Transcription

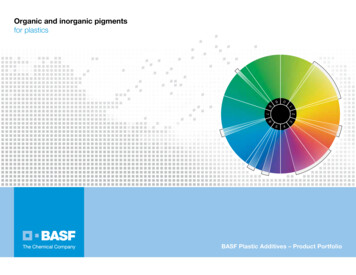

Organic and inorganic pigmentsfor plasticsBASF Plastic Additives – Product Portfolio

Organic and inorganic pigments for plasticsContentIntroductionProduct informationExplanation of data345Organic pigmentsYellowOrange & BlueRed & RubinePink, Magenta & VioletBlue & Green79101314Inorganic pigmentsSicotan Sicopal Sicotrans 151617

Organic and inorganic pigments for plasticsWelcome to an advanced world of color.Same high quality, just easier.Shaping the future of organic and inorganic pigments.At BASF, we create products that help you create yours. In this folder we willfamiliarize you with our range of organic and inorganic pigments for plastics thatare particularly suitable for plastic masterbatches and for straight compounding /mass-coloration. These are part of our range for the plastics industry, comprisingorganic and inorganic pigments, mono-pigment concentrates, polymer solubledyes and effect pigments. We are consistently striving to provide pigments of thehighest quality and are working on further solutions for the plastics industry.Our new portfolio makes your life easier.With the latest changes, our vast portfolio has received hundreds of excitingadditions, creating the need to simplify this immense diversity of products andproduct variant to make finding and ordering easy and convenient for you. Allcolors now follow the proven and tested BASF nomenclature. We are certain youwill find this new consistency most helpful in your daily work.Only the names have changed.Finding the pigments you need to achieve the perfect results is now easier thanever. It all starts with the BASF brand name the product belongs to. Your favoritepigment might have had a name change. If you familiarize yourself with the newname, the rest is pure logic. All pigments have now been integrated in the tried andtested BASF nomenclature and are clearly shown on the BASF color wheel. Therefore, every product in our portfolio has six elements to its name that make up theBASF nomenclature: product brand e.g. Heliogen , followed by basic color shade,area of use, position in the color wheel, serial number and application indicator.For further information please contact your local BASF representative.We make it work for you.The world is a colorful place and our world of color for the plastics industryoffers you the biggest selection of organic and inorganic pigments worldwide,suited for a great variety of applications. Have a look!3

Organic and inorganic pigments for plasticsBASF offers the following organic and inorganic pigments:Organic pigmentsCinquasia , Cromophtal , Irgazin ,Paliogen and Paliotol These products provide the broadest range of high-performance pigments,combining outstanding coloristic properties with excellent fastness to heat, light,chemicals and solvents. In addition, certain products offer excellent weatherresistance.Heliogen These Cu-phthalocyanine based blue and green organic pigments are known fortheir very good to excellent overall properties.Irgalite Classical organic yellow, orange and red pigments with good end-use performance.Inorganic pigmentsSicotan These inorganic mixed-phase yellow and brown pigments have outstandingfastness to heat, light, weather, chemicals and solvents, even in very lowconcentrations. Their exceptionally high heat and chemical resistance makesthem suitable for almost all polymer types. The products do not migrate anddo not influence the warping behavior of HDPE. They are all suitable for usein blends with organic pigments, achieving brilliant shades with high opacity.Sicopal These inorganic pigments with their spinel structure are based on various metaloxides. All have outstanding fastness to light and weather and most of themachieve the highest heat resistance. None of the products migrate, nor do theyinfluence the warping behavior of HDPE.Sicotrans These extremely finely dispersed transparent iron oxide red pigments have excellentfastness to heat, light and weather. The products do not migrate, nor do theyinfluence the warping behaviour of HDPE.Further product rangesFor applications in which ease of dispersion is an important criteria (e.g. films andfibers), it is advisable to use fully dispersed mono-pigment concentrates ratherthan powder pigments. BASF offers a range of mono-pigment concentratessuitable for a selection of polymers. Please see the product table for informationon our products that are available as mono-pigment concentrates. For furtherdetails on these mono-pigment concentrates, please see the respective brochure.BASF is the leading manufacturer of a comprehensive range of additives for theplastics industry. For further information on our stabilizer offer for plastics, pleaserefer to the respective brochures.4

