Transcription

ENGPRODUCTION FOR NDTTRAINING COURSES FOR TECHNICAL PERSONNELQUALIFICATION AND CERTIFICATIONOUTSIDE AGENCY / LEVEL III SERVICESNDT INSPECTIONSTECHNICAL / INDEPENDENT INSPECTIONSINFORTUTMTPTVTETLTIRT

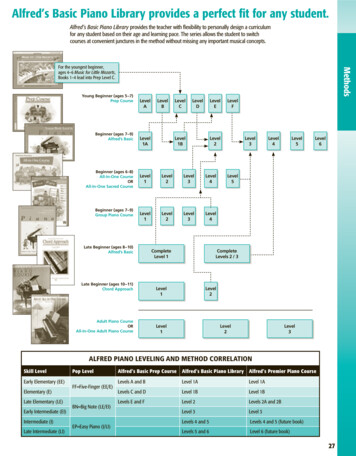

CONTENTWHO ARE WE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1SERVICES FOR NDT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2QUALIFICATION AND CERTIFICATION OF THE TECHNICAL PERSONNEL IN NDT . 2IN WELDING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2IN CORROSION AND PLANT INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2IN THIRD PARTY INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2OUTSIDE AGENCY SERVICES/SERVICES of ndt LEVEL 3 . . . . . . . . . . . . . . . . . . . . . 2INSPECTIONS SERVICES: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3OUR EMPLOYEES: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3PRODUCTS FOR NDT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4SHOP INSPECTION SERVICES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7SITE INSPECTION SERVICES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8OUR APPROVALS AND QUALIFICATION STATUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9TRAINING AND QUALIFICATION SERVICES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10CERTIFICATION SERVICES - ATG CERT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11TRAININGAPI 510 GENERAL COURSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13API 570 GENERAL COURSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14API 653 GENERAL COURSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15ASME SECTION VIII COURSE / REFRESH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16ASME SECTION IX COURSE / REFRESH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17ASME B31.3 - PROCESS PIPING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18IWIP - INTERNATIONAL WELDING INSPECTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19NDT TRAININGBASIC & METHODS’ COURSES / LEVEL 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21MT - MAGNETIC PARTICLE TESTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22PT - PENETRANT TESTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23RT - RADIOGRAPHIC TESTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24RT - DIGITAL INDUSTRIAL RADIOGRAPHY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25RT-FI RADIOGRAPHIC INTERPRETER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26UT - ULTRASONIC TESTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27UT - ULTRASONIC PHASED ARRAY TESTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29UT - TIME OF FLIGHT DIFFRACTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30VT - VISUAL TESTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31VT - VISUAL TESTING OF WELDS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32ET - EDDY CURRENT TESTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33LT - LEAK TESTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34IRT - THEROMOGRAPHIC TESTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35INSPECTORSPLANT INSPECTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36ELECTRICAL & INSTRUMENTATION EQUIPMENT INSPECTOR. . . . . . . . . . . . . . . . 37SHOP/SITE THIRD PARTY INSPECTOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38NON DESTRUCTIVE TESTING EVALUATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39NON DESTRUCTIVE TESTING INSPECTOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

