Transcription

Fashion and Textile TechnologyTextile Construction TechniquesThis edition: April 2018 (version 1.0) Scottish Qualifications Authority 2018

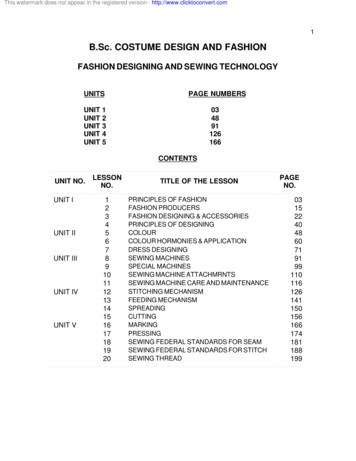

Fashion and Textile Technology —Textile Construction TechniquesThroughout the Fashion and Textile Technology courses, candidates will develop the skillsrequired to carry out a range of textile construction techniques. This document is for the useof candidates and teachers, and lists a range of textile construction techniques thatcandidates may use in the items they make. The range of techniques included in thisdocument is for guidance only and is not definitive. Candidates may choose to use any othersuitable construction technique(s) to make their item.Using this documentThe construction techniques are grouped into sections according to the function they carryout in the item, eg pockets. Some construction techniques may have more than one function,but to avoid duplication of information, each technique is only listed once, eg in the handsewing and embellishment sections, some of the hand sewing stitches may also be used asdecorative techniques.For each construction technique listed, the following information is provided:Construction techniquesThe name of each construction technique is given. Some commercial publications may usedifferent names for what appears to be the same technique, but for the purposes of thisdocument the most commonly used names have been used.DefinitionAn explanation of each construction technique is provided. This is a definitive description ofthe technique named, and may give a range of variations where appropriate. Somedefinitions include a description of some of the stages of construction, but where these areincorporated, they are to help clarify the technique and are not intended as instructions forexecuting the process. Many have illustrations of the finished technique for additionalguidance.FeaturesThis lists the main points of quality that would be important in the completion of eachconstruction technique. A description of the features specific to each technique are included.To avoid repetition, points of quality that would be expected in most techniques, are: fitness for purpose of the chosen technique all threads trimmed neatly pressing for finish — where applicable1

Textile Construction uttons and buttonholesBasic buttonMay be either a two-hole or four-hole flat button, orbutton with a pre-manufactured shank. Securely stitched intoplace.Evenly spaced if morethan one.Neatly finished withno loose threads.Thread used can be contrasting or matching.Button withstitched shankBasic button, may be either a two or four-hole buttonwith a stitched shank, created with a spacer so thatthe button stands away from the fabric. Should be used where extra depth is required, ie onthicker fabrics.Reinforced unstitchedbuttonholeThe buttonhole is reinforced with fusible interfacingor stay-stitched backing.A stiffening fabric is placed on the right side of thefabric, stitching round the buttonhole shape, slittingthe opening and then turning the stiffened fabricthrough to the wrong side of the item. Bound buttonholeTwo folded strips of fabric are placed on the rightside of the fabric and stitched in place.The opening is then slashed envelope-style and thebinding pieces turned through to the wrong side ofthe item and pressed. Securely stitched intoplace.Evenly spaced if morethan one.Neatly finished withno loose threads.On appropriate fabric,with a suitable lengthof shank.Reinforcing fabric isappropriate for thefabric of the item andattached securelywith no loose edges.Buttonholes are thecorrect size forbuttons.Slit is cut on thestraight grain.Evenly spaced if morethan one.Neatly finished withno loose threads.Slit is cut on thestraight grain.Buttonholes are thecorrect size forbuttons.Bound edges areequal in width.Evenly spaced if morethan one.Neatly finished withno loose threads.2

