Transcription

CASESTUDYLarge Printing DivisionReduces Complexity andMinimizes DevelopmentCosts using Windchill PLM

INTRODUCTIONABOUT THE CLIENT:The client is a leading global provider of software, technologies, and products with arich history and tradition in Manufacturing, offers information and technologyservices as well as manufacturing PCs, printers, and computer accessories. The clientdevelops, manufactures and markets digital printing solutions, including printingpresses, proprietary consumables and supplies.Client ChallengesClient was looking to scale up and realize full blown PLM and move up the curve inthe digital transformation journey. The client had only basic functions of PLMimplemented using multiple systems often in silos used by single, internaldepartments. The specifics challenges include the followingNon-Standardized product development processInefficient supply chain and vendor collaborationManual and outdated integrations resulting in loss of control over informationChallenges in achieving Business Intelligence leading to incorrect delivery ofinformationInconsistent information across multiple systemsOpen loop processes causing performance and inefficiency, cost and qualitypressuresPoor end user experience

ITC Infotech SolutionITC Infotech defined requirements, developed step wise implementation model anddeployed a full-blown PLM solution that catapulted the client to higher PLM maturityITC conducted several workshops and assessment drives to understand thecurrent PLM maturity level and developed a ‘PLM framework’ for implementation.The solution was deployed using Agile methodologyConsolidated data from multiple systems and synchronized with other applicationsAutomated and implemented closed loop, optimized processes and best practicesCentralized information resulting in powerful data governance and traceabilityWindchill as single source of truth provide the client agility, scalability, and globalcollaboration. Also, it has improved the way users create, access, and manageproduct data across departments, eliminating unnecessary manual tasks.Implementing a variety of use cases has also enabled the client to have asignificant impact across new product development (NPD).Enabled a full operational bill of process across the enterprise and helps reducethe cost of human errors, accelerating the time to industrialization. The increasedinteractions between designers and manufacturing engineers during developmenthelps the client identify issues early on and ensure manufacturability and agility.DATA CONVERSION AND CONSOLIDATIONITC Infotech executed the data conversion involving 20 years of data that includes5million part records, 1 million documents, 20 million CAD records and files, and 60million relationships with three dry runs, one pre-production and production. Thedata were sourced from multiple systems profiled using ITC standard templates,transformed to clean duplicates and eliminate redundancy and obsolete informationusing ITC boilerplate scripts. Also, established relationship between CAD and Parts,created super loaded BOM that explodes with Mechanical, Electrical & Electronics,and Software components, and dependents, resulting information published inmultiple formats to requesting applications. The production cut-over that spanned116 hours was executed with no disruption to operation.

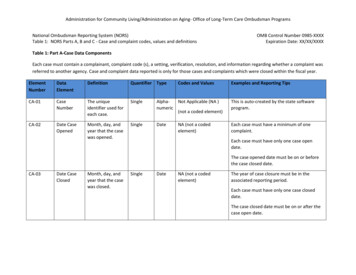

MRPSHOP FLOOR APPLN.CAD MECH/ECADERP 1PDMLINKTEAMCENTERERP 2REPORTSREPORTSPROCESS STANDARDIZATION AND AUTOMATIONITC Infotech deployed a unified PLM thateliminated legacy engineering tools,standardized NPI and change managementprocesses, developed several customreports (BOM Costing and Changeprocesses) that provides real time visibilityand traceability of information at any timeduring the product lifecycle, integratedWindchill with multiple application like ERP,MRP and Mold base that improves datagovernance and traceability, developedcustom intelligent auto Part and CADnumberingapplicationprovidingstandardization. The unified systemenabled efficient collaboration of crossfunction teams and suppliers were notifiedof the changes real time reducingmanufacturing errors.CHANGE PROCESSSTANDARIZATIONChange Request(NCR, ECR, PCR)Eco approvedDesign Docsand CADDocs RevisedChangeOrderECOClosedRecognize the need tochange, Role: CognizantEngineerTechnical Release of theChange Passed Check ListRole-x-DisciplineRelease toQAD/QRDERP/MRPsystems updated

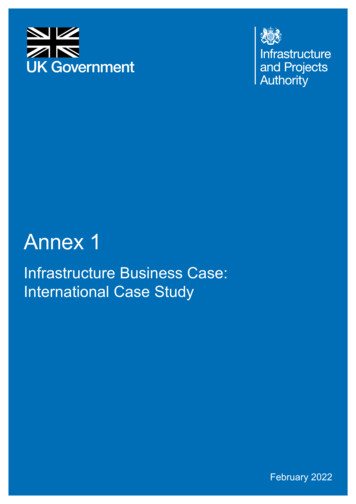

UNIFIED PLMMRPSHOP FLOOR APPLN.ERP 1P/N GenerationCAD MECH/ECADERP 2BIREPORTSDOCUMENTMANAGEMENTEXTERNALPARTNERPART AND CAD NUMBER GENERATIONREPORTS

Bottom LineITC Infotech can help manufacturers in their digital transformation journeyleveraging PLM. The successful example discussed is testimony to ITC Infotech’sdomain expertise and PLM service competency.For details about ITC Infotech PLM capabilities please refer:https://www.itcinfotech.com/AboutITC InfotechITC Infotech is a leading global technology services and solutions provider, led by Business andTechnology Consulting. ITC Infotech provides business-friendly solutions to help clients succeedand be future-ready, by seamlessly bringing together digital expertise, strong industry specificalliances and deep domain expertise. The company provides technology solutions and services toenterprises across industries through a combination of traditional and newer business models, as along-term sustainable partner.www.itcinfotech.com

Open loop processes causing performance and inefficiency, cost and quality . Infotech Solution ITC Infotech defined requirements, developed step wise implementation model and deployed a full-blown PLM solution that catapulted the client to higher PLM maturity . Windchill as single source of truth provide the client agility, scalability, and .