Organic and inorganic pigments for plasticsExplanation of data:IntroductionApplication performanceThe illustrations and data presented in this shade card are intended only as ageneral guide and for assistance in pigment selection. Users are recommended toconduct their own trials, under their own specific conditions to ensure the correctcolor appearance and application suitability.A selection of performance data of the most important properties in polyolefins(HDPE) and PVC (Ba/Zn stabilized flexible PVC) are presented here. All data arebased on the following test methods at a concentration for organic pigments of0.1 % for full shades (FS) and at a ratio of 1:10 for white reductions (WR). For inorganic pigments concentrations of 1% for full shades (FS) and a ratio of 1:4 forwhite reductions (WR) were used.If further information is required on any of the products listed in this shade card,please contact your local BASF representative.Color shadesFor ease of use the shade card is provided as a downloadable PDF. Please note,that due to differences in computer screen color calibration the PDF shade cardcan only help you to roughly estimate the shade, but the colors cannot be binding.All organic pigment shades shown here are based on a full shade concentrationof 0.2 % pigment except violets, where 0.1 % pigment was used. In the whitereductions the illustrations are based on the respective pigment concentration toachieve 1/3 ISD based on 5 % TiO2.Inorganic pigment shades are based on a full shade concentration of 2 % pigmentand a ratio of 1:4 for white reductions.Polymer suitabilityPossible fields of application are shown in the table, opposite each pigment.Please note that these are intended only as a general guide.Key to the tables:RecommendedLimited suitabilityNot recommendedMigration (HDPE and PVC-p)Migration resistance was determined in accordance with DIN 53775 by directcontact between the colored test sheet and a white flexible PVC contact sheet.Staining of the contact sheet was assessed using the ISO 105 A03 Grey Scale forstaining, GS 5 denoting no migration and steps 4 – 5 being subdivided.Heat resistance (HDPE)Heat resistance was determined by injection molding in accordance with ISO12877-2.The results show the highest temperature at which the color difference versus astandard is no greater than GS 4 on the ISO 105 A02 Grey Scale for assessingcolor change.For most of the Sicotan and Sicopal products and some high performanceorganic pigments, a GS rating of 5 is achieved at the highest testing temperatureof 300 C. Therefore, heat resistance above 300 C can be achieved under certaincircumstancesLight fastness (HDPE and PVC-p)Light fastness was determined using Xenon lamp exposure tests in accordancewith the equivalent test methods ISO 4892-2 or ISO 105 B02.The samples were assessed against the 1 – 8 Blue Wool Scale as described inISO 105 B02, Blue Wool 8 denoting the highest light fastness.5

Organic and inorganic pigments for plasticsExplanation of data:Hot light fastness (PVC-p)1/3 ISD (HDPE and PVC-p)Exposure was carried out to 600 kJ/m in accordance with ASTM SAE J 2412(formally ASTM SAE J 1885).2Color changes were assessed using the ISO 105 A02 Grey Scale for assessingcolor change, GS 5 denoting no change and GS 1 denoting the lowest hot lightfastness.Weather resistance (HDPE and PVC-p)Weather resistance was determined using Xenon light exposure tests in accordance with the equivalent test methods ASTM G 155, ISO 4892-2 or the formerCiba internal test method WOM 119/50.The HDPE samples were exposed for up to 3000 hours and the PVC-p samplesfor up to 5000 hours.Color changes were assessed using the ISO 105 A02 Grey Scale for assessingcolor change, GS 5 denoting no change and GS 1 denoting the lowest weatherresistance.NoteColor strength is indicated by the number of parts of colored pigment which, incombination with defined percentage of TiO2 in a particular polymer or compound, gives 1/3 International Standard Depth (ISD) as described in DIN 53.235.DensityDensity was determined in a pycnometer, as described in ISO R787-10, and isexpressed as g/cm3.Bulk densityBulk density was determined from the weight of a product sample that can becontained in a vessel of specified volume and is expressed as kg/l. Assessmentwas in accordance with ISO R787-11.Product formCertain inorganic pigments are also available in a fine granule form (FG). Thisproduct form is low dusting and free flowing.Hot light fastness and weather resistance ratings below GS 3 are not included inthis pattern card. Products with a low performance are not recommended forthese applications.Warping (HDPE)Influence on the warping tendency of injection-molded HDPE articles was determined in accordance with ISO 294-4/ASTM 955.Warping tendency was assessed as follows: None (N): No significant influence under laboratory test conditions and widelyconfirmed in practice. Low (L): Slight influence determined in laboratory testing, but successful inpractice. High (H): Significant influence in the laboratory and in practice. Use for large /complex HDPE injection moldings is not recommended.6

