Transcription

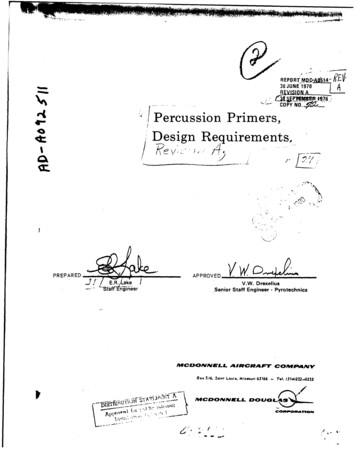

REPORT.MDUC-Ab 14MI30 JUNE 1970"- '-COPY NO.i.[Percussion Primers," Design Requirements,I /'f. S-". A*- .PREPAREDAPPROVED-"ikeer"IV.W.ri DrexeliusSenior Staff Engineer - PyrotechnicsMWCDONNELLAIRCRAFT'Boa 516, Saint Louw.Mlsouri 63166PM'tWCDONrtI'., LL-. -. . . . jm5 . :!:. ::';v * //COMUP4NYTe.r-(3d14.43.-0232S"I/*

PERCUSSION PRIMERS, DESIGN REQUIREMENTSREPORT MDC A051430 JUNE 1970'iABSTRACT#Percussion primers are the key to many critical functionsin aerospace ordnance hardware. This report is to be used asa specification for the use of percussion primers. It alsoprovides th- historical background of priming compositions through to the most recent high temperature resistantmiyes. Input energy to fire a primer with adequate safetymargin is discussed, together with primer output. The influenceof primer reconsolidation, flash hole size and baffling toreduce primer violence are included. Design data sheets forthose primers most frequently used in MCAIR pyrotechnic components are included.I'tFc ISCIDO PCiEL& ARMCRANr

PERCUSSION PRIMERS DESIGN REQUIREMENTSREPORT MDC A0514REVISION A30 SEPTEMBER 1976TABLE OF CONTENTSPAGEABSTRACT .1.0.INTRODUCTION .2.0 PRIMER CHARACTERISTICS .1.2.1General .2.2Selection .2.3Primer Compositions .2.4.1.2.3.1Commercial .2.3.2Military .2.3.3High Temperature .34. 4.Input Characteristics . . 46.1.72.4.1Firing Pin Design .2.4.2Firing Pin Energy .72.4.3Primer Cup Indentation.7.7. . .72.5Output Characteristics .2.6Miscellaneous Characteristics .82.6.1Primer Reconsolidation .82.6.2Primer Flash Hole .2.6.3Primer Back-Up Disc .2.6.4Baffling .INSPECTION AND QUALITY CONTROL.4.0SPECIFIC PRIMER APPLICATION AND SELECTION. . . . .5.0REFERENCES .APPENDIX A.*eC@ dMLLAl WI IAFrli993.0.9. 91012A-i

PERCUSSION PRIMERS, DESIGN REQUIREMENTSREPORT MDC A0514REVISION A30 SEPTEMBER 19764LIST OF FIGURES AND TABLESFiguresPage1.COMMERCIAL OR MILITARY CENTER FIRE PRIMER .2.SHOTSHELL OR BATTERY CUP PRIMER .2.3TablesIIITYPICAL THIOCYANATE/CHLCRATE PRIMING COMPOSITIONS .STORAGE DATA FOR M42 PRIMERS LOADED WITH COMMERCIALLEAD THIOCYANATE/POTASSlUM CHLORATE PRIMIbG MIX AND ASSEMBLEDIN M71 CARTRIDGES . . . . . .IIIPA 101 MILITARY LEAD STYPHNATE PRIMING COMPOSITION .IVHIGH TEMPEPATURE RESISTANT PRIMING COMPOSITIONS .VVI.5.5.COMPARISON OF ENERGY DATA FOR M42 PRIMERS LOADEDWITH COMMERCIAL THIOCYANATE/CHLORATE MIX AND PA 101 MIX .PERCUSSION PRIMER SELECTION LOGIC CHART .IiLIST OF PAGESTITLE, i THROUGH iv1 THROUGH 12, A-i THROUGH A-,9CANONELL ACRArVrI

PERCUSSION PRIMERS DESIGN REQUIREMENTSREPORT MDC A0514REVISION A30 SEPTEMBER 1976INDEX OF PAGE CHANGESREVISION DATEAND LETTERPAGES AFFECTEDEVISED ADDED REMOVED30 Sep 76Rev. AitleiREVISED BYREMARKSE.R. L eivv789 ROVEDV. W. Drexe2us

