Transcription

Prevention First 2006 SymposiumAera Energy LLC

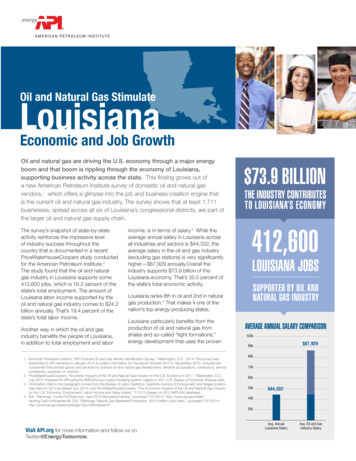

Prevention First 2006 SymposiumAera’s System of Operating Excellence (SOE)Policy & ProgramCompliance Rates10 Elements LEADERSHIP, COMMITMENT &INVOLVEMENT RISK MANAGEMENTEnv. & SafetyIncident RatesOperatingExcellenceOperationalReliability MANAGEMENT OF CHANGE PEOPLE FACILITY DESIGN, OPERATIONAND MAINTENANCE CONTRACTOR STEWARDSHIP ENVIRONMENTAL KEYPROCESSES & PROGRAMS Do no harm to people 100% compliance Protect the environmentResponseEffectiveness HEALTH AND SAFETY KEYPROCESSES & PROGRAMS INCIDENT PREPAREDNESS,RESPONSE AND FOLLOWUP AUDITINGThe EHS visionThe rear view mirrorLook here for Leading Indicators& Process Measures2

Prevention First 2006 SymposiumThe System of Operating Excellence (SOE) framework documentsthe expectations for Aera’s operations The framework identifies the key elements needed toachieve safe and reliable operations There are ten elements (covering 34 expectations) that mustbe mastered to achieve excellence Each expectation calls for “A process is in place to ” The framework provides a benchmark against whichto measure current performance3

Prevention First 2006 SymposiumSOE documentation can be accessed by Aera employees via the intranet 4

Prevention First 2006 SymposiumThe web pages document the five characteristics of the processes inplace to meet each expectation and provide links tosupporting material 5

Prevention First 2006 SymposiumEach Asset within Aera also has an SOE web page to documentand provide links to Asset specific processes 6

Prevention First 2006 SymposiumSOE GovernanceFeedback MechanismsRoles and ResponsibilitiesPolicy and Focus Area DevelopmentRisk ManagementProcess and Program DevelopmentStandardizationCorporate Measures and FeedbackChange ManagementBusiness PlanningImplementationVerification & MeasurementFeedbackProcess ExecutionOperating ExcellenceData QualityFeedbackCEO& SLTWeekly Incident ReportingMonthly Standardized MeasuresMonthly Business Plan ComplianceQuarterly Risk Mgmt DiscussionSOESteering CouncilAera Element Teams &Asset SOE teamsField Operations:Employees & ContractorsBi-monthly Council MeetingsAnnual Focus Area effortTactical Team statusSOE Last PlannerMonthly ReviewsAnnual Plan EffortTeam Morning MeetingUnit Steering TeamsTraining7

Prevention First 2006 SymposiumThe SOE teams form a network thatdrives standardization andexecution Aera Steering CouncilBeta Crew ABeta Crew BAera Element Team 5BreaBeta AMImplementationTeamHB CLAMUnit Steering TeamLA Basin AMImplementationTeamUnit Element Team 5HB PlantsVentura AMImplementationTeamHB EmmySOE linkage from ElementTeams to Process TeamsVentura Gas OpsVentura CLAMAera TeamVentura PlantsCoastal Team8

Prevention First 2006 SymposiumAera - CoastalMorning Meeting Agenda - SOE ProcessesKey SOE processesreview built into theMorning MeetingAgenda Safety Discussion/ Safety Manual ReviewElement 8- Discuss pertinent safety subjects or review sections of the Aera safety manual.- Pre-Job Work Plans? Energy Control?Hazards/Near Hits/IncidentsElement 8- Review any new incidents, Near Hits or reported Hazards, including housekeeping issues,that the group needs to be aware of ?MOC Review – Permanent or TemporaryElement 3- Review any new MOC that impacts the work team, including reviewing any temporarydefeated safety devices.Title V & Other Environmental IssuesElement 7- Review any planned activities that may have a conflict with the PTO or need regulatoryclarification.SOE ReviewElement 1- Review an expectation from the SOE framework. Discuss how team members impact,influence, participate or are affected by a particular expectation. Identify gaps and plans tofill gaps.PODToday's Work ScheduleElement 5- Review work planned for today (Aera employees and contractors). Discuss potentialhazards associated with work.Restricted AccessElement 6- Site Orientations needed? Transient Workers?VIPERCAPP/Planned ObservationsElement 8- Discuss CAPP metrics and planned activities that should be observed.RCFA Review of Root Cause & Follow-upElement 9- Following incident investigations, review the approved Executive Summary including CAP'sISEAElement 10- Discuss ISEA metrics and planned activities that could be audited.ScheduleTraining (weekly)Element 44- Worker Qualification, Adaptability Matrix progress?- Training this week? Upcoming backfill requirements?Risk ManagementElement 24- Are there any new or unresolved operational risks that need to be elevated?9

