Transcription

Process Equipment CatalogSolutions for Industrial Applications

Table of ContentsProcess Equipment Buyer’s GuideContentsAir-Operated Double Diaphragm Pumps Model Overview. 2Pump Selection Key for Husky AODD Pumps. 4Husky 205 Plastic Pumps. 7Husky 307 Plastic Pumps. 9Husky 515 Plastic Pumps. 12Husky 716 Metal Pumps. 15Husky 1050 Plastic Pumps. 18Husky 1050 Metal Pumps. 21Husky 1590 Plastic Pumps. 25Husky 1590 Metal Pumps. 28Husky 2150 Plastic Pumps. 31Husky 2150 Metal Pumps. 34Husky 3275 Aluminum Pumps. 37Husky Transfer Pump Packages. 39Husky Transfer Pump and Agitator Packages. 41Husky Pump Accessories. 42EP Series Hose Pumps. 47Hydra-Clean . 56CycleFlo and CycleFlo II. 59Fast-Flo 1:1. 61Piston Pumps for Ink Applications. 62Surge Suppressors. 66process equipment catalog1

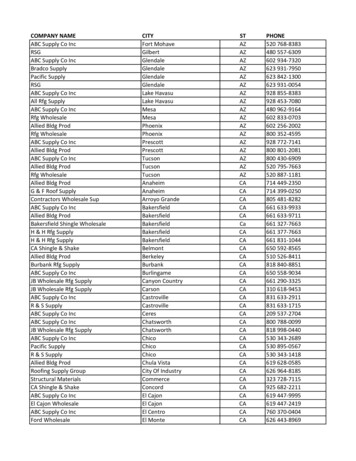

Air-Operated Double Diaphragm PumpsModel OverviewModelHusky 205Plastic1/4 in (6.3 mm)Husky 307Plastic3/8 in (9.4 mm)Husky 515Plastic1/2 in (12.7 mm)Husky 716Metal3/4 in (19.1 mm)Husky 1050Plastic1 in (25.4 mm)Thread TypeNPT or BSPNPT or BSPNPT or BSPNPT or BSPANSI/DIN FlangeAir ValveStandard andRemoteStandardStandard andRemoteStandard andRemoteStandard, Smartand RemoteMaximumFlow Rate5 gpm(19 lpm)7 gpm(26 lpm)15 gpm(57 lpm)16 gpm(61 lpm)50 gpm(189 lpm)MaximumDischargePressureMaterials ofConstructionAvailableCenter SectionAvailable100 psi(7.0 bar, 0.7 MPa)100 psi(7.0 bar, 0.7 MPa)100 psi(7.0 bar, 0.7 MPa)100 psi(7.0 bar, 0.7 MPa)125 psi(8.6 bar. 0.9 MPa)Polypropylene, PVDF, Polypropylene,AcetalAcetalPolypropylene,PVDF, AcetalAluminum, 316Stainless opylenePolypropylene,Conductive Poly,PVDFPolypropylene,Conductive PolyPump Weight2.0 lb (0.9 kg)Polypropylene2.5 lb (1.1 kg)Acetal4.75 lb (2.2 kg)Polypropylene5.2 lb (2.4 kg)Acetal6.5 lb (2.9 kg)Polypropylene7.8 lb (3.5 kg)Acetal8.5 lb (3.9 kg)Aluminum18 lb (8.2 kg)Stainless Steel18 lb (8.2 kg)Polypropylene26 lb (11.8 kg)PVDF0.063 in (1.6 mm)8.5 lb (3.9 kg)PVDF0.094 in (2.5 mm)0.094 in (2.5 mm)0.125 in (3.2 mm)ConnectionSizeMaximumSolids2.8 lb (1.3 kg)PVDF0.06 in (1.5 mm)NEW! Husky 10502process equipment catalog

