Transcription

CHAPTER 14Chapter 14 : Cost Analysis Through Life Cycle Analysis andTarget CostingINTRODUCTIONA major trend occurring at many firms is the early and continuing involvement with newproducts or services by teams comprised of engineers, management accountants, marketing professionals, and logistics personnel. Their involvement ensures that new products and services are launched in a timely manner and that costs are minimized andprofits maximized throughout the products' or services' life cycle.Management accountants need to focus on every stage of the product cost life cycle, notjust the production stage. Management accountants must be involved with the design ofnew products, assisting design engineers and others with cost estimates and target costs.They should also understand the activity value chain and help determine how costs canbe reduced throughout this chain.This chapter presents a framework for estimating and managing costs and assessing theconsequences of decisions made at different stages of the life cycle of a product or service. A key objective is to establish target costs throughout the life cycle of new products or services before they enter production. Two methods used to set target costs arefunctional analysis and activity-based costing systems. The parametric cost estimatingmethod is helpful in estimating costs of new products or services.LIFE CYCLE ANALYSISUnderstanding and analyzing both the product market life and cost life cycles are necessary for effective cost management. Analyzing the consequences of cost-reducing decisions over the life of a product or service can significantly increase a company's profits.Making the correct early decisions in market life and cost life cycles can dramaticallyaffect later stages.THE MARKET LIFE CYCLEA product or service has a market life cycle, which includes five stages:COST ANALYSIS THROUGH LIFE CYCLE ANALYSIS AND TARGET COSTINGPAGE 1

Pre-introductory stage in which the product concept is developed and all activities necessary to produce,market, distribute, and service the product are poised for implementation. Introduction stage in which the product is launched into the market. Growth stage, which is typified by consumer acceptance. Maturity stage, which is characterized by market saturation, strong brand loyalty, and stabilized salesvolume and profits. Decline stage, which is the final stage of the market life cycle. It is marked by a continued decline insales and eventual abandonment of the product or service.At one time, the average market life cycle was about 15 years. Today, it can be less than3 years, and in some cases less than 1 year. For example, new computer products areintroduced at very frequent intervals. When market life cycles were 10 to 15 years ormore, management accountants could report costs on an after-the-fact basis becausethere was sufficient time to make adjustments and improve productivity and profitability.With a market life cycle anywhere from one to three years, however, many factors thatinfluence product or service profitability will be incurred prior to entering production. Intoday's competitive world, management's goal is to get new products to market on time ator less than the target cost. After-the-fact cost reporting is thus of little value in managing costs.1INSIGHTS & APPLICATIONSProduct Development at Pharmaceutical CompaniesNew product development performance is a major factor in winningthe race to market, positioning products successfully against competitors, and minimizing development resource requirements.Pharmaceutical companies have an opportunity to establish a stronger competitive position and superior financial returns by significantly improving product development performance. Highpharmaceutical profit margins make delays in the product launch(i.e., from development to production and marketing) extremelycostly. For example, a six-month delay can result in lost contributions of 40 million or more. Consequently, the reduction in profitpotential that losing the race would entail considerably outweighsthe incremental development resources required to meet targetlaunch dates.aa.Adapted front Charles Beever and Mary Jo Veverka, A Winning Approach to New Product Development (New York: Booz, Allen & Hamilton, 1988).With permission.ANALYZING THE COST LIFE CYCLEThe product cost life cycle presented in Exhibit 14-1 provides a total cost life cycle profile. It includes cost curves starting with product development, then production., and oninto logistics and service support until the product or service market life cycle ends.These life cycle cost curves are particularly important to management accountants andothers who are trying to achieve target costs and make their companies more competitive.Traditionally, management accountants have not been concerned with costs in the development stage of a new product or service, nor with logistics, marketing, and servicecosts. Their primary concern was with production costs. The best time, however, to manage these costs is during development before the product or service goes into production.Many authorities observe that 80 to 90 percent of the life cycle costs of a new product orservice are committed during development. Focusing on costs after the product or service enters production results in only 10 to 20 percent of costs being manageable2. Thus,the key to managing these life cycle costs is to focus attention on the developmentphase3. Decisions made during this phase will impact the enterprise's resources far into1. James A. Brimson, “CAM-I Cost Management Systems Project,” in Cost Accounting, Robotics, and the New Manufacturing Environment, ed. Robert Capettini and Donald K. Clancy (Sarasota, Fla.: American Accounting Association, 1988),p. 5.8.Page 2COST AND MANAGEMENT ACCOUNTING

