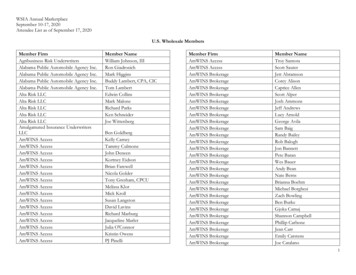

Transcription

TRAININGfor the Injection Molding IndustryWe’re in the Business of Molding Champions

Why RJG Training?Learn from the Global Leaders inSystematic MoldingRJG is a recognized international leader intraining for the injection molding industry, witha focus on processing from the plastic’s pointof view rather than the view of machine setpoints. This isn’t traditional education, though.It’s an effective, comprehensive approach toinjection molding processing training for all skilllevels that delivers measurable results fromdesign to production.Our courses are offered in a variety oflanguages around the globe, including: English,Spanish, French, German, Italian, and Mandarin.Which Training Course Is Best for You?Results of RJG Training: Improved cycle timeImproved machine utilizationReduced scrapImproved qualityReduced time to market (faster startups, reduced cycle times, decreaseddowntime)Ability to uncover and fix problemsDecreased tool damageSatisfied and confident employees(decreased turnover)A standardized processing methodologyCourse Formats Offered: Classroom style instructionHands-on training in our labsReal-world training in your facilityOnline sessionsHighly Experienced ConsultantsAssessment Testing: Find the Right Course for YouWe offer four different types of assessments in order to provide you with highly individualized, strategictraining recommendations:1. Online Assessment TestingOne of the best ways to ensure an enjoyable, rewarding training experience is to choose the right levelfor your position and skill level. If you’re not sure which course is best for you, please take our freeonline assessment test.2. Company-Wide Assessment TestingBased on company goals, assessment scores, job functions, and molding issues, a training coordinatorwill implement a customized training plan to help remedy the issues that your organization may befacing day to day. For more information, contact us to be introduced to the training coordinator in yourarea.3. Systematic Molding Gap AssessmentsAs part of our consulting program, we offer a two-and-a-half-day Systematic Molding Gap Assessmentof your company that audits your internal processes. Once the assessment has been completed, wemake recommendations for improvement to your internal processes, assist your team with a plan forimprovement, and mentor you through the implementation phases.We don’t just have “trainers”—our award winning, problem-solving, troubleshooting consultantsshow others how to do what they do so well. With over 250 years of combined experience insystematic molding, our consultants transfer their knowledge as well as share their industry andconsulting experience with students.Student Knowledge RetentionResearch has shown that 80 percent of lecture-based learning is forgotten within 24 hours. Over the years,RJG has transformed our teaching techniques to overcome this obstacle and create the most effective trainingcourses possible. We’ve worked with experts in the training field to create a participant-centered learningexperience. This training format significantly improves students’ understanding and retention of all coursecontent.World-Class FacilitiesWe have four fully equipped training facilities located in Traverse City, Michigan; Woodstock, Georgia;Gibsonville, North Carolina; and Peterborough, England. Our facilities house over a dozen types of machines,including hydraulic and electric, instrumented with RJG equipment. This variety allows students to gain relevanthands-on training that they can put to use the moment they return to their plant.Our Value Promise to YouWe’re so confident in our training, we’ll give your money back if you don’t feel you’ve received value from thecourse you attend.Consultation ServicesIf training isn’t the right fit, our brilliant consultants are available to assist with varying molding challenges, fromtechnical support to machine capability assessments, mold design reviews, process and tool launch assistance,and more. Visit www.rjginc.com for more details.Our Outstanding ReputationDon’t take our word for it. Hear what our customers have to say: www.rjginc.com/company/testimonials“RJG has been astrong industry partnerfor over 10 years.We would not be thecompany we are todaywithout their support.”Mike ZachariasPresident, Extreme Tool& Engineering