Husky 1050Metal1 in (25.4 mm)Husky 1590Plastic1-1/2 in (38.1 mm)Husky 1590Metal1-1/2 in (38.1 mm)Husky 2150Plastic2 in (50.8 mm)Husky 2150Metal2 in (50.8 mm)Husky 3275Metal3 in (76.2 mm)NPT or BSPANSI FlangeNPT or BSPANSI FlangeNPT or BSPStandard, Smartand RemoteStandard andRemoteStandard andRemoteStandard andRemoteStandard andRemoteDIN/ANSI, NPTand BSPStandard50 gpm(189 lpm)100 gpm(379 lpm)100 gpm(379 lpm)150 gpm(568 lpm)150 gpm(568 lpm)275 gpm(1041 lpm)125 psi(8.6 bar, 0.9 MPa)120 psi(8.3 bar, 0.8 MPa)120 psi(8.3 bar, 0.8 MPa)120 psi(8.3 bar, 0.8 MPa)120 psi(8.3 bar, 0.8 MPa)120 psi(8.3 bar, 0.8 MPa)Aluminum, 316Stainless Steel,HastelloyCoated Aluminum,Polypropylene,Conductive PolyPolypropylene,PVDFAluminum, 316Stainless SteelPolypropylene,PVDFCoated Aluminum,316 Stainless SteelCoated Aluminum,316 Stainless SteelAluminum, 316AluminumStainless Steel,Ductile IronCoated Aluminum, Coated Aluminum, Coated Aluminum316 Stainless Steel 316 Stainless Steel35 lb (16 kg)Polypropylene49 lb (22 kg)PVDF33.5 lb (15.2 kg)Aluminum85 lb (38.6 kg)Stainless Steel49 lb (22 kg)Polypropylene68 lb (31 kg)PVDF58 lb (26.3 kg)Aluminum111 lb (50.3 kg)Stainless Steel0.25 in (6.3 mm)130 lb (59 kg)Ductile Iron0.25 in (6.3 mm)23 lb (10.4 kg)Aluminum36.3 - 41 lb(16.5-18.6 kg)Stainless Steel41 lb (18.6 kg)Hastelloy0.125 in (3.2 mm)0.188 in (4.8 mm)0.188 in (4.8 mm)150 lb (68 kg)Aluminum0.375 in (9.4 mm)1 inch Pump Familyprocess equipment catalog3

Pump Selection KeyHusky AODD PumpsPump DesignationPart numbers are located on ID tag on center section of all Husky diaphragm pumps.DXDiaphragmPump SizePumpXXWettedPartsSeatsXBalls/ChecksPump Size (air motor type and material)XDiaphragmsWetted PartsSeatsBalls1 1/4” (6.35 mm) Standard: polypropylene center section1 Acetal (npt)2 Acetal1 PTFE2 1/4” (6.35 mm) Remote: polypropylene center section2 Poly (npt)3 Stainless Steel2 Acetal3 3/8” (9.52 mm) Standard: aluminum center section3 Aluminum (npt)4 Hardened SST3 Stainless Steel5 1/2” (12.7 mm) Standard: polypropylene center section4 Stainless Steel (npt)5 TPE4 Hardened SST4 1/2” (12.7 mm) Remote: polypropylene center section5 PVDF (npt)6 Santoprene5 TPE5 3/4” (19.05 mm) Standard: polypropylene center section 6 Ductile Iron (npt)7 Buna N6 Santoprene4 3/4” (19.05 mm) Remote: polypropylene center section8 Fluoroelastomer7 Buna N1” (25.4 mm) refer to Husky 1050 Selector Tool, page 5A Acetal * (bsp)9 Polypropylene8 FluoroelastomerB 1-1/2” (38.1 mm) Standard: aluminum center sectionB Poly * (bsp)A PVDF9 PolypropyleneC 1-1/2” (38.1 mm) Remote: aluminum center sectionC Aluminum (bsp)G GeolastA PVDFT 1-1/2” (38.1 mm) Standard: stainless steel center section D Stainless Steel (bsp)G GeolastU 1-1/2” (38.1 mm) Remote: stainless steel center section E PVDF (bsp)B SST with viton sealF 2” (50.8 mm) Standard: aluminum center sectionF Ductile Iron (bsp)C Santoprene withG 2” (50.8 mm) Remote: aluminum center sectionviton sealV 2” (50.8 mm) Standard: stainless steel center sectionH 2 npt Alum ExtendedW 2” (50.8 mm) Remote: stainless steel center sectionG 2 bsp Alum ExtendedK 3” (76.2 mm) Standard: aluminum center section* BSP plastic in 1/2” (12.7mm) pumps 1” Plastic pumps flange connections3” Aluminum pumps flange/npt (f) combination connectionsNote: Above matrix is all possible combinations. All combination may not be available. See specific pump listings for available combinations.Diaphragm Pump Kit DesignationWhen selecting a kit, use the same code numbers as for the pumps regarding pump size, seat, ball/checks and /ChecksXDiaphragmsPump SizeSeatsBalls/ChecksDiaphragm1 1/4 in (6.35 mm)3 3/8 in (9.52 mm)5 1/2 in (12.7 mm) and 3/4 in (19.05 mm) 1” (25.4 mm) refer to Husky 1050Selector Tool, page 5B 1-1/2 in (38.1 mm) metal pumpC 1-1/2 in (38.1 mm) plastic pumpF 2 in (50.8 mm) metal pumpG 2 in (50.8 mm) plastic pumpK 3 in (76.2 mm)023456789ABC123456789AG15678Gprocess equipment catalog No seat Acetal Stainless Steel Hardened SST TPE Santoprene Buna N Fluoroelastomer Poly PVDF SST with viton seal Santoprene withviton sealG Geolast PTFE Acetal Stainless Steel Hardened SST TPE Santoprene Buna-N Fluoroelastomer Poly PVDF Geolast0 No Balls/Checks PTFE TPE Santoprene Buna-N Fluoroelastomer Geolast0 No DiaphragmDiaphragm1 PTFE5 TPE6 Santoprene7 Buna N8 FluoroelastomerG Geolast

