Transcription

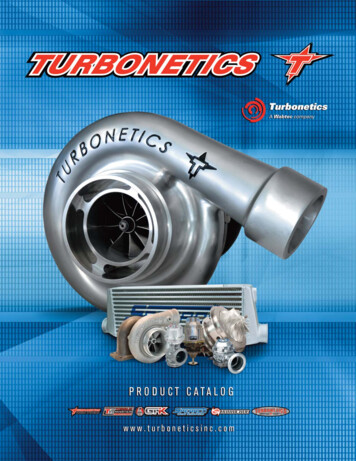

I NTR O D U CTI O NSincehighest quality standards, with years of experience in designing andproducing forced induction parts. And if something goes wrong ourlegendary no fault no hassle warranty has you covered - we are hereto help to get you back behind the wheel quickly.1978, Turbonetics has been a leader in designing andmanufacturing turbochargers, intercoolers, turbo systems, pressurecontrol valves and forced induction components. Turbonetics productsare boosting engines that run on all kinds of fuel, and in all sorts ofenvironments including performance, racing, industrial and militaryapplications. Our commitment to quality and innovation and our abilityto design and deliver customized solutions within days makesTurbonetics products the number one choice for daily drivenperformance vehicles as well as extreme race-only applications fromas little as 250 to over 2000 horsepower on a single turbo.Our range of Turbonetics’ turbos comes with a mind-bogglingchoice of compressor wheels, turbine wheels and end housingconfigurations. We listed as much as possible, but if you cannot findwhat you are looking for, contact us for an even more customizedturbocharger or intercooler. And as we are constantly adding newproducts and options to our portfolio, make sure to checkwww.turboneticsinc.com for the latest innovations as well astechnical information.But with a Turbonetics product you get more than just performance,you get peace of mind that what you install has been made to the2Phone: (805) 581-0333 Fax: (805) 584-1913

TA B L E O F C O N T E N T SINTRODUCTION2Y2K / SUPER THUMPER TURBOCHARGERSTABLE OF CONTENTS3TURBINE WHEELS AND HOUSINGS26-27BALL BEARING TECHNOLOGY4COMPRESSOR WHEELS AND HOUSINGS28-29WARRANTY AND BENEFITS5TURBINE HOUSING FLANGES AND GASKETS30TURBOCHARGER BALANCING6TURBINE HOUSING HEATSHIELDS AND V-BANDS31COMPRESSOR AND TURBINE WHEELS7FLUID LINES & FITTINGS32HOW TO CHOOSE A TURBO8OIL SUPPLY - GASKETS AND FLANGES33A/R RATIO AND TWIN TURBO9PARTS & ACCESSORIES34HOW TO READ A COMPRESSOR MAP10-11EXTERNAL WASTEGATES2535-36INDUSTRIAL SOLUTIONS12BYPASS VALVES AND BOOST CONTROLLERS37MILITARY SOLUTIONS13SILICONE CONNECTIONS AND T-BOLT CLAMPS38UNMANNED SOLUTIONS14INTERCOOLER SELECTION GUIDE/SPEARCO39GT-K BILLET TURBOCHARGERS15AIR TO AIR INTERCOOLER CORES40-42GT-K TURBOCHARGERS16LIQUID TO AIR INTERCOOLER CORES43-45HURRICANE SERIES TURBOCHARGER17MITSUBISHI EVOLUTION X INTERCOOLER KIT46T3 TURBOCHARGERS18SUBARU WRX / STI INTERCOOLER KIT47T3/T4 TURBOCHARGERS19FORD MUSTANG SYSTEM48T04B & T04E TURBOCHARGERS20CHEVROLET CAMARO TURBO SYSTEMS4960-SERIES TURBOCHARGERS21GM DURAMAX DIESEL UPGRADES50T-SERIES TURBOCHARGERS22FORD POWERSTROKE DIESEL UPGRADES51SUPER T TURBOCHARGERS23DODGE CUMMINS DIESEL UPGRADES52MID-FRAME TURBOCHARGERS24TERMS & CONDITIONS / RMA INSTRUCTIONS533turboneticsinc.com

BALL B EAR I N G TE C H N O LO GYCERAMIC BALL BEARINGSWITH PATENTEDWHAT MAKES THE TURBONETICS BALL BEARING SPECIAL?Turbonetics offers a patented Angular-Contact Ceramic Ball Bearing design. ThisTurbonetics exclusive design is made with almost indestructible silicone-nitrideceramic balls. A conventional unit has a capacity of 60-80 lbs. of dynamic thrustload. The patented Turbonetics Angular-Contact Ceramic Ball Bearing canwithstand anywhere from 1000 to 2200 lbs. of loading. The “angular-contact” featureoffers extreme strength because it is used as the loading surface. This results inquicker transient response and ultra-fast spooling of the turbo. With TurboneticsAngular-Contact Ceramic Ball Bearing units, you will build boost faster at the line,reach boost sooner in the RPM band and maintain higher boost in between shifts.TECHNOLOGYTURBONETICS BALL BEARING SERVICEABILITYWhile most of our turbos never need any repairs, many of our customers love to havepeace of mind when it comes to serviceability. Our unique design allows all genuineTurbonetics Ball Bearing units to be rebuilt for less than the cost of a new unit. Contactyour dealer or call us if you need to service your unit. MORE THAN 13X GREATER THRUST CAPACITY25% FASTER SPOOL UPRE-BUILDABLEPATENTED CERAMIC BALL BEARINGSEvery Turbonetics turbocharger from T3 to SuperT comes pre-installed with a special in-line oilfilter to prolong your custom turbos life andprotect it from oil debris damage. See page 53for complete warranty details.4Phone: (805) 581-0333 Fax: (805) 584-1913