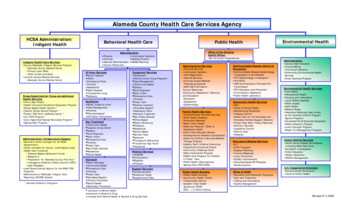

ATGWHO ARE WEATG - Advanced Technology Group is a companyspecialized in NDT - nondestructive testing, providingwide range of services in every standard method ofNDT testing: PT, MT, UT, ET, RT, VT, LT, and IRT,technical inspections and supervising as well.ATG offers:NDT training and certification of NDT operators inLevel I, II, III and Welding inspectors, Corrosioninspectors, Plant inspectors, and Third partyinspectorsDevelopment and production of devices and equipment for NDT testing and weldinginspectionsOutside Agency services - outsourcing of NDT systems of your companyNDT and welding inspections for all industriesInspection activities in the industry - independent assessment of conformity, safety, and quality(ASME Code, PED inspections, shop / site inspections)Our inspectors are reputable professionals with longtime experience from hundreds of projects allaround the World. ATG Ltd. has been approved by API - American Petroleum Institute - as theCertified Training Provider. Therefore at present, we are the only one company in Central Europeable to provide RT, PT, IWI, and Inspector trainings with the final certification by API.We are looking forward to have a good cooperation with you!Yours faithfully,Ing. Zbynek ZavadilPresidentATG - Advanced Technology Groupwww.atgtesting.comwww.atg.cz1

SERVICES FOR NDTQUALIFICATION AND CERTIFICATION OF THE TECHNICAL PERSONNEL IN NDTacc. to EN 473/ISO9712acc. to ASNT Recommendation SNT-TC-1Aacc. to NAS 410/EN 4179 for Aerospaceacc. to ISO 11484/EN 10256 for Tube and Steel productsacc. to UIC Code 960 for railwaysIN WELDINGwelding inspectors (based on IIW IAB procedures)responsible and coordination persons for weldingprocesses weldersIN CORROSION AND PLANT INSPECTIONinspectors for API 510, API 570, API 653, ASME (VI)inspectors acc. to the EN 13387workshop inspectorsplant inspectorsIN THIRD PARTY INSPECTIONshop/site inspectorsexpediting inspectorsOUTSIDE AGENCY SERVICES/SERVICES OF NDT LEVEL 3ATG offers complex and also partial solution for yours NDT systems acc. to the SNT-TC-1A / Level IIIand EN4179/NAS410 services like as follows:creation of company qualification, certification systems, legislative .creation of company NDT system documents documentation (Written Procedures,Written Practice, .)training of NDT personnel for Level I, II, IIItesting procedures processingsupport with the turn over to another qualification systeminstructions for concrete applications support with choosing of NDT methods and testingdevicescreation of company qualification, certification systems, legislative .confirmation of methodologiesoutputs from tests, protocolling of resultstraining and the exam in our classrooms and laboratories, or even at your site2

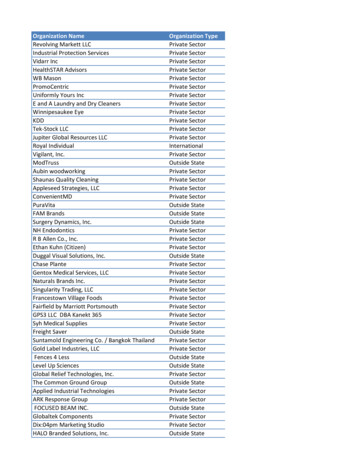

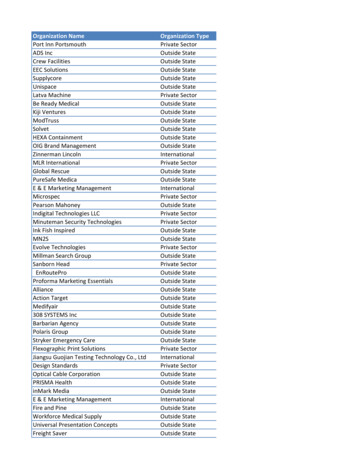

SERVICEScooperation with defining standards of feasibilityconsultancy and NDT Level III technical supportaudits and inspections, process supervisionsupport during customer or independent audits (e.g. EASA or NADCAP for example)support for the gain of experience practice for newly implemented NDT methodsINSPECTIONS SERVICESASME Code inspections, PED inspectionsshop / site inspections - worldwidenondestructive testing using VT, PT, MT, ET, RT, UT, LT, AT, VA, LA, IRT NDT methods,structuroscopyconductivity measurements, coating thickness measurements and thickness measurementsexamination of composite materials and bonded jointsRLA – residual life assessmentCE markingcorrosion inspections and consultancy (corrosion inspections)assessment according to the codes: EN, ASME, API, AWSOUR EMPLOYEESare reputable professionals with longtime experience have experience from hundreds ofprojects worldwidemany of our employees are qualified in NDT Level III, IWI, and EWE/EWI,they are also PED inspectors (certified by HSB International)some inspectors are approved by SAUDI ARAMCO, ENEL/RINA, JGC, ADCO, ALSTOM,SIEMENS, FMC .3

