Transcription

Recommended Proceduresfor Conducting a SkillsUSAWelding Contest

RECOMMENDED PROCEDURESfor CONDUCTING aSkillsUSA WELDING CONTESTFourth EditionPublished ByAmerican Welding Society550 N.W. LeJeune Road, Miami, Florida 33126

International Standard Book Number: 0-87171-739-5American Welding Society, 550 N.W. LeJeune Road, Miami, FL 33126 2005 by American Welding Society. All rights reservedPrinted in the United States of AmericaPhotocopy RightsAuthorization to photocopy items for internal, personal, or educational classroom use only, or the internal,personal, or educational classroom use only of specific clients, is granted by the American Welding Society(AWS) provided that the appropriate fee is paid to the Copyright Clearance Center, 222 Rosewood Drive,Danvers, MA 01923, Tel: 978-750-8400; online: http://www.copyright.com.ii

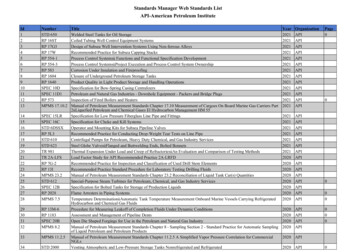

TABLE OF CONTENTSPage No.Introduction. ivThe Contest Committee .1Choosing the Contest Site.1Scheduling the Contest .1Developing the Test.2Judges and Judging .2Securing Materials, Equipment, and Personnel .3Briefing the Contestants .3Contest Coordinators .3Prizes and Award Ceremonies .3Evaluating the Contest.3Appendix ISkillsUSA Welding Requirements .5Appendix IIFigures for SkillsUSA Competition .11Appendix III Judges Rating Sheet.21Appendix IV General Knowledge Test .23Appendix VInstructions for Judges.27Appendix VI Contestant Instructions.29Appendix VII Performance Evaluation .31iii

INTRODUCTIONVocational Education is a vital portion of the educational system in the United States. American Industrycontinues to need a steady supply of skilled craftsman and in particular, Welders. In spite of the need forskilled craftsman vocational technical education carries with it a stigma that those who are vocational students are simply there because they are not capable of higher academic education. The Vocational IndustrialClubs of America (now SkillsUSA) was formed to reverse that image. SkillsUSA recognizes that most vocational students have made a conscious decision to enter the trades to pursue a rewarding and satisfying career.SkillsUSA established the United States Skills Olympics (now called SkillsUSA Championships) as a method ofrecognizing and rewarding vocational students for demonstrating trade skills. It serves as a challenge to vocational students to do their best. There are a great many individuals and organizations who believe in theSkillsUSA objectives and the impact of these objectives on the lives of the thousands of students SkillsUSAserves. They have done so because they want to improve the quality of the vocational programs and betterprepare the students for gainful employment. The American Welding Society is among the largest supportersof SkillsUSA.SkillsUSA contests begin at local vocational schools where contests are held to determine those who willadvance to the regional level. The regional winners compete in state contests to determine those who willrepresent their states in national competition. There are two levels of competition, secondary and postsecondary. Not all states have post secondary SkillsUSA programs but most do have secondary programs.The Education Committee strongly recommends AMERICAN WELDING SOCIETY Section involvement atevery level of competition to provide quality contests.This publication has been prepared using the experience gained in local, national and international SkillsUSAcontests to provide a guide for those wishing to run a SkillsUSA welding skills contest at any level. To get involved in the SkillsUSA welding contests you need to know who is in charge of the SkillsUSA program inyour area. National SkillsUSA will provide you with the name address, and telephone number of your StateSkillsUSA Director, so you can determine when the Welding skills contest will be held, and to volunteer yourSection’s services. You can contact National SkillsUSA at:National SkillsUSAP.O. Box 3000Leesburg, Virginia, 20177Tel: (703) 777-8810Fax: (703) 777-8999Web: www.skillsusa.orgEugene G. HornbergerAuthoriv