WAR R ANTY AN D B E N E FITSCOMPANY WARRANTY POLICYTHE “NO FAULT/NO HASSLE” WARRANTYWe at Turbonetics stand behind our products. And our “No Fault/NoHassle” warranty program shows this commitment.workmanship is covered - no questions asked. This truly exceptionalwarranty program offers peace-of-mind that when you get aTurbonetics product, you get our commitment to quality andperformance. See page 53 for exclusions and details on how tosubmit a claim.We will repair or replace any Turbonetics product that fails, includingproducts used in racing or competition applications, for a period ofone year from the original date of purchase. Any defect in material orCOMPANY /SERVICE FEATUREENGINEERINGMANUFACTURING In-depth aerodynamic and turbochargerengineering expertise In house machining and assembly Custom aerodynamic matching application Component and VSR assembly balancing Fully trained & certified technicians CAD expertise to turn ideas into products quickly Skillful custom fabrication Dynamometers on site- RGA (Returned Goods Authorization)number supplied by Turboneticsclearly marked on outside of boxQUALITY Disciplined quality management system- Description regarding failure ordamage to the component Caterpillar SQEP gold certified- Mileage Gas stand performance testing- Point of purchaseSHIPPINGSALES & TECH SUPPORT Friendly sales staff Excellent tech support FedEx, UPS, DHL and freight forwarding Competitive rates Same day shipping for in stock items Dedicated customer service5turboneticsinc.comDepartment at 805-581-0333.PLEASE PROVIDE:- Warranty Registration NumberRESEARCH & DEVELOPMENT Expert tuning capabilityCall Turbonetics Customer Service

TU R BO C HAR G E R BALAN C I N GCOMPONENT & ASSEMBLY BALANCINGSTEP 2: VSR OR "ASSEMBLY" BALANCINGTurbochargers can spin at speeds of well over 100,000 rpm. Thetiniest imbalance can cause vibration, leading to noisy operation,oiling issues and ultimately bearing failure. Just like the wheels on acar, the wheels on a turbocharger have to be balanced to ensureoptimal performance.The second method is called VSR (Vibration Sorting Rig) balancing.This machine detects imbalance of the complete unit after assembly.As turbos are assembled, there are still tiny imperfections in thrustcollars, nose nuts, wheels and shafts. While each one is adequatelybalanced by itself, once assembled together the sum of all theimbalances can become significant. Using the VSR process, acompleted CHRA (Center Housing & Rotating Assembly - basicallya turbocharger without end housings) is driven by compressed air in aVSR balancer, and accelerometers determine:There are two ways on how a turbocharger can be balanced:Component balancing and VSR or "Assembly" balancing. While manyturbocharger manufacturers choose one or the other method, atTurbonetics we believe that the perfect turbocharger has to beperfectly balanced. And this can only be achieved by using bothmethods - on every turbocharger possible. THE AMOUNT OF IMBALANCESTEP 1: COMPONENT BALANCING THE POSITION OF THE IMBALANCEWhen using a component balancer, both the turbine wheel and thecompressor wheel are balanced individually - before they areassembled into the turbocharger. The wheels are run at relatively lowspeeds, just like new tires at a tire shop. But unlike tires, where weightis added to achieve balance, tiny amounts of metal are removed fromturbocharger wheels through precision milling and grinding to achievethe perfect balance. SHAFT ROTATING SPEED OIL FLOW VOLUME THROUGH ASSEMBLYA certified technician then removes even tinier parts of metal, ensuringthe perfect balance of the entire unit. The result is a perfectly balancedTurbonetics turbocharger that will run smoothly, perform better andlive longer.VSR HIGH SPEED BALANCING PROCESSBalance angleClock indicatingrequired balancepositionSpeed at cursor positionand maximumspeed attainedOil flow throughVibrationturbochargersignalCursor is moved along rev scale.Clock indicating imbalance positionOperatingspeedExample of an out of balance turbocharger.6Phone: (805) 581-0333 Fax: (805) 584-1913