PRODUCTS FOR NDTWe develop and produce the devices and equipment for NDT testing - tailored to your needs!If you need completely new NDT equipment, only partly renovate your lab instruments, orcompletely new design of NDT facility; we will be pleased to prepare a complete proposal, which willinclude all equipment and tools needed for your NDT application. We supply all equipment fromsimple portable instruments up to fully automatic inspection lines with robotic manipulation systems.Equipment calibrations are obviousal. We are supplying NDT material and equipment for eachbasic NDT method (VT, PT, MT, ET, RT, UT).WE DELIVER FOLLOWING EQUIPMENT:PTFPI/Penetrant lines – manual or automatedequipment for electrostatic application of penetrant and developerUV lamps - manual or stationarywater treatment systems for input and output watersurface treatment systems/lines for etching or degreasing processfiltration units with active carbonMTmanual electromagnetic yokesMT portable generatorsMT benches, stationary magnetic flow detectorsdemagnetization unitsautomated and combined MT and UT systemsUTUT systems - automated or portableUT tanksUT linescombined lines UT/ETRTshielding cabins, X-ray bunkersradioscopic systemsETET probes - rotary, special, absolute, differential, multidifferentialET systemsVTtesting equipment/systems, automated testing lines with equipment for calibrationand confirmationNDT accessories as: probes, calibration gauges, etalon sets, calibration parts, test blocks, .Measurement equipment for process confirmationVT equipment - endoscopes, sets of testing gauges for welds, SCRATA replicassets for welding inspectors / inspector kits4

PRODUCTSATG - PRODUCTS FOR NDTUT automated tanksMT yokesMT benchesPT/FPI linesVT inspection kitMT generators for AC/DC5

MT UNIMAG 14000 AC/ACMT UNIMAG 13000 for shafts testing up to 25tMT UNIMAG 1200 Aerotester (quick break)6MT UNIMAG 400 with touch screenDEMAT 300 demagnetization unitMT automated benches for bearings

INSPECTION SERVICESSHOP INSPECTION SERVICESThese services are provided with assistance of collaborating officesworldwide in order to optimize travel expenses. This type ofcooperation allows high flexibility.Supplier selectionDue to our worldwide network of subsidiaries and offices of ourpartners, we are able to find and suggest potential suppliers of rawmaterials and/or finished products for your projects.Suppliers classificationATG performs the qualification audits for new and potential suppliers.We are able to determine whether the supplier has a functionalsystem of quality, qualified personnel, resources and productioncapacities, financial resources, etc.Technical assistanceATG provides proposals including modification of ITP (Inspection Test Plan) or inspectionprocedure. ATG aproves documentation requirements for any equipment, such as Passport ofpressure vessels or MDR (Manufacturer Data Record).Inspection during manufactureThis inspection is based on ITP (Inspection Test Plan) and is a control of production, monitoring ofcompliance with technological procedures, standards, and customer specifications. In the case ofgross deficiencies and exhibited nonconformities the Punch List is created. Then both forms areintegrated as a part of the Inspection Report.Expediting servicesOur expediting services include coordination of expediting with all suppliers, monitoring thedispatch of material, expediting visits, field and desk expediting, recommendations for necessarymeasures, reporting, situation assessment for your overall project, supplier performancemonitoring.7

