Transcription

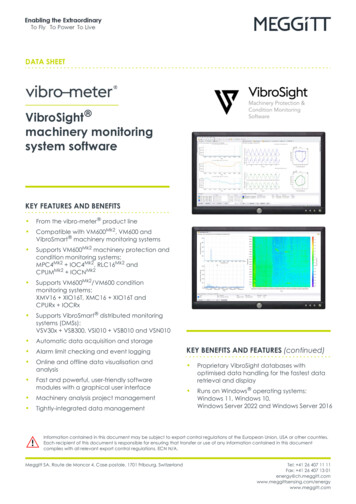

DATA SHEETVibroSight machinery monitoringsystem softwareKEY FEATURES AND BENEFITS From the vibro-meter product line Compatible with VM600Mk2, VM600 andVibroSmart machinery monitoring systems Supports VM600Mk2 machinery protection andcondition monitoring systems:MPC4Mk2 IOC4Mk2, RLC16Mk2 andCPUMMk2 IOCNMk2 Supports VM600Mk2/ VM600 conditionmonitoring systems:XMV16 XIO16T, XMC16 XIO16T andCPURx IOCRx Supports VibroSmart distributed monitoringsystems (DMSs):VSV30x VSB300, VSI010 VSB010 and VSN010 Automatic data acquisition and storage Alarm limit checking and event loggingKEY BENEFITS AND FEATURES (continued) Online and offline data visualisation andanalysis Fast and powerful, user-friendly softwaremodules with a graphical user interfaceProprietary VibroSight databases withoptimised data handling for the fastest dataretrieval and display Runs on Windows operating systems:Windows 11, Windows 10,Windows Server 2022 and Windows Server 2016 Machinery analysis project management Tightly-integrated data managementInformation contained in this document may be subject to export control regulations of the European Union, USA or other countries.Each recipient of this document is responsible for ensuring that transfer or use of any information contained in this documentcomplies with all relevant export control regulations. ECN N/A.Meggitt SA, Route de Moncor 4, Case postale, 1701 Fribourg, SwitzerlandTel: 41 26 407 11 11Fax: 41 26 407 13 gywww.meggitt.com