Pump Selection KeyNEW! Husky 1050 Selector ToolFind the Right Pump for your ApplicationTo order a Husky 1050, use the online selectortool at www.graco.com/process or contactyour distributor.Wetted Parts Material OptionsAcetal Material used for seats, balls & wetted body parts Wide range of solvent resistance Withstands extreme fatigue Good level of abrasion resistance Groundable for use with flammables Not for use with acids or basesAluminum Material used for air motor & wetted body parts Medium corrosion and abrasion resistance Not for use with halogenated hydrocarbonsDuctile Iron Material used for wetted body parts High abrasion resistanceHardened SST Material used for seats and balls Moderate chemical resistance Good abrasion resistance Abrasion resistant balls and seatsPVDF Material used for wetted body parts & seats Strong chemical resistance: acids and bases Good abrasion resistance High temperature resistancePolypropylene Material used for air motor, wetted body parts, seats & balls Wide chemical compatibility General purpose Inexpensive alternativeStainless Steel Material used for air motor, wetted body parts, and seats and balls High level of corrosion and abrasion resistance Passivated for use with waterbase coatingsExample of Product Selector Tool on www.graco.com/process.Buna-N Material used for seats, balls and diaphragms Good for petroleum-based fluids Not for use with strong solvents or chemicals Food grade*Geolast Material used for seats, balls & diaphragms Good abrasion resistance Same chemical compatibility as Buna-N and TPETPE Material used for seats, balls & diaphragms Good abrasion resistance Often substituted for Buna-NSantoprene Material used for seats, balls & diaphragms Good abrasion and chemical resistance Not for use with solvents or hydrocarbons Often substituted for EPDM or EPR Food grade*PTFE Material used for balls & diaphragms Excellent when used with solvents Poor abrasion resistance Widest chemical compatibility with fluids Food grade*Fluoroelastomer Material used for seats, balls & diaphragms High level of corrosion resistance with acids Resists unleaded fuels Food grade*Hastelloy Material used for wetted body parts Good resistance to aggressive chemicals and incorrosive environments Compatible with high temperature fluids*Not recommended for use with Husky 1050 diaphragmsprocess equipment catalog5