CHAPTER 14Exhibit 14-1 Product or Service Life -Target CostingPoint at whichnew product orservice isintroducedMarketing and salesLogistics, and servicesProductionTimeExhibit 14-2 Committed versus Incurred CostsPercentage of total costsCommitted costsIncurred costsProductor servicedevelopmentProduction startsTimethe future. As some authorities point out, one dollar spent on activities that occur prior toproduction, such as market research and product or service design based on target costing, can save from 8 to 10 in production, marketing and sales, logistics, and servicecosts4.2. James R. Anderson, “Unit Manufacturing Cost Tracking Systems at Xerox,” in Cost Accounting for the 90s: Responding to Technological Change (Montvale, N.J.: Institute of Management Accountants, formerly the National Associationof Accountants, 1988), p. 187. With permission.3. Michael D. Shields and S. Mark Young, “Managing Product Life Cycle Costs: An Organizational Model,” in Emerging Practices in Cost Management, ed. Barry J. Drinker (Boston: Warren Gorham Lamont, 1992), p. G3-1. With permission.4. Richard L. Engwall, “Cost Management Systems for Defense Contractors,” in Cost Accounting for the 90s: Responding to Technological Changes (Montvale, N.J.: Institute of Management Accountants, formerly the National Associationof Accountants, 1988), pp., 205-225. With permission.COST ANALYSIS THROUGH LIFE CYCLE ANALYSIS AND TARGET COSTINGPAGE 3

LINEAR APPROACH VERSUS SIMULTANEOUS ENGINEERINGThe linear approach is a sequential, uncoordinated design process in which each functional area of the enterprise focuses on its own needs and priorities. It is an “over-thewall” approach to bringing a new product or service to market. The phrase “over-thewall” refers to a department's (e.g., engineering) interest in completing its objectiveswhile giving little consideration to how the work it produces impacts the work of otherdepartments (e.g., production, logistics, marketing)5. In essence, a department completesits assigned work and then throws the work over-the-wall to the next departmentinvolved in the project. The over-the-wall process is symptomatic of linear project management in which departments do not work collaboratively. The result is a failure to satisfy all the functional needs of the company (i.e., marketing's need for a product withconsumer appeal, service department's desire for a product that is easy to service,finance's goal to use the least expensive parts, and manufacturing's need to have a simplemanufacturing process with few parts to assemble). By failing to design quality in andconsider downstream life costs, this uncoordinated, expedient approach ultimatelyincreases costs throughout the product's life cycle6.INSIGHTS & APPLICATIONSThrowing the New Car Design over the WallAt Clunker Motors, the engineers designed a car with an engine thatrequired many different holes to be drilled and tapped at multipleangles. A simpler engine with fewer parts would have been lessexpensive to produce and easier to service.But manufacturing had to make the engine according to engineeringdesign specifications. Clunker's vehicles are designed in a linear (orserial) fashion with little or no co-operative involvement with thoseat the next step of the process. Such an approach does not support a“meeting of the minds” between design, manufacturing, marketingand sales, and service. The linear approach to product or servicedesign not only causes problems with manufacturing, an internal customer, but can result in dissatisfied external customers, as shown inthe next Insights &Applications.The over-the-wall approach is not only costly, but it lengthens the time it takes to get aproduct or service to market. Alternatively, simultaneous engineering (also called concurrent engineering) is a concurrent and collaborative design process, which strives tointegrate and balance product or service development, from initiation of the concept tocustomer feedback. Simultaneous engineering reduces the time-to-market (i.e., the timeit takes to convert a product idea into a marketable product) and involves all key playersin the product team. Everyone receives the same information at the same time, so allteam members can work together toward a common goal of “doing it right the first time.”According to the National Institute for Defense Analysis, there are tangible benefits tosimultaneous engineering versus the linear approach. For example, simultaneous engineering is credited with reducing development time by 30 to 70 percent, reducing thenumber of engineering changes by 65 to 90 percent, improving overall quality by 200 to600 percent, and increasing return on assets by 20 to 120 percent.Collaboration by members of the cross-functional product team reduces the myopicfocus by integrating the various people and activities required to develop, manufacture,market, distribute, and service high-quality, innovative products quickly and successfully. A key performance measurement of a product team is time-to-market, which is ameasure of the team's effectiveness at converting ideas into marketable and profitableproducts. Some typical improvements from simultaneous engineering include the following:5. Peter Drucker, “The Corning of the New Organization,” Harvard Business Review, January-February 1988, pp. 45-53.6. Shields and Young, op. cit, p. G3-3.Page 4COST AND MANAGEMENT ACCOUNTING