ConstructiontechniqueDefinitionFeaturesButtons and buttonholesMachinedbuttonholeWorked on a sewing machine.A buttonhole foot is required. Can be made using anautomatic buttonhole setting, or be a four-stepprocess, depending on the machine type. These should be cut once worked to give correctsizing for the buttons used. Buttonholes should be: horizontal on stressed areas such as collars andwaists vertical on non-stressed areas such as shirtfrontsHand-stitchedbuttonholeMade by hand using buttonhole stitch, usually onfabric either unsuitable for machine buttonhole due tobeing too lightweight or sheer, or on tailored jackets.Buttonholes should be: horizontal on stressed areas such as collars andwaists vertical on non-stressed areas such as shirtfronts Fabric-coveredbuttonButtons to be covered can be made of metal orplastic.Buttons may be covered using a specialist coveringtool or by hand. Button covering toolSlit is cut on thestraight grain.Buttonholes are thecorrect size forbuttons.Vertical or horizontalas appropriate.Slit or keyhole style isused as appropriate.Accurately cut.Evenly spaced if morethan one.Neatly finished withno loose threads.Slit is cut on thestraight grain.Buttonholes are thecorrect size forbuttons.Vertical or horizontalas appropriate.Even-sizedbuttonhole stitchused.Accurately cut.Evenly spaced if morethan one.Neatly finished withno loose threads.Smooth finish — nopuckers or pleatseither on top or edgeof button.All edges of coveringfabric secured.Any motifs or patternswell centred.Back securelyattached.Button is securelyattached to the item.The photo shows a wellfinished example on theleft, and a poorly finishedexample on the right.3

ConstructiontechniqueDefinitionFeaturesButtons and buttonholesMultiple RouleauloopsRouleau loops are made from fabric cut on the bias,and can be either: stitched along the length and then turned rightside out and pressed flat made by folding both edges to the middle of thestrip on the wrong side, bringing the foldededges together and edge stitched closed Rouleau loopsFine Rouleau loops Fabric should be cuton the bias.Rouleau should besmooth and flatwithout kinks orpuckers.Rouleau should becorrect size to slideover the buttonwithout pulling, andkeep the buttonsecure once fastened.Each end of theRouleau should bewell secured.Multiple loops shouldbe evenly spaced.Collars Applied readymade collar This is an example of a ready-made collar. It wouldbe attached to the garment after the neckline hasbeen finished appropriately.It could be attached completely with hand stitching,or made removable with the addition of hand stitchedloops and buttons.Whatever the methodof attachment, thecollar is appliedsecurely.Collar shape matchesor complimentsneckline shape.Collar should liesmoothly against theneck edge.For a fixed collar small stitches areused and do not showon the collarFor a removable collar buttons/loops shouldbe positioned so thatthe collar lies in thecorrect position loops should hold thebuttons securely4

le piececollarCollar, with only one piece, which would be attachedto the neck edge, standing upright, then falling overto lie flat. Peter Pan collarA collar with two pieces, which can be shaped into acurved edge or a point. It is attached to the neckseam line, and lies flat against the right side of thegarment. Mandarin collarAn upright collar, which is attached to the neckline,and doesn’t fold over. Can meet at the front opening,or may slightly overlap. The top edge of the collar can either be rounded orangled. Collar is attachedsecurely.The outer edge of thecollar is completedwith an appropriateedge finish.Well-turned corners.Both sides of thecollar aresymmetrical.No pleats or puckersin neck seam line.Collar lies flat againstthe garment.Collar accuratelyassembled.Collar is attachedsecurely.Both sides of thecollar aresymmetrical.No pleats or puckersin neck seam line.Centre front pointsmeet accurately withno gap or overlap.Collar lies flat againstthe garment.Collar accuratelyassembled.Collar is attachedsecurely.Front edges of collarare symmetrical.Collar an even depththroughout.No pleats or puckersin neck seam line.Centre front pointsmeet/overlapaccurately.Collar stands uprightfrom the neck seam.5

ied preribbed collarRibbed knitted fabric collar, joined at neck edge,either with overlocked edge, or finished seam edge.Often found on sportswear, or casual garments. Multiple piececollarThese include a notched collar, a flat collar with afacing attached, a shawl collar, or a shirt collar with astand. Collar is attachedsecurely.Collar is an evendepth throughout.Front edges of thecollar aresymmetrical.No pleats or puckersin neck seam line.Collar ribbing is notstretched/compressed.Appropriate edgefinish is used whereattached to thegarment.Collar accuratelyassembled.Stand is anappropriate and evendepth throughout.Front edges of thecollar aresymmetrical.Collar is attachedsecurely.Collar fall meetscentrally whenfastened with nogap/overlap.This image indicates shirt collar with a stand.Craft SkillsFabric paintingColour is applied either using fabric pens, or fabricpaint and brushes. Can be applied free hand or may use stencils. Many media need to be set with the heat of aniron. Colour should beapplied accuratelyand according to thedesign.There should be nopaint out with thedesign area.Edges of colourshould be welldefined.Paint should beapplied evenly.6

