Transcription

RegenerativeAgricultureWhat is regenerative agriculture,and how is it relevant to organic? CCOF Foundation Helps Anheuser-Busch Go OrganicCCOF Finds Support for Organic Among State LegislatorsUpdate on Inspections During the COVID-19 Pandemicwww.ccof.orgSummer 2020

RELIABLE . GENUINE .We are the first organic fertilizer manufacturer that isISO 22000 accredited so you can be confident that thebest food safety practices start from the ground up.Find out more at www.true.ag

CERTIFIEDOrganicCCOF, Inc. Board of DirectorsPhil LaRocca, Chair, LaRocca Vineyards; Malcolm Ricci, Vice Chair, BolthouseFarms; Thaddeus Barsotti, Treasurer, Capay Organic and Farm Fresh to You;Genevieve Albers, Traditional Medicinals; Karen Archipley, Archi’s Acres;Nadine Lew Basile, Soter Vineyards; Grant Brians, Heirloom Organic Gardens;Steven Cardoza, Cardoza & Cardoza Farms; Chad Crivelli, Crivelli Ranch;Rich Ferreira, Side Hill Citrus; Nickie Hughes, Lundberg Family Farms;Esteban Macias, Grupo U; Jutta Thoerner, Manzanita Manor Organics;Ted Vivatson, Eel River Brewing; Steve Zaritsky, SZ RanchCCOF Certification Services, LLCManagement CommitteeKelly Damewood, Chair, CCOF, Inc.; Charles Fowler, Fowler Ranch (retired);Jenneke de Jong, Bonanza View Dairy; Brad Samuelson, Corigin; Tom Willey,T&D Willey Farms (retired)CCOF Foundation TrusteesKelly Damewood, Chair, CCOF, Inc.; Lee Altier, Ph.D., CSU Chico College ofAgriculture; Karen Archipley, Archi’s Acres; Allen Harthorn, Harpos Organics;Phil LaRocca, LaRocca Vineyards; Malcolm Ricci, Bolthouse FarmsMagazine ProductionEDITOR-IN-CHIEF Rachel WitteSENIOR EDITOR Laura MathiasADVERTISING & PRODUCTION MANAGER Lourdes GarciaART DIRECTION/DESIGN Sarah Watters16Regenerative AgricultureWhat is regenerative agriculture, and howis it relevant to organic?Departments05 First WordsFrom CCOF’s CEO07 Member NewsMembers doing great things11 Foundation ProgramsCCOF Foundation at work15 Chapter UpdateStaying active with your chapter23 Organic AdvocacySupporting organic interests25 OTA UpdateOTA’s report from the Capitol27 Certification NewsKeeping you compliant30 Member ListingsNew CCOF members and supporters30 Advertisers IndexFind our partners’ adsCertified Organic magazine is published quarterly by CCOF and serves CCOF’sdiverse membership base and others in the organic community, includingconsumers and affiliated businesses. Letters to the publisher should be sentto marketing@ccof.org. CCOF reserves the right to edit or omit submissionsand letters received. For more information, contact CCOF, Inc. atmarketing@ccof.org.AdvertisingFor over 40 years, CCOF has been a trusted source of information on organicfarming and food production. Our information resources include full-colorpublications and online media targeted to all segments of the organic sectorthroughout the United States and beyond. For more information, visitwww.ccof.org/advertise or contact advertising@ccof.org.MAGAZINE AD DISCLAIMERCCOF appreciates the gracious support of advertisers who make thispublication possible. However, paid advertisements featured in thismagazine have been provided by the advertising company and do notnecessarily reflect a certification status of the company or productsadvertised. CCOF does not endorse or guarantee the quality or approvedstatus of any materials, products, or services. Please direct questionsregarding authenticity of advertised products and services to the advertiser.CCOF reserves the right to refuse advertisements deemed inappropriate.For every pound of paper used to print this editionof Certified Organic, an equivalent number oftrees are planted through Trees for the Future, anorganization dedicated to planting trees with ruralcommunities in the developing world, enablingthem to restore their environment, grow more food,and build a sustainable future. Our American-madepaper contains post-consumer recycled material.ISSN 1940-8870 CCOFwww.ccof.org20203

