Transcription

HAYDEN HOMES CASE STUDYHayden HomesPrepared for GrowthThe Central Oregon-based production builder overhauled its processesand implemented Sapphire Build software in preparation for growth.Homebuilders tend to be entrepreneurs whoexcel at making a new deal but sometimesstruggle with the mundane tasks of operatinging homes in multiple communities withthousands of variables to demanding customers can stretch any system. Hayden Homes,the Bend, Ore.-based production builder,has prided itself for years on its ability to usehigh levels of customer service.But in 2011, it recognized the technology had passed it byand its systems could use a major tweaking and upgrade.So, in April of that year, the management of the company,led by CEO Hayden Watson (co-founder with his father,Robert Watson) purchased the Sapphire Build and directed purchasing manager, Mike Newell to implement theprogram across its enterprise.Newell and production manager, Cindy Ohlde traveledto Oakwood Homes, Denver, to see the Sapphire Buildin setting up the processes for the company and directingtion, FAST. But more importantly, Newell was intimatelyinvolved in establishing the management processes bywhich Hayden Homes sold and produced its homes.When the time came to move to Sapphire Build, Newellsaw both a struggle to implement but also an opportunityto be in place and running as smoothly as possible.proving the company processes and systems as it was inpreparing the company for growth.-and had been working with the program for more than 5years. Newell was especially interested in learning how toimplement the program, not just use it.Newell had worked with Hayden Homes for almost 20years. He had risen to the level of vice president, but tooktraveling around the country and the world. During his1

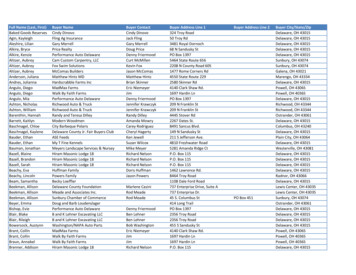

HAYDEN HOMES CASE STUDYNewell says, “Here at Hayden Homes, we say ‘Today isabout tomorrow,’ and we knew that we were growing.We’d expanded our communities from 18 to over 50 now.We have moved into Idaho and Montana. And we knewthat we needed a system to help us continue for whenthings did come back from the downturn. A system thatwould allow us to grow with control. Our current systemwouldn’t allow us to accomplish what we wanted to accomplish.”Among the many Saaphire features that attracted HaydenThe ProcessBut even the best system in the world can drive a buildercrazy if the implementation is messy. In fact, one of thebiggest objections builders have to adopting modern techthe new system and then on the back end determining thatit wasn’t worth the trouble.Sapphire Build provides support to ensure that doesn’thappen, and the Hayden Homes manner of implemened a rudimentary trade portal with their existing program, tation is a good road map for how to do it quickly andbut the integrated program with Sapphire improved commuaccess to all the same data that was updated in real time,including scheduling and invoicing.was the ability to employa robust email systemthat tied into thecomplete program. Whilea trade portal and emailsystem integrationseem like minoradvantages, manybuilders are stillpushing throughon older systemsthat don’t havethose features.In addition toOctober 2011. To achieve that end, Newell and his teamprioritized the implementation process, so that it could bedone on a critical path schedule. In short, the implementation followed this general process:Step One:der. Set up options and homes, sothat all the products were properly installed in the system.Step Two: Build out thesales module to allow themarketing departmentto do prospecting andfollow-up systems withpotential homebuyersBuild outcludes documenttemplatesfor salesletters,contracts,etc. SinceHaydenof the Sapphiresystem, thegreatest formanybuilderswill bea simpleupgrade tomodern technology.Timeline.Infrastructure: Hardwareand Software SetupMarch 8-June 242Internal CurrentProcess AnalysisMarch 21-June 24Establish Schedule forWeekly/Bi-Weekly MeetingsApril 18