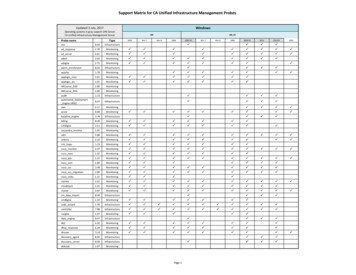

APPLICATIONS Machinery vibration monitoring and analysis Rolling-element bearing analysis Hydro air-gap and magnetic-flux monitoringand analysis Dynamic combustion monitoring and analysisDESCRIPTIONVibroSight machinery monitoringsystem softwareThe VibroSight machinery monitoring systemsoftware, from Meggitt’s vibro-meter productline, is a highly-integrated software suite thatsupports the effective monitoring of all rotatingmachinery.Designed for operation with VM600Mk2/ VM600rack-based systems and VibroSmart distributedmonitoring systems (DMSs), the VibroSight software is an essential part of these machinerymonitoring systems. The software is used for systemconfiguration, operation and management andenables the predictive methodologies which canbe used to optimise the operational efficiency ofindustrial machinery.In particular, a VibroSight-based machinerymonitoring system can be used to: Minimise downtime through the planning andscheduling of maintenance activities. Maximise component life by avoiding knowncritical operating conditions. Improve equipment reliability through theeffective prediction of equipment failures. Use condition monitoring techniques tomaximise equipment performance.When used by technicians, operators andengineers, VibroSight enables them to identify aproblem rapidly, evaluate the situation anddetermine the appropriate action to take in orderto protect machinery and reduce operatingcosts.Machinery monitoring system operationThe VibroSight software is designed to be easy touse: from the configuration of parameters andmeasurements for the machinery beingmonitored, to automated data acquisition andsignal processing, and the display of data to assistin the advanced analysis and diagnosis ofindustrial machinery (using VibroSight Vision).DATA SHEETVibroSight machinery monitoring system software2 / 28The configuration of the system depends on theactual machinery monitoring system hardwareused and the machinery monitoring application.For example: VibroSight Protect is used to configureVM600Mk2 systems (MPC4Mk2 IOC4Mk2,RLC16Mk2, CPUMMk2 IOCNMk2 ) formachinery protection (MPS) applications. VibroSight Capture is used to configureVM600Mk2 systems (MPC4Mk2 IOC4Mk2) forcondition monitoring (CMS) applications. VibroSight Configurator is used to configureVM600 systems (XMx16 XIO16T) for conditionmonitoring (CMS) applications and toconfigure VibroSmart systems(VSV30x VSB300, VSI010 VSB010) formachinery protection (MPS) and/or conditionmonitoring (CMS) applications.In general, with VM600Mk2/ VM600 andVibroSmart systems, data acquisition iscontinuous with a typical measurement dataupdate rate of 1 s (100 ms max.), there isextended alarm (severity state) handling withmultiple alarms per output, and extendedprocessing capabilities. In addition, VibroSightbased systems have the ability to adaptautomatically to the criticality of the machinerybeing monitored by applying specific datalogging scenarios, depending on machineoperating conditions (machine states).The VibroSight software takes advantage ofindustry standard platforms and runs onWindows 11, Windows 10, Windows Server 2022and Windows Server 2016 operating systems. Ituses a proprietary, highly-optimised system ofVibroSight databases to ensure performance andenable tightly-integrated data management(compared to an off-the-shelf database). And ithas an intuitive, fully graphical interface for easeof use.An example application of a VibroSight -basedsolution is shown overleaf.Document reference DS 660-020-005-224AVersion 24 – 16.05.2022

Document reference DS 660-020-005-224AVersion 24 – rt Plant data highway (Ethernet)VibroSight ServerMachinery monitoring system parameters forcritical assets and balance of plant (BOP) equipment such asvibration, speed, pressure, temperature, etc.Configuration and localdata display(VibroSight Protect,Capture, Configurator)Offline analysis(VibroSight Vision)Process parameters such astemperature, flow rate, level, pressure, etc.Third-party systemssuch as DCS or PLCData display workstations(VibroSight Vision, Mimic, Event Viewer)EXAMPLE APPLICATIONDATA SHEETVibroSight machinery monitoring system software3 / 28

DESCRIPTION (continued)VibroSight software architectureAs shown below, the software uses apredominantly client-server architecture todistribute the functional requirements andworkload across different software modules andapplication specific packages. The VibroSight software uses a truly modulardesign that adapts to different machinerymonitoring applications.VibroSight client software modulesApplication packages (optional)Protect *CaptureVisionMimic*Configurator**Event ViewerVibroSight serversoftware moduleVibroSight databaseServerSystem ManagerScope***Hydro air-gapmonitoringCombustionmonitoringExternal datafile tionengineExternal interfaces (optional)Modbus clientand/or serverOPC clientand/or serverRule box software(optional)VibroSightdiagnosticsrule boxMachinery monitoring system hardwareVM600Mk2VM600Mk2/ VM600VibroSmart MPC4Mk2 IOC4Mk2XMV16 XIO16TVSV30x VSB300RLC16Mk2XMC16 XIO16TVSI010 VSB010CPUMMk2 IOCNMk2CPUx IOCx* The VibroSight Protect software module is used to configure VM600Mk2 systems (MPC4Mk2 IOC4Mk2, RLC16Mk2,CPUMMk2 IOCNMk2) for machinery protection (MPS) applications, while the VibroSight Capture software module is used toconfigure VM600Mk2 systems (MPC4Mk2 IOC4Mk2) for condition monitoring (CMS) applications.** The VibroSight Configurator software module is used to configure VM600Mk2/ VM600 systems (XMx16 XIO16T) for conditionmonitoring (CMS) applications and to configure VibroSmart systems (VSV30x VSB300, VSI010 VSB010) for machineryprotection (MPS) and/or condition monitoring (CMS) applications.*** The VibroSight Scope software module is used to display data from VibroSmart systems only.DATA SHEETVibroSight machinery monitoring system software4 / 28Document reference DS 660-020-005-224AVersion 24 – 16.05.2022