CHAPTER 14 Reducing number of parts Reducing nonvalue-added activities Improving quality Increasing manufacturability Increasing flexibilityAs can be readily seen, all these improvements are in concert with world-class manufacturing.INSIGHTS & APPLICATIONSThrowing the New Car to the CustomerScott Farley is manager of mechanics at Wilson Motors, a local cardealer that sells Clunker cars. Winnie Gorham, an owner of aClunker, drives her new car into Wilson Motors' shop, gets out ofthe car, and approaches Scott. “Hi Scott,” says Winnie. “Goodmorning, Winnie,” Scott responds. “What can I do for you?” “Theengine in my new Clunker is acting up. Maybe it needs a tune-up,new spark plugs. Can I have it done by noon?” “Maybe by noonday after tomorrow,” Scott laughs.“You've got to be kidding,” Winnie says, somewhat frustrated.“No I'm not kidding,” says Scott, now frowning. “To do a simpletune-up, we have to dismount the engine so we can reach two sparkplugs that we otherwise can't get to. The engine is poorly designedand difficult to service.” “And what's all this going to cost me?” Winnie asks. “Assuming it's a regular tune-up, it'll cost you 250,” Scottreplies. “What?” Winnie exclaims. “I can't believe a simple tune-upwill cost 250.” “It's the labor cost, Winnie,” Scott explains. “Amechanic has to dismount the engine and move it away from thechassis to replace two of the spark plugs and make other adjustments.Maybe Clunker Motors will redesign the engine next time for easierservice.” “There won't be a next time for me,” says Winnie. “I'll notbuy another Clunker, ever!” “I can't say that I blame you,” Scottresponds.Chapter 12 emphasized how preventive measures can eliminate downstream costs ofquality, especially final inspection, internal failure, and external failure costs. This prevention-based philosophy is important because the earlier in the product developmentprocess that prevention techniques (e.g., modular design, prototype testing, designingfor manufacturability) can be applied, the lower the final inspection, internal failure, andexternal failure costs that will be incurred. Simultaneous engineering teams design quality in before the production stage begins. Some traditional companies, using the lineardesign approach, try to achieve quality during production, an inopportune time to bethinking about quality.USING QUALITY FUNCTION DEPLOYMENTQuality function deployment (QFD) is a method that assures quality while the productor service is still in the development stage7. The key focus of QFD is on determiningcustomer requirements and then developing the product or service to meet or exceedthose requirements. QFD reduces the need to redesign and make modifications after theproduct or service is launched into the market-place. One of the major ideas presented inChapter 12 was “designing quality in”; QFD is the method that supports this idea.Most of the time, customer requirements are determined from ideas, complaints, characteristics, issues, and so forth expressed by customers. The development team is thereforefaced with a great deal of verbal, qualitative data gathered from customer surveys andother market research methods. QFD helps the team organize and prioritize these data.7. For a full treatment of QFD, see James L. Bossert, Quality Function Deployment: 4 Practitioner's Approach (Milwaukee, Wis.; ASQC Quality Press, 1991); R. John Aalbregtse, “Target Costing,” in Handbook of Cost Management, ed.Barry J. Brinker (Boston: Warren Gorliani Lamont, 1992); and Yoji Akao, ed., Quality Function Deployment. IntegratingCustomer Requirements into Product Design (Cambridge, Mass.: Productivity Press, 1990).COST ANALYSIS THROUGH LIFE CYCLE ANALYSIS AND TARGET COSTINGPAGE 5

