Transcription

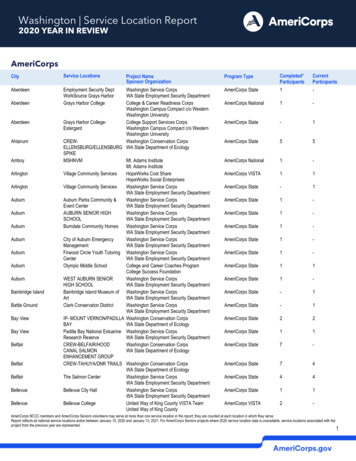

QoranoIll Illllll 111111111111111111R11881925March 21 , 2018Ms. Andrea DorseySubcontractor AdministratorBechtel National , Inc.2435 Stevens Center PlaceRichland , WA 99354Orano FederalServices LLC2101 Hom Rapids RdRichland, WA 99354Tel: 1 509 371 1893Dear Ms. Dorsey:BECHTEL NATIONAL, INC. CONTRACT NO. 24590-CM-HC4-HXYG-00240IQRPE STRUCTURAL INTEGRITY ASSESSMENT REPORT FOR DFLAWEMF DEP CRITICAL PIPING ANCILLARY EQUIPMENT (IA-3021153-000)The integrity assessment of the subject Critical Piping Ancillary Equipmenthas been completed per the contract requirements and is enclosed for youruse. The assessment found that the design is sufficient to ensure that theCritical Piping Ancillary Equipment is adequately designed and has sufficientstructural strength , compatibility with the waste(s) to be processed/stored /treated , and corrosion protection to ensure that it will not collapse ,rupture , or fail.If you have any questions, please contact Tarlok Hundal at (509) 371-1975, orvia email at tarlok.hundal@orano.group.Sincerely,Tess KlattContract AdministratorOrano Federal Services LLCRichland OfficeLapcc: J.S. Evans, w/Enclosure (1)www.orano.group

0oranoIA-3021153-000IQRPE STRUCTURAL INTEGRITY ASSESSMENT REPORTFORDFLAW EMF DEPCRITICAL PIPING ANCILLARY EQUIPMENTPlease note that source, special nuclear and byproduct materials, asdefined in the Atomic Energy Act of 1954 (AEA), are regulated at the U.S.Department of Energy (DOE) facilities exclusively by DOE actingpursuant to its AEA authority. DOE asserts that pursuant to the AEA, ithas sole and exclusive responsibility and authority to regulate source,special nuclear, and byproduct materials at DOE-owned nuclear facilities.Information contained herein on radionuclides is provided for processdescription purposes only.www.orano.group

0oranoIA-3021153-000IQRPE STRUCTURAL INTEGRITY ASSESSMENT REPORTFORDFLAW EMF DEPCRITICAL PIPING ANCILLARY EQUIPMENT"I, Tarlok Singh Hundal, have reviewed and certified a portion of the designof a new tank system component located at the Hanford Waste TreatmentPlant, owned/operated by Department of Energy, Office of RiverProtection , Richland , Washington . My duties were independent review ofthe current design for the DFLAW EMF DEP Critical Piping AncillaryEquipment, as required by the Washington Administrative Code,Dangerous Waste Regulations, Section WAC-173-303-640(3)(a) through (g) applicable components .""I certify under penalty of law that I have personally examined and amfamiliar with the information submitted in this document and all attachmentsand that, based on my inquiry of those individuals immediately responsiblefor obtaining the information , I believe that the information is true , accurate,and complete. I am aware that there are significant penalties for submittingfalse information , including the possibility of fine and imprisonment."The documentation reviewed indicates that the design fully satisfies therequirements of the WAC.The attached review is seventeen (17) pages numbered one (1) throughseventeen (17).www.orano.group

IQRPE Structural Integrity Assessment Report for DFLAW EMF DEPCritical Piping Ancillary Equipment 800Scope ofthis IntegrityAssessmentSummary ofAssessment3/21/18IA-3021153-000This integrity assessment addresses the critical piping ancillary equipment associated with the DFLA W EffluentManagement Facility (EMF) DVP system. The critical piping ancillary equipment included pipelines, valves, and otheritems associated with numerous vessels, miscellaneous units or plant items, are conspicuously delineated on the P&IDdrawings listed in the References section below. The critical piping ancillary equipment herein will be mainly termed asancillary equipment, throughout the report.For each item of "Information Assessed" (i.e., Criteria) on the following pages, the documents listed under "Source ofInformation" were reviewed and found to furnish adequate design requirements and controls to ensure that the design fullysatisfies the requirements of Washington Administrative Code (WAC), Chapter 173-303 WAC, Dangerous WasteRegulations, W AC-173-303-640, Tank Systems.Note: Numerous change documents were issued against various documents listed in the " References" section and " Source ofInformation" column below. The change documents were reviewed and those which had any impact on the " Assessment"results were appropriately included, however, those which did not have any impact on the "Assessment" results were notincluded herein .Page I of 17Orano Federal Services LLC