SkillsUSA Welding ContestThe Contest CommitteeThe local American Welding Society Section shouldbe the center point of any welding contest. Thesuccessful administration of a welding contestdepends on the selection of an active committeewith an interest in vocational welding programs.The Committee will be required to: Devise a test. Select a contest site. Supply equipment and material. Supply judges. Set up the contest site. Arrange for awards and awards ceremonies.The committee should consist of a variety of competencies. The individuals must be willing to dedicate some of their own time and should have aninterest in working with students. Some sourcesfor members may be found among the followingdisciplines: Engineers. Technicians. Superintendents. Foreman. Distributors. Welders. Welding Inspectors. Certified Welding Inspectors.quire considerably more effort on the part of thecommittee to stage the contest, but it is usuallyworth the effort for the exposure the welding contest receives. The national contest, which consists offorty-eight testing stations, has been held in arenasaround the country since 1979. The Committeeshould review available areas, looking for suchthings as: Sufficient room for contestants, judges, andsupport personnel. Adequate welding equipment and power forinstallation of additional equipment. Well lit, clean with adequate ventilation. Access to a room for briefing and debriefing ofthe contestants. An area away from the contest site for the contestants to spend their casual time, while awaiting their turn. Access to refreshments and sanitary facilities. A location accessible to all and easy to find. An area designated as a tool room for storage.Since additional equipment and test project material will likely be arriving before the contest date, asecure storage area is needed.If the contest is held at a local vocational schoolvisitors are not encouraged. They can be disruptiveto the contest and present a safety problem. If thecontest is held in a public arena, visitors are definitely encouraged.A contest chairman should be selected, who in turnnames coordinators, who are responsible for different areas of the test (Judges, material, power supplies, etc.). It is recommended that WeldingInstructors not be named to the Contest Committeeto avoid conflicts.If you are using a public vocational school it isextremely important to get the complete supportof the individual in charge of the institution for itsuse. A visit to the individual in charge, to securetheir permission, confirmed by a written letter ofagreement indicating their affirmative response isessential.Choosing the Contest SiteScheduling the ContestThe contest site will be largely determined by thenumber of students involved, the complexity of thecontest, and the availability of space. Local and regional contests are usually held at a local vocationalschool. There is a growing trend to hold state contests in public arenas. While arenas do maximizethe public’s exposure to skills contests it does re-It is wise to schedule the events leading up to thecontest. The actual date of the contest should bescheduled as far in advance as possible. It is best tohave at least six months notice for planning. Acheck list should be made up, listing goals anddates for completion. Long lead time items, such asadditional welding equipment, should be identifiedAWS Practical Reference Guide 1