SITE INSPECTION SERVICESSite Inspection includes visual review of completed site welded connections, review of connectionsduring erection, NDT inspection, monitoring of installation procedures, witness the applications,conformance reviews of structural steel members etc.Inspection of shipmentsPerforms checks completeness and damage after delivery to the construction site. Control ofcompleteness, damage, corrosion, paint damage, etc. The photo documentation, reports and NCR(Non-Conformity Report) are included in the final result.Inspection during constructionWe can establish a complete QC (Quality Control) team that will monitor all processes on site:QC Site Manager: Responsible for full compliance with the quality, coordination,inpection, solving technical problems and disagreements, communication withcustomers and suppliers.Civil Inspector: Responsible for supervision and process control.Supervision of excavation, shoring, concrete, masonry, insulation, finishes, etc.Mechanical Inspector: Responsible for installation of steel structures, pressureequipment, boilers, pumps, compressors, etc.Welding Inspector: Responsible with the assessment of WPS, PQR, welders,welding supervision, preheating, solution non-conformities, etc.NDT Inspector Level II: Supervision of the implementation and performing of differentNDT testing methods, calibration, etc.NDT Inspector Level III: Responsible for the approval of NDT procedures for testsevaluations, and solution of NCRsElectrical / Instrumentation Inspector: Responsible for the installation of electricalequipment, including conductors, cables, in-process testing, protection, etc.8

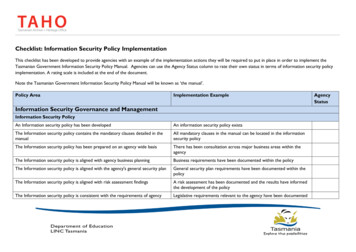

APPROVALS AND CERTIFICATESOUR APPROVALS AND QUALIFICATION STATUSADCO - Abu Dhabi Company for Onshore Oil OperationsAPI - American Petroleum Institute (Certified Training Provider)Czech Gas Association for training in VT – weldsCzech NANDTB (National Aerospace NDT board)Czech Welding Society ANB training center for IIW (International Institute of Welding)European Agency for Safety Aviation (EASA Part 145 approval D1) - license to servicesFMC Technologies - petroleum exploration, production, transportationHartford Steam Boiler International Inc.Honeywell for MT and PT testing in Level III/SCAIraqi Civil Aviation Authority for NDT trainings NAS410/EN 4179 (all methods in level I, II)Ministry of Electricity of Iraq (MoE) / of Oil (MoO) / of Industry and Minerals of Iraq (MoI)Ministry of Education of the Czech Republic for NDT Level II trainingsReaktortest Ltd. - accredited certification body, notified RTPO acc. to 97/23/ERSector Cert GmBH - accredited certification body, notified RTPO acc. to 97/23/ERTÜV Nord - accredited certification body, notified RTPO acc. to 97/23/ERYou can find all our approvals and certificates you can find at: www.atg.cz.ATG STATUS IN INDEPENDENT CERTIFICATION SERVICESATG statusScope of trainingApproved l Welding InspectorsAuthorizedTraining BodyQualification of corrosion inspectorsAuthorizedTraining BodyRailways NDT operators qualification– maintenance according to theEN 473, UIC code 960NDT personnel - according toEN 4179 and NAS 410EN 10256 and ISO 11484 for tubeproduction NDT personnelCWS ANB (Czech Welding Society- AuthorizedNational Body by IAB, EWF and EOTC)SECTOR Cert, TÜV Cert and Reaktortest(all notified as Rec. Third. Party Org. for PED Pressure Pressure Equipment Directive97/23/EC); Recognized Third PartyOrganizationAPC - Association for Personnel CertificationReaktortest (EN and ISO codes for training,qualification and certification)ŽSR VVUZ Žilina- Railways of the SlovakRepublicOutsideAgencyOutsideAgencyLevel IIINDT personnel acc. toEN 473National Aerospace NDT BoardAccredited qualification ( certification bodyReaktortest certification body is accredited forISO 11484)ATG STATUS IN EMPLOYER BASED CERTIFICATION SERVICES:ATG statusOutside AgencyScope of trainingASNT Recommendation SNT-TC1A, oriented for production,inspection and supervision ofcompanies, ASNT CP-189Use byASME and API applications9