6process equipment catalog

Husky 205 Plastic PumpsAir-Operated Double DiaphragmOrdering tsXXDiaphragmsBalls/ChecksPump Size (air motor type and material)Wetted PartsSeatsCHECK VALVESDiaphragm1 1/4” (6.35 mm) Standard: polypropylene center section1 Acetal (npt)0 No Seats2 Acetal1 PTFE2 1/4” (6.35 mm) Remote: polypropylene center section2 Poly (npt)9 Polypropylene6 Santoprene5 PVDF (npt)A PVDFPopular ModelsPart Number Part Number(NPT Ported)(BSP Ported)Standard Remote*Standard Remote* Materials for Materials forMaterialAir ValveAir ValveAir ValveAir Valve Check lypropylene D12091D22091D12091D12096D22096D12096* Requires Cycleflo or external valve control** Air control includes air regulator and filter with ePTFESantoprenePTFESantopreneFluidAirKitAir Kit 46946246946246946Technical SpecificationsHusky 205 Plastic PumpsAcetalPolypropylenePVDFMaximum fluid working pressureMaximum free flow delivery*Maximum pump speedDisplacement per cycle**Maximum suction lift (D12096)Maximum size pumpable solidsMaximum operating temperature***Maximum diaphragm operating temperature***PTFESantoprene100 psi (7 bar, 0.7 MPa)5.0 gpm (18.9 lpm)250 cpm0.012 gallon (0.045 liter)10 ft (3 m) dry0.06 in (1.5 mm)180 F (82 C)100 psi (7 bar, 0.7 MPa)5.0 gpm (18.9 lpm)250 cpm0.012 gallon (0.045 liter)10 ft (3 m) dry0.06 in (1.5 mm)180 F (82 C)100 psi (7 bar, 0.7 MPa)5.0 gpm (18.9 lpm)250 cpm0.012 gallon (0.045 liter)10 ft (3 m) dry0.06 in (1.5 mm)180 F (82 C)220 F (104.4 C)180 F (82.2 C)70 dBa220 F (104.4 C)180 F (82.2 C)70 dBa220 F (104.4 C)180 F (82.2 C)70 dBa9.0 scfm (0.252 m3/min)20 to 100 psi(1.4 to 7 bar, 0.14 to 0.7 MPa)1/4 npt(f)1/4 npt(f)1/4 npt(f)2.5 lb (1.1 kg)Acetal with Stainless Steel fibers,PTFE, Acetal, Santoprene9.0 scfm (0.252 m3/min)20 to 100 psi(1.4 to 7 bar, 0.14 to 0.7 MPa)1/4 npt(f)1/4 npt(f)1/4 npt(f)2.0 lb (0.9 kg)Glass-filled Polypropylene,Santoprene, PTFE, Polypropylene9.0 scfm (0.252 m3/min)20 to 100 psi(1.4 to 7 bar, 0.14 to 0.7 MPa)1/4 npt(f)1/4 npt(f)1/4 npt(f)2.8 lb (1.3 kg)PVDF, PTFE, Santoprene308652308652308652Typical sound level at 70 psi(4.9 bar, 0.49 MPa) air @ 125 cpmMaximum air consumptionAir pressure operating rangeAir inlet sizeAir exhaust port sizeFluid inlet & outlet size****WeightWetted parts(in addition to ball, seat and diaphragmmaterials– which may vary by pump)Instruction manual** Displacement per cycle may vary based on suction condition, discharge head, air pressure and fluid type*** Actual pump performance may be affected by prolonged usage at temperature**** Hybrid thread allows for either 1/4 npt or 1/4 bspt fittingprocess equipment catalog7

Husky 205 Plastic PumpsPerformance ChartsFLUID OUTLET PRESSURE psi (bar, MPa)Husky 205 Performance120(8, 0.8)6(0.17)100(7, 0.7)5(0.14)A80(5.5, 0.55)A4(0.11)B60(4.1, 0.41)40(2.8, 0.28)BC3(0.085)2(0.057)C1(0.028)20(1.4, 0.14)AIR CONSUMPTION scfm (m3/min)Dimensions6.8 in (173 (11.4)3.5(13.3)FLUID FLOW(Pump tested in water with inlet submergedAIR PRESSUREA at 100 psi (7 bar, 0.7 MPa)B at 70 psi (4.8 bar, 0.48 MPa)C at 40 psi (2.8 bar, 0.28 MPa)LEGENDAir ConsumptionFluid Flow6 in(145 mm)3.7 in(94 mm)Typical System DrawingsHusky 205 Wall-Mount with CycleFlo8process equipment catalog

Husky 307 Plastic PumpsAir-Operated Double DiaphragmOrdering tsXBalls/ChecksXDiaphragmsPump Size (air motor type and material)Wetted PartsSeatsBallsDiaphragm3 3/8” (9.52 mm) Standard: polypropylene center section1 Acetal (npt)2 Acetal1 PTFE1 PTFE2 Poly (npt)3 Stainless Steel3 SST5 TPE9 Polypropylene5 TPE6 SantopreneA Acetal * (bsp)6 Santoprene7 Buna NB Poly * (bsp)7 Buna NPopular ModelsPart Number Part Number(NPT Ported)(BSP Ported)Standard RemoteStandard Remote Materials for Materials for Materials forMaterialAir ValveAir ValveAir ValveAir 5NAD3A255D31277NAD3A277D31311NAD3A311Polypropylene 2966NAD3B966D32977NAD3B977* Air control includes air regulator and filter with tainless SteelAcetalAcetalAcetalStainless SteelStainless ntoprenePTFETPESantopreneBunaFluidAirKitAir Kit 246946246946246946246946246946246946246946process equipment catalog9