Training Progression at a GlanceIntroductory CoursesMath for Molders – 9 hoursEngineering PathManufacturing PathSpecialty CourseseDART Template MatchRigorous Mold Tryout*Master Molder II*Smartflow Scientific CoolingSmartflow Scientific CoolingAdvanced eDART TrainingMold Design for Injection MoldingMaster Molder ITrain the Trainer Qualification* Enhance your math skillsThis online course is intended for anyonewho seeks to master the math skills neededto successfully complete injection moldingprocessing courses. It is a self-paced class thatfocuses on the math skills required to processusing scientific molding techniques. Studentshave 30 days to complete the 9 hours oftraining—they’re able to stop and start back upagain whenever it’s convenient for them.Machine MaintenanceSystematic Molding for LSRSuccessful Strategiesfor Tool Launches*DECOUPLED MOLDING Workshop*Autodesk Moldflow Insight Advanced Cool & WarpSystematic MoldingMaterial HandlingAutodesk Moldflow Insight Advanced FlowAutodesk Moldflow AdviserUnderstand the injection molding processThis course is designed for anyone new toinjection molding or with no formal education inthe science of polymer behavior. It provides asolid foundation for understanding the injectionmolding process and the critical practice of goodproduction techniques. Participants learn theelements and variables involved in the injectionmolding process as well as key terminology thatwill help them communicate and solve moldingAutodesk Moldflow Insight FundamentalsMath for Molders Calculating area, tonnage,intensification ratio, and morePressure equation triangle for force,pressure, and areaVerifying the machine is capableIdeal for:Personnel with hands-on processingresponsibilities who score less than 4out of 6 on the RJG online assessmentproblems.Course Highlights: Nature and properties of plasticsBasic injection moldingHow to avoid common molding problemsIdeal for: BeginnersMold settersSupport (tooling, quality, planning, etc.)Available In: English, Español, Français, Deutsch, Italiano, 中文Material Handling – 1 DayReduce errors and inconsistencies in processingInjection Molding Essentials Available In: EnglishInjection Molding Essentials – 2 DaysPart Design for Injection MoldingCourse Highlights:This course walks students through theproper techniques for material handling andtroubleshooting. It also explains the ins andouts of raw material management and whatto watch out for when choosing materials,examining product labels, and determining dryerrequirements. Emphasis is on the main materialconsiderations and how drying affects theprocess.Course Highlights: Understanding material labelsDrying and grinding basicsMaterial storageIdeal for: BeginnersMold settersSupport (tooling, quality, planning, etc.)Material handlersAvailable In: EnglishAdvancedIntermediateIntroductoryTake our Online Assessment Testfor recommmendations on where to start*Prerequisites required—seewww.rjginc.com for details“RJG training is agood choice. I wouldconsider it a must.”David WisniewskiEngineering Manager,World Class Plastics

Intermediate CoursesSystematic Molding – 3 DaysGain the knowledge to improve your processThis course builds the foundation for all trainingsessions and allows team members from alldepartments to speak the same language.Through a combination of classroom instructionand activity-driven learning, students leavewith a better understanding of how to developa machine-independent process, how tomake data-driven improvements to existingprocesses, and how to effectively troubleshootusing scientific and systematic approaches.Intermediate CoursesMachine Maintenance – 3 DaysCourse Highlights: The four plastic variables of injection moldingUniversal setup sheets based on plasticconditionsOverview of the molding systemIdeal for: Process engineersDesign engineersProject managersManagement (including shift supervisors)Support (tooling, quality, planners, etc.)Ensure your machine reaches expected performanceThis course is designed for machinemaintenance personnel responsible for upkeep,troubleshooting, and preventive maintenanceof injection molding machines and ancillaryequipment. The performance of the press iscritical to a molder’s ability to deliver consistentparts. Maintenance personnel must understandhow to identify and fix press performanceconcerns in order to optimize press tuning.Course Highlights: Screw and barrel wear evaluationHydraulic systems: closed and openloop, variable displacement pumps,and proportional valvesElectric machines: servo andfrequency drivesIdeal for: Maintenance personnelProcess techniciansSetup techniciansAvailable In: English, EspañolAvailable In: English, Español, Français, Deutsch, Italiano, 中文DECOUPLED MOLDING Workshop* – 3 DaysMaster your skills by putting them to practiceThis workshop is designed to provide studentswith valuable hands-on machine time toreinforce the methodologies they learned inSystematic Molding. It offers the exact sameexercises as Master Molder I, but with halfthe practice time and none of the testing.Companies that are not allowed by theircustomers to make changes to processes cansubstitute the Template Match Workshop forthe Decoupled Molding Workshop.Course Highlights: Machine qualification testsMold performance requirements andweakness identificationBuilding robust Decoupled processes andtemplatesIdeal for: Systematic Molding graduates with handson processing responsibilitiesProcess engineersAvailable In: English, Español, Deutsch, Italiano, 中文“Decoupled IImolding hasbecome our globalstandard.”-Doug ThorpeDirector, NyproSuccessful Strategies for ToolLaunches – 3 DaysDetect mold design issues before the steel is cutThis course is specifically intended fordesigners, mold builders, and tooling engineerswho are looking to incorporate progressivestrategies into the design and build of a moldto ensure robustness. The goal is to preventbad part designs and molds from getting intoproduction. Participants also develop the toolsto measure the mold, machine, and processcapability interactions and determine the bestrecipe for successful tool launches.Course Highlights: How the mold design and build affectsquality and total product costsHow molds can be tried out systematicallyHow plastic behaves as it travels throughthe stages of a processIdeal for: DesignersMold buildersTooling engineersAdvanced processorsNew product launch teamAvailable In: English, 中文“RJG traininghelped us improveour delivery performanceby 33%. Invest in yourpeople, and you’ll seethe rewards.”-Jay SmithPresident of BD,CI Medical