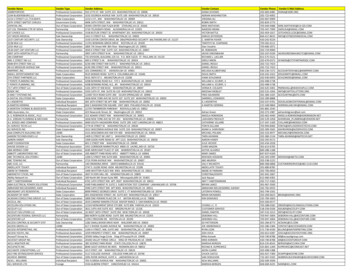

IQRPE Structural Integrity Assessment Report for DFLAW EMF DEPCritical Piping Ancillary Equipment','' ,:IA-3021153-000'Plant Drawings:"'CJ t Drawings 3/21/ 1824590-BOF-Pl-25-00001, Rev. I, Balance of Facilities LAW Effluent Process Bldg & LAW Effluent Drain Tank BldgGeneral Arrangement Plan at El. 0' - 0";24590-BOF-Pl-25-00002, Rev. I, Balance of Facilities LAW Effluent Process Bldg & LAW Effluent Drain Tank BldgGeneral Arrangement Sections A, B & C;24590-BOF-MS-V l 7T-000 12, Rev. 0, Process Flow Diagram Direct Feed Effluent Evaporator (System DEP);24590-BOF-MS-V l 7T-000 13, Rev. 0, Process Flow Diagram Direct Feed Concentrate Transfer (System DEP and DVP);24590-BOF-M6-DEP-00002001, Rev. I, P&ID-BOF/EMF Direct Feed LAW EMF Process System Evaporator Feed VesselDEP-VSL-00002;24590-BOF-M6-DEP-00003001, Rev. 1, P&ID-BOF/EMF Direct Feed LAW EMF Process System Evaporator SeparatorDEP-EVAP-00001 ;24590-BOF-M6-DEP-00003002, Rev. 1, P&ID-BOF/EMF Direct Feed LAW EMF Process System Evaporator ReboilerDEP-RBLR-00001 ;24590-BOF-M6-DEP-00003004, Rev. 1, P&ID-BOF/EMF Direct Feed LAW EMF Process System Evaporator CondensersD EP-CON D-00001/2/3;24590-BOF-M6-DEP-00003006, Rev. 1, P&ID-BOF/EMF Direct Feed LAW EMF Process System Reboiler CondensateDEP-VSL-00008 .Page 2 of 17Orano Federal Services LLC