DESCRIPTION (continued)Due to its modular client-server architecture, theVibroSight software can run on a single host(stand-alone) computer or be distributed across anumber of computers (multi-servers) connectedto the machinery monitoring system hardware(VM600Mk2/ VM600 racks and/or VibroSmart systems) by an Ethernet network. This allowsconfiguration, acquisition, data visualisation andanalysis, and troubleshooting tasks to beperformed from a single location or distributedbetween several workstations.Advantages of distributed configurations includeallowing specific functions to be performed ondedicated computers by the appropriatepersonnel. Distributed configurations also enableremote data collection and analysis, allowingconfiguration and troubleshooting tasks to beperformed via remote access if necessary.For integration in industrial environments,VibroSight supports external interfaces thatenable the exchange of data with third-partysystems using industry standard protocols.For example, this enables the correlation ofvibration data with other parameters that arealready available from separate field devices, sothat there is no need to remeasure.VibroSight software modules, editions andapplication specific packagesVibroSight’s software architecture consists ofseveral software modules for use with VM600Mk2modules, VM600 modules/cards and VibroSmart modules and devices. This allows a range ofVibroSight software editions to be provided tomeet the requirements of different machinerymonitoring applications. Each software editionincludes different software modules and alsofeatures application specific packages: Hydro air-gap monitoring – for the monitoringand analysis of hydroelectric generators. Combustion monitoring – for the monitoringand analysis of combustion chamberdynamic-pressure data. External data file import (database mirroring)– for the import of external data intoVibroSight Servers (*.vshdf) using CSV and/orVibroSight historical data archive (*.vshda)files.Document reference DS 660-020-005-224AVersion 24 – 16.05.2022 Custom mathematical calculation engine – toenable math post-processing on the data inVibroSight Servers (*.vshdf) in order tocalculate and create new data andinformation.It is important to note that the base/standardVibroSight (that is, the VibroSight Classic edition)provides full support for vibration analysis,including a complete catalogue of plots and thefunctionality required for the display and analysisof absolute vibration, relative vibration, position,displacement, eccentricity expansion and so on.This is in addition to its included applicationspecific package: Hydro air-gap monitoring.See Software editions on page 18 for furtherinformation.VibroSight external interfacesVibroSight’s external interfaces include industrystandard interfaces such as Modbus and OPC toenable data sharing between a VibroSight Server(*.vshdf) and third-party systems through theimport and/or export of data.For VM600Mk2/ VM600 systems containing aCPUMMk2 IOCNMk2 module or CPUx / IOCxmodule/card pair, data can equally be exportedvia industry standard fieldbuses such as Modbusor PROFIBUS.Similarly for VibroSmart systems containing aVSI010 VSB010 module, data can equally beexported via Modbus, PROFIBUS or the IEC 61850GOOSE protocol.DATA SHEETVibroSight machinery monitoring system software5 / 28

DESCRIPTION (continued)VibroSight / VM600Mk2 systemsconfiguration and operation of VM600Mk2 systemsdepending on the functionality required:In VibroSight / VM600Mk2 systems (that is, thesecond generation of VM600 rack-basedsystems), the MPC4Mk2 IOC4Mk2 module canprovide machinery protection system (MPS)functionality and/or condition monitoring system(CMS) functionality, depending on therequirements of the application. VibroSight Protect supports the configurationand operation of the machinery protection(MPS) functionality for a VM600Mk2 system. VibroSight Capture supports the configurationand operation of the condition monitoring(CMS) functionality for a VM600Mk2 system.As shown below, the VibroSight software usescompletely separate software modules for theMachinery protection system (MPS)VibroSight software moduleProtectVM600Mk2 hardwareRLC16Mk2CPUMMk2 IOCNMk2MPC4Mk2 IOC4Mk2CaptureVibroSight software moduleCondition monitoring system (CMS)Using separate software modules(VibroSight Protect and Capture) for theconfiguration and operation of VM600Mk2functionality/systems helps ensure completeseparation (“segregation”) of MPS and CMS in asingle VM600Mk2/ VM600 rack.DATA SHEETVibroSight machinery monitoring system software6 / 28For example, a VibroSight / VM600Mk2 systemconsisting of MPC4Mk2 IOC4Mk2 modules caninitially be installed and used as a MPS only. Then,CMS functionality can be quickly and easilyadded at any time by upgrading the licenses forthe MPC4Mk2 IOC4Mk2 module(s) and forVibroSight software, as required.Document reference DS 660-020-005-224AVersion 24 – 16.05.2022