TRAINING AND QUALIFICATION SERVICESAll our courses fulfill all requirements of the most used qualification standards as ASNT SNT-TC-1A,ISO 9712, EN 473 etc. Our courses are designed to hand on the maximum of our professionalexperience. Our trainees will get practical skills in our testing rooms and required theoryunderstanding in our lecture rooms as well. Our lecturers are highly educated experts, with long-timeexperience on sites, prepared for practical discussions and your support during the training. Allcourses fulfill requirements of ISO TR 25107 (NDT Guidelines for NDT training syllabuses).Our QUALIFICATION and TRAINING services are particularly aimed at the following processes1. NDT (Non Destructive Testing)2. Welding inspection3. Plant Inspection including painting and Corrosion Inspection4. Third Party InspectionAll qualifications are used especially forOperators in above-mentioned processes (NDT, Welding, Plant, TPI inspection)Designers and techniciansInspectors and operators of release departmentWelding operators, supervisors and inspectorsMiddle and operating managementtraining for operators or middle and top managementWe can provide various courses for every standard NDT method, each suited to your particularrequirements. The type of course depends on how much experience you have, whether you havereceived training previously or currently hold a certificate, and also what type of certification you wantto obtain. Shortly, we are able to use your previous qualification.Other coursesL AL u b r i c a t i o nA n a l y s i saccording to ISO 18436 and EN4179/NAS410I R T I n f r a r e d T h e r m o g r a p h yaccording to ISO 18436 and EN4179/NAS410VA Vibration Analysis – in preparationaccording to ISO 18436 and EN4179/NAS410AE Acoustic Emission – in preparationReT Replica Testing and MetallographyRadiation safety – Health and safety management forRadiographic testing and using X-raysCERT10Our courses are based on practical exercises and testingDuring the training you will have all our professional equipmentat your disposal. You can use the FPI lines, MT benches, UTmanipulators, handy digital or analogue ET and UT devices,

TRAINING AND CERTIFICATION SERVICEShandy magnetizers, X-Ray cabinet, VT gauges and inspection sets, hundreds of samples withdiscontinuities etc. - depending on your training course.Behind the qualification training ATG offersRefreshing programs for all systems of personnel recertificationTechnical qualification of the company staff - it means supervision, refreshing, testing, technicaltraining for operators or middle and top managementAll training courses and exams are managed according to the scheduleor can be realized on demand, according to the individual offer.Please contact ATG training or examining center for more details.ATG has full right to change term of any training course and exams in case of necessity.ATG CERTCERTIFICATION SERVICESWe provide the final certification process to all our training courses. The certificate can be issuedaccording to required qualification system in the specified system, method, sector, level, and code.You can choose the accredited, non-accredited, or employer-based certificates. Most of allcertificates are valid for 5 years, the renewing is possible for the next 5 years after the applying. Therecertification exam follows after this period.ProcessNDTWELDINGNDTPLANT AND CORROSIONINSPECTIONNDTWELDINGAPI Q1 INTERNAL AUDITORNDT for AerospaceNDTWELDINGPLANT AND CORROSIONINSPECTIONQualification andcertification standardISO 9712/EN 473UIC 960 codeISO 14731, IIW IAB-04112001 /EWF-450-02EN 473, ISO 11484,ISO 18436SNT-TC-1A, EN 4179/NAS 410, EN10256, ISO 11484ISO 14731API Q1 codeEN 4179/ NAS 410EN 473, SNT-TC-1A, ISO 11484,ISO 14731ISO 18436Certification BodyREAKTORTESTSECTOR CertTÜV NordAPC (Association for PersonnelCertification)NIKIMT (in preparation, for Russia)Slovak railwaysCWS ANBATG - RTATGATGATGATGATG approved by Czech NANDTBAPI TPCPAPI TPCP (in preparation)API TPCP (in preparation)11