FARMING FOR OUR FUTUREThe future comes fast. You plan, you adapt,you innovate, because that’s what keepsyou in business and what keeps this countryfed. And we’re here to help — for all thetomorrows to come.W E ARE FARM CR E DITA nationwide network of customer-ownedassociations supporting rural communitiesand agriculture with reliable, consistentcredit and financial services.FarmCreditAlliance.com(855) 611-4110 toll free4www.ccof.orgAmericanAgCreditCoBankFarm Credit WestFresno Madera Farm Credit

firstWORDSReplenish, Reinvigorate, RejuvenateReading this issue’s feature story on the emerging“regenerative” agricultural movement caused me to reflect onthe word “regenerate.” What does it mean? The first synonymI find in my trusty thesaurus is “rebirth.” Other synonymsinclude "replenish," "reinvigorate, and "rejuvenate."Discovering these powerful synonyms brought to mindmy need to regenerate my personal well-being. During theworldwide pandemic over the last few months, I have feltdepleted at times. My friend and teacher asked me, “What areyou doing to fill your well?” She reminded me that I cannotgive to others when my own well is dry. My mental, physical,and emotional well-being requires that I remember to rest andre-nourish.My need to regenerate helps me empathize with our soils andnatural resources. I imagine most of our fields and rangelandswould appreciate more rest and nourishment from the hardwork we ask them to do. The organic movement has workedtirelessly to build awareness of the principle that we mustreturn what we take—we cannot sustain crop production andraise healthy livestock without replenishing the health of oursoils.In my current favorite read, Braiding Sweetgrass, author RobinWall Kimmerer explains a canon of indigenous principlescalled the Honorable Harvest, which asks us “to give back inreciprocity for what we have been given.” Kimmerer explains:“A harvest is made honorable when it sustains the giver as wellas the taker.”I hope that this issue’s feature leaves you feeling encouragedby the collective effort to regenerate our soils and re-establisha more honorable harvest. I also sincerely hope that you arefinding ways to replenish, reinvigorate, and rejuvenate yourown well-being.Kelly DamewoodCCOF CEONow, an even broader movement of farmers, businesses, andchangemakers are bringing regenerative practices into focus.They are building on the organic movement and challengingus to ask what else we can do to replenish what has beendepleted. How can we not only regenerate the health of oursoils but also the health of our communities? How can werealize the potential of organic farming practices and make soilour ally in storing carbon and combatting climate change?Issue ContributorsRegenerative Agriculture, Page 16Ellen Vessels is a freelance writer and copy editor with a passion for environmental issues, theoutdoors, and social justice. She is a staff writer covering small business news and generationalmarketing for TheAmericanGenius.com, and an assistant to fermentation revivalist and authorSandor Katz. She has written for outdoor magazines and environmental nonprofits, andformerly served as a project manager for Florida Organic Growers.Vessels is a self-taught herbalist who grows organic herbs and maintains a communityapothecary. When not writing, Vessels performs original music and puppet shows. A samplingof her writing can be found at clippings.me/EllenVessels, while her music can be found athelenskeleton.bandcamp.com.www.ccof.org5

CultivateYour BestWith Sustainable SolutionsFor Optimal GrowingSoil Health & FertilityMonitoring & TrappingBiological Pest ControlInsecticides & Disease ControlExplore 1000s ofnatural & organic ccof.org 2020 ARBICO Organics . All Rights Reserved.Serving Growers Since 1979.05/2020