DESCRIPTION (continued)For the VM600Mk2 MPC4Mk2 IOC4Mk2 machineryprotection and condition monitoring module,machinery protection functionality is available bydefault for all versions of the module, whilecondition monitoring functionality is optional.Accordingly, MPC4Mk2 condition monitoring canbe used by either (1) ordering a version of themodule with condition monitoring enabled or (2)ordering and uploading a condition monitoringlicense to a version of the module withoutcondition monitoring enabled (usingVibroSight System Manager).VibroSight is also used for the configuration ofany CPUx / IOCRx rack controller andcommunications interface modules/card pairs,if used.Note: MPC4Mk2 condition monitoring also requiresa VibroSight software edition / license thatsupports condition monitoring. Hardware / system compatibilityFor VM600Mk2 machinery protection applications,theVibroSight softwareincludesVibroSight Protect, which is designed specificallyfor operation with VM600Mk2 systems (that is, thesecond generation of VM600 rack-based systems)and modules: VM600 Mk2 MPC4 Mk2 IOC4Mk2 module –machinery protection (MPS) functionality VM600 Mk2 RLC16Mk2 relay moduleVM600 Mk2 CPUM Mk2 IOCNMk2.For VM600Mk2 condition monitoring applications,theVibroSight softwareincludesVibroSight Capture, which is designed specificallyfor operation with VM600Mk2 systems (that is, thesecond generation of VM600 rack-based systems)and modules: For VibroSmart machinery protection and/orcondition monitoring applications with lowerchannel counts, the VibroSight software supportsthe following VibroSmart modules and devices: VSV30x VSB300 monitoring modulesVSI010 VSB010 communications interfacemoduleVSN010 real-time Ethernet switch.Applications informationAs part of a VM600Mk2/ VM600 and/orVibroSmart solution, the VibroSight machinerymonitoring software is ideal for the monitoringand protection of critical assets such as gas,steam and/or hydro turbines, other high-valuerotating machines, as well as balance of plant(BOP) equipment such as compressors,gearboxes, motors, pumps and fans.The VibroSight software is fast and powerful: sofast, that it has to be seen to be believed. Evenhigher channel count applications monitoring alarge numbers of assets from a single databasepose no problem. In practice, this makesVibroSight easier to use and results in quickerdata analysis.For further information, contact your localMeggitt representative.VM600 Mk2 MPC4 Mk2 IOC4Mk2 module –condition monitoring (CMS) functionality.For VM600Mk2/ VM600 condition monitoringapplications, the VibroSight software is designedto take advantage of the extended processingcapabilities and high data throughput of theVM600Mk2/ VM600 XMx16 extended conditionmonitoring modules: XMV16 XIO16T for vibration monitoringXMVS16 XIO16T for vibration monitoringXMC16 XIO16T for combustion monitoring.Document reference DS 660-020-005-224AVersion 24 – 16.05.2022DATA SHEETVibroSight machinery monitoring system software7 / 28