Husky 307 Plastic PumpsTechnical SpecificationsHusky 307 Plastic PumpsAcetalPolypropyleneMaximum fluid working pressureMaximum free flow delivery*Maximum pump speedDisplacement per cycle**Maximum suction lift (D31255)Maximum size pumpable solidsMaximum operating temperature***Maximum diaphragm operating temperature***PTFESantopreneBuna-NTPETypical sound level at 50 psi(3.5 bar, 0.35 MPa) air @ 50 cpmMaximum air consumptionAir pressure operating range100 psi (7 bar, 0.7 MPa)7.0 gpm (26.5 lpm)330 cpm0.02 gallon (0.076 liter)12 ft (3.7 m) dry0.06 in (1.5 mm)150 F (65.5 C)100 psi (7 bar, 0.7 MPa)7.0 gpm (26.5 lpm)330 cpm0.02 gallon (0.076 liter)12 ft (3.7 m) dry0.06 in (1.5 mm)150 F (65.5 C)220 F (104.4 C)180 F (82.2 C)180 F (82.2 C)150 F (65.5 C)75 dBa220 F (104.4 C)180 F (82.2 C)180 F (82.2 C)150 F (65.5 C)75 dBa6 scfm (0.17 m3/min)20 to 100 psi(1.4 to 8.4 bar, 0.14 to 0.84 MPa)1/4 npt(f) or bspt(f)3/8 npt(f)5.2 lb (2.4 kg)Acetal with StainlessSteel fibers, PTFE3085536 scfm (0.17 m3/min)20 to 100 psi(1.4 to 8.4 bar, 0.14 to 0.84 MPa)1/4 npt(f) or bspt(f)3/8 npt(f)4.75 lb (2.2 kg)Polypropylene, PTFEAir inlet sizeFluid inlet & outlet size****WeightWetted parts (in addition to ball, seat anddiaphragm materials–which may vary by pump)Instruction manual308553*Flow rates are with muffler and do not vary based on diaphragm material**Displacement per cycle may vary based on suction condition, discharge head, air pressure and fluid type***Actual pump performance may be affected by prolonged usage at temperaturePerformance ChartHusky 307 Performance6(0.17)100(7, 0.7)5(0.14)AA80(5.5, 0.55)4(0.11)BB60(4.1, 0.41)40(2.8, 0.28)CC3(0.085)2(0.057)D1(0.028)20(1.4, (22.7)FLUID FLOW(Pump tested in water with inlet submergedAIR PRESSUREA at 100 psi (7 bar, 0.7 MPa)B at 70 psi (4.8 bar, 0.48 MPa)C at 40 psi (2.8 bar, 0.28 MPa)D at 20 psi (1.4 bar, 0.14 MPa)10process equipment catalogLEGENDAir ConsumptionFluid Flow7(26.5)8(30.0)AIR CONSUMPTION scfm (m3/minFLUID OUTLET PRESSURE psi (bar, MPa)120(8.4, 0.84)

Husky 307 Plastic PumpsDimensions3.14 in(80 mm)4.98 in(126.5 mm)2.53 in(64.5 mm)1/4 npt(f)Air InletFluid Outlet:3/8 npt(f)6.18 in(157 mm)6.05 in(153.55 mm)8.13 in(206.5 mm)7.24 in(184 mm)0.66 in(17 mm)3/8 npt(f)Air Exhaust(muffler included)6.3 in (160 mm)8.12 in (206.5 mm)1.06 in(2.7 mm)Fluid Inlet:3/8 npt(f)3.5 in (89 mm)5.3 in (134.5 mm)Typical System DrawingsHusky 307 Wall-Mount with Siphon FeedHusky 307 Drum-Mount with Siphon FeedAir Control Kitprocess equipment catalog11