Advanced CoursesAdvanced CoursesMaster Molder I – 2 WeeksBecome a problem solver and problem preventerWhere It All BeganRJG launched the Master Molder Program in 1998 after we saw a great need in the industry for anintensive injection molding training. Molders needed something new, something immersive, somethingpractical. Nobody in the industry was teaching methods from the plastic’s point of view in a real-worldproduction floor environment, and that had to change.The Industry StandardThis course is designed for those who need tounderstand and demonstrate injection moldingskills at the machine. Participants are able todemonstrate the development of a DecoupledII process and apply methods, strategies, andtechniques of injection molding from the plastic’spoint of view. This hands-on, in-depth trainingenables students to leave with solid skills thatcan be applied immediately in their facility.There is a reason Master Molder is listed as a requirement in job descriptions across the globe.Students who have completed Master Molder courses consistently deliver higher quality productsand less scrap. This hands-on, in-depth training enables students to leave with solid skills that can beapplied immediately in their facility.Don’t Take Our Word for It“RJG’s Training provided a way for our fast-growing global company to build multi-functional teams withinthe individual plants who can properly build a valid DECOUPLED process that exposes issues instead ofcovering them, reduces the effects of normal variation, provides evidence of abnormal variation, providesa machine independent process results record, and allows for remote support.”– Doug Thorpe, NyproCourse Highlights: Materials, molds, machines,hydraulics, and instrumentationProcess development using DECOUPLEDMOLDING techniquesProcess documentationand data interpretationIdeal for: Process techniciansEngineersManagersAvailable In: English, Español, 中文Master Molder II* – 2 WeeksAdvanced techniques for daily processing strugglesIn this course, participants learn to apply cavitypressure control strategies to accomplishDecoupled III techniques using instrumentationand data acquisition. This course also covershow to use the eDART system to create andsave a template of a robust process that canbe moved with the tool to any machine in theworld. Participants will then be able to matchthat process at the new machine to createimmediate good parts.Course Highlights: Cavity pressure control using DecoupledIII molding techniquesMatching processes on different pressesusing cavity pressure dataEvaluation of molding machineperformanceThe optimization of a process throughdata collectionIdeal for: Graduates of Master Molder IAvailable In: English, Español

