Transcription

CARGO PUMPING SYSTEM

FRAMO CARGO PUMPING SYSTEMFramo hydraulically driven submerged cargo pumps providesafe, efficient and flexible cargo handling of any type of liquidcargo. Improved cargo handling performance gives quickerturnaround time, more ton-miles and fewer voyages in ballast.HIGH VESSEL UTILISATIONCLEAN SEASSAVE TIMESpend less time on cargooperations Quick cargo unloading Efficient stripping Less slop treatmentM/T ”STOLT NORLAND” 43.000 tdw chemical tanker.Owner Stolt-Nielsen, Netherlands. Built STX Norway Florø, 2009.Made to performThe Framo cargo pump is of a robust constructionmade to efficiently empty any cargo tank containingthe most heavy, viscous or aggressive cargoes.The hydraulic driveline is designed for a safe andreliable pumping and final stripping of the mostvolatile or dangerous cargoes carried in bulk.No risks of any build up of heat due to a fail-safedesign where the pump motor and bearings areconstantly lubricated and cooled by the hydraulicoil driving medium.Load any type of cargoThe Framo cargo pump can handle any typeof cargo. One voyage it may be a petroleumproduct, next voyage an acid or somethingheated/cooled/volatile or viscous.Efficient switch between different cargoesA cargo pumping system must be able todischarge, drain and clean the cargo tanks inan efficient manner to make the vessel readyto receive a new cargo.3

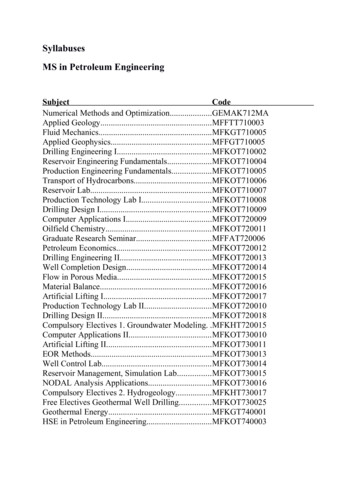

CONTENTSHYDRAULIC PIPINGPage 16CONTROL SYSTEMPage 14CARGO PIPINGPage 18Framo cargo pumping system2The submerged cargo pump6Safe operation8Cargo heating10Submerged ballast pumps12Submerged tank cleaning pumps13Hydraulic drive14Framo piping16Cargo piping18Cargo cooling20Cargo circulation21Floating production, storageand offloading22Technical data24Research and development26Customer support28Framo AS30DECK MOUNTED CARGO HEATERPage 10HYDRAULIC DRIVE FOR DECK MACHINERYPage 15HYDRAULIC POWER UNITPage 14SUBMERGED BALLAST PUMPPage 12SUBMERGED CARGO PUMPPage 6BOW THRUSTER MOTOR4Page 155

THE SUBMERGED CARGO PUMPThe Framo cargo pump is a vertical single stage centrifugal pumppowered by a hydraulic motor for safe and efficient operation.All our cargo pumps are made in stainless steel material anddesigned with a smooth and easy-to-clean surface with a limitednumber of flanges which gives a superior ability to pump any liquid.Cargo purgingconnectionThe hydraulic highpressure pipe is locatedinside the low pressurereturn oil pipe.The entire hydraulicsection is separatedfrom the cargo bya cofferdam ventilatedto atmosphere.PressuretransmitterLocal controlvalveSpeed torquecontrol valveCargodischarge valveStripping valveThe cargo pump hasTop platea built-in hydraulicmotor connected tothe impeller by a shortExhaust trapResilientmountingCofferdampurgingDeck trunkindependent shaft.Motor, shaft andbearings are lubricatedand cooled by thehydraulic driving oil.Cofferdamcheck pipeCofferdampipeCargostripping pipeHydraulicreturn pipeCargo pipeHydraulicpressure pipeHydraulicmotorBearingsDesign features Vertical single stage, single suction impeller, axiallybalanced Robust hydraulic drive with short and stiff drive shaft Fail-safe design; Lubrication and cooling of pumpby the hydraulic driving oil medium Pump material stainless steel Concentric hydraulic pipes for maximum safety Cofferdam, ventilated to atmosphere, protectingthe entire pump Mechanical seal against hydraulic oil Double lip seal against cargo, only exposed tostatic pressure Anti-rotation brake; loading through pump Smooth pump exterior; self draining and easy to clean6PerformanceThe Framo cargo pump is easy tooperate. The hydraulic drive providesfor a remote and local stepless capacitycontrol through the Speed TorqueControl (STC) valve on the pump’s topplate. The cargo pump can pumpanything liquid, regardless of specificweight or viscosity.It is impossible to overload or to overspeed the pump. The STC valve auto- matically regulates hydraulic oil pressureand flow to the hydraulic motor accordingto the given discharge situation.The pump design allows operation witha minimum of liquid in the tank whichsaves time spent for drainage and tankcleaning. The Framo cargo pump hasa built-in efficient stripping system.Condition based maintenanceSeal monitoring is performed fromthe cargo pump top plate by purgingthe ctionwellMechanicaloil sealCargo sealsSleeveWear ringsReplacement of wear and tear partsis easily done from inside of the tankwithout interfering with the hydraulicsection.7

