Transcription

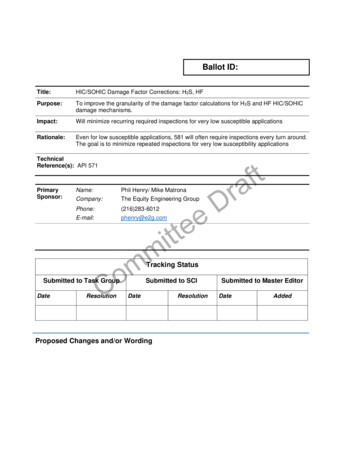

Ballot ID:Title:HIC/SOHIC Damage Factor Corrections: H2S, HFPurpose:To improve the granularity of the damage factor calculations for H 2S and HF HIC/SOHICdamage mechanisms.Impact:Will minimize recurring required inspections for very low susceptible applicationsRationale:Even for low susceptible applications, 581 will often require inspections every turn around.The goal is to minimize repeated inspections for very low susceptibility applicationsTechnicalReference(s): API 571PrimarySponsor:Name:Company:Phil Henry/ Mike MatronaThe Equity Engineering mmoCtfarDTracking StatusSubmitted to Task GroupDateResolutionSubmitted to SCIDateProposed Changes and/or WordingResolutionSubmitted to Master EditorDateAdded

Proposed Change to Table 6.3Rationale: The changes being recommended to chapters 9 and 14 require a new row to be added to table6.3 for an SVI of 0.5.SVIEDTable 6.3 – SCC Damage Factors – All SCC MechanismsInspection Effectiveness1 Inspection2 Inspections3 ,0001,000250502,0005008010SVIED4 .210.320.7525eteInspection Effectiveness5 InspectionsDCBA6 .50.311002520.7501010.52500125512505021

Proposed change to Chapter 9Rationale: Proposal is to add a VERY LOW susceptibility for HIC/SOHIC – H2S cracking. We are alsorecommending the removal of the asterisks from the high category in table 9.2 because a “very high”category does not exist in the method. The goal is to minimize repeated inspections for very lowsusceptibility applications.For Table 9.2, the defined pH ranges were changed. API 571 states hydrogen diffusion through steel isminimal at pH 7, while noting the rate of diffusion increases at both higher and lower pH levels. The tablewas reconstructed in a manner that illustrated these claims.The 50 ppm column was separated into two columns: 5, and 5-50 ppm. API 571 provides the followingjustification:tfarD“An arbitrary value of 50 wppm H2S in the water phase is often used as the defining concentrationwhere wet H2S damage becomes a problem. However, there are cases where cracking has occurred atlower concentrations or during upset conditions where wet H 2S was not ordinarily anticipated. Thepresence of as little as 1 wppm of H2S in the water has been found to be sufficient to cause hydrogencharging of the steel.”This resolution increases the granularity of the method while providing more conservative values for H2Sconcentrations near 50 ppm.iteteTable 9.1 – Data Required for Determination of the DF – HIC/SOHIC-H2S CrackingRequired DataSusceptibility(Very Low, Low, Medium, High)Presence of Water(Yes or No)oCmmH2S Content of WaterpH of WaterPresence of Cyanides(Yes or No)Sulfur Content of Plate SteelCommentsThe susceptibility is determined by expert advice or using theprocedures in this paragraph.Determine whether free water is present in the component.Consider not only normal operating conditions, but also start-up,shutdown, process upsets, etc.Determine the H2S content of the water phase. If analytical resultsare not readily available, it can be estimated using the approach ofPetrie & Moore (see Reference 31).Determine the pH of the water phase. If analytical results are notreadily available, it should be estimated by a knowledgeableprocess engineer.Determine the presence of cyanide through sampling and/or fieldanalysis. Consider primarily normal and upset operations but alsostart-up and shutdown conditions.Determine the sulfur content of the steel used to fabricate thecomponent. This information should be available on MTRs inequipment files. If not available, it can be estimated from theASTM or ASME specification of the steel listed on the U-1 form inconsultation with materials engineer.

