Transcription

Product Identification, Traceability, and InspectionStatusOP-85-02 rev NCProductIdentification,Traceability, andInspection StatusEffective Date: 5-11-18Andrew Adams, Quality Assurance Manager, on 5-11-18Management Approval by Craig O. Garneau, President on 5-11-18Printed copies of this document are for information purposes only and are uncontrolled.Printed copies are not valid after the date of printing.1. PurposeTo define the processes used at QNP for Identifying outputs and materialsMaintaining traceability, andDetermining inspection/test status.2. ResponsibilityThe table below identifies QNP personnel and their responsibilities relating to this procedure:PersonResponsibilityRecord initials, dates, and other information as appropriate onquality plans (shop orders), FM-81-01.Production & InspectionPersonnelPerform inspections at the appropriate stages of production anddocument the results on the Production Inspection Form, FM-8601.Ensure that production lots and materials are readily identifiableand that traceability is maintained as appropriate.Quality AssurancePersonnelDepartment SupervisorsAssist personnel in performing inspections when required.Resolve discrepancies in product identification and traceabilityMRB MembersOP-82-01 rev NC: Product Identification, Traceability, and Inspection Status

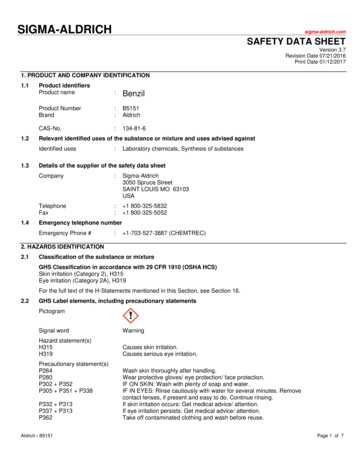

3. Applicable Forms and ReferencesThe table below identifies the number and the title of the forms and references that are applicable tothis procedure;Form/ReferenceNumberTitleAS9100Quality Management Systems - Requirements for Aviation, Space andDefense OrganizationsOP-75-01Control of Documented InformationOP-84-02Verification of Purchased ProductOP-85-03Control of Customer PropertyOP-85-05Control and Issuance of StampsOP-86-01Production InspectionsOP-87-01Control of Nonconforming OutputsFM-81-01Shop Order (Quality Plan)FM-81-02Job Tracking Record/CardFM-85-01Material Control LabelFM-85-02Age Sensitive Material Control LabelFM-85-05Ink and Paint Control LabelFM-86-01Production Inspection LogOP-82-01 rev NC: Product Identification, Traceability, and Inspection StatusDate Printed

4. - Product Identification4.1 - A QNP Shop Order, FM-81-01, or a Job Tracking Card, FM-81-02, accompanies a customer'sorder throughout the production process. The table below shows the means by which a production lotis identified.Shop Order/Lot IDA Shop Order NumberExplanationThe Unique, Primary identifier of a specific productionlot - referenced on all related Certificates ofCompliance, Packings Slips, Invoices, etc.B Customer ID number and nameC Customer purchase order numberSecondary identifiersD Part number and revision4.2 - For some job types, a Job Tracking Card, FM-81-02, is generated by Photo DepartmentPersonnel when the material stock is requisitioned. It is placed in the Shop Order Envelope, and maybe used to identify the production lot.Because stock is not requisitioned by the photo department for Thermaplot, Markem, or Mimakiprocess orders, a Job Tracking Card, FM-81-02, is typically not generated unless it is required foridentification purposes.4.3 - In some cases, product that is recognizable or unique in such a manner that its identity cannotbe mistaken or confused with any other product may travel unaccompanied by a Shop Order or JobTracking Card if necessary.OP-82-01 rev NC: Product Identification, Traceability, and Inspection Status

5. - Product Status5.1 - The following quality records are used to identify the status of parts during the ies a customer order throughout the production process.Shop OrderEnvelope,FM-81-01Operations are initialed and dated with a flat/strip/part count/estimate on theShop Order Envelope.Changes in the production plan are to be signed/initialed and dated by anauthorized user.OP-82-01 rev NC: Product Identification, Traceability, and Inspection Status

QualityRecordJob TrackingRecordFM-81-02ExplanationIf a batch of product must be separated from its shop order envelope, the productmay be identified by a printed Job Tracking Record, FM-81-02. This recordshows most of the same information seen on the Shop Order Envelope.Travels within the Shop Order Envelope, FM-81-01.ProductionInspectionReportFM-86-01The results of production inspections for a lot of materials is recorded on theProduction Inspection Form, FM-86-01 in accordance with the policies of OP-8601, Production Inspections, and related work instructions. Additional informationmay be recorded on supplementary forms as appropriate.Note: As QNP develops methods to digitally record in-process inspections,inspection data may be stored and made accessible through Job TrackingRecords, FM-81-02, rather than written on the Production Inspection Form, FM86-01.OP-82-01 rev NC: Product Identification, Traceability, and Inspection Status