STAINLESS STEELCHEMICAL TANKERSSAFE OPERATIONDangerous chemicals, acids, oils or edibles must be handled in a safeway for people and environment. The tanker must be equipped with cargopumps that can efficiently empty cargo tanks and associated cargo pipingto meet the most stringent requirements, and withstand the tough impactduring hours of tank cleaning afterwards. Switch between cargoes withoutcargo contamination. Carry anything from acids to drinking water.The stainless steel chemicaltanker fleet comprises the mostsophisticated tankers sailing onthe high seas. These ships are constructed with stainless steelcargo tanks, a fully segregatedcargo pumping arrangementand designed to carry the mostaggressive, corrosive or volatileliquids.M/T “BOW SIRIUS” 40.000 tdw chemical tanker.Owner Odfjell, Norway.Built Szczecin Shipyard, Poland 2006.HIGH SPECIFIC GRAVITY100%S.g.HEAD (mlc)S.g.0,81,0S.g.1,5S.g.1,80 FLOW Q ( M3/h) 50%150%100% Hydraulic drive and torque control, no riskof overloading Any specific gravity of cargo, no limitationHIGH VISCOSITY100%1cSt100cStHEAD (mlc)400cSt850cSt0 FLOW Q ( M3/h)50%100%150% Full torque at any speed Extremely viscous cargoes, molasses etc.The Framo cargo seal arrangement is exposedto static cargo tank pressure only.Optimal operating conditions are maintainedat all pumping conditions. Volatile or heatsensitive cargoes can be discharged efficientlyin a safe manner.8StrippingWhen the cargo tank is empty, the speed ofthe cargo pump is reduced to perform thefinal stripping of tank: Close the cargo valve Open the small ball valve on the stripping line Pressurize the pipe stack by connectingthe purging hose with compressed airor nitrogen Press cargo out through the stripping lineand into the cargo lineTERMINAL BACK PRESSUREDesign Point100%HEAD (mlc)High or low temperature, volatile anddangerous cargoesThe Framo cargo pump is designed for anycargo temperatures prevailing in tankers. Thepump is continuously temperature controlledby the circulating hydraulic drive oil.Discharging100% volumeParcelUnloading10Actualdisharge timeDesigndisharge time Increase the discharge rate at lower back pressure Shorter discharge time20HoursThe pump impeller rotates and acts asa non-return valve to prevent cargo from returning back to tank.Purging and seal monitoringfrom deck levelThe pump’s cofferdam is purgedbefore and after discharge operation.Any leakage across the cargo sealsor hydraulic oil seals collected inthe cofferdam, will be forced to theexhaust trap on deck where it canbe measured.This is a simple and reliable sealcondition monitoring system. Noneed for any electric sensors norany automatic control system.Vacuum drainThe standard Framo cargo pumpdesign meets all applicable rulesfor stripping under the IMOAnnex II requirements.However, as an option, the Framocargo pump can be equippedwith a vacuum drain line that willempty suction well completelyand allow for a dry tank top andquick re-loading of cargo.9