WarpingMigration FS 0.1%Light FS 0.1%Light WR 1:10Hot light 600 kJ FS 0.1%Hot light 600 kJ WR 1:10Weather 5000 h FS 0.1%Weather 5000 h WR 1:10Cromophtal Yellow K 0990 FPold: Cromophtal Yellow 8GNPC.I. Pigment Yellow 128Disazo condensation526026087-84-53N587-854-54-540.21 0.20 1.47 0.13Paliotol Yellow K 1070old: Irgalite Yellow WGPC.I. Pigment Yellow 168Monoazo salt5260240773-N57-87----0.37 0.37 1.66 0.25Cromophtal Yellow K 1210 FPold: Cromophtal Yellow 3GNPC.I. Pigment Yellow 93Disazo condensation528028086-74-N587-85543-40.15 0.15 1.45 0.144.226026076-73-4-L4.887-8544-530.15 0.15 1.40 0.205300300774-54L57-8744--0.18 0.15 1.62 0.302-32002006-76---4.766----0.13 0.11 1.63 0.2153003007-874-5-L587-8544-0.15 0.11 1.40 0.214.62002007-86-7---576----0.10 0.08 1.34 0.21525026077--L577----0.35 0.33 1.59 0.20Cromophtal Yellow 2GFC.I. Pigment Yellow 155Disazo condensationCromophtal Yellow K 1310old: Cromophtal Yellow 4GVC.I. Pigment Yellow 215PteridineIrgalite Yellow K 1320old: Irgalite Yellow BRMOC.I. Pigment Yellow 14**DiarylideCromophtal Yellow K 1410old: Cromophtal Yellow 2GOC.I. Pigment Yellow 180BenzimidazoloneIrgalite Yellow K 1415C.I. Pigment Yellow 13**DiarylidePaliotol Yellow K 1420old: Irgalite Yellow WSRC.I. Pigment Yellow 62Monoazo saltMicrolith KPWeather 3000 h WR 1:100.21 0.18 1.80 0.40Bulk densityWeather 3000 h FS 0.1%-DensityLight WR 1:10-1/3 ISD in PVC (1% TiO2)Light FS S270PS280PO4-5WhitereductionPVCPaliotol Yellow K 0961old: Paliotol Yellow K 0961 HDC.I. Pigment Yellow 138*QuinophthaloneFullshadeMicrolen MCPVC-pHeat WR 1:10HDPEHeat FS 0.1%FibersAvailablepreparationsMigration FS 0.1%GeneralPhysicalpropertiesMicranyl QApplications performanceEupolen PEApplications1/3 ISD in HDPE (1% TiO2)Organic pigments* Products with this C.I. number may vary in color and resistance properties in different polymer systems.** At temperatures above 200 C diarylide pigments may decompose. Users are advised to follow the recommendations of ETAD information No. 2.7

WarpingMigration FS 0.1%Light FS 0.1%Light WR 1:10Hot light 600 kJ FS 0.1%Hot light 600 kJ WR 1:10Weather 5000 h FS 0.1%Weather 5000 h WR 1:1030028076-7--L57643-4--0.23 0.18 1.70 0.104.420020077---587-853-4--0.07 0.05 1.51 0.20Paliotol Yellow K 1760 FPold: Cromophtal Yellow HRPNC.I. Pigment Yellow 191: 1Monoazo salt530030076-73-4-N5874-53-4--0.35 0.31 1.43 0.21Paliotol Yellow K 1800old: Paliotol Yellow K 2270C.I. Pigment Yellow 183Monoazo salt530030076-73-4-L5874-53-4--0.43 0.34 1.80 0.405240240873-L4.5763-43-4--0.14 0.10 1.60 0.30Irgazin Yellow K 2060 FPold: Cromophtal Yellow 3RLPC.I. Pigment Yellow 0 0.30 1.80 0.23Irgazin Yellow K 2070old: Cromophtal Yellow 2RLTSC.I. Pigment Yellow 6 0.20 1.67 0.25Irgazin Yellow K 2080old: Cromophtal Yellow 2RLPC.I. Pigment Yellow 4 0.22 1.78 0.27Irgalite Yellow K 1740old: Irgalite Yellow B3RNC.I. Pigment Yellow 83**DiarylidePaliotol Yellow K 1841 / FPC.I. Pigment Yellow 139*IsoindolineMicrolith KPWeather 3000 h WR 1:105Paliotol Yellow K 1700C.I. Pigment Yellow 183Monoazo saltBulk densityWeather 3000 h FS 0.1%0.14 0.13 1.36 0.14DensityLight WR 1:10-1/3 ISD in PVC (1% TiO2)Light FS -7ABS7-8PS280PO280Cromophtal Yellow K 1500 FPold: Cromophtal Yellow GRPC.I. Pigment Yellow 95Disazo condensationWhitereductionPVC5FullshadeMicrolen MCPVC-pHeat WR 1:10HDPEHeat FS 0.1%FibersAvailablepreparationsMigration FS 0.1%GeneralPhysicalpropertiesMicranyl QApplications performanceEupolen PEApplications1/3 ISD in HDPE (1% TiO2)Organic pigments* Products with this C.I. number may vary in color and resistance properties in different polymer systems.** At temperatures above 200 C diarylide pigments may decompose. Users are advised to follow the recommendations of ETAD information No. 2.8