Prevention First 2006 SymposiumEach team has their own SOE web page for easy access tocommonly used information 10

Prevention First 2006 SymposiumSOE Business Plans developed to ID and Prioritize gaps and focusresources Milestones/MonthInstructions: Code those Actions completed in Green, Leave incomplete Actions in Red but do not change due ovide refreshertraining for ProcessTeams on Elements3&4Provide refreshertraining for ProcessTeams on Elements5&6Provide refreshertraining for ProcessTeams on Elements7&8Provide refreshertraining for ProcessTeams on Elements9&10Complete EmmyPHAPlan PHA expansionat SOE2 teammeetingLegend: Green Done, Red Not Done, Black Due Date TBD1Increase the amount of time Supervisors and Specialists spend in the fieldWork with LeanGroup to "loadlevel" VenturaCLAM Supervisorand Specialist timeBegin trackingSupervisor andSpecialist time inthe fieldLoad Level HB CLAM and/or Ventura Plants TeamConduct "loadleveling" effort forProcess TeamProvide refreshertraining for ProcessTeams on Elements1&22Complete HB TankFarm PHA344.14.24.3MiscEnsure completionof MEDIUM auditaction item on100% MESTattendanceComplete mergingof 3 Asset 4.1System GuidesProvide training forPHA facilitation(move to 1Q2006)Ensure completionof MEDIUM auditaction item on 4.1 Close gap on 4.3MEDIUM audit itemWorkerQualfor local trainingexpansionComplete mergingof 3 Asset 4.2System GuidesComplete mergingof 3 Asset 4.3System Guides"Mature" on SAPWQ data clean-upitemsIdentify SAP WQclean-up needed byprocess teamsStandardize ET4WQ metric forinclusion in Aerawide SGDecide/assign"essential"requirements toSAP WQ (Aeraeffort sched for2006?)11

AprJu -00nAu -00gO -00cD t-00ecFe -00bAp -01rJu -01nAu -01gO -01ctD -01ecFe -01bAp -02rJu -02nA u 02gO -02ctD -02ecFe -02bAp -03rJu -03nA u 03gO -03ctD -03ecFe -03bAp -04rJu -04nA u 04gO -04ctD -04ecFe -04bAp -05rJu -05nAu -05gO -05cD t-05ecFe -05bAp -06rJu -06n06Recognition Rate %100%90%2385%80%1975%70%Recognition Rate65%Number of Measures60%50%1511Number of MeasuresPrevention First 2006 SymposiumKey metrics are tracked for each SOE Element and Process Teams arerecognized for meeting goals Monthly Operating Excellence RecognitionProcess Team Average Recognition Rate2795%55%712