CARGO HEATINGCHEMICAL/PRODUCTOIL TANKERSFramo deck mounted cargo heaters eliminate the need for in-tankheating coils. The cargo tank interior can be made with flush tanktop free from coils, brackets and clamps. A flush tank top facilitatesquicker stripping with less cargo remaining in the tank. The cargotank washing can be performed quicker, with less consumption ofwashing water and less slop handling.Most of the world’s production ofvegetable oils, commodity chemicalsand refined petroleum products aretransported on the large fleet ofmodern chemical/product tankers.Typically designed with coated cargotanks, six to eight cargo segregations,no pump room, submerged ballastpumps, in-tank cargo pumps anddeck mounted cargo heaters.PerformanceHigh flexibility to heat all traded cargoes, suchas heavy fuel oils, oil products, palm oils andother chemicals that may be temperature sensitiveand requires a gentle heating procedure.The specially shaped heating elements secureeasy cargo circulation and have a low surfacetemperature against cargo.The high capacity and low pressure dropthrough the cargo heater gives a low power10consumption during circulation and securea good mixing and heat distribution insidethe cargo tank.The heating medium can be saturated steam,hot water or thermal oil.Framo deck mounted cargo heating systemis supplied as an integral part of the cargopumping system for all sizes of oil tankers,chemical tankers and FPSOs.Cargo heating Circulate the cargo through the deckmounted cargo heater Adjust heating capacity to meet cargorequirements Heat gently with careful temperatureincrease across the heater High circulated cargo flow givesa good heat distribution inside thecargo tankM/T “OVERSEAS ATALMAR” 45.900 tdwchemical/product tanker. Owner OSG, USA.Built STX Shipbuilding, Korea 2004.Design features Made for a tough marine environment Stainless steel Compact welded plate type design Large heating surface Low pressure drop Vertical self draining Easy to clean Easy to inspect Cargo heater is only exposed to cargowhen in use11

SUBMERGED BALLAST PUMPSInstallation of ballast pumps inside the double side ballast tanksin combination with a submerged cargo pump in each cargo tankmake the pump room superfluous. This arrangement providesa safer ship design and make more space available for carrying cargo.Submerged ballast pumps have become the standard arrangementin modern tankers and FPSOs.LONG RANGE TANKERSThe use of one submergedhydraulically driven cargopump per tank provides safesegregation between cargoes.It makes the stripping and tankcleaning quicker. Efficientswitch between cargoes givesa substantially higher numberof ton miles.M/T “SKS DOURO” 120.000 tdw product tanker.Owner Kristian Gerhard Jebsen, Norway.Built Hyundai Samho Heavy Industries, Korea 2010.Increased cargo volumeNormally installed inside two of thedouble side ballast tanks located aftof the manifold area, one in eachside. On oil tankers, a fuel-oil tankcan separate the engine room andcargo section. No pump room required Larger volume available for cargoSubmerged installationThe Framo submerged ballast pumpis a centrifugal pump, designed forinstallation inside the ballast tanks.The pump unit is mounted insidethe air separator and protected by acofferdam. A fail-safe design ensuresthat impeller will always be immersedin water.Design features Impeller always immersed in water Built-in self priming system Individual capacities of up to 3.000 m3/h Stepless capacity control Robust design with a short and rigiddrive shaft Lubrication and cooling of motorand bearings by the hydraulic drive oil Cofferdam between ballast waterand hydraulic section Concentric hydraulic pipes for maximumsafety Easy to install, operate and maintain Can be connected to any ballast watertreatment systemThis is a compact design which savesspace and makes the installationeasy. An air ejector is connected tothe pumps suction side. Automaticstart and stop of the air ejectormakes the pump self priming.The pump is manufactured fromstainless steel with seawater resistantbronze impeller.Increase the cargo volume with submergedballast pumps. Eliminate the pump room.The Framo ballast pump has a fail safedesign with impeller always immersed in water.12SUBMERGED TANK CLEANING PUMPSThe Framo submerged tank cleaning pump is based on the submergedcargo pump design and equipped with a suction arrangement to allowfor suction from sea chest and technical fresh water tank.Framo also supply a range of tank cleaning pumps for dry installation.Any Framo pump with hydraulic drive is 100% explosion proof, andcan be installed in hazardous areas.13