PRODUCT HIGHLIGHTSThe VibroSight software incorporates the following main product features and benefits:VibroSight databasesVibroSight uses VibroSight databases – a specialised system of files designed andoptimised for the high-speed storage and retrieval of data generated by highperformance machinery monitoring systems.VibroSight databases use a proprietary database (data repository) system,consisting of VibroSight historical data folders (*.vshdf) for handling and logging ofdata by a VibroSight Server, and VibroSight historical data archives (*.vshda) fordisplay, analysis and sharing of historical data without a VibroSight Server.Compared to systems using off-the shelf databases, the combination of VibroSightdatabases and the optimised data handling implemented by VibroSight result in asystem that: Is fully adapted to the data handling needs of high-performance machinerymonitoring systems. Is much faster than a standard database. Is very responsive when analysing large quantities of data. Requires less storage (disk space) and memory to store, work with and share thesame quantity of information. Integrates seamlessly.Fully-integrateddata managementVibroSight includes fully-integrated support for VibroSight database managementthat simplifies the configuration and operation of the database backup, databasepurge and management of offline data storage.This extremely easy to use data management configuration means that no externaldata/database management tools are required.VibroSight Vision foreasy data analysisVibroSight Vision offers exceptional data handling and visualisation capabilities sothat it is effortlessly fast for the display and analysis of data.It includes a complete catalogue of plots with cursor synchronisation that allows allof the information relevant to a particular event or time period to be more easilydisplayed for even quicker analysis.Data from multiple VibroSight databases (*.vshda) can be worked with at thesame time using simple drag and drop operations in order to more easily comparepresent and historical data across multiple sites and time periods.Rapid, optimised zooming in plots encourages the discovery of additional data/plotfeatures. For example, the Long Waveform plot can be used to display allmeasurement points in a continuous long-duration waveform – making the analysisof machinery data so much easier.Whenever a plot is updated in VibroSight Vision, VibroSight automatically processes(“filters”) the measurement data using super-fast algorithms in order to optimallyselect the data points required to accurately display the data in the plot.Transientmachine statesVibroSight supports transient machine states that automatically detect the typicalmachine states associated with the transitory operation of a machine, such as runups, run-downs, aborted run-ups and aborted run-downs. These transient machinestates help to quickly identify relevant data for the analysis of transient conditions.Transient machine states are in addition to VibroSight’s support for (standard)machine states which are used to identify the steady-state operation of machinery.Corbit plotVibroSight Vision includes the Corbit (cascaded orbit) plot type which displaysmultiple orbits on the same 3D plot as a function of time or speed, optionally withtheir waveforms. A Corbit plot typically consists of many individual orbits or filteredorbits superimposed one on top of another for the selected time range.Corbit plots can be used to quickly see and examine the overall envelope (shape)of an orbit to see how it changes against time or speed, for example, to examine aparticular bearing. A Corbit plot can also display multiple orbits for multiple Orbitmeasurements, for example, in order to allow bearings to be investigated in moredetail or compared.DATA SHEETVibroSight machinery monitoring system software8 / 28Document reference DS 660-020-005-224AVersion 24 – 16.05.2022