ATG CERTCERTIFICATION BODYATG CERT is an independent certification body which providespersonnel qualification and certification of special processes for:NDT (all methods in Level I, II, III)Welding (IWIP, ASME CODE SECTION IX)Inspection of machinery / Plant Inspector: API 510, API 570,API 653, Corrosion InspectorIndependent inspection – specialized for the concreteneeds of specific industry (Aerospace, Engineering, Power plants )How to obtain the certificationBasic rules for ATG CERT certification, there is necessary to meet the requirements of thecertification and make a request. All ATG CERT certification systems are based on the requirementof meeting 5 basic attributes:educationdocumented qualifications with a defined minimum length and contentdocumented experience in the processpass the exam with a defined contentphysical abilityATG CERT provides the personnel certification with these certification bodies:ATG CERT (Czech Republic)API (USA)HSB (USA)CWS ANB (Czech Republic)GAS (Czech Republic)TÜV Nord Czech (Czech Republic)TÜV Nord International (Germany)Reaktortest (Slovak Republic)SECTOR Cert (Germany)APC (Czech Republic)ATG CERT Certification systems are structured in this way:Process System Method Qualifying level Sector.All qualifying systems ATG CERT are workingwith three qualification levels, level 1 is the lowest(with the smallest powers and responsibilities)and level 3 is the highest the process managerin the company).For obtaining the qualification in level 3 the „Basic exam” is necessary to pass.PED - Pressure Equipment Directivequalification is possible to obtain after passingthe specific exam.12

TRAININGAPI 510GENERAL COURSECode: API 510The inspection code API 510 covers the maintenance inspection, repair, alteration, and reratingprocedures for pressure vessels in petroleum or chemical process industries.Based on:recommended practice SNT-TC-1A.Used codes: API 510, RP 572, RP 573, RP 574, RP 576, RP 579, ASME Section V, VIII, andSection IX, NACE RP 0472, MR 0175What you will learnThe participants will be familiar with the inspection practices and types of inspection; learn how toevaluate repairs, alterations, and rerating of pressure vessels. They gain insights what testingmethods are required. Emphasis will be placed on corrosion and minimum thickness evaluation,estimated remaining life and inspection interval determination. Requirements for NDE inspectionand testing will be provided.Upon completion of this course, participants will have an overview of: pressure vessel maintenance,including inspection, evaluation of various defects, and repair/alteration rules of various Codes andStandards. They will be able to extend the expertise in defect assessment and equipment integrityanalysis.Level 2 training highlightsTypes and definition of maintenance inspectionCorrosion and minimum thickness evaluationEstimated remaining life and corrosion rateRisk based analysis and fitness for serviceTestingRepair methodsInspection record and reportsHealth, Safety and EnvironmentAbout CertificationThe examination and certification process is directly related to qualification system. In case whenthe training is performed in accordance with EN473 / ISO 9712 the certificate can be issued byindependent European certification body ATG CERT.Additional details about training and certification are related to specific needs of client and shall bediscussed individually. Please refer section "contacts" or our website www.atgtesting.com.API Training provider certificationThe training and examination are provided under qualification systemapproved by API - American Petroleum Institute. You can obtain finalcertificate with API logo !13

API 570GENERAL COURSECode: API 570The inspection code API 570 covers the maintenance inspection, repair, alteration, and reratingprocedures for piping systems that have been in-service in petroleum or chemical processindustries. However it may be extended for any piping systems.Based on:recommended practice SNT-TC-1A.Used codes: API 570, RP 574, RP 578, RP 579, 570, ASME Section VIII, and IX and B 31.3,NACE RP 0169, RP 0170, RP 0274, RP 0275What you will learnThe participants will be familiar with the inspection practices and types of inspection; learn how toevaluate repairs, alterations, and rerating of piping systems. They gain insights what testingmethods are required. Emphasis will be placed on corrosion and minimum thickness evaluation,estimated remaining life and inspection interval determination. Requirements for NDE inspectionand testing will be provided.Upon completion of this course, participants will have an overview of: piping system maintenance,including inspection, evaluation of various defects, and repair/alteration rules of various Codes andStandards. They will be able to extend the expertise in defect assessment, and equipment integrityanalysis.Level 2 training highlightsTypes and definition of maintenance inspectionTypes and definition of maintenance inspectionCorrosion and minimum thickness evaluationEstimated remaining life and corrosion rateRisk based analysis and fitness for serviceTesting and assessment of inspectionfindingRepair methodsInspection record and reportsHealth, Safety and EnvironmentAbout CertificationThe examination and certification process is directly related to qualification system. In case whenthe training is performed in accordance with EN473 / ISO 9712 the certificate can be issued byindependent European certification body ATG CERT. Additional details about training andcertification are related to specific needs of client and shall be discussed individually. Please refersection "contacts" or our website www.atgtesting.com.API Training provider certificationThe training and examination are provided under qualification systemapproved by API - American Petroleum Institute. You can obtain finalcertificate with API logo !14