Migration FS 0.1%Light FS 0.1%Light WR 1:10Hot light 600 kJ FS 0.1%Hot light 600 kJ WR 1:10Weather 5000 h FS 0.1%Weather 5000 h WR 1:101/3 ISD in HDPE (1% TiO2)0.23 0.20 1.66 0.30Irgazin Orange K 2910old: Cromophtal DPP Orange TRPC.I. Pigment Orange 4--0.23 0.17 1.40 0.17528028054--L554----0.30 0.27 1.70 0.183-42002006-75---4.76-75-6----0.16 0.10 1.37 0.16Cromophtal Orange K 2960old: Cromophtal Orange GPC.I. Pigment Orange 21 0.21 1.59 0.39Irgazin Orange K 2990old: Irgazin DPP Orange RAC.I. Pigment Orange ---0.35 0.37 1.30 0.29Cromophtal Brown K 3001old: Cromophtal Brown 5RC.I. Pigment Brown 23Disazo condensation52602606-7753-4-4.987-8554-0.16 0.15 1.55 0.21Paliotol Orange K 2920C.I. Pigment Orange 79*Azo saltIrgalite Orange K 2925old: Irgalite Orange F2GC.I. Pigment Orange 34**DiarylideMicrolith KPWarping3-4Bulk densityWeather 3000 h WR 1:104DensityWeather 3000 h FS 0.1%51/3 ISD in PVC (1% TiO2)Light WR 00ABS300PS5WhitereductionPOIrgazin Orange K 2890old: Cromophtal Orange 2GC.I. Pigment Orange 61IsoindolinoneFullshadePVCLight FS 0.1%PVC-pHeat WR 1:10HDPEHeat FS 0.1%FibersAvailablepreparationsMigration FS 0.1%GeneralPhysicalpropertiesMicrolen MCApplications performanceMicranyl QApplicationsEupolen PEOrganic pigments(MP)* Products with this C.I. number may vary in color and resistance properties in different polymer systems.** At temperatures above 200 C diarylide pigments may decompose. Users are advised to follow the recommendations of ETAD information No. 2.9