SkillsUSA Welding Contestand ample time allowed for procurement, deliveryand installation.When the test is developed, consideration must begiven to the time allowed for welding the project. Ifyou have fifteen contestants and five welding machines you must make sure that there is adequatetime to allow each contestant to complete theirproject without making the overall contest time toolengthy. Start the contest as early in the day as practical to allow extra time in event of any trouble.Have the judges and helpers report at least a halfhour before the test starts for orientation and placement. Judges meetings held in advance of the contest are usually poorly attended, and you will findyou still have to conduct an orientation the day ofthe contest. Start the test promptly and allow timebetween contestant groups for orderly changes.Developing the TestThe test project you give will determine the successof your contest. You should obtain a copy of theSkillsUSA Championships, Technical Standards.This is available from National SkillsUSA and liststhe minimum competencies that are expected of acompetitor at the national level (see Appendix I).You must decide whether you will use destructiveor nondestructive testing. Nondestructive testingmay simply consist of visual examination or youmay decide to use a more elaborate method. Forexample, liquid penetrant examination requireslittle time, and provides something that can be displayed. Availability of equipment and personnelwill dictate what method you will choose.Destructive testing is popular, since specimens areproduced that may be put on display, however it istime consuming, and requires cutting and grinding,which presents a safety hazard.The material for the test must be considered. Carbon steel is widely used and all schools have accessto it. However this should not eliminate the use ofother materials. The major portion of the projectshould be written for carbon steel with other materials included as available. You should limit yourproject materials to carbon steel, stainless steel, andaluminum (see Appendix II for examples of national welding contest projects).2 AWS Practical Reference GuideWhen the requirements of the test are defined, it istime for the test project to be put on paper. A drawing of the project should be made using standarddrawing room practices. Welding symbols, terms,and definitions should be in accordance with thelatest American Welding Society standards. Welding Procedure Specifications (WPSs) should bewritten explaining how the project is to be assembled and welded. The WPSs should be included onthe project drawing, or attached to it. Using thecontest drawing, a judges rating sheet can be developed. A sufficient number of examination pointsshould be made to provide a good evaluation of theproject. Appendix III shows examples of judges rating sheets. Copies of the test project should be keptin a secure place. Advance copies of the contestproject should be kept to a minimum.Written tests are an integral part of the contest.Public vocational welding programs should includesome welding theory to better prepare the studentfor employment. A test should be given to samplethe students knowledge of welding and cuttingsafety, welding terms, and process theory. Appendix IV displays a typical general knowledge test.Judges and JudgingJudges are important to a successful contest. Sincethey are a key component in the contest a coordinator should be assigned whose sole charge is to takecare of the judges. It is essential to have fair and impartial judging. Judges that are selected should befamiliar with the processes and materials they arejudging. Sources of judges are engineers, foremen,inspectors superintendents, Certified WeldingInspectors, welders, technicians, and salesmen.Judges should be briefed thoroughly before thecontest. At the Judges orientation the contestproject is explained to them, along with judgingpoints and criteria. It is desirable to have a weldedtest project available for examination and discussion (see Appendix V for Judges’ instructionsheets).Each contestant should be judged by a minimum ofthree judges, all of whom shall not know the contestant. SkillsUSA rules require each contestant beassigned a number known only to the contest chairman. The identity of contestants is revealed onlyafter the contest is concluded, and the winnersselected.

SkillsUSA Welding ContestJudging of the welded projects should be in compliance with some welding standard, such as AWSD1.1.Securing Materials, Equipment,and PersonnelThe true value of an active Contest Committee willshow itself when you begin to procure supplies andequipment for the contest. SkillsUSA contests arenon-profit functions and supplies can be a problem.Industrial members on the committee should besolicited to provide base materials for the testproject. Local distributors will usually supply fillermetals and may be able to loan welding equipmentas well. Another source of equipment can be temporary loan of equipment from other vocationalinstitutions in the area.Be sure to acknowledge, with letters of appreciation, the donation or loan of equipment andsupplies. Be careful to preserve the condition ofloaned equipment, and arrange for the promptreturn of that equipment.When you begin to look for people to serve asjudges, tool room attendants, material handlers, etc.the local American Welding Society Section is anexcellent resource. Also consider vocational students who are not participating in the contest andlocal Apprenticeship programs. Wherever you getthem it is essential to have those people to keep thecontest moving.Briefing the ContestantsIt is a good idea to get all the contestants together afew days before the contest to tell them what to expect. You do not want to tell them exactly what thecontest will consist of, but you do want to cover thegeneral areas. Tell them what time to report, whatto bring, what the schedule will be and any otherinformation regarding the contest. Remember thatmost of them are nervous and may not rememberwhat you have told them. Provide them with awritten hand-out covering the contest informationitems (see Appendix VI).Contest CoordinatorsContest coordinators are essential to a well run contest. These individuals are crucial the day of thecontest. A coordinator’s duties will include: Seeing that all helpers, material handlers, andtool room attendants, are in attendance. Greeting the contestants and escorting them tothe waiting area. Briefing contestants before the contest, handingout the project material, and answering generalquestions. Maintaining the time schedule. Directing helpers in event of a breakdown. Debriefing contestants, pointing out strong andweak areas. Collecting rating sheets and welded projects. Handing out filler metals.Prizes and Award CeremoniesAll contestants should receive some recognition.This can be in the form of a certificate of participation, a cloth patch or some other memento. Thewinners should receive something additional to reward them for their success. Plaques, complimentary membership in the American Welding Society,welding safety products or small welding machineare some of the items that may be presented.Official announcement of the winners is usually aresponsibility of SkillsUSA at an awards ceremony.Contest results should not be released in advance ofthe official ceremony. After SkillsUSA announcesthe results, welding contest winners should be invited to local American Welding Society Sectionmeetings where they can be recognized.Keep in mind that the objectives of awards shouldbe to reward those who have demonstrated tradeexcellence, not to see who can win the most prizes.Evaluating the ContestThe primary reason for American Welding Societyparticipation in SkillsUSA welding contests is toAWS Practical Reference Guide 3