TRAININGAPI 653GENERAL COURSECode: API 653The inspection code API 653 covers the maintenance inspection, repair, alteration, relocation, andreconstruction for steel storage tanks that have been in-service in petroleum or chemical processindustries. API 653 employs the principles of construction code API Standard 650, specifically manyof design, welding, examination, and material requirements.Based on:recommended practice SNT-TC-1A.Used codes: API RP 571, RP 577, RP 575, RP 579, St 650, RP 651, RP 652, RP 653,API Std. 2000, ASME Section IXWhat you will learnThe participants will be familiar with the material, design, fabrication, erection, and testingrequirements; learn the requirements for inspection, repair, alteration, evaluation andreconstruction of storage tanks. Emphasis will be placed on mechanical design requirements,suitability for service, and tank repair and alteration. Requirements for inspection, NDEexamination, and hydrostatic testing will be provided.Upon completion of this course, you will have an overview of: storage tanks design, maintenance,including inspection, evaluation of various defects, and repair/alteration rules of various Codes andStandards. You will be able to extend the expertise in defect assessment, and equipment integrityanalysis.Level 2 training highlightsDesign requirements and optionsInspection of welds, parts testing and repairsTank component evaluationTank repair and alterationDismantling and reconstructionExamination and testingInspection record and reportsHealth, Safety and EnvironmentAbout CertificationThe examination and certification process is directly related to qualification system. In case whenthe training is performed in accordance with EN473 / ISO 9712 the certificate can be issued byindependent European certification body ATG CERT. Additional details about training andcertification are related to specific needs of client and shall be discussed individually. Please refersection "contacts" or our website www.atgtesting.com.API Training provider certificationThe training and examination are provided under qualification systemapproved by API - American Petroleum Institute. You can obtain finalcertificate with API logo !15

ASMESECTION VIII COURSE / REFRESHCode: ASME VIIIThis course will introduce participants to the ASME Section VIII, Division 1 code for UnfiredPressure Vessels. It will provide an understanding of the background of the overall ASME Boiler andPressure Vessel Code, its organization, and applicability. This course should be attended byengineers, designers, fabrication personnel, QA supervisors, and inspectors who work for pressurevessel owners, fabricators, inspection companies, and government agencies. As well individualsinvolved in the purchase, design, fabrication or inspection of pressure vessels, or professionals whoestimate jobs which impose the requirements of Section VIII, Division 1 are welcome.Based on:ASME VIIIWhat you will learnThe participants will become familiar with the background and requirements of Section VIII, Division1 in order to facilitate interpreting, understanding and compliance with that Code; learn about designrules and formulas, materials, fabrication, examination, inspection, testing certification anddocumentation. Emphasis will be placed on learning about material types, design for pressurevessels fabricated by welding. Requirements for pressure vessels constructed of carbon and lowalloy steels will be provided.Upon completion of this course, you will be able to understand the background of the Code, applythe Code rules to more common design and fabrication situations.Training highlightsMaterial and designFabricationWeldingNon-destructive evaluationAcceptance standardsHydrostatic and pneumatic testingInspection

inspectors for API 510, API 570, API 653, ASME (VI) inspectors acc. to the EN 13387 workshop inspectors plant inspectors shop/site inspectors expediting inspectors ATG offers complex and also partial solution for yours NDT systems acc. to the SNT-TC-1