capability, as a dedicated field balancer, or as alaser alignment calculator. Put together any combination ofcapabilities to match your requirements. Additional modulesare also available for transient andstructural analysis.Fault frequency overlays is just one of many advanced analysistools available in the field with the CSI 2130.Advanced Cross-Channel AnalysisStandard data collection serves as an excellent base foridentifying developing machinery faults, but cross-channelanalysis is often required to identify the root cause of thefault. Expand the vibration analysis application of the CSI2130 with the cross-channel module to determine the actualmovement of the shaft during operation and to identifystructural faults such as cracks and resonances. While thedual-channel CSI 2130 can display orbits for turbomachineryanalysis, the optional Advanced Cross-Channel applicationexpands these capabilities to include impact testing andother types of cross-channel analysis.4The Cascade application captures machine vibration duringstartup, coast-down, or over an extended period of time. Tophalf of screen shows spectra individually; bottom half of screenshows cascade plot.www.assetweb.com/mhm

CSI 2130 Machinery Health Analyzer April 2012Expand the Power of Your CSI 2130with Transient AnalysisThe Advanced Transient Analysis application expands thepower of a single- or dual-channel CSI 2130 to record theraw vibration signal over a prolonged period of time forpost-processing and analysis. This is essential for diagnosticsof turbomachinery, startup and coastdown or machineswith short, repetitive duty cycles. This data can be examineddirectly on the CSI 2130 or in AMS Machinery Manager.Field BalancingThe Advanced Balancing application allows you to usethe CSI 2130 as a powerful field balancer. This applicationcombines advanced technology with simple, straightforwardoperation for a fast, effective solution to your balancingproblems. The graphical user interface automaticallyguides you through the balance checklist so that onlyminimal training is required for effective operation.The application offers a basic mode for simple one- or twoplane balancing and an advanced mode for more complexjobs. Full job documentation can be printed or stored inAMS Machinery Manager.The Advanced Balancing application offers two solutions tothe typical challenges of field balancing:Vector Averaging – This technique systematically removesbackground vibration that would otherwise contaminate thecalculated solution.Balancing Watchdog – This patented technologyautomatically checks the vibration data on the machinewhile you perform the balance job. The Watchdog is ableto identify and alert you of severe structural faults (such aslooseness or resonance) that would otherwise make thejob difficult or impossible to complete. The user can takecorrective action to remove the structural fault, balancethe rotor, and leave the machine in reliable operatingcondition.Laser AlignmentThe Advanced Transient Analysis application records thevibration signature from machine startup, coastdown orduring process disruptions for advanced analysis.The Live Move option updates the change in alignmentcondition during the machine move. Full job documentationis available in AMS Machinery Manager.The Laser Alignment Expansion Pak adds this importantcapability to any CSI 2130.Motor Current AnalysisTogether with the MotorView module in AMS MachineryManager, the CSI 2130 performs non-intrusive analysis of therotor and stator condition in induction motors. This can beaccomplished with a standard current clamp or Emerson’spatented flux monitoring. Industrial RatingsDesigned for use in industrial environments, the CSI 2130has received an IP 65 rating certifying that is dust- andsplashwater-tight. It also complies with international safetystandards for hazardous areas in the United States, Canadaand Europe.The Advanced Laser Alignment application offers agraphically-driven user interface and wireless operationto quickly and easily complete alignment jobs. Emerson'sadvanced laser system uses built-in dual inclinometers toautomatically determine the shaft position, so you simplyrotate the shaft and the

uploaded to AMS Suite: Machinery Health Manager for analysis and reporting. AMS Machinery Manager integrates data from multiple technologies, including vibration and oil analysis, thermography, and alignment and balancing into a singe database. Alerts generated by AMS Machinery Manager can be exported automatically to AMS Suite: AssetFile Size: 802KBPage Count: 14