WarpingMigration FS 0.1%Light FS 0.1%Light WR 1:10Hot light 600 kJ FS 0.1%Hot light 600 kJ WR 1:10Weather 5000 h FS 0.1%Weather 5000 h WR 1:102802808743H587-853-44-0.15 0.12 1.40 0.23524024042--H542----0.31 0.18 1.70 0.334.93003007-87-83-4-L4.97-8743-43-4-0.18 0.15 1.38 0.18Cromophtal Red K 3830old: Cromophtal Red GC.I. Pigment Red 220Disazo condensation53003007-87-83-N4.877----0.20 0.17 1.40 0.25Irgazin Red K 3840old: Cromophtal Red 2030C.I. Pigment Red 254Diketo-pyrrolo-pyrrole5300300884-H58855530.16 0.15 1.63 0.18Irgazin Red K 3840 LWold: Cromophtal Red 2028C.I. Pigment Red 53-40.16 0.15 1.63 0.18Irgazin Red K 3845old: Irgazin DPP Red BOC.I. Pigment Red 254Diketo-pyrrolo-pyrrole53003008853H5885553-40.23 0.23 1.62 0.33Irgazin Red K 3845 LWold: Cromophtal DPP Red BOCC.I. Pigment Red 254Diketo-pyrrolo-pyrrole53003008853LIrgalite Red K 3690old: Lithol Red K 3690C.I. Pigment Red 53:3*β-Naphthol (Sr)Irgazin Flame Red K 3800old: Cromophtal DPP Flame Red FPC.I. Pigment Red 272Diketo-pyrrolo-pyrroleNot suitable in PVC0.23-Microlith KPWeather 3000 h WR 1:105Paliogen Red K 3580C.I. Pigment Red 149PeryleneBulk densityWeather 3000 h FS 0.1%0.20 0.18 1.47 0.19DensityLight WR 1:10-1/3 ISD in PVC (1% TiO2)Light FS 0.1%3-4PA4-5PET5PP7PUR8Rubber5Cromophtal Scarlet K 3540old: Cromophtal Scarlet RNC.I. Pigment Red 166Disazo itereductionPVC5FullshadeMicrolen MCPVC-pHeat WR 1:10HDPEHeat FS 0.1%FibersAvailablepreparationsMigration FS 0.1%GeneralPhysicalpropertiesMicranyl QApplications performanceEupolen PEApplications1/3 ISD in HDPE (1% TiO2)Organic pigments1.62 0.33* Products with this C.I. number may vary in color and resistance properties in different polymer systems.10

WarpingMigration FS 0.1%Light FS 0.1%Light WR 1:10Hot light 600 kJ FS 0.1%Hot light 600 kJ WR 1:10Weather 5000 h FS 0.1%Weather 5000 h WR 1:10Cromophtal Red K 3900 FPold: Cromophtal Red BNFPPPC.I. Pigment Red 214Disazo condensation53003007-874-5-H587-8553-0.14 0.13 1.55 0.10Paliogen Red K 3911old: Paliogen Red K 3911 HDC.I. Pigment Red 178Perylene5300300873-4-H58754--0.26 0.18 1.60 0.22Cromophtal Red K 4035old: Cromophtal Red 2BC.I. Pigment Red 221Disazo condensation52602607-86-73--57-86-753--0.12 0.11 1.33 0.30Irgalite Red K 4060 FPold: Irgalite Red 2BSPC.I. Pigment Red 48:3*BONA (Sr)524026064--L565-6----0.17 0.14 1.82 0.22Irgazin Rubine K 4080 / K 4085old: Cromophtal Rubine TR /Irgazin DPP Rubine TRC.I. - / Pigment Red -44-5-0.11 0.09 1.40 0.26Paliogen Red K 4090old: Cromophtal Red A3BC.I. Pigment Red 177Anthraquinone52602607-87-83-N587-854--0.19 0.15 1.43 0.3453003008854H5885554-50.17 0.13 1.50 0.36Paliogen Red K 4180C.I. Pigment Red 179PeryleneMicrolith KPWeather 3000 h WR 1:100.14 0.12 1.52 0.14Bulk densityWeather 3000 h FS 0.1%-DensityLight WR 1:103-41/3 ISD in PVC (1% TiO2)Light FS S300PS300PO5WhitereductionPVCCromophtal Red K 3890 FPold: Cromophtal Red BRNPC.I. Pigment Red 144Disazo condensationFullshadeMicrolen MCPVC-pHeat WR 1:10HDPEHeat FS 0.1%FibersAvailablepreparationsMigration FS 0.1%GeneralPhysicalpropertiesMicranyl QApplications performanceEupolen PEApplications1/3 ISD in HDPE (1% TiO2)Organic pigments* Products with this C.I. number may vary in color and resistance properties in different polymer systems.11