HYDRAULIC DRIVERemote control panelA complete system designed andmanufactured by Framo. Hydraulicdrive provides the most flexibleand safe power transmission for acargo pumping system on tankers.El./hydr.control valveassemblyNot FM supplyPortable pumpTripod for portable pumpCargo heaterDeckmachineryHydraulic power unitThe hydraulic power pack prime movers can beelectric motors or diesel engines.A combination of electric motor and diesel engineprime movers allows the ship’s generators to bedesigned for the relatively low power requirement insea-going mode rather than the considerably higherrequirement during cargo unloading. The ship’sauxiliary engines can therefore operate with aneconomic load while at sea where the majority ofrunning hours will be. The diesel hydraulic powerpacks will provide any additional power needed fora high capacity/high head cargo discharge.Hydraulicpower unitAll power packs, stainless steel system tank, oilcooler, and full flow filter are mounted, piped andwired on a module for resilient installation onboard.This Hydraulic power unit is full scale tested togetherwith the control system module before shipment.The hydraulic pumps are of the variable displacement type and fitted with a pulsation damper formaximum reductions in pulses and noise.A power saving device incorporated into the Framocontrol system automatically regulate and share theload between each power pack in operation.Hydraulic oiltransfer unitSubmergedtank cleaning pumpControlThe hydraulic power unit and all cargo pumps andother consumers are operated and monitored fromthe Framo control panel.Submergedballast pumpSubmergedcargo pumpSubmergedcargo pumpBow thrusterThe control system can be interfaced with shipsIntegrated Control System.Hydraulic power unit with electricmotor driven power packs forsmall and medium sized tankers.14Hydraulic power unit with a combination of electric motor drivenpower packs and diesel engine driven power packs for mediumand large sized tankers.Hydraulic power unit with high voltage electric motor drivenpower packs for FPSO and FSO applications.15

BUNKER TANKERSFRAMO PIPINGThe need for quality hydraulic installation onboard vesselsoperating in severe marine environment has led to the developmentand manufacturing of Framo hydraulic piping systems.The hydraulic piping system is based on high quality componentsand piping materials.Bunker tankers with an increasednumber of cargo segregations,equal to that of product/chemicaltankers, provide safe handlingof multiple fuel qualities. Newregulations on marine fuel qualityrequire ships to bunker severalgrades of fuel to meet the legalrequirements in different emissionzones.Quality and competenceDuplex stainless steel on all high pressure branchpipes and pilot pipes on deck. Stainless steelAISI 316L on all low pressure hydraulic pipes ondeck.Prefabrication of the piping systemto any level of complexity froma single spool piece to a full systemis available.The hydraulic pipes are of high standard withsmooth internal surface intended for hydraulicoil with high cleanliness. All service valves aremade from stainless steel.The Framo hydraulic piping system is designedwith extensive use of cold bending in order tolimit the number of flanged connections.16M/T ”TATIANA-B” 3.500 tdw product/chemical tankerOwner Maritima, FranceBuilt STX Braila, Romania 2008.M/T “ELKA ATHINA” 102.500 tdw product tanker.Framo supply specially designed flanges for allpressure ratings, flexible bulkhead penetrations,resilient pipe clamps, anchor supports, andother accessories for the hydraulic pipingsystem.Framo AS has a highly specialized manu facturingplant in Norway for the design and manufactureof all the components in the hydraulic pipingsystem.Owner European Navigation, Greece.Built Brodosplit Shipyard, Croatia 2004.In all areas of design special attentionis given to reduce vibration and noisefrom components and pumps. Thecargo pumps, hydraulic power unitsand hydraulic piping are all resilientinstalled.17

CARGO PIPINGThe cargo piping arrangement depends on the type of vessel, the cargoescarried and the number of segregations required. In close cooperationwith shipowner and yard Framo can assist in designing an optimal cargopiping layout. A functional system should not only be designed with thepurpose of a quick loading and discharge operation, but also providefor efficient draining and cleaning.1819