Husky 515 Plastic PumpsAir-Operated Double DiaphragmOrdering tsXBalls/ChecksXDiaphragmsPump Size (air motor type and material)Wetted PartsSeatsBallsDiaphragm5 1 /2” center (12.7 mm) or 3/4” ends (19.05)1 Acetal (npt)2 Acetal1 PTFE1 PTFE2 Poly (npt)3 Stainless Steel3 Stainless Steel5 TPE5 PVDF (npt)9 Polypropylene5 TPE6 SantopreneA Acetal * (bsp)A PVDF6 Santoprene7 Buna NB Poly * (bsp)D Urethane Duckbill7 Buna N8 FluoroelastomerStandard: polypropylene center section4 1 /2” center (12.7 mm) or 3/4” ends (19.05)Standard: polypropylene center section* BSP plastic in 1/2” (12.7 mm) pumpsE PVDF (bsp)8 Fluoroelastomer0 DuckbillPopular ModelsPart Number Part Number(NPT Ported)(BSP Ported)Standard Remote*Standard Remote* Materials for Materials for Materials forMaterialAir ValveAir ValveAir ValveAir 6D5AD06D51D07D41D07D5AD07Polypropylene D5EA11D55A88D45A88D5EA88*Required Cycleflo or external valve control** Air control includes air regulator and filter with gauge12process equipment lPTFEAcetalTPEAcetalBunaStainless Steel PTFEStainless Steel Stainless tainless Steel PTFEStainless Steel Stainless SteelStainless Steel Stainless SteelPolypropylene PTFEPolypropylene TPEPolypropylene SantoprenePolypropylene BunaPolypropylene FluidAirKitAir Kit 46946246946246946246946

Husky 515 Plastic PumpsTechnical SpecificationsHusky 515 Plastic PumpsAcetalPolypropylenePVDFMaximum fluid working pressureMaximum free flow delivery*Maximum pump speedDisplacement per cycle**Maximum suction liftMaximum size pumpable solidsMaximum operating temperature***Maximum diaphragm operating erTypical sound level at 70 psi(4.9 bar, 0.49 MPa) air @ 125 cpmMaximum air consumptionAir pressure operating range100 psi (7 bar, 0.7 MPa)15 gpm (57 lpm)400 cpm0.04 gallon (0.15 liter)15 ft (4.5 m) dry0.09 in (2.5 mm)180 F (82 C)100 psi (7 bar, 0.7 MPa)15 gpm (57 lpm)400 cpm0.04 gallon (0.15 liter)15 ft (4.5 m) dry0.09 in (2.5 mm)150 F (66 C)100 psi (7 bar, 0.7 MPa)15 gpm (57 lpm)400 cpm0.04 gallon (0.15 liter)15 ft (4.5 m) dry0.09 in (2.5 mm)150 F (66 C)220 F (104.4 C)180 F (82.2 C)180 F (82.2 C)150 F (65.5 C)250 F (121.1 C)74 dBa220 F (104.4 C)180 F (82.2 C)180 F (82.2 C)150 F (65.5 C)250 F (121.1 C)74 dBa220 F (104.4 C)180 F (82.2 C)180 F (82.2 C)150 F (65.5 C)250 F (121.1 C)74 dBa28 scfm (0.672 m3/min)30 to 100 psi(2.1 to 7 bar, 0.21 to 0.7 MPa)1/4 npt(f)3/8 npt(f)1/2 npt(f) or bspt(f)7.8 lb (3.5 kg)Groundable Acetal, PTFE, SST28 scfm (0.672 m3/min)30 to 100 psi(2.1 to 7 bar, 0.21 to 0.7 MPa)1/4 npt(f)3/8 npt(f)1/2 npt(f) or bspt(f)6.5 lb (2.9 kg)Polypropylene, PTFE, SST28 scfm (0.672 m3/min)30 to 100 psi(2.1 to 7 bar, 0.21 to 0.7 MPa)1/4 npt(f)3/8 npt(f)1/2 npt(f) or bspt(f)8.5 lb (3.9 kg)PVDF, PTFE308981308981308981Air inlet sizeAir exhaust port sizeFluid inlet & outlet size****WeightWetted parts(in addition to ball, seat and diaphragm materials–which may vary by pump)Instruction manual*Flow rates are with muffler and do not vary based on diaphragm material. **Displacement per cycle may vary based on suction condition, discharge head, air pressure and fluid type***Actual pump performance may be affected by prolonged usage at temperature. **** Hybrid thread allows for either 1/4 npt or 1/4 bspt fittingPerformance ChartsHusky 515 PerformanceFLUID OUTLET PRESSURE psi (bar, MPa)A80(5.5, 0.55)60(4.1, 0.41)AB40(2.8, 0.28)24(0.67)18(0.50)B12(0.37)CC20(1.4, 0.14)6(0.17)DAIR CONSUMPTION scfm (m3/min)30(0.84)100(7, 0.7)D0gpm(lpm)04(15.2)8(30)12(45.42)16(60.56)FLUID FLOW(Pump tested in water with inlet submergedAIR PRESSUREA at 100 psi (7 bar, 0.7 MPa)B at 70 psi (4.8 bar, 0.48 MPa)C at 40 psi (2.8 bar, 0.28 MPa)LEGENDAir ConsumptionFluid FlowD at 20 psi (1.4 bar, 0.14 MPa)process equipment catalog13