Migration FS 0.1%Light FS 0.1%Light WR 1:10Hot light 600 kJ FS 0.1%Hot light 600 kJ WR 1:10Weather 5000 h FS 0.1%Weather 5000 h WR 1:101/3 ISD in HDPE (1% TiO2)0.37 0.33 1.51 0.21Cinquasia Red K 4111old: Cromophtal Red TBRC.I. Pigment Violet 19Quinacridone4.8260260884-53L587-84-54-54-0.29 0.29 1.50 0.24Irgalite Red K 4170 FPold: Irgalite Red 2BPC.I. Pigment Red 48:2*BONA (Ca)522024076--L576----0.13 0.12 1.57 0.18Irgalite Rubine K 4270 FPold: Irgalite Rubine 4BPC.I. Pigment Red 57:1*BONA (Ca)52402606-74-5--L564----0.15 0.10 1.50 0.17Irgalite Rubine K 4275 FPold: Irgalite Rubine 4BFPC.I. Pigment Red 57:1*BONA (Ca)52202406-74--L56-76----0.15 0.10 1.57 0.22Cinquasia Red K 4330old: Cinquasia Red B RT-195-DQuinacridone5290300884-L58854-54-540.30 0.29 1.59 0.20Microlith KPWarping3-4Bulk densityWeather 3000 h WR 1:104-5DensityWeather 3000 h FS 0.1%51/3 ISD in PVC (1% TiO2)Light WR S300PS5WhitereductionPOCinquasia Red K 4104old: Cromophtal Red 2020C.I. Pigment Violet 19QuinacridoneFullshadePVCLight FS 0.1%PVC-pHeat WR 1:10HDPEHeat FS 0.1%FibersAvailablepreparationsMigration FS 0.1%GeneralPhysicalpropertiesMicrolen MCApplications performanceMicranyl QApplicationsEupolen PEOrganic pigments* Products with this C.I. number may vary in color and resistance properties in different polymer systems.12

Migration FS 0.1%Light FS 0.1%Light WR 1:10Hot light 600 kJ FS 0.1%Hot light 600 kJ WR 1:10Weather 5000 h FS 0.1%Weather 5000 h WR 1:101/3 ISD in HDPE (1% TiO2)0.20 0.20 1.50 0.10Cinquasia Pink K 4430 FPold: Cromophtal Pink PTC.I. Pigment Red 122Quinacridone5300300884-53-4L587-8554-54-50.20 0.19 1.49 0.15Cinquasia Magenta K 4535 FPold: Cromophtal Magenta PC.I. Pigment Red 202Quinacridone53003008843L587-854-54-540.23 0.20 1.67 0.14Cinquasia Violet K 5350 FPold: Cromophtal Violet RPC.I. Pigment Violet 19Quinacridone530030087-84-L57-874-54430.23 0.15 1.49 0.17Paliogen Red Violet K 5411old: Paliogen Red Violet K 5011C.I. Pigment Violet 29Perylene53003008843H5885553-40.18 0.06 1.60 0.23Cromophtal Violet K 5700old: Cromophtal Violet BC.I. Pigment Violet 37Dioxazine4.928026087-84-53L57-86-74-5-3-4-0.09 0.07 1.32 0.38Cromophtal Violet K 5800old: Cromophtal Violet GTC.I. Pigment Violet 23Dioxazine3-42402607-83-443-4L4.386-74-534-5-0.07 0.06 1.42 0.35Microlith KPWarping4-5Bulk densityWeather 3000 h WR 1:104-5DensityWeather 3000 h FS 0.1%51/3 ISD in PVC (1% TiO2)Light WR S300PS5WhitereductionPOCinquasia Pink K 4410old: Cromophtal Pink 2000C.I. Pigment Red 122QuinacridoneFullshadePVCLight FS 0.1%PVC-pHeat WR 1:10HDPEHeat FS 0.1%FibersAvailablepreparationsMigration FS 0.1%GeneralPhysicalpropertiesMicrolen MCApplications performanceMicranyl QApplicationsEupolen PEOrganic pigments13