HAYDEN HOMES CASE STUDYHomes does all its own materialpurchasing, the team entered all estimating information and completeproduct needs by home and community. Finally, the team added logisticalsystems, such as the trade portal.was implemented toward the end of the process,because the production team neededsince homes would be sold long inadvance of any service or warrantyissues, those modules could be set uplive.was mapped out in a critical pathschedule, available to all the participants in a spreadsheet and on Ganttcharts. James Hinson of Sapphire Build served as theproject manager to facilitate the implementation. Oneof Hinson’s most important tasks, besides making sureSapphire Build worked to the full expectation of HaydenHomes, was helping the implementation team keep onschedule and move rapidly from task to task.One caveat to the implementation of the sales modules isthat while it was implemented early, it did not go live untilmuch later in the process. Hinson says, “It might havebeen slower than I would have done,” but Hayden Homeswanted to make sure it had complete buy-in from the salespeople before rolling it out. To ensure that, the companymade certain every piece of the sales module functionedaccording to plan, so there wouldn’t be disgruntlement atthe new processes.ference calls, hosted by Hinson. “James is a rock star,” saysNewell. “He’d train us on how to do something, and thenwe’d have to implement it. We had weekly task assignments, something for each of us.”Hinson also agreed to let the team record the trainingor refresh their memories, they could just refer to the tape.But all the scheduling and all the conference calls don’ttation process is achieved by day-to-day work that hitsfront burner so everyone see the progress.Get the Product Set Uphomebuilders relies in large part on building a database ofhomebuilder needs to make when setting up the databasewhether that database can be imported from their previous technology. Hayden Homes, learning from the struggles at Oakwood Homes (see our previous case study), decided it would be best to enter new all the data on optionsand homes rather than import. Not only did the strugglesof Oakwood—which eventually abandoned the import.TimelineKey Records: SapphireData Object SetupMarch 21-July 25Options CatalogMarch 21-September 26ProspectingManagementMarch 21-July 25SalesContractingMay 16-October 103

HAYDEN HOMES CASE STUDYVITAL STATSprocess and entered new data—inform their decision, butthe desire to improve the process and streamline their ownproduction meant they would build a new database almostfrom scratch.Hayden Homes, Bend, Ore.Founded in 1989 by Robert Watson, HaydenHomes specializes in entry-level and move-uphousing, promising “to provide the highest quality home at the lowest possible cost.” The companySimplicity Homes division.2012 Closes: 785Markets:Oregon — Ben, Redmond, Sisters, CottageVeneta, Albany, Salem, Portland, ForestGroveWashington — Moses Lake, Quincy,Airway Heights, Spokane, Spokane Valley,PullmanCollege Place, Kennewick, Pasco, Richland,Walla WallIdaho — Post Falls, Boise, MeridianSapphireinput process. Cindy Ohlde is the operations manager atHayden Homes and the task of building the database fellto her. “Up until I saw what Sapphire could do, I thought ourold system was pretty good,” she says. “It was all a dosSapphireibility in making it do what you want.”Even with the promise of a new system and new abilities, the familiarity of an existing system can be a securitying. “I was a little scared,” says Ohlde, “to have to createa whole new database and start over.” It wasn’t until shewent to Denver to visit Oakwood Homes and spoke totheir production people about how much easier it was towork with Sapphire and do what you want that she becameme a lot,” she says. “It was the turning point that I thoughtthis was going to be great and be a good thing.”data, and they entered it by hand. “We elected to do that,”says Ohlde. “We took the opportunity to start fresh andwere structural to their processes.-Communities: 52time—Central Oregon, the Interstate 5 Region in Oregon,and Washington. If I made a change to a plan, I had toSapphirehave one house built the same way and everyone uses thatsame built house.”Models:In addition, Ohlde wanted to have more global bids. Forexample, Hayden Homes uses the same electrician for allTimeline.StartsManagementJune 27-October 104Graphics (Maps,Images, and Redlines)May 16-September 19ProductionApril 25-October 10Customer ServiceAugust 22-October 10

HAYDEN HOMES CASE STUDYof Oregon, so the bids cover the entirestate. “If you have one bid for eachcommunity, you have to change it 20times,” she says.daily work Ohlde had to complete, ofcourse. “We had it mapped out what weneeded done by certain dates,” Ohldesays. She started in the beginning ofMarch, and they originally picked aSeptember deadline. To get a community ready, the sales side of the databaseHayden Homes was going to wait toimplement the sales procedures untilrunning.“At the time I was thinking, I was making great progress,” she says. “But when it came time for usto go live, sales was up and running great, but productiondone, Hayden Homes freed up some of Ohlde’s time, andOctober.plans and communities, entering options and establishingshares:Hayden Homes buys all its materials, so the Bill of Materials (BOM) IDs included in Sapphire are more generic anddidn’t match the company’s processes closely enough.Ohlde created new BOM IDs to match their methodology.board and start at the same time. Hayden Homes plannedto roll it out to production in bite-size pieces, where theytogether with Sapphire that waiting on the scheduling.TimelineWeb SitesAugust 1-September 26production. Ohlde’s conclusion? Start all facets at once.community has been entered in the spreadsheet, includto upload the data to Sapphire and make any later changes inSapphire than in the spreadsheet.Getting the Interface LiveEntering all the data in the spreadsheets and uploading itto Sapphire provide the essentials that make it work. Butone of the great strengths of Sapphire is the interface withent process at Hayden Homes.-Tallie Belitz is the marketing manager at Hayden Homes.She’s been there for seven years. “I came into the projectin about April 2011 to see how marketing aspects of Sapphirewould be implemented. How were we going to pretty it upto present to the consumer and buyer?”Accounting IntegrationAugust 15-October 10MiscellaneousSeptember 5-26Go LiveOctober 245