PRODUCT HIGHLIGHTS (continued)Rolling-elementbearing analysisVibroSight includes support for rolling-element bearing analysis as follows: Demodulation (envelope) signal analysis – a complex and detailed vibrationwaveform signal analysis that uses a dedicated demodulation spectrum to monitorand analyse frequency-specific measurements which are related to particularrolling-element bearing defects/failures frequencies (such as BPFI, BPFO, BSF andFTF). This technique detects problems in rolling-element bearings at the earliestpossible opportunity, thereby allowing maintenance intervals and operationalefficiency to be optimised. Crest factor measurements – a simple indicative vibration waveform signalanalysis that calculates the crest factor, a measurement which is related to generaldeterioration in a rolling-element bearing. This technique indicates problems inrolling-element bearings that have already developed, that is, much later thandemodulation (envelope) signal analysis.Note: Rolling-element bearing analysis can be used with VM600Mk2/ VM600 XMV16modules and/or VibroSmart VSV30x modules.OPC HDAVibroSight includes support for OPC HDA (historical data access) such that aVibroSight OPC Server can be used to easily export data from a VibroSight Server(*.vshdf) to any third-party system with an OPC HDA client.In this way, data analytics applications can use tools such as MATLAB andLabVIEW for further in-depth processing and analysis of VibroSight system data.OPC UAVibroSight includes support for OPC UA (unified architecture) so that aVibroSight Server can more easily export data from a VibroSight Server (*.vshdf) tothird-party systems such as a DCS, PLC or data analysis tools.Advantages of OPC UA include platform independence, improved security,multiple properties per data item (tag), and easier system configuration andoperation.Note: Support for OPC UA is in addition to the existing support for OPC Classic(OPC DA and OPC HDA).CSV data importVibroSight includes support for importing data from CSV files into a VibroSight Server(*.vshdf) in order to allow data from third-party systems such as other monitoringsystems and/or process parameters from control systems (DCS or PLC) to be easilyincorporated. This enables a single VibroSight plant-wide database that can takeadvantage of the speed and power of VibroSight for all machinery monitoring,remote monitoring and diagnostics.Cybersecure remotemonitoring anddiagnosticsRemote VibroSight database (*.vshda) files can be imported into a local VibroSightServer (*.vshdf) in order to create a replica/mirror of the remote VibroSight systemto support applications such as central diagnostics centres.File generation, importation and synchronisation is performed automatically in quasireal-time.While primarily intended for working with remote monitoring systems installed incybersecure environments (behind a “data diode” or firewall), this feature is alsouseful for remote sites that have unreliable network connections.Enterprise viewVibroSight Vision, VibroSight Event Viewer and VibroSight Mimic support concurrentconnections to multiple different VibroSight Servers at the same time in order tosupport applications such as central diagnostics centres.For example, this allows a single Enterprise level Mimic in a remote diagnosticscentre to easily monitor machinery in different locations/sites from a single display.Agile softwaredevelopmentThe VibroSight software is developed using an Agile software development modelwhich ensures the timely and regular (quarterly) delivery of continuously improvingsoftware.Separation ofMPS and CMSSeparate software modules (VibroSight Protect, Capture and Configurator) andsystem hardware (VM600Mk2 MPC4Mk2 and VM600Mk2/ VM600 XMx16) helps ensurecomplete separation (“segregation”) of MPS and CMS in a VM600Mk2/ VM600 rack.Document reference DS 660-020-005-224AVersion 24 – 16.05.2022DATA SHEETVibroSight machinery monitoring system software9 / 28

SOFTWARE MODULESThe VibroSight software architecture consists of the following software modules:ProtectVibroSight Protect is the client application software module used for theconfiguration and operation of VM600Mk2 systems for machinery protectionapplications (that is, the second generation of VM600 rack-based systems).More specifically, VibroSight Protect is used to configure VM600Mk2 systems using: MPC4Mk2 IOC4Mk2 modules, RLC16Mk2 modules (and any associatedCPUMMk2 IOCNMk2 module).Notes: VibroSight Protect is completely separate and distinct to VibroSight Captureand VibroSight Configurator in order to ensure the complete separation(“segregation”) of machinery protection functionality and condition monitoringfunctionality in a VM600Mk2/ VM600 rack.(For reference, VM600 system hardware (that is, the first generation (Mk1) of VM600),namely the MPC4 / IOC4T, AMC8 / IOC8T and RLC16 (and CPUM / IOCN) modules/cards are compatible with the VM600 MPSx software.)CaptureVibroSight Capture is the client application software module used for theconfiguration and operation of VM600Mk2 systems for condition monitoringapplications (that is, the second generation of VM600 rack-based systems).More specifically, VibroSight Protect is used to configure VM600Mk2 systems using: MPC4Mk2 IOC4Mk2 modules.Notes: VibroSight Capture is completely separate and distinct to VibroSight Protectand VibroSight Configurator in order to ensure the complete separation(“segregation”) of machinery protection functionality and condition monitoringfunctionality in a VM600Mk2/ VM600 rack.(For reference, VM600 system hardware (that is, the first generation (Mk1) of VM600),namely the MPC4 / IOC4T, AMC8 / IOC8T and RLC16 (and CPUM / IOCN) modules/cards are compatible with the VM600 MPSx software.)ConfiguratorVibroSight Configurator is the client application software module used for theconfiguration of VM600 rack-based machinery condition monitoring system (CMS)hardware and VibroSmart distributed monitoring system (DMS) hardware.More specifically, it is used to configure: VM600Mk2/ VM600 XMx16 XIO16T modules (and any associatedCPUx / IOCx modules/card pairs). VibroSmart VSV30x VSB300 modules, VSI010 VSB010 modules (andVSN010 devices).The configuration determines the required measurements from the machinerybeing monitored. The configuration of specific parameters for the machinery beingmonitored is also required, for example, in order to allow data logging and thecapture of transients. VibroSight Configurator is also used to configure other systemfunctionality such as external interfaces using industry standard protocols such asModbus and OPC to third-party devices.System ManagerVibroSight System Manager is the client application software module that providesthe tools to manage the machinery monitoring system hardware.System Manager is used to activate software, upgrade firmware, configure IPaddresses and NTP server settings.DATA SHEETVibroSight machinery monitoring system software10 / 28Document reference DS 660-020-005-224AVersion 24 – 16.05.2022