QualityRecordHold TagsFM-87-02Rework TagsFM-87-03ExplanationHold, Rework, and Scrap tags may be used to identify and control the status ofparts in accordance with the policies of OP-87-01, Control of NonconformingOutputs.To be placed in a conspicuous manner on the related parts or Shop Orderenvelope, FM-81-01, and placed in a controlled area.Scrap TagsFM-87-045.2 - If the inspection and test status of an order cannot be determined by referencing the abovequality records, the product in question should immediately be brought to the attention of theDepartment Supervisor, a Material Review Board Member, and/or a member of the quality assuranceteam.5.3 - Unidentified product should be considered nonconforming and controlled in accordance withOP-87-01, Control of Nonconforming Outputs, until such time as it can be positively demonstratedthat parts meet all requirements.5.4 - The use and control of inspection stamps is documented in OP-85-05, Control and Issuance ofStamps. Records of stamp ownership is maintained in our Inspection Stamp Database and EmployeeTraining Records.OP-82-01 rev NC: Product Identification, Traceability, and Inspection Status

6. - Maintaining Traceability6.1 - As required, the lot number or unique identifier for the raw materials used to manufacture anorder are recorded on the shop order envelope. Material certs are stored within our Material Certdatabase and records can be searched based on those lot numbers. Shop Order Envelopes andMaterials Certs are saved as quality records in accordance with customer specified retention periodsaccording to the policies of OP-75-01, Control of Documented information.See below for an example of where the unique lot identifiers are recorded on shop orders.AArea for documenting the heat, lot, coil or other unique identifier for the materiallot/substrate used on a specific order.BArea for documenting the lot number of the adhesive or laminate used on a specific order.6.2 - Material certs and traceability information is typically made available to customers withCertificates of Conformance and First Article Inspection Reports.6.3 - As appropriate, when a customer’s parts require sequential numbering (serial numbers), QNPrecords the serial numbers that are produced in our Price Cards database so they remain a part ofthe quality plan data for that Shop Order.7. - Material Identification7.1 - Raw materials (flats of steel, aluminum, brass, vinyl, polycarbonate, polyester, etc.) in the stockdepartment are identified by a Material Control Label, FM-85-01, that are applied during theVerification of Purchased Product, per OP-84-02. Once material has been requisitioned and cut for aspecific order, the material then travels with the appropriate Shop Order, FM-81-01, or Job TrackingCard, FM-81-02.7.2 - Age Sensitive Materials are identified and controlled through the use of FM-85-01, MaterialControl Label, and/or FM-85-02, Age Sensitive Material Labels.OP-82-01 rev NC: Product Identification, Traceability, and Inspection Status

7.3 - Reference the table below as guide for how various materials and items are identified at QNP.Materials/Production ItemsLocationIdentified ByComputer Art FilesArt DepartmentFile name assigned by the Art Dept.Negatives/FilmsPhoto DepartmentNegative number assigned by the PhotoDepartmentPrinting ScreensScreen Prep Roomand Print Dept.Number on side of frameMetalphoto Raw MaterialsMetalphotoDepartmentVendor Supplied Labeling; Group,Thickness, Size, etc.PaintsPaint DepartmentFM-85-05 Ink and Paint Control LabelInksPrint DepartmentFM-85-05 Ink and Paint Control LabelCustomer Owned PropertyVariousControlled and identified per OP-85-03,Control of Customer PropertySteel, Aluminum, Brass, Vinyl,Polycarbonate, Polyester SkidsStock DepartmentFM-85-01 Material Control LabelThermaplot Printing Foils/Mimakiink cartridgesTP DepartmentVendor Supplied Labeling on side ofCartridge indicating ColorThermaplot/Mimaki SubstratesTP DepartmentVendor Supplied Labeling on box andinside of core indicating material, and/orvendor part numberThermaplot/Mimaki LaminatesTP DepartmentFM-85-01 Material Control Label orVendor Supplied LabelingMarkem Printing FoilsMarkemDepartmentVendor Supplied Labeling on core, colorand vendor part numberMarkem Substrates & LaminatesMarkemDepartmentVendor Supplied Labeling on core orvendor part numberIndigo & Scitex InksArt DepartmentVendor Supplied LabelingOP-82-01 rev NC: Product Identification, Traceability, and Inspection Status

Indigo Substrates and LaminatesArt DepartmentFM-85-01 Material Control Label and/orFM-85-02 Age Sensitive Material ControlLabelAdhesive and LaminatesLaminate/AdhesiveDepartmentFM-85-01 Material Control Label and/orFM-85-02 Age Sensitive Material ControlLabelTooling and DiesMachineDepartment andTool RoomUnique Serial Number8. Records/Objective EvidenceThe retention duration for records referenced in this procedure are available on-line in the FM-75-01Master Document List with Revision History.Records are maintained in accordance with OP-75-01 Control of Documented Information.9. Revision HistoryRevision, approved date, effective date, and a document change summary for this document islocated on-line in the FM-75-01 Master Document List with Revision History.OP-82-01 rev NC: Product Identification, Traceability, and Inspection Status

7. - Material Identification 7.1 - Raw materials (flats of steel, aluminum, brass, vinyl, polycarbonate, polyester, etc.) in the stock department are identified by a Material Control Label, FM-85-01, that are applied during the Verification of Purchased Product, per OP-84-02. Once material has been requisitioned and cut for a