HAYDEN HOMES CASE STUDYTHE PLAYERSHayden Homes Leadership TeamHayden Watson, Owner/CEOHayden Watson founded Hayden Homes with hisfather, Robert Watson, in 1989 and became president in 1992. In 1999, when Robert retired, Haydenassumed the CEO duties.was to have a program that integrated with the website.Dennis Murphy, PresidentDennis Murphy started with Hayden Homes in 1993.-site. With its single database approach, Sapphire allows a usercompany throughout Washington and Oregon. In1999 he became President of Hayden Homes.system touches from production to sales to the website toDeborah Flagan, Vice President of Salesand MarketingWith Hayden Homes since 2000, Deborah Flagan isvice president of sales and marketing, overseeingthe sales team throughout the Northwest as well asSteve Klingman, Vice President of OperationsSteve Klingman has served Hayden Homes sincemoving to Central Oregon in 2000. Starting asa construction project manager, he is now vicepresident of operations and oversees supply chain,purchasing, estimating, architectural design and IT.Implementation TeamMike Newell, Purchasing ManagerMike Newell has served two stints with Haydenturned, he took the position of Purchasing Manager.Cindy Ohlde, Operations ManagerCindy Ohlde has worked at Hayden Homes for 14years, rising to the position of Operations Manager.Among her duties has been the implementation ofthe Sapphire Build program.Tallie Belitz, Marketing ManagerFor seven years, Tallie Belitz has led the marketingcoordinating the Sapphire implementation with theweb presence.James Hinson, Senior Project ManagerJames Hinson has worked in home buildingsoftware solutions for more than 20 years andhas been involved with Sapphire Build since2006.6Hayden Homes wanted to push Sapphire to allow morecustomization. “We were probably a bit more of a painto Sapphire than I’m sure a lot of homebuilders were,” sheadmits, but the end result is Sapphire worked with HaydenHomes to deliver a more robust program that suited thehomebuilder’s unique needs.information would be accurate. A home sold would noFor Belitz, that meant the workload in her departmentwould drop as they no longer needed to enter all thechanges in the website. To get to that point, though, reTo get the information on the website, the plan department, primarily in the person of Karen Scrabeck, tookpassed them along to Belitz, who colored them accordingto their scheme to show what was a basic plan and whatwere options. After the plans were uploaded to Sapphire, itreturned to the plan department, where it would be redformat, and Belitz used Adobe Illustrator to convert it to a.png file. Redlining is done through the Sapphire system.Originally Belitz thought she could do the redlining herself, but she found that the scope of the project was largeenough it worked better to break it up. While the plansmunities.-Since Sapphire allows homebuyers to select their own floorinitial take on the brochure delivered a four-page document, but the sales department wanted to get that downcustomization of the Sapphire system since Hayden Homesbrochure that were outside the basic design.