Prevention First 2006 Symposium2000 Recognition MetricsElement 5PM Compliance Total Equipment – over 90%PM Compliance Critical Equipment – over 95%PM/(PM CM) ratio Total Equipment – over 35%PM/(PM CM) ratio Critical Equipment – over 35%Front Line Maintenance over 20%Element 7PM Compliance Environmental – over 95%Element 8CAPP Coverage 1X observation - 90% coverageCAPP Coverage 2X observation - 60% coverageCAPP PIP's vs. Target 100%PM Compliance Safety – over 95%Element 10ISEA Observations 100% of goalISEA YTD % Follow Ups completed over 50%SOE processes have grown andmatured over time 2005 Recognition MetricsElement 1 - Leadership, Involvement and Commitment# of Certificates of Recognition awarded - goal is at least 2* proactive COR’sawarded by each process team to one of the team membersSOE Refresher Training on ScheduleElement 2 - Risk ManagementRisk analyses completed and coded on work orders released and used forprioritization - goal 95% of CORR and MEAS work ordersElement 3 - Management of ChangeBusiness closed orders requiring MOC with a user status of MOCC - at least90% (YTD beginning 11/02)Element 4 - People ProcessWork Improvement Team actions implemented - goal is that action(s) are takeneach month to positively impact Safety or Environmental Performanceand Production or ExpensesWorker Qualification ProgressElement 5 - Facility Design and OperationPM Compliance - Total Equipment - over 90%PM Compliance - Critical Equipment - goal is 100%PM/(PM CM) ratio - Total Equipment over 30%PM/(PM CM) ratio - Critical Equipment over 40%Proactive to Reactive Maintenance over 65%Vibration Pen Readings One Time CoverageCBM CAP’s completed on timeElement 6 - Contractor StewardshipFeedback submitted on Contractor Performance - goal is one feedback form amonthElement 7 - Environmental Key Processes and ProgramsPM Compliance - Environmental – 100%Element 8 - Health and Safety Key Processes and ProgramsCAPP 1X Coverage - 90% coverageCAPP 2X Coverage - 70% coverageCAPP PIP's vs. Target 100%CAPP Coaching Contacts - 2X coverage at least 90%PM Compliance - Safety - 100%Element 9 - Incident Preparedness, Response and Follow-upEHS TapRoot compliance - % of recordable or reportable EHS incidents YTDthat have a completed TapRoot analysis - Goal is 100%Equipment RCFA compliance - % equipment failures YTD that meet thebusiness rules that have a completed TapRoot analysis - Goal is 80%EHS and Equipment RCFA CAP Completion - Goal is to complete all CAP’s bydue datePIPER Reviews and ER Drills – one per monthElement 10 - AuditsISEA Audits 100% of goalISEA Follow Ups completed over 70% (12 month rolling average)Level III Audit CAP’s completed on time13

Prevention First 2006 SymposiumResults are alsoshown by Element tohelp identify systemicgaps and associatedimprovementopportunities Average Goal Attainment RateElement 1100%90%Element 10Element 280%70%60%50%40%Element 9Element 330%20%10%0%Element 8Element 4Element 7Element 5Element 6May-062005 avg.14

Prevention First 2006 SymposiumEach SOE expectation is periodically audited PROCESS STATUSPROCESS EFFECTIVENESS The process is mature, having undergone atleast one feedback, review, and improvementcycle. Revisions to process documentation have beenmade, if requiredLevel 4 The quality of process execution is excellent Execution of the process conforms to essentiallyall process requirements Essentially all process objectives are beingachievedLevel 3 Execution of the process conforms to theimportant requirements and most other requirements The quality of process execution is good Most process objectives are being achieved The process is deployed in the organization Procedures for key process tasks, based onrisk, are documented. Ongoing verification and measurement occurs The five characteristics of the managementsystem processes are documented, approved,and resourced Procedures for key process tasks, based onrisk, have been identified and are underdevelopment. Deployment is underway A documented process is being developed toaddress the potential hazards of the operationand to improve performanceLevel 2Level 1 Execution of the process conforms to theimportant process requirements. The quality of process execution is acceptable A majority of process objectives are beingachieved Execution of the process does not always conformto the process requirements The quality of process execution needsimprovement Some process objectives are achieved15

Prevention First 2006 Symposium4Audit results haveimproved over time 3Status2Effectiveness10200120022003LocationNumber ofDeficiencies2001: Initial SOE Audit - Coastal01.72.32002: Midway Sunset03.33.22003: Belridge03.53.42004: Coastal03.53.92006: Aera-Wide03.73.920042006Audit ScoresStatus Effectiveness16

Prevention First 2006 SymposiumSOE has contributed to a significant improvement inAera’s EHS Performance Aera’s Key EHS Performance IndicatorsInjury Rate1998 1999 2000 2001 2002 2003 2004 2005Lost Time RateOther Injury Rate% Annual ComplianceEHS Task ComplianceCombined Injury Rates1005001998 1999 2000 2001 2002 2003 2004 2005Employee & Contractor Injury RatesTRIR/LTIREHS Task ComplianceSpill HistoryNOVs05200420032002200120002099191998Volume# Spills# NoticesNotices of Violation from Agency Inspection1998 1999 2000 2001 2002 2003 2004 2005Spills to WaterSpills to LandVolumeSpills & Volume17

Prevention First 2006 SymposiumSOE expectationssupport Aera’sVision 18

Aera - Coastal - Discuss pertinent safety subjects or review sections of the Aera safety manual. - Review any new incidents, Near Hits or reported Hazards, including housekeeping issues, that the group needs to be aware of ? - Review any new MOC that impacts the work team, including reviewing any temporary defeated safety devices.