Advanced CoursesRigorous Mold Tryout* – 3 DaysPrevent bad molds from going into productionThe goal of this course is to demonstrate howto prevent bad part designs and molds fromgoing into production. Attendees learn aboutthe levels of risk involved in launching any newtool and how to reduce those risks to create amold that will produce quality parts soon afterintroducing it to the plant floor. Students leavewith a complete understanding of qualifying amold on a machine-independent basis.Advanced CoursesCourse Highlights: Identify mold performance requirementsand select the best machine for the moldBuild robust, repeatable Decoupled II andIII processes and templatesPerform machine qualification testsIdeal for: EngineersPersonnel involved in transferring orsetting up toolsAvailable In: EnglishPart Design for InjectionMolding – 3 DaysSave costs by designing moldable parts upfrontThis course provides a common language andthe core knowledge required to successfullydesign and produce plastic injection moldedcomponents. Class topics address goodmanufacturing processes for plastic partdesign, fundamental material characteristics,key mold concepts, and more. Building a solidfoundation of knowledge is required to designrobust parts that reduce the risk of less thanoptimum mold designs, therefore minimizingexposure to injection molding non-conformities.Course Highlights: Materials, tooling, and machinerequirementsProcessing, non-conformities,and tolerancesPart design: wall thickness, flow length,features, radius, draft, glossIdeal for: Product design engineersMold designersMoldersAvailable In: EnglishSmartflow Scientific CoolingCourse – 2 DaysManage mold cooling to produce consistent partsThis comprehensive class is for those whowant to better understand and control theeffects of mold cooling. Participants learn thetools needed to analyze heat energy and themold cooling management required to produceconsistent, profitable parts. This course willalso introduce advanced methods, such asflow simulation, thermal imaging, and hightemperature cooling systems.Course Highlights: Learn energy principles in relationto specific polymers Understand how heat transferand energy flow affect part qualityand cycle time Create heat budget and balancing usingenergy flow calculationsIdeal for: Mold builders / designersTooling engineersMold techniciansAvailable In: EnglishMold Design for InjectionMolding – 3 DaysSave costs by avoiding mold reworkThis course provides mold makers, designengineers, and molders with the commonlanguage and core knowledge required tosuccessfully design robust injection molds thatmeet cycle time, cost, part quality, and leadtime requirements. Class topics address goodmanufacturing practices (GMP) for part design,including fundamental material characteristics,necessary processing techniques, andmolding non-conformities, with a focus onrobust mold design.Course Highlights: Part design: wall thickness, flow length,features, radius, draft, glossMold design: line of draw, steel, coatings,actions, gating, venting, support pillars,cooling, ejection, instrumentationIdeal for: Mold designersProduct design engineersMoldersAvailable In: English

Specialty CoursesSpecialty CoursesAutodesk Moldflow Adviser – 3 DaysHands-on exercises on the features of AutodeskMoldflow AdviserIn this official Autodesk training course,students will learn the features, functionalities,and workflows of Autodesk Moldflow Adviser.Students will review the injection moldingprocess to better understand the relationshipof part to process, thermoplastic materials andtheir families and abbreviations, and designprinciples and how to apply them, in addition todesign philosophies and procedures. The classwill provide hands-on instruction to improvethe students’ use of Standard, Premium, andUltimate licenses.Autodesk Moldflow InsightFundamentals – 3 DaysWalk through the entire flow analysis processIn this official Autodesk training course,students will learn the fundamental features,functionalities, and workflows in AutodeskMoldflow Insight. Attendees will review theinjection molding process, thermoplasticmaterials and their families and abbreviations,design principles and how to apply them, anddesign philosophies and procedures.Course Highlights: Learn how to use the interface and jobmanager and how to customize databasesQuick Fill-Pack-Warp Analysis: the stepstypically used for any analysis projectLearn to import and check models fromCAD systemsIdeal for: Beginner Autodesk Moldflow AdviserusersAutodesk Moldflow InsightAdvanced Flow – 3 DaysThe features and functions of Autodesk MoldflowInsight Advanced FlowIn this official Autodesk training course,students will learn the different features ofAutodesk Moldflow Insight Standard, whichwere not covered in the Autodesk MoldflowInsight Fundamentals course. Students learnabout the more complex analysis typesavailable in Autodesk Moldflow Insight.Course Highlights: Learn to create personal databases of alltypes and how to use themLearn to analyze family tools, includingfinding processing conditions, combiningstudies, and balancing runnersLearn the types of multiple gate problemsthat occur and how to analyze themIdeal for: Any Autodesk Moldflow Insight userAvailable In: English, EspañolAvailable In: English, EspañolCourse Highlights: Learn to navigate and use the interfaceQuick Cool-Fill-Pack-Warp Analysis: thesteps typically used for any analysisprojectDesign philosophies and proceduresThe mesh characteristics necessary for ahigh quality digital prototypeIdeal for: Beginner Autodesk Moldflow Insight usersAvailable In: English, EspañolAutodesk Moldflow Insight AdvancedCool & Warp – 3 DaysGain the knowledge to improve quality of LSR partsThis official Autodesk training coursecovers the features, functionalities, andworkflows in the Autodesk Moldflow InsightPremium package. It covers features of thepremium license that are not covered in theFundamentals or Advanced Flow courses.Course Highlights: Learn to prepare for, run, and interpret theresults of a core shift analysisLearn about fill and pack analysis for fiber filledmaterials and why and when to do an analysisUnderstand the importance of cooling andthe basic concepts of cooling injection moldsIdeal for: Any advanced Autodesk MoldflowInsight userAvailable In: English, Español