CARGO COOLINGCARGO CIRCULATIONThe Framo cargo cooling system enables chemical carriers to alsotransport low-boiling-point cargoes and semi-gases. Cargoes suchas Propylene Oxide and Isoprene are often transported on boardchemical carriers, which use our cooling system to maintain a safecargo temperature.To prevent sediments settling on the tank-topduring transport and to maintain the liquidquality, a Framo diffusor can be installed onthe outlet of the dropline. During voyage cargois circulated through the diffusor by runningthe cargo pump at intervals.The Framo cargocooling systemComprises individualcargo coolers for eachtank, chiller units and aring-line for the coolingmedium. The cargocooler is installed submerged inside the cargotank and is equippedwith an integrated cargocirculation unit. TheFramo cargo coolingsystem is an independentsystem that easily canbe retrofitted.A one-pump-per-hold systemthat is easy to operate and toclean has been specially designedfor combination vessels that arealternating between wet and drycargoes. The cargo pumps areinstalled in protective enclosedcorrugations between the holds.Cargo piping and cargo heatersare located on deck.M/T “SKS MERSEY” 121.000 tdw OBO carrier.Owner Kristian Gerhard Jebsen, Norway.Built Hyundai Heavy Industries, Korea 2003.Cooling mediumstorage tankRefrigerating unitCirculationpumpCompressorCondenserOBO ed insidethe tank formaximum safety.Cooling waterin/outCargoes such asPropylene Oxideand Isopreneshould not becirculated outside their tanks.M/T “RABIGH SUN” 35.500 tdw chemical tanker.Owner Iino Kaiun, Japan. Built Kurushima Onishi, Japan 2008.Framo diffusorsThe diffusors are specially designed for individual cargo tanks,and each diffusor contains several nozzles, whose number anddimensions are determined on the basis of the dimensionsand shape of the tank-top.Diffusors are normally produced in high-molybdenum stainlesssteel for exposure to Phosphoric Acid, but are also availablein AlSl 316L for other cargoes. Forced cargo circulation shouldbe repeated at regular intervals throughout the voyage.20InstallationThe OBO cargo pump is installedin a closed corrugation at theaft end of each cargo hold.Only the volute casing of the pumpis submerged in cargo inside asuction well, with a free-flow ductconnection to the cargo hold. Theupper part of the pump-head andthe complete pipe-stack remaindry within the corrugation, whichmay be regarded as a standardcofferdam.21

FLOATING PRODUCTION,STORAGE AND OFFLOADINGFPSOs produce revenuesFPSOs are producing oil in remote offshore areas under harshenvironmental conditions. The highest standards for safetyand operation regularity apply to designs and equipment.A reliable cargo offloading system on the FPSO is key to returnon investment.of substantial magnitudes.A reliable cargo offloadingsystem makes a difference.FPSO “DALIA” 2 mill bbls for Elf Exploration AngolaFPSO “BONGA” 2 mill bbls for Shell Nigeria.(Total). Built Samsung Heavy Industries, Korea.Service at Dalia field in Angola since 2006.Built Samsung Heavy Industries, Korea.Service in Nigeria since 2005.FPSO “BOHAI BAY QHD 32-6” 1 mill bbls forCNOOC/Texaco. Built Dalian New, China.Service in China since 2001.FPSO “P-54” 2 mill bblsfor Petrobras. Conversion VLCC.Service in Brazil since 2008.Safety and operation regularityFramo submerged offloading pumps use ahydraulic drive technology developed throughextensive experience from the tanker industryand further refined for FPSO applications.The hydraulic motor is located close to theimpeller, connected with a short rigid shaft.The motor and shaft assembly is continuouslylubricated and cooled by the hydraulic drive oil.This is a design that provides a technical soundconstruction that allows for transmission ofhigh pumping power and that is suitable forvery deep storage tanks.22The Framo offloading pumps are equipped withstepless capacity regulation, ensuring that thepump capacity always can meet any variationsof pumping requirements on the FPSO.In-tank offloading pumps provide safe offloadingconditions. Pump room and in-tank suction linesare avoided. Each tank is effectively isolatedfor safe tank entry. International classificationsocieties and regulative bodies advise the useof submerged offloading pumps for FPSOs.Design requirements 100 - 200.000 bbls/day production rate 10 - 30 years field operation Offload crude oil at required flow rate Crude oil transfer between any storage tanks Pump produced water and skim oil fromsettling tanks Allow for COW during transfer or offloading Effectively drain the storage tanks when requiredHull process pumpsIn addition to crude offloading service, the Framosubmerged cargo pumps are used for continuouspump duties for in-hull processing.Continuous transfer of: oil from wash tanks to settling tanks settled water from wash tanks/settling tanks to process stabilised oil to storage tanks methanol, MEG etc.Desalting wash tanks and continuous settling tanksequipped with separate in-tank pumps for producedwater and oil provides for an advanced and costefficient processing.23