Weather 5000 h WR 1:101/3 ISD in HDPE (1% TiO2)8855H58853-43-43-40.09 0.08 1.62 0.2153003008855H58854-54-540.11 0.09 1.60 0.3253003008855H5884-54-5540.10 0.08 1.60 0.3253003008855H5884-54-5540.09 0.07 1.60 0.3352602807-87-84-54-5H4.586-753-4540.09 0.08 1.60 0.2052802808855H5884-554-54-50.12 0.09 1.60 0.2053003008855H57-87-84-54-54-53-40.11 0.09 1.60 0.3253003008855L5884-5443-40.11 0.09 1.60 0.2053003008855H5885554-50.24 0.19 2.10 0.3053003008855H5885554-50.30 0.26 2.10 0.40Microlith KPWeather 5000 h FS 0.1%220Microlen MCHot light 600 kJ WR 1:10220Bulk densityHot light 600 kJ FS 0.1%5DensityLight WR 1:10PAPETPPPURRubberPMMAPCPETPA6ABSPSLight FS 0.1%Heliogen Green K 9360C.I. Pigment Green 36Cu-phthalocyanineMigration FS 0.1%Heliogen Green K 8730 / FPC.I. Pigment Green 7Cu-phthalocyanineWarpingHeliogen Blue K 7104 LWC.I. Pigment Blue 15:4Cu-phthalocyanineWeather 3000 h WR 1:10Heliogen Blue K 7096old: Irgalite Blue GBPC.I. Pigment Blue 15:3Cu-phthalocyanineWeather 3000 h FS 0.1%Heliogen Blue K 7090 / FPC.I. Pigment Blue 15:3Cu-phthalocyanineLight WR 1:10Heliogen Blue K 6916C.I. Pigment Blue 15:1Cu-phthalocyanineLight FS 0.1%Heliogen Blue K 6911 / K 6912 FPold: Heliogen Blue K 6911 D / FPC.I. Pigment Blue 15:1Cu-phthalocyaninePVC-pHeat WR 1:10Heliogen Blue K 6907C.I. Pigment Blue 15:1Cu-phthalocyanineHDPEHeat FS 0.1%Heliogen Blue K 6902C.I. Pigment Blue gration FS 0.1%Heliogen Blue K 6850 / K 6860C.I. Pigment Blue eralPhysicalpropertiesMicranyl QApplications performanceEupolen PEApplications1/3 ISD in PVC (1% TiO2)Organic pigments14

Applications performanceWeather 3000 h FS 1%Weather 3000 h WR 1:4WarpingMigration FS 1%Light FS 1%Light WR 1:4Hot light 600 kJ FS 1%Hot light 600 kJ WR 1:4Weather 5000 h FS 1%Weather 5000 h WR 1:41/3 ISD in PVC (1% TiO2)555(1/9Sicotan Yellow K 1011C.I. Pigment Yellow 53Ni/Sb/Ti oxide5Sicotan Yellow K 2001C.I. Pigment Brown 24Cr/Sb/Ti oxideSicotan Yellow K 2011C.I. Pigment Brown 24Cr/Sb/Ti oxideSicotan Yellow K 2111C.I. Pigment Brown 24Cr/Sb/Ti oxideSicotan Yellow K 2112C.I. Pigment Brown 24Cr/Sb/Ti oxideSicotan Brown K 2611C.I. Pigment Yellow 164Mn/Sb/Ti oxideSicotan Brown K 2711C.I. Pigment Yellow 164Mn/Sb/Ti oxideFG form availableLight WR S5WhitereductionPOSicotan Yellow K 1010C.I. Pigment Yellow 53Ni/Sb/Ti oxideFullshadePVCLight FS 1%PVC-pHeat WR 1:4HDPEHeat FS 1%FibersMigration FS 1%GeneralPhysicalpropertiesBulk densityApplicationsDensityInorganic pigmentsSicotan 3.34.50 0.90ISD)3.13003008855N5885555(1/94.40 0.80ISD)53003008855N58855552.74.50 0.6053003008855N58855553.84.50 0.7053003008855N58855553.04.40 0.8053003008855N58855553.44.40 0.9053003008855N58855553.24.30 0.9053003008855N58855552.54.80 0.9015

ApplicationsApplications performanceWeather 3000 h FS 1%Weather 3000 h WR 1:4WarpingMigration FS 1%Light FS 1%Light WR 1:4Hot light 600 kJ FS 1%Hot light 600 kJ WR 1:4Weather 5000 h FS 1%Weather 5000 h WR 1:41/3 ISD in PVC (1% TiO2)Density---1.04.10 0.80Sicopal Yellow K 1160 FGC.I. Pigment Yellow 184Bismuth vanadate52802608855N588----1.64.10 0.8053003008855N58855552.24.80 0.7553003008855N588----1.65.30 0.7053003008855N588----0.55.20 0.5053003008855N58855553.44.00 0.5053003008855N58855553.14.50 0.4053003008855N58855552.64.50 0.50Sicopal Orange K 2430C.I. Pigment Orange 82Sn/Zn/Ti oxideSicopal Brown K 2595C.I. Pigment Yellow 119Zn/Fe oxideSicopal Brown K 2795 FGC.I. Pigment Brown 29Fe/Cr oxideSicopal Blue K 6210C.I. Pigment Blue 28Co/Al oxideSicopal Blue K 6310C.I. Pigment Blue 28Co/Al oxideSicopal Blue K 7210C.I. Pigment Blue 36Co/Al/Cr oxideBulk densityLight WR S5WhitereductionPOSicopal Yellow K 1120 FGC.I. Pigment Yellow 184Bismuth vanadateFullshadePVCLight FS 1%PVC-pHeat WR 1:4HDPEHeat FS 1%FibersMigration FS 1%GeneralPhysicalpropertiesFG form availableInorganic pigmentsSicopal 16