SkillsUSA Welding Contestimprove the quality of vocational welding education in the United States and to set standards for excellence. At the awards ceremony the top threewelding students are recognized while the resthave no indication of their performance. The student and his instructor need feedback on theirperformance so they can work on weak areas. Yourdo not want to provide the student with a rank4 AWS Practical Reference Guideorder. It serves no good purpose to tell someonethat they came in last. You can however, providethem with information that will allow them to measure their performance against specific tasks without telling them where they placed (see AppendixVII). This figure is derived from a computeranalysis of the welding contest. Manual scoring willprovide the same information.

SkillsUSA Welding ContestAPPENDIX I–SkillsUSA WeldingRequirementsc.WELDINGd. Spare spatter and filter lenses/plates forarc welding, helmet, and oxyacetylenegoggles.PurposeTo evaluate each contestant’s preparation for employment and to recognize outstanding studentsfor excellence and professionalism in the field ofwelding.Welding helmet with appropriate filterplate/lens and protective cover plate/lensin a flip or slide front for OFC, PAC. Autodarkening shields are permissible.e.Pocket calculator.f.Lead pencil and/or ballpoint pen.g. Soap stone with holder.h. Scribe with magnet.First, refer to General Regulations.i.Combination square set.Clothing Requirementj.10-foot (3.1 meters) steel tape measure.Official SkillsUSA khaki work shirt and pants, andblack or brown leather work shoes should be worn.Safety glasses with side shields or goggles are required. (Prescription glasses can be used only ifthey are equipped with side shields. If not, theymust be covered with goggles.) To purchase officialwork clothes, contact Midwest Trophy Manufacturing Co. Inc. by calling 1-800-324-5996 or orderonline at:k. Fillet weld gauge.http://www.mtmrecognitiom.com/skillsusa.p. 6-inch (152 millimeters) needle nose pliers.Eligibilityq. Chipping hammer with or without . Center punch.n. 10-inch (254 millimeters) vise grips.o.r.Open to active SkillsUSA members enrolled in programs with welding as the occupational objective.6-inch (152 millimeters) side cutting pliersor diagonal cutting pliers.Stainless steel wire brush.Specific Rules for Contest ParticipantsEquipment and Materials1.1.Contestants must correctly use the weldingequipment during the contest. The contestchairman and contest coordinator may stop acontestant at any section of the contest if theydeem a contestant’s manner to be hazardous toeither themselves or others. Such stoppageshall disqualify the participant for that sectionof the contest. If the contestant is warned a second time, he or she will be disqualified as acontest participant.2.Contestants will be assigned a contest numberfor use during the welding contest. The contestants will be known to the contest judges bytheir assigned number only.3.While the contest is in progress, there shall beno communication between the contestants orbetween the contestants and anyone else,Supplied by the Contest Committee:a.All necessary welding equipment andmaterials.b.All instructions and procedure sheets withdrawings.c.All necessary information and furnishingsfor judges and the technical committee.2. Supplied by the contestant:a.Hearing and/or ear protection.b.Welding helmet with appropriate filterplate/lens and protective cover plate/lensin a flip or slide front. Auto darkeningshields are permissible.AWS Practical Reference Guide 5