C O M PR E SS O R AN D TU R BI N E WH E E LSCOMPRESSOR WHEEL DESIGNpressure. Racers and enthusiasts continue to strive for greaterpower and Turbonetics compressor wheel designs are constantlyevolving to meet the demands and deliver higher boost pressures.Compressor wheels deliver pressurized air to the engine.Turbonetics compressor wheels are manufactured from one of threedifferent materials: cast 354 aluminum that is heat treated andHipped, A-2618 forged aluminum and Titanium depending on theapplication requirements. Computer aided design (CAD) allows fornew blade designs to create maximum airflow efficiency andOur wide range of compressor wheel sizes, trim blade configurationsand blade shapes can be categorized into three groups:T-SERIES BASED WHEELS: Known for their outstanding durabilityand solid air flow characteristics, this category includes well establishedcast wheels such as T3, 60-1, 62-1, T04B, T04E.HP (HIGH PRESSURE) WHEELS: To meet the need for higher boostHPC Billet Compressor Wheelpressures and efficiency, Turbonetics developed the HP- Serieswheels with new blade shapes providing optimized air flow. Primarilycast components and under more stress than T-series based wheels,these wheels go through a process called Hot Isostatic Processing(HIP). This process removes any air bubbles that could be trapped inthe castings. Imperfections in the castings can cause wheel bursts,and we are not prepared to compromise on durability.HP Compressor WheelH PC WH E E LS: The "C" stands for "Competition". A furtherNew aerodynamics and improvements in blade design andmaterials are always in the works at Turbonetics.Check our website for the latest updates and learn moreabout wheel diameters and trim atdevelopment over the HP wheels, these Turbonetics billet wheelsprovide even greater efficiency and airflow. To withstand the extremepressures, HPC compressor wheels are machined from forged blanksinstead of standard bar stock. Wheels machined from forged blankshave stronger blades and wheel hubs and allow maximizing airflowwhile minimizing rotating mass.www.turboneticsinc .comTURBINE WHEELF1-SERIES TURBINE WHEELS*Turbine wheels harness the hot exhaust gas energy for theturbocharger. All Turbonetics turbine wheels are made from 713CInconel, a nickel-based super alloy. This material is much strongerand can withstand higher temperatures than most other turbine wheelmaterials. Turbonetics exclusive F1-series turbine wheels feature a10-blade design and tall tip height configuration to maximize theexhaust gas energy and keep backpressures low. Backpressure isthe opposite of boost pressure. It is the pressure of the exhaust gastrying to get past the turbine wheel. High backpressure can preventoptimum flow through the engine, limit theturbocharger from making boost andreduce potential horsepower. Unlikeconventional T style turbine wheels,our F1-series design minimizesbackpressure to allow the mosthorsepower possible for a givenwheel size.FAMILYT3T3T3T3 or T4T3 or T4T3 or T4T4MID-FRAMEMID-FRAME (coming soon)Y2KY2KTHUMPERTHUMPERTHUMPERF1 turbine wheel provides unequaled exhaustflow while keeping backpressures 1-89F1-101F1-96F1-106F1-112*Wheel names also denotes turbine exducer diameter in 5010001150 NEW12001250 NEW12001250185019002000

H OW TO C H O O S E A TU R BOCHOOSING THE RIGHT TURBO FOR YOUHOW TO CHOOSE A TURBOThere are many variables to consider when choosing the perfect turbo for your engine. This section will help narrow down your choice.Check www.turboneticsinc.com for more detailed information. Here are some things to consider.ESTABLISH YOUR GOALS:POWER: HOW MUCH HORSEPOWER DO YOU WANT TO MAKE? Think in horsepower. The horsepower output is the single most important factor to size a turbo. Don't think in boost pressure. Boost is just a number that you will have to run on yourengine to make a certain horsepower. Can your vehicle (not just the engine, but the entire setup) handle yourpower target? Think of pistons, connecting rods, head studs, etc. Translate your targeted wheel HP into a crankshaft HP. Rule of thumb:add 20%INTENDED USAGE What are you using the vehicle for? Are you targeting peakhorsepower or fast boost response? The way that you will be using the vehicle dramatically changesthe sizing of the turbocharger and intercooler needs. Your choice of transmission type and gearing will greatly affectthe performance and characteristics of the turbocharger.PACKAGING Will the turbocharger(s) fit in your vehicle’s space constraints? Consider using differently sized compressor housings to more easily fit a given location.BOOST RESPONSE OR MAXIMUM HORSEPOWER?In street/autocross/drift applications, a faster response is generallypreferred, and a smaller turbocharger achieves exactly that.Conversely, dedicated drag racers for example need peak power, notboost response. Therefore larger frame turbochargers are used tomaximize horsepower.This is the most important and most discussed question whenconfiguring your turbocharger. The basic dilemma is: Do you want tomaximize the horsepower output of the engine at a very small rpmrange and accept a slower boost response at lower rpms, or do youneed immediate throttle response throughout the rpm range and arenot too concerned with the maximum horsepower number?Here are 3 steps to select the turbine wheel and housing combinationf

turboneticsinc.com 3 table of contents introduction 2 table of contents 3 ball bearing technology 4 warranty and benefits 5 turbocharger balancing 6 compressor and turbine wheels 7 how to choose a turbo 8 a/r ratio and twin turbo 9 how to read a compressor map 10-11 industrial solutions 12 military solutions 13 unmanned solutions 14 gt-k billet turbochargers 15 gt-k turbochargers 16