memberNEWSOrganic DistilleriesShift Production toHand SanitizerTwenty seconds. Happy birthday to you, two times through.During the challenging times of COVID-19, we are remindedthat washing our hands is one of the necessary ways weprotect both ourselves and our communities. It is not alwayspossible to wash our hands; hand sanitizer has become anessential part of our daily lives.Hand sanitizer is regulated and typically only produced by drugmanufacturers. On March 27 the FDA published temporaryguidelines for hand sanitizer production. Distilleries havepermits to buy or make ethyl alcohol, which they can use asthe main ingredient in the World Health Organization (WHO)formula that the FDA provided in their guidance. The otheringredients in the approved formula include glycerin andhydrogen peroxide. The formula is simple, but ethyl alcoholis the toughest ingredient to find. To meet the growingneed, several CCOF-certified distilleries have reduced spiritproduction and filled their stills with hand sanitizer.Humboldt Distillery is in Fortuna, California, nestled along thenortheast shore of the Eel River. I spoke with Abe Stevens, whofounded the distillery in 2012, inspired by his love for HumboldtCounty and his affinity for chemistry. While Humboldt Distillerytypically fills their stills with vodka or rum made from organiccane sugar, reduced demand caused by recent restaurant andbar closures has given them the capacity to produce handsanitizer in addition to their spirits.WRITTEN BYMegan WestersundPHOTOThe entire hand sanitizer manufacturing process takes abouta week to complete, and Humboldt Distillery can make 250gallons of hand sanitizer per batch. Having three pot stills aswell as a continuous column still gives them a high capacityrelative to the size of their distillery. “We've made about 700gallons of sanitizer to date [end of April], which is over twotons worth. So far, it's all been donated for free, mostly to firstresponders and health care workers, but some also to retailbusinesses that remain open as essential services. We've beenhappy to cover the cost of production ourselves without anyoutside funding, but that does have its limits and we mayconsider selling a portion of our next batch.”The process has included some obstacles. “We did have somedifficulty finding glycerin locally for our first batch, and a localsoap company was kind enough to donate some for free. Sincethen we’ve been able to order more ourselves, but there are stillother supply issues getting packaging materials. For instance,there is a shortage of the typical plastic pump-style dispensercontainers you often see with sanitizer and liquid hand soap,and we have been unable to get any. So we've just been usingour standard glass vodka bottles to distribute so people can atleast use it to refill their existing containers.”Stevens expects there to be continued challenges for thedistilled spirits industry, due in part to economic uncertainty.For now, Humboldt Distillery has been able to continueemploying eight out of nine of its workers and is fortunate tohave received continued support from their current customers.The future is unknown, but Humboldt Distillery is doingwhat they can to support their community. Learn more aboutHumboldt Distillery at www.humboldtdistillery.com.Additional CCOF-certified distilleries have been producing handsanitizer, and I gathered details from a few of them. In total,Courtesy of Humboldt Distillerywww.ccof.org7