Husky 515 Plastic PumpsDimensions1/4 npt(f)Air Inlet1/2 npt(f) or bspt(f)Fluid Outlet5.01 in(127 mm)4.7 in(119 mm)3/4 npt(f)Outlet10.63 in(270 mm)9.94 in(252.5 mm)7.75 in(196.9 mm)8.56 in(217.4 mm)3/4 npt(f)Inlet6.12 in(155.4 mm)1/2 npt(f) or bspt(f) Fluid Inlet3/4 npt(f) or bspt(f) Fluid InletTypical System DrawingsHusky 515 Wall-Mount with Drum Feed14process equipment catalogHusky 515 Drum-Mount with Siphon Feed

Husky 716 Metal PumpsAir-Operated Double DiaphragmOrdering tsXBalls/ChecksXDiaphragmsPump Size (air motor type and material)Wetted PartsSeatsBallsDiaphragm5 3/4” (19.05 mm) Standard: polypropylene center section3 Aluminum (npt)2 Acetal1 PTFE1 PTFE4 3/4” (19.05 mm) Remote: polypropylene center section4 Stainless Steel (npt)3 Stainless Steel3 Stainless Steel5 TPE9 Polypropylene5 TPE6 SantopreneC Aluminum (bsp)A PVDF6 Santoprene7 Buna ND Stainless Steel (bsp)D Duckbill7 Buna N8 Fluoroelastomer8 FluoroelastomerPopular ModelsPart Number Part Number(NPT Ported)(BSP Ported)Standard Remote*Standard Remote* Materials for Materials for Materials forMaterialAir ValveAir ValveAir ValveAir 8D43288D5C288D4C288AcetalFluoroelastomer FluoroelastomerD53311D43311D5C311D4C311Stainless Steel PTFEPTFED53331D43331D5C331D4C331Stainless Steel Stainless Steel PTFED53355D43355D5C355D4C355Stainless Steel TPETPED53366D43366D5C366D4C366Stainless Steel ess Steel BunaBunaD53388D43388D5C388D4C388Stainless Steel Fluoroelastomer ne PTFEPTFED53955D43955D5C955D4C955Polypropylene TPETPED53966D43966D5C966D4C966Polypropylene opylene D07D4CD07DuckbillBunaStainless Steel D5D311D4D311Stainless Steel PTFEPTFED54331D44331D5D331D4D331Stainless Steel Stainless Steel PTFED54335D44335D5D335D4D335Stainless Steel Stainless Steel TPED54336D44336D5D336D4D336Stainless Steel Stainless Steel SantopreneD54355D44355D5D355D4D355Stainless Steel TPETPED54366D44366D5D366D4D366Stainless Steel ess Steel BunaBunaD54388D44388D5D388D4D388Stainless Steel Fluoroelastomer ne PTFEPTFED54966D44966D5D966D4D966Polypropylene SantopreneSantopreneFluidAirKitAir Kit 6241657246946* Requires CycleFlo or external valve control** Air control includes air regulator and filter with gaugeprocess equipment catalog15