Steel Product Form(Plate or Pipe)Determine what product form of steel was used to fabricate thecomponent. Most components are fabricated from rolled andwelded steel plates (e.g., A285, A515, A516), but some smalldiameter components are fabricated from steel pipe and pipingcomponents. Most small-diameter piping is fabricated from steelpipe (e.g., A106, A53, API 5L) and piping components (e.g., A105,A234), but most large diameter piping (above approximately NPS16 diameter) is fabricated from rolled and welded plate steel.AgeUse inspection history to determine the time since the last SCC(years)inspection.Inspection Effectiveness Category The effectiveness category that has been performed on thecomponent.On-Line MonitoringThe type of proactive corrosion monitoring methods or tools(Hydrogen Probes, Processemployed, such as hydrogen probes and/or process variableVariables, or Combination)monitoring.Number of InspectionsThe number of inspections in each effectiveness category that havebeen performed.moCtimetetfarD

Table 9.2 – Environmental Severity – HIC/SOHIC-H2S CrackingpH of Water 45.54 to 6.55.5 6.6 to 7.57.6 to 8.38.4 to 8.9 9 50 ppmLowVery LowLow Very LowLow Very LowLow Very LowLowEnvironmental Severity as a Function of H2S content of Water5 to 50 ppm50 to 1,000 ppm 1,000 to 10,000 ppm 10,000 ery oderateModerate*High*LowModerateHigh*High*Note: *If cyanides are present, increase the susceptibility to HIC/SOHIC-H2S one category for pH 7.6 8.3 and H2S concentrations greater than 1,000 ppm.moCtimetetfarD

Table 9.3 – Susceptibility to Cracking – HIC/SOHIC-H2S CrackingSusceptibility to Cracking as a Function of Steel Sulfur Content(1)High-SulfurSteelLow Sulfur SteelProduct Form –Environmental 0.01% S 0.01%Seamless/Extruded MediumLowLowLow Very LowLowMediumLowLowLow Very LowLowLow Very LowVery LowLowLowVery LowVery LowVery LowVery LowNotes:1. Typically includes A 70, A 201, A 212, A 285, A 515, and most A 516 before about 1990.timetetfarDTable 9.4 – Determination of Severity Index – HIC/SOHIC-H2S CrackingmoCSusceptibilityHighMediumLowVery LowNone1Severity Index –Notes:1. A susceptibility level of “none” is indicative of the damage mechanism being inactive.1001010.50SVI

Proposed change to Chapter 14Rationale: Proposal is to add a VERY LOW susceptibility for HIC/SOHIC – HF cracking. The goal is tominimize repeated inspections for very low susceptibility applications.Table 14.1 – Data Required for Determination of the DF – HIC/SOHIC-HFRequired DataCommentsSusceptibilityThe susceptibility is determined by expert advice or using the(Very Low, Low, Medium, High) procedures in this paragraph.Presence of HFDetermine whether HF may be present in the component.(Yes of No)Consider not only normal operating conditions but also upsetconditions that may allow carryover of HF from other components.Sulfur Content of Plate SteelDetermine the sulfur content of the plate steel used to fabricatethe component. This information should be available on thematerial test report (MTR) in the equipment files. If not available,it can be estimated from the ASTM or ASME specification of thesteel listed on the U-1 form in consultation with a materialsengineer.Steel Product FormDetermine what product form of steel was used to fabricate the(Plate or Pipe)component. Most components are fabricated from rolled andwelded steel plates (e.g., A285, A515, A516), but some smalldiameter components are fabricated from steel pipe and pipingcomponents. Most small-diameter piping is fabricated from steelpipe (e.g., A106, A53, API 5L) and piping components (e.g., A105,A234), but most large-diameter piping (above approximately NPS16 diameter) is fabricated from rolled and welded plate steel.AgeUse inspection history to determine the time since the last SCC(years)inspection.Inspection Effectiveness Category The effectiveness category that has been performed on thecomponentNumber of InspectionsThe number of inspections in each effectiveness category that havebeen performedmoCtimetetfarD

WeldConstructionNon-PWHTPWHTTable 14.2 – Susceptibility to Cracking – HIC/SOHIC-HFSusceptibility to Cracking as a Function of Steel Sulfur ContentHigh-Sulfur Steel Plate(1)Low-Sulfur SteelProduct Form – 0.01% S 0.01% SSeamless/Extruded Pipe(2)HighHighLowHighMediumLowNotes:1. Typically includes A 70, A 201, A 212, A 285, A 515, and most A 516 before about 1990.1.2. A Very Low susceptibility can be assigned to Seamless/Extruded Pipe under guidance of expert opinion.Table 14.3 – Determination of Severity Index – HIC/SOHIC-HFSusceptibilitySeverity Index –HighMediumLowVery LowNone1eteNotes:1. A susceptibility level of “none” is indicative of the damage mechanism being inactive.moCtimSVItfarD1001010.50

API 571 states hydrogen diffusion through steel is minimal at pH 7, while noting the rate of diffusion increases at both higher and lower pH levels. The table was reconstructed in a manner that illustrated these claims. The 50 ppm column was separated into two columns: 5, and 5-50 ppm. API 571 provides the following justification: “An arbitrary value of 50 wppm H 2 S in the water phase is .

![API Ballot: [Ballot ID] – API 510 & API 570, Deferrals, Rev05](/img/5/api510andapi570deferralsrev5.jpg)