TECHNICAL DATACCARGO PUMPSAB(in mm)318SD 100(in mm)CARGOFLANGEof 10 m pump394500DN100325 kgD52430496SD 150(in mm)30448SD 125C(in mm)50057430WEIGHTDN125500CAPACITYWEIGHTpr m503 kgDN150BALLAST PUMPS558 kgDA(in mm)DCB(in mm)(in mm)(in mm)WEIGHTof 10 m pumpWEIGHTpr m20 kgSB 200500 m3/h790596250200510 kg15 kg28 kgSB 3001000 m /h14638963503001060 kg30 kg30 kgSB 4002000 m /h163011004504001540 kg30 kgSB 6003000 m /h171012506005002100 kg30 kgSD 20063540715500DN200963 kg46 kgSD 25071060810500DN2501153 kg53 kgSD 30079665910500DN3001600 kg65 kgSD 35010001001100500DN3502247 kg80 kg333ACDBMLCCAPACITY RANGE CARGO PUMPS180A170CARGO HEATERSCAPACITY160150140130(in mm)(in mm)(in mm)CWEIGHTABHE 225360 kw1200366100175 kgHE 430800 kw1600560160425 kgHE 5001600 kw1637700160500 B807060PORTABLE PUMPS50BTK 80TK 150TK 6LN 150TK 125CAPACITY70 m3/h300 m3/h500 m3/h150 m3/h50 m3/hHEAD70 mwc60 mwc40 mwc45 mwc10 barMATERIALAlSl 316LAlSl 316LAlAlSl 316LAlWEIGHT25 kg78 kg85 kg76 kg86 kgPUMPHEADø250 mmø300 mmø520 mmø300 mmø300 mmHEIGHT625 mm598 mm640 mm595 mm1000 mmm3/h0050110150200250300350400500600700800900 1000 1100 1200 1300 1400 1500 1600 1800 2000STAINLESS STEEL QUALITIESSUCTION WELLSDESCRIPTION CHEMICAL COMPOSITION % 021,026,0Standard acid resistantStandard acid resistantlow carbon contentSpecial acid resistanthigh nickel content(2 RK 65)240,020,72,0CrAPPROXIMATE S 316316L1.4432SUS 316L4,01,2904L1.45395,02,0The Framo cargo pumping system is equippedwith a portable pump type TK80 or TK150in accordance with class requirements for“a secondary means of unloading”.Stainless steel suction wellspressed to shape are availableas an option.Hydraulic drive outperforms any other powertransmission for pumping extremely viscouscargoes. For emergency cargo unloading, anextended range of portable pumps models andhydraulic power units is available for rental.All pumps are individually run and tested with respect to capacity, head, hydraulic pressure and oil flow.The Framo system is delivered according to the requirements of any classification society and nationalor international maritime authorities.25

RESEARCH AND DEVELOPMENTFramo aim to supply the safest cargo pumps there are, designedfor handling the most difficult cargoes carried on tankers.Excellent performance will contribute to the improved profit forowners and charterers.Safeguarding future improvementsResearch and extensive testing is the very foundation forthe development of Framo cargo pumping systems fortomorrow. The tanker industry’s operational and safetyrequirements, as well as international maritime legislation,are getting stricter by the years. The awareness of thehazards of carrying liquid cargo in bulk, and the potentialdamage it can cause to people and environment in caseof an accident has become a top priority issue.26PerformanceWe have a fully integrated company securinghigh and uncompromised quality in all areasof our business. We continuously work to improvesystem performance and reliability. In closedialogue with our customers world wide welearn and benefit from their vast operational experience from ships in service.TestingFull scale testing facilities and our in-housedry dock with stainless steel deep tanks giveus the advantage of special testing or testingout new ideas in full.27