Specialty CourseseDART Template Match – 3 DaysSuccessfully transfer a process across machinesIn this course, students learn how to documentan existing process and transfer it to anothermachine utilizing calculations, conversions,and eDART templates. Students also examinerobust documentation and matching processesbased on the plastic variables, learn how toexamine a setup sheet, and identify moldperformance requirements. They also reviewmachine variables and determine if twomachines are compatible.Specialty CoursesCourse Highlights: Using the plastic variables to troubleshoota processMaintaining process matchTransferring an existing processto another machineIdeal for: Train the Trainer Qualification* – 2 WeeksCreate a community of problem solversThis course is designed for those who fullyintend to instruct others in their organization onthe methodologies and techniques learned intheir Master Molder training. Qualified trainersare eligible to teach Math for Molders, InjectionMolding Essentials, Systematic Molding, andthe DECOUPLED MOLDING Workshop.eDART system usersProcess techniciansSupport (tooling, quality, planning, etc.)Create a better process, identify molding problemsThis course is intended for anyone whoneeds to know how to effectively run aneDART process controller or identify moldingproblems. Attendees learn how to connect andverify that sensors are properly installed, startand stop jobs, verify alarms and templates,and set up the eDART sytem for abnormal partcontainment. This course introduces DecoupledIII Machine Control, but does not cover buildinga process.Course Highlights: How to interpret eDART data and graphsPart containment using cavity pressuretechnologyHow to identify machine and processchanges using the eDART systemIdeal for: eDART system usersProcess techniciansSupport (tooling, quality, planning, etc.)Available In: English, Español, Français, 中文 Daily evaluation by the instructor and classon teaching skillsDevelop training materials to supportlearning objectivesHands-on lab sessions that encouragestudent participationIdeal for: Available In: English, FrançaisAdvanced eDART Training – 3 DaysCourse Highlights:Graduates of Master Molder I who scored90% or higher in the last five years andwant to instruct others in their organizationAvailable In: EnglishSystematic Molding for LSR – 3 DaysGain the knowledge to improve quality of LSR partsThis course provides the fundamentals forbuilding a robust and repeatable process.Students leave with a better understandingof how to develop an LSR process, how tomake data-driven improvements to existingprocesses, and how to effectively troubleshootusing scientific and systematic approaches.This will allow students to make informeddecisions for lasting solutions.Course Highlights: Material delivery systemsUnderstanding the plastic variablesAvoiding quality defectsIdeal for: Process techniciansSupport (tooling, quality, planning, etc.)Anyone who wants to develop asystematic approach to molding LSRAvailable In: English“I have workedwith few companies thathave such a robust trainingcapability andoutstanding technicalsupport as RJG.”-John PorterVP of Operations,iMARK Molding

LocationsUSARJG USA (Headquarters)Traverse City, MIphone: 01 231 947-3111SE Regional Training CenterWoodstock, GAphone 01 678 401-7494North Carolina Training CenterGibsonville, NC 01 336 310-8594e-mail: sales@rjginc.comweb: www.rjginc.comMexicoRJG MexicoChihuahua, Mexicophone: 52 614 4242281e-mail: sales@es.rjginc.comweb: es.rjginc.comFranceRJG FranceArinthod, Francephone: 33 384 442 992e-mail: sales@fr.rjginc.comweb: fr.rjginc.comGermanyRJG GermanyKarlstein, Germanyphone: 49 (0) 6188 44696 11e-mail: sales@de.rjginc.comweb: de.rjginc.comUK/IrelandRJG Technologies LtdPeterborough, Englandphone: 44 (0)1733 232211e-mail: sales@rjginc.co.ukweb: www.rjginc.co.ukItalyNext Innovation SrlMilano, Italyphone: 39 335 178 4035e-mail: sales@it.rjginc.comweb: it.rjginc.comSingaporeRJG (S.E.A.) PTE LTDSingapore, Republic of Singaporephone: 65 6846 1518e-mail: sales@swg.rjginc.comweb: en.rjginc.comChinaRJG ChinaChengdu, Chinaphone: 86 28 6201 6816e-mail: sales@cn.rjginc.comweb: zh.rjginc.comKoreaCaeproSeoul, Koreaphone: 82 02-2113-1870e-mail: sales@ko.rjginc.comweb: www.caepro.co.krwww.rjginc.comRJG Headquarters

training for the injection molding industry, with a focus on processing from the plastic’s point of view rather than the view of machine set points. This isn’t traditional education, though. It’s an effective, comprehensive approach to injection molding processing training f