they have produced over 4,800 gallons of hand sanitizer so far,which adds up to over six million sets of sanitized hands.Their first donations were to Marin County Sheriff’s office andto PG&E workers. The sanitizer is available for the public topurchase and is matched by Hanson with a donation to the SanFrancisco Marin Food Bank. When not making sanitizer, theyproduce several types of vodka from distilled wine, includingoriginal, cucumber, Meyer lemon, mandarin, and habaneroflavors. Learn more at www.hansonofsonoma.com.J.J. Pfister Distilling CompanyBethel Rd. Distillery (owned by Castoro Cellars)Bethel Rd. Distillery in Paso Robles, California, teamed upwith a label designer and label printer, who both donated theirservices. Distiller Max Udsen noted “It has been a challenge tosource any type of spray bottles, small or large, so we decidedto focus on what we can readily source—wine bottles.” Theyhave made contributions to local shelters and frontline workers,and they make it easy for the public to donate sanitizer online.Castoro Cellars produces wine, and their Bethel Rd. Distillerymakes organic brandy with estate grown grapes. Learn more atwww.bethelrddistillery.com.Central Coast DistilleryCentral Coast Distillery in Atascadero, California collaboratedwith a local pharmacy to develop sanitizer using their distilledethyl alcohol as the base. They are donating 50 percent of allproduction to frontline workers and the local homeless shelter.Owner and distiller Eric Olson takes a culinary approach tomaking spirits, sourcing through local farmers, ranchers, andbeekeepers. Their Forager Gin is certified with CCOF, and hasnotes of Mignonette pepper, coriander, and juniper berry. Learnmore at www.foragerspirits.net.Hanson of Sonoma DistilleryAt Hanson of Sonoma Distillery in Sonoma, California, wineis distilled for three days to produce ethyl alcohol for handsanitizer, the same starting process as their flavored vodka.8www.ccof.orgThe team at J.J. Pfister Distilling Company in Sacramento,California, is producing alcohol distilled from grains, and theyhave hired restaurant professionals currently out of workto ramp up production. Their distilled spirits are made fromorganic produce sourced from the Klamath River Basin andthe Sacramento Valley. Before they began producing handsanitizer, they introduced their first vodka, distilled fromorganic potatoes, in 2017. It has since been joined by whiskey,gin, and rum, among others. Learn more at www.jjpfister.com.A Promising Model forCommunity Dairies:Straus Family CreameryEllen Straus served tea and cookies when her son Albertpresented a business plan to the family about transitioningtheir dairy to organic and developing their own creamery. Thiswas 26 years ago, when Straus’ vision of creating a brand forsustainable organic farming that revitalized rural communitiesand family farms was unprecedented. Straus Family Creamerywas the first ever certified all-organic creamery in the UnitedStates and the first ever certified dairy farm west of theMississippi River. In the past decades, Straus Family Creameryhas developed truly innovative models to serve their localcommunities and help reverse climate change, in spite ofeconomic challenges facing dairies today.Though most students across the country receive conventionalmilk in paper cartons with their school lunches, close to 6,000students in 13 public schools in five Bay Area school districtsare now served Straus organic milk from dispensers. By usingPHOTOCourtesy of Bethel Rd. Distillery