CUSTOMER SUPPORTFramo AS service organization provides technical supportduring the installation phase of a project, as well as professionalservice throughout the lifetime of the vessels. Condition based maintenance and correct operation are the best ways of ensuring optimal equipment performance. The Framo service organizationis there to support you 24/7.CommissioningFramo engineers provide assistance andguidance during installation of the cargopumping system at the shipyard. Installation,start-up and testing of the system is carriedout under our supervision in close cooperation with the yard and the ship owner.TrainingFramo Training School organizes seminarsand tailor-made courses at Framo trainingfacilities in Bergen, Rotterdam, Houston,Singapore, Pusan, Tokyo, Shanghai and atthe Norwegian Training Centre in Manila.28Framo seminars qualify the participants for a coursecertificate. The Framo programme also comprisestraining at the yard upon vessel delivery as well ason-board training.Service bulletinsTechnical updates aredistributed to helpowners and operatorsto best utilize theinstalled FramoCargo PumpingSystem.M/T “BRIMANGER” 46.000 tdw chemical/product tanker. Owner Westfal Larsen, Norway.Built Hyundai Mipo Dockyard, Korea 2009.Service and repairsTo safeguard a high system availability, annualinspection, pre-docking inspection and hydraulicoil monitoring program can be provided.Advisory service in connection with systemoperation, service or repair is available.Framo engineers are available when required.Spare partsOur own service and repair facilities locatedin Bergen, Rotterdam, Houston, Singapore,Busan, Tokyo, Shanghai and Rio de Janeirohave spare parts in store to suit all the Framosystems in operation.Condition based exchange of wear and tearparts reduces your operation cost and ensuresthat your cargo pumps perform with optimalcapacity at all times.We are available around the clock.29

FOUNDED IN 1938We at Framo AS take a long term view on customer relations.We shall actively cooperate with our customers, be someone to trust,with experience and competence. Through continuous researchand development we are preparing for tomorrow. Framo AS isa part of Alfa Laval and is the centre of marine pumping systemswithin the Alfa Lava group.positioned globallysupport locallyquality pumpsmade in NorwayBERGENROTTERDAMBUSANHOUSTONDUBAIMEXICO CITYSINGAPORELUANDARIO DE JANEIRO30TOKYOSHANGHAI

BODONIHead office: P.O. Box 23, NO-5329 Florvåg, Norway, Phone: 47 55 99 90 00, Telefax: 47 55 99 93 80, E-mail: marine@framo.noFRAMO Nederland, Edisonweg 18, P.O. Box 305, NL-3200 AH Spijkenisse, The Netherlands, Phone: 31 181 619311, E-mail: fm.nederland@framo.noFRAMO USA, 3002 East 13th Street, La Porte, Texas 77571, USA, Phone: 1 281 884 4800, E-mail: fm.houston@framo.noFRAMO Singapore, 17 Tuas View Circuit, Singapore 637575, Republic of Singapore, Phone: 65 6210 2400, E-mail: fm.sin@framo.noFRAMO Japan, Kotsu Building 5F, 15-5, Shinbashi, 5-chome, Minato-ku, Tokyo 105-0004, Japan, Phone: 81 3 5776 2405, E-mail: fmnippon@framo.co.jpFRAMO Korea, Rm 608, Centum Sh Valley, 35, Centum Dong – Ro, Haeundae – Gu, Busan, Korea, 612-020, Phone: 82 51 743 6942/3, E-mail: fmk@framosk.comFRAMO Shanghai, Building No.5, 123, Lane 1165, Jin Du Road, Min Hang District, Shanghai, China 201108, Phone: 86 21 6115 5000, E-mail: fmcn@framo.com.cnFRAMO Brasil, Av. Presidente Vargas, 463 /19 andar, Rio de Janeiro - CEP 20071-003, Brazil, Phone: 55 21 2507 7898, E-mail: framobr@framobr.com.brFRAMO México, Francisco Petrarca 223-901, Col Chapultepec Morales, CP 11560 México DF, Phone: 52 55 63 91 22 15, E-mail: mexico@framo.noFRAMO Services AS, P.O. Box 44, NO-5329 Florvåg, Norway, Phone: 47 55 99 92 00, E-mail: service@framo.noFRAMO Fusa AS, Venjaneset, NO-5641 Fusa, Norway, Phone: 47 55 99 96 00, E-mail:marine@framo.noFRAMO Holsnøy AS, Rosslandsvegen 933, NO-5918 Frekhaug, Norway, Phone: 47 55 99 75 00, E-mail: piping.marine@framo.noFRAMO Flatøy AS, Flatøyvegen 24, NO-5918 Frekhaug, Norway, Phone: 47 55 99 94 00, E-mail: oil&gas@framo.no

powered by a hydraulic motor for safe and efficient operation. All our cargo pumps are made in stainless steel material and designed with a smooth and easy-to-clean surface with a limited number of flanges which gives a superior ability to pump any liquid. THE SUBMERGED CARGO PUMP The pump design allows operation with saves time spent for drainage and tank cleaning. The Framo cargo pump has a .