REPORT MDC A0514PERCUSSION PRIMERS, DESIGN REOUIREMENTS30 JUNE 19701.0INTRODUCTIONThe purpose of this report is to acquaint, refresh and guide the aerospaceordnance designer with the fire points of selection and use of center firepercussion primers for aerospace application.Percussion primers, which appear to have been independently invented about1815, by an American, Joshua Shaw of Philadelphia and an Englishman, Joseph Egg(References 1 and 2), form part of a general family of pyrotechnic componentsclassified as initiators. Included in this grouping but of 20th century vintageare stab primers, stab detonators and electric initiators. While the electricinitiator requires the application of an electric current to heat up a resistivebridgewire to provide the igniting stimulus, both the percussion and stab primersas well as stab detonators function by the application of mechaiical energy inthe form of e. rapidly impacting firing pin.The percussion primer is probably the smallest component the pyrotechnicdesigner is likely to encounter. As such it is likewise the most frequentlyoverlooked and misunderstood component. Its function may be likened to an energytransducer, wherein it converts mechanical energy from a suitable energy sourceinto chemical energy in the form of a deflagrating (to near detonating) pyrotechnic reaction. Since the primer functions as the link between the energysource and the ordnance device end.operation, it becomes the key to many criticalfunctions. Contrary to popular belief, percussion primers do sometimes fail tofunction despite the application of adequate input energy. Failure analysis innearly every case reveals that the malfunction is due to either incorrect primerinspect:.on or installation. The purpose of this report is to provide the pyrotechnic -agineer with design parameters, as well as new information on the us geof percussion primers. This report covers the following design points:"* Selection of the proper primer to fit the specific ignition requirements."* 3election of the optimum priming mix for the temperature environmentanticipated."* X-ray inspection and dimensional selection of the primers prior toinstallation."* Primer pocket sizing and reconsolidation recommendations."* Firing pin design and firing energy requirements."* Primer output energy.2.0PRIMER CHARACTERISTICS2.1GENERALTypical construction of a center fire p,-rcussion primer is shown in Figure 1,AvkO@wNmLLANCAFY

REPORT MDC A051430 JUNE 1970PERCUSSION PRIMERS, DESIGN REGUIREMENTSwhich also depicts both the two and three legged blunt anvil variations common toThe pointed anvil design shown in Figure 2 isdifferent primer manufacturers.used exclusively for shotgun shell primers (sometimes referred to as battery cupprimers). Primer assembly consists of loading an impact sensitive mix into theprimer cup, covering it with a paper disc and then pressing the anvil into place.Impact by a suitably constructed hemispherical en. firing pin on the metal primercup produces an indentation in the latter. This locally compresses the impactsensitive mix between the indentation and the anvil causing it to deflagrate.Since the primer cup is not perforated, the percussion primer unlike the stabprimer, is capable of maintaining a relatively high pressure gas seal. Theprimer cups are generally constructed from a ductile metal such as cartridgebrass, to permit the required deformation by the firing pin while still maintaining integrity of the primer cup.-Paper DiscAAnvi Pdmirq CompesittonTPSI,-31n N,Filwe 1 Commercial or Military Center Fire Primer 'r

REPORT MDC A051430 JUNE 1970PERCUSSION PRIMERS, DESIGN REQUIREMENTSFAnvilPrimer Cup.,Paper Disc--Battery CupFigure 2 Shotshell or Battery Cup PrimerTP6831- 1The impact sensitive mixes, which are rore frequently referred to as primingmixes or compositions, consist generally of a primary explosive, an oxidizer, afuel and occasionally an abrasive material to increase sensitivity to initiation.Primary explosives are incorporated because of their ability to explode whenexposed to either shock, friction (and heat) or any combination of these stimuli.The earliest knowr primary explosives, namely platinum, gold and silver fulminates(from the Latin, fulmenare, meaning strike with lightning) were described asearly as 1602. Some fifty years later mercury fulminate was discovered and by1800 its preparation and properties had been well established. In the late 1930'smercury fulminate formulations were gradually replaced by the much more stablelead styphnate which had first been reported in 191h. Despite this trend mercuryfulminate did not completely disappear from general use until after World War II.The presence of an oxidizer, such as a chlorate or nitrate, in primingcompositions is necessary due to the poor oxygen balance of the primary explosivepresent. Probably the most frequently used fuel for priming compositions isantimony trisulfide, since it also doubles as an abrasivc.2.2SELECTIONAs previously stated, the designer of an explosive train has two forms ofinitiating stimuli available, namely electrical and mechanical energy. In selecting the latter mode, which frequently involves less constraints thae. imposed byPAgeONWJLANRACFT