five-gallon milk dispensers from which students obtain theirserving size of choice, some districts have actually savedmoney by reducing milk waste. The effort to get organic milkdispensers in schools was spearheaded by Miguel Villarreal,former director of food and nutritional services in Novato,California, who estimated that five to ten gallons of milkwere wasted daily in every Pre-K through fifth grade school.Despite the decreased food waste in this new system, Albertconfirms it remains challenging to continue to provide organicmilk in schools due to the school bidding system requiredfor suppliers. Straus Family Creamery milk costs morebecause they pay farmers the true cost of producing certifiedorganic milk in a sustainable way. The bidding war of schoolcommodity purchasing does not tend to consider the true costof food production and many schools will opt for the lowestprice. Albert wants to create alternative purchasing modelswherein we consider our food system differently and supporttruly evolving our communities. Students are now enjoyingincreased nutritional benefits of organic milk, supporting localsustainable businesses, and saving the school districts moneyby not discarding unnecessary milk. The model has proven to bea win for all parties.While Straus Family Creamery milk fuels children in schools,the energy produced on the Straus Dairy Farm* is fuelingon-farm vehicles, including an electric feed truck that feedsthe cows that, in turn, power the truck. Companies nottypically associated with agriculture, such as BMW Group,are recognizing the value of energy produced on dairy farms.Through California’s Low Carbon Fuel Standards (LCFS)Program, the Straus Dairy Farm and BMW Group are able toforge a collaboration and receive incentives. The California AirResources Board is providing an economic incentive to dairiesinterested in harnessing their methane into renewable energythrough its LCFS program, where producers of fossil fuels usedfor California transportation must trade credits from lowcarbon fuel makers, thereby subsidizing the cost of producinglow-carbon fuels.Albert is in the process of implementing a pilot tank-basedmethane digester that digests manure in 2 ½ to 5 days insteadof the standard 30 days under his existing covered lagoondigester installed in 2004. This system is significantly morecompact and relatively less expensive, and Albert expectsa two to five year return on investment on this system dueto the LCFS partnership with BMW Group. Albert is alsodemonstrating an economical farming model that promotesbenefits to the environment and provides incentives and valueto dairy farms. Under the LCFS program, a dairy farm can earn5 to 10 times more revenue for selling their renewable energycredits to a third party like BMW Group compared to a standardpower purchase agreement with a utility buyer. This is areplicable and sustainable model for other dairies in California,making it more likely that small-scale organic dairy farmerswill invest in biodigesters. These technological innovations areheralded by Albert as an effective means to help combat climatechange. He is also working with organic certifiers and otherreporting agencies to help streamline organic certification andmake the paperwork more manageable for farmers.At the Straus Dairy Farm, Albert has implemented computersystems to understand the cost of production and how to bemore efficient and profitable. Albert is also planning to usethe State of California’s cost of production worksheet for thegroup of dairies providing organic milk to the creamery to helpbenchmark and improve financial viability. To further enhancethe Pasture Rule verification, Albert is in collaboration withscientists, including one who uses NASA satellite imagery thatmeasures pasture growth. He hopes the data can be utilizedas a tool for both producers and certifiers to monitor pastureand grazing activity, and to demonstrate the benefits of carbonfarming using pasture-based animals.While Straus Family Creamery has innovated their practicesover the past decades, they continue to prioritize theirrelationships with partnering dairies. Milk checks are deliveredin person twice per month. Meetings are held quarterly todiscuss product sales and any challenges the dairies are facingthat need to be addressed, and to determine the volume neededfor the next quarter of production based on the creamery’sproduct sales. Initially farmers were recruited with assistanceto help them transition to organic practices, while now newerdairies that join the creamery tend to be already certified asorganic practices have become more prevalent. With organicmilk in local schools, methane fueling nearby vehicles, anddairies surviving in the face of a national dairy crisis, itappears that Straus Family Creamery has established a trulysustainable and community-based way of life that could serveas a replicable model for other regional dairies. The risk-taking,pioneering, and community building that were necessary inthese past 26 years to make that happen gives promise to moredecades of sustainable dairy production to come. One mightponder that if Ellen Straus were serving tea and cookies at herkitchen table today, that they would be accompanied by StrausFamily Creamery organic milk.*Albert’s farm is one of twelve certified organic family dairy farms providing milk to the Creamery.WRITTEN BYKelly KormanPHOTOCourtesy of Straus Family Creamerywww.ccof.org9

Committed to preservingour environmentfor generations to come.We proudly support the CCOF Foundation in their ongoingefforts to advance organic agriculture throughcertification, education, advocacy and promotion.CALIFORNIA TABLAND RAISINSWe proudly support theCCOF Foundation in theirongoing efforts to advanceorganic agriculture throughcertification, education,advocacy and promotion.PREMOWNED FAMILYFCEC E R T I F IEEGDRAPESEYELORMAEMPWWW.CALORGANICFARMS.COMIU MOFRESH PRDUOUR FUTUREOUR LEGACYWe proudly support the CCOF Foundationin their ongoing efforts to advance organicagriculture for a healthy world.TAPRODUCE.COM10www.ccof.org