SkillsUSA Welding Contestexcept as directed by a judge, contest coordinator or contest chair.4.The welding contest will be of a performancenature.5.All terms and definitions and welding symbolswill be in accordance with the current editionsof AWS A3.0, Standard Welding Terms and Definitions, and AWS A2.4, Standard Symbols forWelding, Brazing, and Nondestructive Examination.Blueprint Reading*1. Use information found in the informationblock of the drawing.*2. Read anddrawings.understandthree-dimensional*3. Identify the basic views used in blueprints including assembly, detail, and fit-up drawings.6.Time limits will be established on the contestprocedure sheets for all segments of the test.*4. Identify common types of lines, abbreviations,and symbols in accordance with nationaldrawing standards—ANSI.7.Evaluation of the completed project will be byvisual examination. Nondestructive and/ordestructive tests may be used to complete theproject evaluation.*5. Identify basic welding symbols and components of a symbol (such as arrow, referenceline, tail, size, or length) in accordance with thenational welding symbols standards—AWS.8.Welding and cutting operation instructionswill be specified in drawings and proceduresheets provided to the contestants.Scope of the ContestContestants will demonstrate their ability to perform jobs and skills selected from the following listof competencies as determined by the SkillsUSAChampionships technical committee.Note: The following items marked * should be consideredessential.Safety*1. Demonstrate personal safety.*2. Demonstrate general shop safety.*3. Demonstrate gas, electrical, and chemicalsafety.*4. Demonstrate knowledge of proper actions tobe taken in an emergency.Measurements*1. Identify basic metal-working tools used inmeasuring.*2. Use visual measuring tools to accuracy of1/32 inch.*3. Employ the components of a combinationsquare set.*4. Use layout and marking tools as required.*5. Determine wire feed speed as indicated ondrawing.6 AWS Practical Reference GuideShielded Metal Arc Welding (SMAW)*1. Demonstrate safety procedures for SMAW.*2. Demonstrate ability to correctly set upSMAW power sources, related welding equipment, and do basic process and equipmenttroubleshooting.* 3. Correctly identify base metal prior to welding.*4. Set up and shut down equipment for weldingof carbon steel and/or stainless steel.*5. Select correct type of filler metal size of electrode based on carbon steel and/or stainlesssteel plate (1/4 inch to 1/2 inch thickness).*6. Prepare carbon steel and/or stainless steel forwelding.*7. Start, stop, and restart stringer beads oncarbon steel and/or stainless steel in the flat,horizontal, vertical up and down, and overhead positions.*8. Weld a pad with a multipass weld on carbonsteel and stainless steel plate in the flat, horizontal, vertical up and down, and overheadpositions.*9. Weld a lap joint with a single pass, fillet weldon carbon steel and stainless steel sheet/platein flat, horizontal, vertical up and down, andoverhead positions.*10. Weld a lap joint with a multipass, fillet weldon carbon steel and stainless steel plate in theflat, horizontal, vertical up and down, andoverhead positions.