ConstructiontechniqueDefinitionFeaturesCraft SkillsWet feltingWet felting is constructed and then cut to the shaperequired or shaped by hand. It may include one ormore colour and other fibres may be incorporated fortexture. Flat needle feltingFlat needle felting makes a two-dimensional designon an item, for example a heart shape attached to agarment. Needle feltedmoulded shapesNeedle felting is made into a 3-dimensional shapesuch as a flower, snowflake or Scottie dog, using amould or cutter for shaping. Details may be added in another colour. Fibres should besecurely bonded.Fabric made shouldbe an even thicknessthroughout.Shape should beaccurate, according tothe design.Fibres should besecurely bonded.Fabric made shouldbe an even thicknessthroughout.Pattern or shape isclear and accurate.Fibres should besecurely bonded.Pattern or shape isclear and accurate.Additional details areappropriate to thedesign and securelyattached.7

ConstructiontechniqueDefinitionFeaturesCraft SkillsFree hand needlefeltingThe felted fabric is shaped freehand into, eg flowersor animals. Can be two or three dimensional.Other details such as beads may be used to addtexture or decoration.Single stitchknitting/crochetingAny item, or part item, eg a knitted band for a bag, ora crochet overlay for a pocket. Made using only onetype of stitch with knitting needles or crochet hook.Items, or part items that do not include shaping, eg aknitted scarf, or a square of crochet.May be one colour or multiple colours to formhorizontal stripes.Two stitchknitting/crochetingAny item, or part item may be made using two ormore types of stitches with knitting needles orcrochet hook and yarn. Simple shaping, eg decreasing/increasingstitches in knitting or crochet. Simple shapes in crochet, eg hearts. Colour changing is used to introduce a pattern. Fibres should besecurely bonded.Accurate shaping sopattern/design isclear.Additional details areappropriate to thedesign and securelyattached.Appropriate methodof casting on andcasting off, carried outcorrectly.Correctly executedtechnique.Even tension.Ends finished neatlywith no loose yarn.Appropriate methodof casting on andcasting off, carried outcorrectly.Appropriate choice ofstitches which shouldbe complementary.Correctly executedtechniques.Even tension.Ends finished neatlywith no loose yarn.8

ConstructiontechniqueDefinitionFeaturesCraft SkillsMultiple stitchknitting/crochetingAny item, or part item made using two or more typesof stitches or with a complex pattern to be followed,eg cable knit with knitting needles or crochet. Thepiece will include a degree of shaping, eg babybooties with a strap, or a 3-dimensional toy. Multiple colours may be used to form a pattern orpicture. Appropriate methodof casting on andcasting off, carried outcorrectly.Appropriate choice ofstitches which shouldbe complementary/reflect thepattern/picture.Correctly executedtechniques.Pattern followedcorrectly.Shaping accuratelyachieved, andsymmetrical whererequired.Even tension.Ends finished neatlywith no loose yarn.Simple tie dyeingMade using a single colour and a simple tyingtechnique to form circles or stripes. Clear lines of pattern.Design is clear,without seepage ofdye into other areas.Detailed tie dyingDesign includes multiple colours and/or patterns.Complex folding/tying techniques form more complexshapes, eg diamonds. The design may include more than one technique.A wax resist may be used to create complexpatterns. Clear definition ofpatterns.Design is clear,without seepage ofdye into other areas.Wax removedcompletely, if used.Wadding or batting is inserted between two layers offabric and held in place with simple lines of stitching.Stitching may be: patterns such as lines, squares or diamonds ditch stitched between patchwork pieces Simple machinequilting Appropriate stitchlength to avoidpuckering.Pattern evenlyspaced.Stitching securelystarted and finished.Neatly finished withno loose threads.9

ConstructiontechniqueDefinitionFeaturesCraft SkillsDetailed quiltingWadding or batting is inserted between two layers offabric and held in place with lines of stitching.Stitching may: create complex patterns enhance a design More layers of wadding may be added to specificareas/motifs to add texture or further highlights. Simple patchworkBasic shapes of fabric such as squares or rectanglesare cut and stitched together. ComplexpatchworkComplex shapes of fabric a

required to carry out a range of textile construction techniques. This document is for the use of candidates and teachers, and lists a range of textile construction techniques that candidates may use in the items they make. The range of techniques included in this document is for guidance only and is not definitive. Candidates may choose to use any otherFile Size: 1MBPage Count: 45