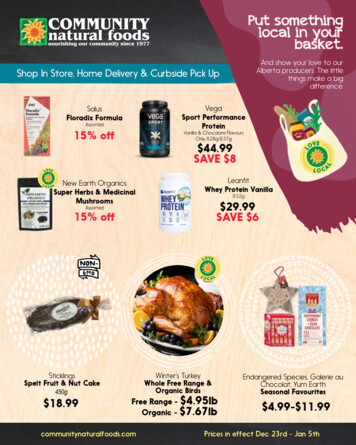

foundationPROGRAMSYou may have seen the hip Pure Gold ad during the Super Bowllast February, featuring people dancing, playing sports, andcooling down at a beach party with the help of the light goldbeer. The advertisement promised that for every six-pack ofbeer purchased in the United States, Anheuser-Busch wouldtransition six square feet of farmland to organic. The CCOFFoundation is a key partner in the 6 For 6-Pack Contract forChange campaign and is supporting this promise througheducation, technical advising, and grant making.Education and Technical AdvisingCCOF FoundationHelps AnheuserBusch Go OrganicBeginning in 2003, the CCOF Foundation hosted GoOrganic, a series of workshops and peer-to-peer mentorshipopportunities across California, funded by the CaliforniaState Water Board and the Clarence E. Heller Foundation.The workshops were designed to help conventional farmerstransition to organic by educating growers about the organicrule and soil health and by unpacking cultural barriers totransition. Between 2003 and 2006 the 63 workshops helpedtransition 4,000 acres to organic. In 2015, funded by the USDASound and Sensible Initiative, the CCOF Foundation revivedthe Go-Organic program, creating a self-assessment forconventional farmers interested in converting to organic, andfacilitating workshops throughout California on regional cropssuch as berries, stone fruit, vegetables, and grapes. Theseearly programs established the CCOF Foundation as a leaderin helping farmers from diverse backgrounds transition toorganic practices.Fast forward 17 years. The CCOF Foundation is now usingsimilar educational programs to help one of the world’slargest beverage companies to realize the goal of producingan internationally recognized certified organic beer. BrewerAnheuser-Busch began organic beermaking two years agowith the launch of their certified beer, Michelob ULTRA PureGold.At the beginning of March, Foundation Director Jessy BeckettParr traveled to Idaho Falls, Idaho to host a week of workshopson organic farming for the Anheuser-Busch agronomy teamand the farming community it serves. The first three dayswere an intensive on organic farming with a focus on barley,and were also attended by Idaho State Cooperative Extension,the Idaho State Department of Agriculture Organic Program,and the Idaho Barley Commission.To co-lead the trainings, CCOF partnered with the OrganicAgronomy Training Service (OATS, which is part of the GROWOrganic program under the Organic Trade Association) andNate Powel-Palm, a CCOF inspector and organic grain andlivestock farmer from Montana. Mallory Krieger, nationalprogram director for OATS, co-designed and co-facilitated thetrainings.The Anheuser-Busch agronomy team, 15 members strong,supports hundreds of contract farmers throughout Idaho,Colorado, Utah, Montana, and North Dakota who grow hopsand malt barley for their brewing operations. Some teammembers have decades of experience advising for AnheuserBusch, and several members of the team come from familieswho farm malt barley. The agronomy team deftly integratedtheir historical growing knowledge with the new informationabout crop rotation, organic techniques for nitrogen building,weed control, and fertility management, and the terms andregulations of the organic standards.After the three-day agronomy team intensive, the CCOFFoundation and partners held two one-day farmer trainings inIdaho Falls and Twin Falls for conventional farmers interestedin hearing more about organic farming. The trainings werewell attended. Participants heard from the Anheuser-Buschagronomy team, Nate Powel-Palm, OATS, CCOF, and veteranorganic farmers from the local region about the necessarysteps to transition. Many of the farmers who left the trainingsare now interested in converting to organic practices.The CCOF Foundation continues to support the AnheuserBusch team as they assist their farmers in transition. NateWRITTEN BYJessy Beckett ParrPHOTOCourtesy of Anheuser-Buschwww.ccof.org11

Marciano E N L IGH T E N E D FO OD SXalbadoraHONOR & SUSTAIN THE LANDWITH ORGANICALLY SOURCED INGREDIENTSVitalis Organic Seeds:INNOVATOR IN ORGANIC SEEDPRODUCTION AND BREEDINGOffering a broad assortment of certified organicvegetable and herb varieties adapted to open field andprotected culture production systems.For more information or to request our catalogue pleasecall 831-757-2300 or view on-line atwww.vitalisorganic.com.Organic SeedsWWW.SWEETEARTHFOODS.COM12www.ccof.orgBreeding and Producing Organic Seeds