Applications performanceWeather 3000 h FS 1%Weather 3000 h WR 1:4WarpingMigration FS 1%Light FS 1%Light WR 1:4Hot light 600 kJ FS 1%Hot light 600 kJ WR 1:4Weather 5000 h FS 1%Weather 5000 h WR 1:41/3 ISD in PVC (1% TiO2)Density5552.94.90 0.90Sicopal Green K 9710C.I. Pigment Green 50Co/Ti/Ni/Zn oxide53003008855N58855552.94.80 0.7053003008855N58855551.54.90 1.0053003008855N58855551.45.20 0.70Sicopal Black K 0095C.I. Pigment Brown 29Fe/Cr oxideInorganic pigmentsSicotrans ApplicationsApplications performanceWeather 3000 h WR 1:4WarpingMigration FS 1%Light FS 1%Light WR 1:4Hot light 600 kJ FS 1%Hot light 600 kJ WR 1:4Weather 5000 h FS 1%Weather 5000 h WR 1:4--0.58 4.40 0.30Sicotrans Red K 2915C.I. Pigment Red 101Iron oxide53003008855N588----0.27 5.10 0.50Bulk densityWeather 3000 h FS 1%-DensityLight WR S5WhitereductionPOSicotrans Red K 2819C.I. Pigment Red 101Iron oxideFullshadePVCLight FS 1%PVC-pHeat WR 1:4HDPEHeat FS 1%FibersMigration FS 1%GeneralPhysicalproperties1/3 ISD in PVC (1% TiO2)Sicopal Black K 0090C.I. Pigment Black 27Co/Cr/Fe/Mn oxideBulk densityLight WR S5WhitereductionPOSicopal Green K 9610C.I. Pigment Green 50Co/Ti/Ni/Zn oxideFullshadePVCLight FS 1%PVC-pHeat WR 1:4HDPEHeat FS 1%FibersMigration FS 1%GeneralPhysicalpropertiesFG form availableApplicationsFG form availableInorganic pigmentsSicopal 17

Organic and inorganic pigmentsfor plasticsAsiaNorth AmericaNoteBASF East AsiaRegional Headquarters LimitedPerformance Chemicals45th Floor, Jardine HouseNo. 1 Connaught PlaceHong KongBASF CorporationPlastic Additives100 Campus DriveFlorham Park, NJ 07932USAThe descriptions, designs, data and information contained herein are presented in good faith,Phone: 852 2731-0111Fax: 852 2731-5633Phone: 1 973 245-6000Fax: 1 973 895-8002and are based on BASF’s current knowledge and experience. They are provided for guidanceonly, and do not constitute the agreed contractual quality of the product or a part of BASF’sterms and conditions of sale. Because many factors may affect processing or application/useof the product, BASF recommends that the reader carry out its own investigations and teststo determine the suitability of a product for its particular purpose prior to use. It is the responsibility of the recipient of product to ensure that any proprietary rights and existing laws andlegislation are observed. No warranties of any kind, either expressed or implied, including, butnot limited to, warranties of merchantability or fitness for a particular purpose, are maderegarding products described or designs, data or information set forth herein, or that theSouth AmericaBASF Schweiz AGPlastic AdditivesKlybeckstr. 1414057 BaselSwitzerlandBASF S. A.Sede AdministrativaAv. das Nações Unidas,14.171, Morumbi04794-000 São Paulo, SPBrasilPhone: 41 61 636-1111Fax: 41 61 636-1212Phone: 55 11 2039-2273products, descriptions, designs, data or information may be used without infringing the intellectual property rights of others. Any descriptions, designs, data and information given in thispublication may change without prior information. The descriptions, designs, data and information furnished by BASF hereunder are given gratis and BASF assumes no obligation orliability for the descriptions, designs, data or information given or results obtained, all suchbeing given and accepted at the reader’s risk. registered trademark of BASF plastic-additives@basf.com

Color shades For ease of use the shade card is provided as a downloadable PDF. Please note, that due to differences in computer screen color calibration the PDF shade card can only help you to roughly estimate the shade, but the colors cannot be binding. All organic pigment shades shown here are based on a full shade concentration