REPORT MDC A051430 JUNE 1970PERCUSSION PRIMERS, DESIGN REQUIREMENTSthe use of electric initiators, the designer also has the option of choosingeither stab or percussion initiated components.The former is of value when theavailable mechanical initiating energy is low but it suffers from the possibledisadvantage of back venting through the perforated cup. While the percussionprimer provides a gas seal, it does necessitate the availability of approximatelytwice the energy required for initiating the stab devices. As a general rule itis best for the designer to select the least sensitive initiator available thatis compatible with all of his requirements.Once the designer has decided upon the use of a percussion primer he mustfurther select one compatible with the train to be initiated. For example, apyrotechnic delay generally requires the least brisant primer available in orderto provide surface ignition and to prevent column breakup from the shock.Initiation of an explosive train, on the other hand, is aided by the use of themost brisant primer in order to build up the detonation rates as rapidly aspossible.2.3PRIMING COMPOSITIONS2.3.1 Commercial Formulations - Commercial priming compositions today can bestbe divided into the non-corrosive and the corrosive type for7Aulations.Becauseof the maintenance impact on the small arms users (Reference 3), primers containing the non-corrosive compositions are by far the most commonly used, andare generally referred to as the styphnate type. Exact formulations for thesecommercial lead styphnate compositions are considered, by the individual primermanufacturers to be proprietary and are therefore not available for publication.The second class of commercial priming compositions, namely the corrosivetype, contain no primary explosive materials. The earliest formulation of thisclass was developed in about 1922 by the Winchester Arms Company specificallyas a replacement for the mercury fulminate priming composition which had beenfound to deteriorate rapidly under tropical conditions. These compositionswere based upon the reaction between lead thiocyanate and potassium chlorate,wherein the former acts primarily as a fuel, but also exhibits a marked sensitizing effect upon the latter. Winchester's first formulation was subsequentlysold (for one dollar) to the government after which the Army assigned it thenow well known FA-TO designation (Reference 4).Three typical lead thiocyanate/potassium chlorate priming mix formulations are shown in Table I for informationalpurposes. The corrosive effects of this type composition result from the formation of soluble chloride combustion by-products produced by the chlorate oxidizer.The vendor advertised elevated storage specification for both corrosive and noncorrosive priming compositions are a minimum of one year at 160*F dry storage,however, Table II data on the M42 primer indicates a limited higher temperaturecapability. NOTE: Any utilization of primers above the specified temperaturelimits must be with the written approval of MCAIR.2.3.2 Military Formulations - Because of proprietary problems associated withthe commercial priming compositions, the U.S. Army through their PicatinnyArsenal facilities developed a number of formulations based on lead styphnate.The formula for the most frequently used military equivalent, designatedPA 101 is shown in Table III. Although this was historically developed as asubstitute for the commercial thiocyanate/chlorate priming compositions,IVE LASN@ AFrr"4

PERCUSSION PRIMERS, DESIGN REOUIREMENTSREPORT MDC A051430 JUNE 1970K#primarily for the ignition of pyrotechnic time delays (Reference 9), it isconsiderably more brisant.Table I Typical hiocyanate/Chlorate Priming CompositionsCommercial(Approx imate)Percent by WeightLead ThiocyanatePotassium ChlorateAntimony TrisulfileTNTMilitary (6)(FA-70)Percent by Weight25332532553175173530310010010014Calcium SilicideMilitary (7)Percent by Weight15-TP834-6Table 11Storage Data for M42 Primers Loaded with Commercial Lead Thiocyanate/Potassium Chlorate Priming Mix and Assembled into MU71 Cartridges (8)Temeuuture(OF)Safe Exposure LimitsDurationFiring DataUnsafe Expsure LimitsDurationFiring Data14016018039 Months121 Weeks41 Wueks100% Fired100% Fired100% Fied42 Months146 Weeks42 Weeks100% Misfired100% MIsfired40% Esfdired20016 Weeks100% Fired17 Weeks80% MisfiredTP8134-9Tahie III PA 101 Military Lead Styphnate Priming Composition (6 & 9)Percent by WeigM532210105Led StypzMe (sic)Bari NitraeAntine TrisulfidtAlumium (Pflueed)Tevacre1005

PERCUSSION PRIMERS, DESIGN REOUIREMENTSREPORT MDC A051430 JUNE 19702.3.3 High Temperature Formulations - As a result of examining initiatorsrecovered from a B52 crash in April 1957, Frankford Arsenal found that theyshowed degradative effects, particularly in the primers, from exposure totemperatures in excess of the normally accepted high of 165

primers). Primer assembly consists of loading an impact sensitive mix into the primer cup, covering it with a paper disc and then pressing the anvil into place. Impact by a suitably constructed hemispherical en. firing pin on the metal primer cup produces an indentation Author: E R LakePublish Year: 1976