The CCOF Foundation’sORGANICTRAININGINSTITUTEPowel-Palm has been hired to provide ongoing weekly supportsessions for the agronomists and CCOF Foundation staff willpublish recommendations for ongoing work within AnheuserBusch to ensure the success of their organic initiative.Grants for Organic TransitionIn addition to providing education and technical advising,Anheuser-Busch committed 500,000 in direct support grantsto farmers who are transitioning to organic across the UnitedStates. The CCOF Foundation is facilitating the grantingprocess with two applications periods, one in the spring andone in the fall of 2020. One hundred 5,000 grants will supportexisting growers as they implement their Organic System Plan.ELIGIBILITY:Through hands-on trainings, workshops, andseminars, the Organic Training Institute providesresources to aspiring and current organicprofessionals about the latest organic research andbest production and marketing practices.Our educational offerings for the second half of2020 feature a diverse lineup of topics, including1.Producers of all crop types eligible for organic certificationare encouraged to apply. Please note, cannabis and hempproduction are not eligible for funding.2.Applicant must reside and farm in the United States(including U.S. territories).3.Applicant must have a minimum of three years inproduction (3 Schedule F tax return required forapplication).4.Applicant must demonstrate their intent to farmorganically.5.Grant funds may only be used to support the applicant’stransition to USDA NOP certified organic productionmethods.6.Applicant agrees to submit a final report at the end ofthe grant period and report on the organic status of theirfields for the three years after the grant.7.Applicant must be 21 years of age or older at the time theapplication is submitted. soil health marketing strategies for farms that sell directlyto consumers trainings for farmers’ market managersLearn more about upcoming OrganicTraining Institute events atwww.ccof.org/oti »You can check out recordings of previous webinarsin the CCOF Foundation webinar library.FUNDING PRIORITIES:Popular recordings include1.farmers with at least five years of production experience2.applicants who are underrepresented in the organicindustry, including women, people of color, veterans,farmworkers, and people with disabilities3.applicants who have demonstrated interest in organicproduction methods4.applicants who have a plan, or who have identified ameans to develop a plan, for transitioning to certifiedorganic production5.farmers who can demonstrate financial need6.preference for farmers who are new to organic farming How to Get Ready for a FSMA Produce SafetyRule Inspection in California Organic 101 for Small and Midsized FarmsWebinar FSMA Basics for Small and Medium-SizedProduce Farms WebinarView recordings of past webinars atwww.ccof.org/oti-recordings »The Organic Training Institute’s 2020 events are supported inpart by funding from private donors, the California Departmentof Food and Agriculture, and the following entities within the U.S.Department of Agriculture: Agricultural Marketing Service, NationalInstitute of Food and Agriculture, and the Risk Management Agency.For more information on grants for organic transition, pleasevisit www.ccof.org/foundation.www.ccof.org13

The scientific explanation.Reduction of surface tensionOROBOOST reduces tension of pesticide droplets todeliver more droplets in more uniform sizes to leaf surfaces.When applying contact pesticides this more completecoverage eliminates the risk of leaving areas untreatedthat could result in reduced control.OROBOOSTdramaticallyimproves spreadingand wettingOROBOOSTopens channelsthrough theepicuticular waxIncreased penetration of systemic pesticidesAt higher label rates, the proprietary OROWET technologyin OROBOOST softens the waxy protective lipid-containingstructures to improve penetration of the pesticide solutionon plants and insects for better pesticide performance.Improved translocationOROBOOST, with proprietary TransPhloem technology,accelerates the movement of systemic pesticides and foliarnutrients into a plant’s phloem for rapid translocationthroughout the plant for improved efficacy.University of Illinoisphosphorescent imageof a glyphosate and C14radio isotope foliarapplication showstranslocation of theherbicide and OROBOOSTspreading throughout alambsquarter weed anddelivering material toroots within 12 hours.Benefits of OROBOOST include: WSDA Certified Organic Material Contains pro

In my current favorite read, Braiding Sweetgrass, author Robin Wall Kimmerer explains a canon of indigenous principles called the Honorable Harvest, which asks us "to give back in reciprocity for what we have been given." Kimmerer explains: "A harvest is made honorable when it sustains the giver as well as the taker."