SkillsUSA Welding Contest*11. Weld a T-joint with a single-pass, fillet weld oncarbon steel and stainless steel sheet/plate inthe flat, horizontal, vertical up and down, andoverhead positions.*12. Weld a T-joint with a multipass fillet weldon carbon steel and stainless steel plate in theflat, horizontal, vertical up and down, andoverhead positions.*13. Weld a butt joint with a single-pass, squaregroove weld on carbon steel, stainless steelsheet/plate in the flat, horizontal, vertical upand down, and overhead position.*14. Weld a butt joint with a partial joint penetration, single pass, double V-groove weld oncarbon steel and stainless steel plate in the flat,horizontal, vertical up and down, and overhead positions.*15. Weld a butt joint with a multipass, V-grooveweld on carbon steel and stainless steel plate inthe flat, horizontal, vertical up and down, andoverhead positions.*16. Weld a butt joint with complete joint penetration, multipass, double V-groove weld on carbon steel and stainless steel plate in the flat,horizontal, vertical up and down, and overhead positions.*17. Weld 2-inch to 8-inch diameter schedule 40 toschedule 80 carbon steel and stainless steelpipe, single/multipass V-groove weld in the2G, 5G, and 6G positions.*18. Lay out, weld, cut, and prepare coupons forevaluation.*19. Test prepared coupons.Gas Metal Arc Welding (GMAW)*1. Demonstrate correct safety procedures forGMAW.* 5. Select correct type of filler metal size of electrode, type of shielding gas, wire feed speed,and voltage based on carbon steel, stainlesssteel, and/or aluminum sheet and/or plate(1/16 inch to 3/8 inch thickness).*6. Prepare the carbon steel, stainless steel, and/oraluminum for welding.*7. Start, stop, and restart stringer beads on carbon steel, stainless steel, and aluminum steelsheet/plate in the flat, horizontal, vertical upand down, and overhead positions.* 8. Weld a pad with a multipass weld on carbonsteel, stainless steel, and aluminum sheet/plate in the flat, horizontal, vertical up anddown, and overhead positions.*9. Weld a lap joint with a single-pass, fillet weldon carbon steel, stainless steel, and aluminumsheet/plate in flat, horizontal, vertical up anddown, and overhead positions.*10. Weld a lap joint with a multipass, fillet weldon carbon steel, stainless steel, and aluminumplate in the flat, horizontal, vertical up anddown, and overhead positions. Interrupt rootpass at midpoint and restart arc.*11. Weld a T-joint with a single-pass, fillet weld oncarbon steel, stainless steel, and aluminumsheet/plate in the flat, horizontal, vertical upand down, and overhead positions.*12. Weld a T-joint with a multipass, fillet weld oncarbon steel, stainless steel, and aluminumplate in the flat, horizontal, vertical up anddown, and overhead positions.*13. Weld a butt joint with a single-pass, squaregroove weld on carbon steel, stainless steel,and aluminum sheet/plate in the flat, horizontal, vertical up and down, and overheadpositions.*3. Correctly identify base metal prior to welding.*14. Weld a butt joint with a partial joint penetration, single-pass, double V-groove weld oncarbon steel, stainless steel and aluminumplate in the flat, horizontal, vertical up anddown, and overhead positions.*4. Set up and shut down equipment for shortcircuiting, globular and spray, transfer, andpulsed welding of carbon steel, stainless steel,and/or aluminum.*15. Weld a butt joint with a multipass, singleV-groove weld on carbon steel, stainless steel,and aluminum plate in the flat, horizontal,vertical up and down, and overhead positions.*2. Demonstrate ability to correctly set up GMAWpower sources, related welding equipment anddo basic process and equipment troubleshooting.AWS Practical Reference Guide 7

SkillsUSA Welding Contest*16. Weld a butt joint with complete joint penetration, multipass, double V-groove weld oncarbon steel, stainless steel, and aluminumplate in the flat, horizontal, vertical up anddown, and overhead positions.*17. Weld 6-inch (150 millimeter) or 8-inch(200 millimeter) diameter and smaller, schedule 40, carbon steel, stainless steel, and aluminum pipe, single/multipass V-groove weld inthe 2G, 5G, and 6G positions.*18. Lay out, weld, cut, and prepare coupons forevaluation.*19. Test prepared coupons.Fluxed Cored Arc Welding (FCAW)*1. Demonstrate correct safety procedures forFCAW.flat, horizontal, vertical up, and overhead positions. Stop and restart in middle of joint.*11. Weld a T-joint with a single-pass, fillet weld oncarbon steel and stainless steel sheet/plate inthe flat, horizontal, vertical up, and overheadpositions.*12. Weld a T-joint with a multipass, fillet weldon carbon steel and stainless steel plate inthe flat, horizontal, vertical up, and overheadpositions.*13. Weld a butt joint with a single-pass, squaregroove weld on carbon steel and stainless steelsheet/plate in the flat, horizontal, vertical up,and overhead positions.*14. Weld a butt joint with a partial joint penetration, single pass, double V-groove weld oncarbon steel and stainless steel plate in the flat,horizontal, vertical up, and overhead positions.*2. Demonstrate ability to correctly set upFCAW power sources, related welding equipment and do basic process and equipmenttroubleshooting.*15. Weld a butt joint with a multipass, V-grooveweld on carbon steel and stainless steel plate inthe flat, horizontal, vertical up, and overheadpositions.*3. Correctly identify base metal prior to welding.*16. Weld a butt joint with complete joint penetration, multipass, double V-groove weld on carbon steel

tional welding contest projects). When the requirements of the test are defined, it is time for the test project to be put on paper. A draw-ing of the project should be made using standard drawing room practices. Welding symbols, terms, and definitions should be in accordance with the latest A