Transcription

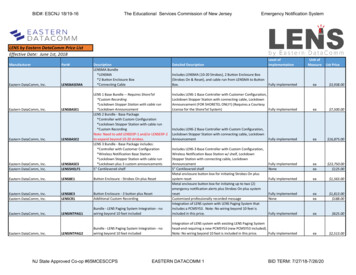

Page 1 of 11Effective Date:06 Oct 2015Prepared: T. O’ReillyIssued: 29 Sep 2015Issue: 1SI No: P3359Reviewed by: J. EvansApproved by: M. SandersDate: 29 Sep 2015Date: 30 Sep 2015Date: 05 Oct 2015(DD/MMM/YYYY)(DD/MMM/YYYY)(DD/MMM/YYYY)Title: Maintenance procedure for the 9222 and 9232 printers1Introduction:1.1The purpose of this procedure is to document the process for routine andscheduled maintenance of the 9222 and the 9232 shop floor printersTo keep the printers at optimum performance; routine maintenance needs to becarried out as per schedule outlined belowOnly trained members of staff to perform maintenance activities; if in doubt contactproduction engineering2Scope:2.1 This procedure is applicable to all Clement Clarke International respiratoryProduction engineers, Production manager, team leaders, senior productionoperators and operatives deemed qualified to carry out this procedure.2.2Team leaders, senior production operators and operatives must be fully trainedbefore commencement of any maintenance activities.3Equipment:9222 Markem Imaje printer9232 Markem Imaje printerFilter kit (A40989) Ink & air filter replacement every 18 months or 10000 hours(Whichever comes sooner) Work can be performed by a trained production engineeralternatively a Markem Image engineer can be called to perform the necessary work.Maintenance kit (A40846) the schedule of the pressure pump replacement is relatedto the type of ink used 10000 hours for standard ink 6000 hours for special ink.Drainage and flushing of the printerWork can be performed by a trained production engineer alternatively a MarkemImage engineer can be called to perform the necessary work.Note: Ink & air filters must also be changed every time the pressure pump isreplaced.SI No: P3359, Issue 1, 29 Sep 2015

Page 2 of 114Definitions:3.1 As per operation instruction manual5Internal / External Documents:4.1 Internal documentsN/A4.2 External documentsN/A6Responsibilities:4.1 Production manager and team leader Operate using Good manufacturingpractices (GMP) at all times. Bring to the attention of production engineering when18 month service of the printer is due this will be indicated on the machine.Adhere to this procedure at all times.Bring to the attention of the Production engineering department any nonconformingissues.Effectively implements, monitors & maintains this procedure.Deals; appropriately with any issues that may arise.A weekly start up and shut down schedule is in place in the cleanroom and must bestrictly adhered to unless the machine is in production use.Warning safety precautionsInk, additive, and cleaning liquids are highly flammableWearing contact lenses when handling consumables is strictly prohibitedInk resistant gloves and safety goggles are highly recommended during filling andcleaning operationsFire preventionNever leave containers containing ink, make up or cleaning products or ink soakedrags (even dry) near the printer.Ensure the printer is kept particularly clean, as dry ink deposits remain highlyflammableInk, Make-up and cleaning solutions must be stored in an adequate chemicalcupboard.7Method:The 9222 and 9232 printers are a sensitive piece of equipment and must bemaintained in accordance with the manufacturers recommended maintenanceschedules, processes and proceduresBoth the 9222 and 9232 show when the machine is due for its18 month or 10,000 or6000 hour service this can be located on the machine in tools maintenance menu. ASI No: P3359, Issue 1, 29 Sep 2015

Page 3 of 11notice is also attached to the machines when the next service is due the machine willalso give notification four weeks prior to the service9232 ink jet maintenance guideTo keep it in optimum condition; the following checks must be performed diligentlyFrequencyDaily Before start upDaily Before start upDaily After start upCheckRemove head cover andcheck that head andcover are cleanCheck ink and additivecartridge levelsCheck print qualityDailyEnsure printer is shutdown correctly at the endof the day as perprocedure P3358WeeklyClean the print headWeeklyShut down and restartprinterWeeklyTurn on any unused orspare printers and run forat least 4 hoursGeneral clean of cabinetand check cablingWeeklyEvery 18 monthsor 14,000hours(depending onink type)SI No: P3359, Issue 1, 29 Sep 2015Printer requires servicingActionClean the print head if dirty,leave if all is okCheck with productionengineeringEnsure print head isapproximately 10mm fromproduct; Check print headis clean, If dirty clean printhead and re-check quality.If power is cut by mistake,switch back on as soon aspossible, even if notcurrently needed andswitch off properly as thiswill flush the print headclean internallyIf not cleaned daily, it isgood practice to clean theprint head at least once aweekFor printers that run 24 / 7 itis good practice to switchoff then re-start the printeras during shut down theprinter performs an internalflushIf not to be used for morethan 15 days; the printerwill require a full flushWipe over cabinet withdamp cloth and ensure allcabling is secure toaccessories and mainsContact productionengineering or alternativelyContact Markem-Imajewhen the 4 week warningappears on screen

Page 4 of 11Print head cleaningTo clean the print head we must first stop the jet; either by turning the printer off orby using the stop jet command by pressing Tools Head operations Jet shut downSI No: P3359, Issue 1, 29 Sep 2015

Page 5 of 11Then place print head in wash station, remove head cover and spray wash solutionover cannon, plates and gutter pipe, also clean head cover if required. It is importantto also dry the head with the drier supplied.Now re start the jet and if all ok; replace the head coverIf after two cleans; there still appears to be a blockage, then perform the followingroutine in the head operations maintenance screen.Additive introduction for 10 seconds while spraying wash solution onto cannonUnblock nozzle for 10 seconds while spraying wash solution onto cannonCheck stability for 10 secondsClean and dry the print head and re start the jetPlease refer to production engineering should problems persist.Consumable replacementConsumable identificationSI No: P3359, Issue 1, 29 Sep 2015

Page 6 of 11Consumable replacementConsumable status screenNote that the status screen indicates what consumable is contained within the printerSI No: P3359, Issue 1, 29 Sep 2015

Page 7 of 11SI No: P3359, Issue 1, 29 Sep 2015

Page 8 of 118Critical Faults:SI No: P3359, Issue 1, 29 Sep 2015

Page 9 of 11SI No: P3359, Issue 1, 29 Sep 2015

Page 10 of 11If in doubt contact production engineering!SI No: P3359, Issue 1, 29 Sep 2015

Page 11 of 11RevisionHistoryPrepared by:TerryO’ReillyReviewed Approvedby:by:JustinMarkEvansSandersSI No: P3359, Issue 1, 29 Sep 2015RevisionVersion:1Date:29 Sep2015Reason for change:Procedure Originated

9232 Markem Imaje printer Filter kit (A40989) Ink & air filter replacement every 18 months or 10000 hours (Whichever comes sooner) Work can be performed by a trained production engineer alternatively a Markem Image engineer can be called to perform the necessary work. Maintenance kit (A40846) the schedule of the pressure pump replacement is related to the type of ink used 10000 hours for .