With the data structured, the development team not only understands what the customerssay they want but, possibly, what the customers want but are not expressing. These unexpressed wishes lead to what has been called “exciting quality” and “customer delight.”The development team has to design in “expected quality,” or no one will buy the product or use the service. But today many companies are trying to look beyond expectedquality to design in exciting quality. An example in the manufacturing sector was theaddition of cup holders in cars. Ten or fifteen years ago, few cars except Japanese carshad cup holders.INSIGHTS & APPLICATIONSSimultaneous Engineering at BoeingBoeing aimed to shrink the time needed to manufacture a plane frommore than a year to just six months by 1998. Its traditional methodfor designing aircraft was a three-phase process with each phasebeing completed in sequence. Worse, the three groups have little contact until their initial designs are completed. As a result, tooling specialists often receive blueprints for parts that either can't bemanufactured or are too expensiveto produce. In such cases they send blueprints back for revision.The process forces each group to turn out reams of corrections, consuming millions of hours a year. Boeing hopes to capture huge savings by enabling groups to design new aircraft simultaneouslyrather than in sequence. When the group decides to alter the designof a major part, it has the authority to make the changes itself, ratherthan waiting months for approvals from higher-ups. Reengineeringefforts, just-in-time inventory management, and simultaneous engineering are innovations that are expected to give Boeing the billionsin savings that it needs. Says Grace Robertson, program director,“We expect a substantial reduction in design, development, andmanufacturing costs.”aa.Adapted from Shawn Tully, “Can Boeing Reinvent Itself?” Fortune, March 8, 1993, pp. 66-73. 1993 Time Inc. All rights reserved.Customers did not look for this feature in a car, but they were pleased when they got it.Later, the cup holder, once a customer delight, became a customer requirement8. In themerchandising sector, Nordstrom Department Stores, located in the western UnitedStates, offers not only expected service, but a delightful and satisfying shopping experience. In Nordstrom's case, this kind of quality didn't just happen, it was designed in.As also seen in the Pacioli Bookstore case (later in the chapter), QFD is not just for manufacturing companies. Unlike a product, a service is not a measurable material objectbecause it is often intangible and immediate. Nevertheless, the service industry (e.g.,hospitals, retailers, hotels, restaurants) is finding it necessary to use QFD in developing aquality design for its services. QFD makes it possible to clarify, plan, and design a service to be offered and to conduct total quality management (TQM) throughout the service's life cycle.MATCHING CAPACITY WITH DEMANDProduct or service cost life cycles can also be reduced by optimally matching productioncapability with product or service demand. This capacity matching is illustrated inExhibit 14-3. The capacity line represents a step function because capacity is acquired inwhole increments; that is, one cannot purchase part of a machine.A company that is planning to introduce a new product or service is willing to invest inexcess capacity because it anticipates growth in demand during the growth stage. Withall else constant, this capacity ensures that the product or service is delivered to customers without delay.As soon as the product or service moves through the growth and maturity stages, decisions to add capacity are weighed carefully because excess capacity is very costly. If the8. Bossert, op cit., pp. 18-19.Page 6COST AND MANAGEMENT ACCOUNTING

CHAPTER 14Exhibit 14-3 Resource Capacity Matched with Product or Service DeclinestageCostsIntroductionStageProduct orservice marketlifecycleCapacityTimecompany is introducing a new product or service or revitalizing the present one, then aproper level of capacity must be acquired to meet a new growth stage.INSIGHTS & APPLICATIONSBashing Silos But Not QualityChrysler's enterprisewide study led to its platform team concept(i.e., the simultaneous engineering team approach) composed ofdesign engineers, manufacturing personnel, management accountants, and vendors. With this new approach, departmental “silos”have gone the way of the K car.No longer is a product tossed over-the-wall from vertical department to vertical department. Once the company decides it will builda new car “platform” of certain dimensions, functions, cost, andprice, the platform team works to see that these parameters are met.The Viper was the first car produced under the new workingarrangement. It was designed and built under the target cost in threeand a half years instead of the normal five.SETTING TARGET COSTS WITH FUNCTIONAL ANALYSISA goal of management is to produce products or services that meet consumer needs andprice and quality expectations over the product's or service's entire life cycle. For theproduct or service to be profitable, it must be designed within the established target cost.One method used to achieve the target cost is functional analysis.WHAT IS TARGET COSTING AND HOW IS IT USED AS A COSTMANAGEMENT METHOD?Target costing is a cost management method for reducing the overall cost of a productor service over its entire life cycle by employing better specification and design procedures at the lowest possible cost. Target costing is not a method for day-to-day cost management. Rather, it is a cost planning method that focuses on controlling designspecifications, production techniques, and logistics. Target costing contributes to thegoal of delivering a competitive product or service to the marketplace. Target cost iscomputed as follows:COST ANALYSIS THROUGH LIFE CYCLE ANALYSIS AND TARGET COSTINGPAGE 7