SOFTWARE MODULES (continued)MimicVisionEvent ViewerScopeServerVibroSight Mimic is the client application software module that is used to provide anoverview of the machinery being monitored, using live measurement data.Shortcuts in Mimic can also be used to automatically open VibroSight Vision anddisplay a measurement in more detail.Different hierarchical views (Mimics) of the machinery being monitored can becreated from a library of predefined objects, then customised and associated withspecific measurements, using a simple to use drag-and-drop interface. Forexample, one object could display the current value of a measurement, whileanother object could change colour whenever a measurement exceeds apredefined alarm limit.VibroSight Vision is the state-of-the-art client application software module for theeffective monitoring of machinery. It allows the live measurement data beingstreamed from VM600Mk2/ VM600 XMx16 modules and/or VibroSmart modules anddevices, and the measurement data stored in VibroSight databases (*.vshdf and*.vshda) to be displayed.In Vision, a catalogue of plots are available to optimise the visualisation and analysisof measurement data, including waveforms, spectra and orbit plots (see Plots onpage 15). The plots are fully customisable and navigation tools such as cursors,scaling and zooming facilitate the interpretation of the data.VibroSight Event Viewer is the client application software module that is used to logand view the events stored in VibroSight databases.Such events may have been created automatically by the machinery monitoringsystem or defined by users. For example, Event Viewer can provides acomprehensive overview of alarms (severity states), which may have beentriggered by factors such as excessive vibration levels in the machinery beingmonitored.VibroSight Scope communicates directly with a VibroSmart distributed monitoringsystem, whether it is a single module or a network of multiple measurement blocks.Unlike most of the VibroSight software modules, which use a client-serverarchitecture, Scope is a lite-client application that communicates directly withVibroSmart modules (bypassing VibroSight Server).Scope has a simplified user interface that allows the live static measurement databeing streamed from VibroSmart modules to be displayed. It also allows the controland monitoring of DSI inputs such as alarm bypass (AB), alarm reset (AR) and tripmultiply (TM).VibroSight Server is the core server software module that interacts with all other partsof the machinery monitoring system. Server is the only software module to accessthe VibroSight historical data folder (*.vshdf) used for data storage.All requests for information from a VibroSight Server (*.vshdf), machinerymonitoring system hardware and external device interfaces must pass through aServer. Server also manages the connections, data acquisition, alarms, datalogging, licenses and verifies system access.Document reference DS 660-020-005-224AVersion 24 – 16.05.2022DATA SHEETVibroSight machinery monitoring system software11 / 28

BASE AND APPLICATION SPECIFIC PACKAGESThe base/standard VibroSight software (VibroSight Classic edition) includes all of the features required fortypical machinery vibration monitoring and analysis. That is, it provides full su

VibroSight software architecture The VibroSight software uses a truly modular design that adapts to different machinery monitoring applications. As shown below, the software uses a predominantly client-server architecture to distribute the functional requirements and workload across different software modules and application specific packages.