HAYDEN HOMES CASE STUDYA major concern for Hayden Homes is that the Sapphireintegration would work smoothly with the existingwebsite and support their web goals such as searchengine optimization (SEO) strategies. To accomplishthat, Sapphire met with Hayden Homes’ web designservice providers to ensure what was going to be pulledin from Sapphire and what was going to reside on thewebsite servers. So, on the Hayden Homes website, thebulk of the information resides on the company’s serversite, but individual elements, such as the communitymap, get pulled in from the Sapphire database.by November. Hayden Homes didn’t have to redesign thewebsite; it really just needed to replace certain elements.Out went the static maps that Hayden Homes needed toupdate monthly. In came the Sapphire map which was upreplacing with Sapphire information,” says BelitzKEYS TO SUCCESS1. Prior Preparation Prevents Poor Performance.When Hayden Homes started a task, they tookimplementation task worked correctly. Then, aftercompleting one correctly, such as implementationof an option, they continued the process of implementing all the others.2. Managing Change. Hayden Homes allowed someitems which had lower priority on the implementation process to be adopted more slowly. Thatchanges. One major item was the sales module.Hayden Homes implemented it well after it couldhave, because the company wanted to make surethat everything worked absolutely correctly andBelitz provided the template for the design, includingall the elements she wanted. (She got lots of feedbackfrom sales and other people to make sure the website3. Make a Record. Hayden Homes recorded everytraining session with James Hinson. That provideda record of the instructions and goals, and prevented them from having to go back to ask questions and wait for answer. Plus, they could play therecording for anyone in the company who neededaccess to the information.put it all together. What fell to Belitz and her group wasuploading all the content into the design.4. Focus on the Core. The company focused on thecore components when building data, instead ofNot part of the website, but an important part of theprocess was the need to upload all the option photos intosamples, granite, etc. Many of the photos came from thesuppliers, and needed to be compressed and uploaded.tions, working through option screens in Sapphire.-One hiccup in the process was the sheer amount of dataand images Hayden Homes uploaded. Sapphire had notapparent that the amount of data was so large, the images needed to be resized and compressed even further.Hayden Homes thought they would have to spend about aweek to do that, but Hinson provided them with a method for compressing batches of images that allowed themto complete the process in only a day.content management systems. If you make images suchrectly proportioned. In addition, if she re-uploaded it, sheperipheral things.5. Plan for Time. An implementation process requiresHayden Homes allowed for the extra work andburden, and in some instances provided temporary6. Simplify. A new program involves lots of new andHayden Homes kept one thing very simple bykeeping model names the same across communities. That allowed them to reuse data options andnot have to add them again for each community.7. Identify the Pain Point. Sapphire Build is designedto help you run your homebuilding business moreDuring the implementation, though, those elements on which you excel should get lower priority.If you don’t have problems with customer serviceor warranty, for example, don’t start with that. Ifyou have horrible customer service, get that liveearlier. Identify those things early to adjust theimplementation.7

HAYDEN HOMES CASE STUDYTO IMPORT OR NOT TO IMPORTAny homebuilder operating on a reasonablysophisticated software program has tons of dataalready entered. The question when switching toSapphire Build is whether to try to import thatdata or enter it all new.“I have done imports,” says James Hinson, theproject manager for Sapphire Build “I’ve doneimports where we didn’t know the other system.And we’ve done database to database. We can dowould have to go back and redline the plans all over again.the same size so they appear correctly.with Hayden Homes, but as with most companies,there are things they wanted to change about thedata. By building the database from scratch, theycan make the changes to the database they want.ResultsAs with all homebuilders, Hayden Homes went through awere so thin. Ultra thin,” says Newell. “We hired a bunchNewell expects that to come as the company grows.FOR MORE INFORMATIONRegarding options, Newell says, “We’re religious aboutkeeping our numbers, our plans and even our optionsSapphire Build provides integrated software solu-to attract more buyers and provide higher customization.“Sapphire has given us the ability to provide a wider range ofoptions to all buyers,” he says. “Before, they were dividedinto packages.” Some packages had one group of optionsactive experience for home buyers and builders,allowing builders to manage their complicated busi-experiences, and simpler reporting.To learn more about Sapphire Build, please visit thewebsite at www.sapphirebuild.comMiTek Sapphire Build400 Trade Center, Suite 5900,Woburn, MA 01801mentation. “We are thrilled with Sapphire . It’s really aligned Phone: 781.569.0090with the systems we have in place. We believe in havingFax: 781.569.0092one across all three tiers, —entry level, mid-level and luxury.good control and systems, which has allowed us to manageour geographic diversity. Sapphire brings additional capabili areas in Oregon, Washington and even Montana that wehave not yet pursued.”8

HAYDEN HOMES CASE STUDY 1 Hayden Homes Prepared for Growth Homebuilders tend to be entrepreneurs who excel at making a new deal but sometimes struggle with the mundane tasks of operating -ing homes in multiple communities with thousands of variables to demanding custom-ers can stretch any system. Hayden Homes, the Bend, Ore.-based production .