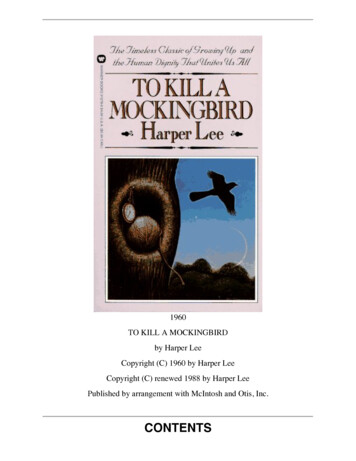

INSIGHTS & APPLICATIONSUsing QFD to Design the Bookstore for ProfessorPacioliProfessor Marvin Pacioli has just retired. He plans to open a bookstore to supplement his rather meager retirement income. Beforeembarking on this entrepreneurial venture, he calls one of his previous students, Kristy Paton, for assistance. The following are parts oftheir conversation. “Before I launch my bookstore, I want to makesure that I've covered all bases and don't spend money on things thatare not important to my customers,” said Professor Pacioli. “Icouldn't agree with you more,” said Kristy. “In fact, we are currentlystudying quality function deployment, or QFD, which helps peopledesign quality into a product or service before it is introduced to themarket. This method is certainly in line with your wish to do thingsright the first time.” “I think this is exactly what I'm looking for tohelp me design my bookstore from a quality viewpoint before opening it. Would you mind helping me apply the QFD method?” saidProfessor Pacioli. “Not at all,” said Kristy. “As a matter of fact, TomHardaway, Heidi Franz, and myself are looking for a project to doas part of the course requirement. Tom is an industrial engineeringmajor and Heidi is a marketing major. I'll be the managementaccountant. We'll form a simultaneous engineering team.” “Thatsounds great,” said Professor Pacioli excitedly. “When can we getstarted?” “Let me coordinate with the team members. Then, I'll callyou next Monday and we'll set up a definite schedule,” said Kristy.After meeting with Professor Pacioli, Kristy's team performed amarketing survey to determine customer requirements and customerratings. The team used the planning and design matrix shown inExhibit 14-4. After conducting a session with Professor Pacioli andbenchmarking the competition-the university bookstore-the matrixwas completed. “You know, this QFD method has really opened myeyes,” said Professor Pacioli. “However, I wish that we had donethis three weeks earlier.”“Why is that?” Tom asked. “Well, I have already signed a lease thatwill give me the space for a reading room, and now I discover thatcustomers don't want that facility. That means I'll be spending aboutone-third more for rent than required. This is very unfortunate. Ishould have been more careful. I didn't practice what I preached; thatis, doing it right the first time. Now, I'm committed to a 10-yearlease with about 1,500 square feet of space that I don't need.” “All isnot lost,” said Heidi. “While using QFD, the team is supposed tolook for exciting quality or customer delight. I believe we've done athorough job in analyzing what customer requirements are and relating them to the design parameters for your bookstore. If you invest inthese design parameters, you will be providing quality that the customer expects. And you'll be performing better than your competitor.But there is that nagging problem of wasted space. Maybe we canuse that space for an exciting quality or customer delight.” “What ifyou used the extra space as a place where your customers can sit,relax, and enjoy snacks while runners gather books, charge them,and deliver them to the customers?” asked Kristy. “The runnerswould be trained to know how to gather the books quickly for allsubjects. On the customer delight side, customers wouldn't have tostand in line. This design would not only support, but go beyond fastservice, high attentiveness, and quick book availability. Customersbuying a few items and not needing runners would have ready accessto an express checkout lane.” “Well, that sounds like a good idea,”said Professor Pacioli. “But I need to know what this would mean interms of revenue and cost. “The team conducted another customersurvey to determine the value of Kristy's and Heidi's idea. Sixty percent of those surveyed said that they would buy books at the newbookstore if this design parameter was installed. An expected valuefor revenue was calculated, resulting in additional revenue of 5,000per month. Expenses including the 900 rent for the extra spaceamounted to 4,300 per month. Therefore, the expected profit is 700 per month. “I am really pleased with the work you people havedone,” said Professor Pacioli. “I now have a clear vision of how I'mgoing to design quality into the bookstore before it is opened. To celebrate, you all are invited to my house Saturday for lasagna. I make agreat lasagna! Then, after we eat, I'll show you a video of The History of Double Entry Bookkeeping!”Target cost Target price - Target profitA product's or service's sales price is heavily influenced by prevailing market forces.Individual companies are rarely able to sell a product or service for a price higher thanthe market price unless they are able to differentiate their product or service from thecompetition. A company can differentiate its product or service in several ways: Product enhancements, such as eliminating product defects and uncovering additional uses for the product Ancillary product enhancements, such as making product packaging more appealing and improving customer serviceAdditional product development, such as providing features not previously available9If a company chooses not to differentiate its product or service (i.e., decides to competeon price), it must offer the product at a target price equal to or less than the market pricein order to obtain its target profit. To compete on price, a company must thoroughlyunderstand the pricing strategy of its competitors. If, for example, a competitor is using a9. Chester R. Wasson, Dynamic Competitive Strategy & Product Life Cycles (St. Charles, Ill.: Challenge Rooks, 19741, p.174.Page 8COST AND MANAGEMENT ACCOUNTING