Husky 716 Metal PumpsTechnical SpecificationsHusky 716 Metal PumpsAluminumStainless SteelMaximum fluid working pressureMaximum free flow delivery*Maximum pump speedDisplacement per cycle**Maximum suction liftMaximum size pumpable solidsMaximum diaphragm operating erTypical sound level at 70 psi air(4.9 bar, 0.49 MPa) air @ 200 cpmMaximum air consumptionAir pressure operating range100 psi (7 bar, 0.7 MPa)16 gpm (61 lpm)400 cpm0.04 gallon (0.15 liter)15 ft (4.5 m) dry0.09 in (2.5 mm)100 psi (7 bar, 0.7 MPa)16 gpm (61 lpm)400 cpm0.04 gallon (0.15 liter)15 ft (4.5 m) dry0.09 in (2.5 mm)220 F (104.4 C)180 F (82.2 C)180 F (82.2 C)150 F (65.5 C)250 F (121.1 C)74 dBa220 F (104.4 C)180 F (82.2 C)180 F (82.2 C)150 F (65.5 C)250 F (121.1 C)74 dBaAir inlet sizeAir exhaust port sizeFluid inlet & outlet sizeWeightWetted parts (in addition to ball, seat anddiaphragm materials–which may vary by pump)28 scfm (0.672 m3/min)30 to 100 psi(2.1 to 7 bar, 0.21 to 0.7 MPa)1/4 npt(f)3/8 npt(f)3/4 npt(f) or bspt(f)8.5 lb (3.9 kg)Aluminum, Stainless Steel, PTFE,Buna-N, Santroprene, Zinc-Plated SteelInstruction manual30898128 scfm (0.672 m3/min)30 to 100 psi(2.1 to 7 bar, 0.21 to 0.7 MPa)1/4 npt(f)3/8 npt(f)3/4 npt(f) or bspt(f)18 lb (8.2 kg)Acetal, Polypropylene, Stainless Steel,Polyester, Santoprene, Fluoroelastomer,Nickel-Plated Brass, Epoxy-Coated Steel308981*Flow rates are with muffler and do not vary based on diaphragm material**Displacement per cycle may vary based on suction condition, discharge head, air pressure and fluid type***Actual pump performance may be affected by prolonged usage at temperaturePerformance ChartsHusky 716 PerformanceFLUID OUTLET PRESSURE psi (bar, MPa)A80(5.5, 0.55)60(4.1, 0.41)AB40(2.8, 0.28)24(0.67)18(0.50)B12(0.37)CC20(1.4, 0.14)6(0.17)DD0gpm(lpm)04(15.2)8(30)12(45.42)FLUID FLOW(Pump tested in water with inlet submergedAIR PRESSUREA at 100 psi (7 bar, 0.7 MPa)B at 70 psi (4.8 bar, 0.48 MPa)C at 40 psi (2.8 bar, 0.28 MPa)D at 20 psi (1.4 bar, 0.14 MPa)16process equipment catalogLEGENDAir ConsumptionFluid Flow16(60.56)AIR CONSUMPTION scfm (m3/min)30(0.84)100(7, 0.7)

Husky 716 Metal PumpsDimensions3/4 npt(f) or bspt(f) Fluid Outlet4.25 in(108 mm)1/4 npt(f)Air Inlet2.76 in(62.5 mm)3/4 npt(f)Outlet4.44 in(112.8 mm)3/4 npt(f)or bsp(f)Fluid Outlets10.43 in(264.9 mm)9.18 in(233.2 mm)7.37 in(187.2 mm)7.8 in(198.1 mm)6.62 in(168.1 mm)4.29 in (109 mm)3/4 npt(f) or bspt(f) Fluid Inlets3/4 npt(f)Inlet3/4 npt(f)or bsp(f)Fluid Inlets6.04 in (153.4 mm)Typical System DrawingsHusky 716 Wall-Mount with Drum FeedHusky 716 Drum-Mount with Siphon Feedprocess equipment catalog17

Husky 1050 Plastic PumpsAir-Operated Double DiaphragmNEW! Husky 1050 Selector ToolTo order a Husky 1050, use the online selector tool atwww.graco.com/process or contact your distributor.PART NO.CONFIGURATION NO.DATE CODE SERIES MAX WPR PSI-barSERIAL NO.MADE INPump IDNOTE: Options for seats, check balls, diaphragms, and sealsvary for the 1050A, 1050C, 1050F, 1050H, 1050P, and 1050Spump models.Pump ConfigurationsPump(1 inch ports, 50 gpm)1050C ConductivePolypropylene1050PPolypropyleneExample of Product Selector Tool on www.graco.com/process.Center Section andAir Valve AP01BP01CP01DP

1" (25.4 mm) refer to Husky 1050 Selector Tool, page 5 A Acetal * (bsp) 9 Polypropylene 8 Fluoroelastomer B 1-1/2" (38.1 mm) Standard: aluminum center section B Poly * (bsp) A PVDF 9 Polypropylene C 1-1/2" (38.1 mm) Remote: aluminum center section C Aluminum (bsp) G Geolast A PVDF .