CHAPTER 14Exhibit 14-4 Planning and Design Matrix for a new StoreMcustomer requirementscompetitiveevaluationcustomer ratingSspecial lightingquick checkoutSfacilitiesreading roomsgood mannerscustomer serviceenergeticclassify and displaydatabasecustomer informationknowledgelarge inventoriesJITDesign parametersBook inventory[draw line toconnect all Csand Ns1 2 3 4 51 fast servicec2 high attentivenesscn 5n4S3 quick book availabilitySSSS4 friendly and conversational5 wide selectionMMMSWcMncc6 easy access to booksWWSW7 answers to questionsSSWW8 additional facilitiesSn 5cWSS2n 5n 5cn 5nc1S strong relationshipkey to competitive analysisM moderate relationshipc what competition offersW weak relationshipN what new store will offercompetitive ratings1 least desirable2 most desirableprice skimming strategy, which provides the opportunity for large marginal profits, a target costing strategy must take into account the possibility of a price war, which the lowcost producer most likely will win. On the other hand, if the competition is using a market penetration pricing strategy, which provides limited marginal profit, a target costingstrategy may prove to be more effective because the competitors' low profit margins willallow little room for price reductions. In either case, any company using target costingwould be well advised to develop extensive and continuing knowledge of its industry soas not to become the victim of a price war.As an example, a company, after conducting extensive industry research, determines thatthe market sales price for a particular type of lawn mower is 500. Additionally, thecompany determines that its competitors have large profit margins and that, to be aneffective competitor, it needs to have a target profit of 230 per unit. With this information, the company calculates its target cost for its new lawn mower at 270.This targetcost information enables the company to influence the lawn mower design costs prior togoing into production-this is when cost management can have its greatest impact.Designers design the lawn mower so that it can be produced at the target cost of 270.COST ANALYSIS THROUGH LIFE CYCLE ANALYSIS AND TARGET COSTINGPAGE 9

This approach is sometimes referred to as “design to cost.” A target cost is attainable, butonly with considerable effort and analysis10.INSIGHTS & APPLICATIONSCosting at Masterson Industries“What is this target costing I keep hearing about?” said RobertCooper, a long-time cost accountant at Masterson Industries.“The focus is on the total cost of the product,” said Edna Mallory,newly hired management accountant. “I don't understand yourpoint,” Robert responded. “In the past, we've focused on ourdepartments. But customers don't buy our departments. They buya product that performs a certain way or a service that achieves agoal. Customers will pay a certain price range for a particularproduct or service. We have to make sure thatour costs will be low enough to meet this price constraint andmake a profit. By focusing on measuring departments, we mayactually cause customers not to get what they want and to go toour competitors,” said Edna. “I still don't understand,” statedRobert.

The product cost life cycle presented in Exhibit 14-1 provides a total cost life cycle pro-file. It includes cost curves starting with product development, then production., and on into logistics and service support until the product or service market life cycle ends. These life cycle cost curves are particularly important to management .