IQRPE Structural Integrity Assessment Report for DFLAW EMF DEPCritical Piping Ancillary EquipmentIA-3021153-000Plant Drawings (cont' d):-. "'00CJ CJDrawings :r. 3/21/1824590-BOF-P3-DEP-GV00005001 , Rev. 0, Balance of Facilities Isometric (Line No. DEP-GV-00005-S l lX-1 );24590-BOF-P3-DEP-PW00006001 , Rev . 0, Balance of Facilities Isometric (Line No. DEP-PW-00006-S 11 X-18);24590-BOF-P3-DEP-PW00006002, Rev . 0, Balance of Facilities Isometric (Line No. DEP-PW-00006-S 11 X-18);24590-BOF-P3-DEP-PW000l 7001 , Rev. 0, Balance of Facilities Isometric (Line No. DEP-PW-00017-Sl 1X-2);24590-BOF-P3-DEP-PW000 17002, Rev. 0, Balance of Facilities Isometric (Line No. DEP-PW-00017-S 11 X-2);24590-BOF-P3-DEP-PW000l 7003, Rev. 0, Balance of Facilities Isometric (Line No. DEP-PW-00017-S 11 X-1.5);24590-BOF-P3-DEP-PW000 1800 I, Rev. 0, Balance of Facilities Isometric (Line No. DEP-PW-00018-S 11 X-2);24590-BOF-P3-DEP-PW000 1900 I , Rev. 0, Balance of Facilities Isometric (Line No. DEP-PW-00019-S 11 X-2);24590-BOF-P3-DEP-PW00020001 , Rev. 0, Balance of Facilities Isometric (Line No. DEP-PW-00020-S 11 X-2);24590-BOF-P3-DEP-PW00020002, Rev. 0, Balance of Facilities Isometric (Line No. DEP-PW-00020-S 11 X-4);24590-BOF-P3-DEP-PW0002 I 00 I, Rev. 0, Balance of Facilities Isometric (Line No. DEP-PW-00021-S 11 X-4);24590-BOF-P3-DEP-PW0002 I 002, Rev. 0, Balance of Facilities Isometric (Line No. DEP-PW-00021-S 11 X-4);24590-BOF-P3-DEP-PW00023001 , Rev. 0, Balance of Facilities Isometric (Line No. DEP-PW-00023-S 11 X-3);24590-BOF-P3-DEP-PW00023002, Rev. 0, Balance of Facilities Isometric (Line No. DEP-PW-00023-S 11 X-3);24590-BOF-P3-DEP-PW00023003 , Rev. 0, Balance of Facilities Isometric (Line No. DEP-PW-00023-S 11 X-1.5);24590-BOF-P3-DEP-PW0002400 I, Rev. 0, Balance of Facilities Isometric (Line No. DEP-PW-00024-S I I X-3);24590-BOF-P3-DEP-PW0002500I , Rev. 0, Balance of Facilities Isometric (Line No. DEP-PW-00025-S 11 X-4);24590-BOF-P3-DEP-PW0003900I , Rev. 0, Balance of Facilities Isometric (Line No. DEP-PW-00039-S 11 X-2);24590-BOF-P3-DEP-ZR0005000 I, Rev. 0, Balance of Facilities Isometric (Line No. DEP-ZR-00050-N 11 F-2);24590-BOF-P3-DEP-ZR0005 I 00 I, Rev. 0, Balance of Facilities Isometric (Line No. DEP-ZR-00051-N 11 F-2);24590-BOF-P3-DEP-ZS0003500 I, Rev. 0, Balance of Facilities Isometric (Line No. DEP-ZS-00035-N 11 F-16);24590-BOF-P3-DEP-ZS00035002, Rev. 0, Balance of Facilities Isometric (Line No. DEP-ZS-00035-Nl lF-16);24590-BOF-P3-DEP-ZS00036001 , Rev. 0, Balance of Facilities Isometric (Line No. DEP-ZS-00036-Nl IF-12);24590-BOF-P3-DEP-ZS00054001, Rev. 0, Balance of Facilities Isometric (Line No. DEP-ZS-00054-N 11 F-12);24590-BOF-P3-DEP-ZS000 17001 , Rev. I, Balance of Facilities Isometric (Line No. DEP-ZS-00017-S 11 C-02);24590-BOF-P3-DEP-ZS000 17002, Rev. 0, Balance of Facilities Isometric (Line No.DEP-ZS-00017-S 11 C-02);24590-BOF-P3-DEP-ZS000 17003, Rev. 0, Balance of Facilities Isometric (Line No. DEP-ZS-00017-S 11 C-02).Page 3 of 17Orano Federal Services LLC

IA-3021153-000IQRPE Structural Integrity Assessment Report for DFLAW EMF DEPCritical Piping Ancillary Equipment.,.Plant Drawings (Cont' d).-- "00 "'Q,I Drawings Q,II,., Engineered Pipe Support Drawings:24590-BOF-DEP-H00187, Rev. 0, Pipe Support Drawing;24590-BOF-DEP-H00 I 88, Rev. 0, Pipe Support Drawing;24590-BOF-DEP-H00l98, Rev. 0, Pipe Support Drawing;24590-BOF-DEP-H00I 99, Rev. 0, Pipe Support Drawing;24590-BOF-DEP-H0I 047, Rev. 0, Pipe Support Drawing;24590-BOF-DEP-H0I 146, Rev. 0, Pipe Support Drawing;24590-BOF-DEP-H0l 147, Rev. 0, Pipe Support Drawing;24590-BOF-DEP-H0l438, Rev. 0, Pipe Support Drawing;24590-BOF-DEP-H0J439, Rev. 0, Pipe Support Drawing;24590-BOF-DEP-H01466, Rev. 0, Pipe Support Drawing;24590-BOF-DEP-H0l640, Rev. 0, Pipe Support Drawing;24590-BOF-DEP-H0J660, Rev. 0, Pipe Support Drawing;24590-BOF-DEP-H0 I 661 , Rev. 0, Pipe Support Drawing;24590-BOF-DEP-H01682, Rev. 0, Pipe Support Drawing;24590-BOF-DEP-H0J686, Rev. 0, Pipe Support Drawing.Q,I 3/21 / 18Standard Pipe Support Drawings:24590-WTP-PH-50-0000100 I, Rev. 4, Standard Pipe Support Details, Axial Stop-Welded (AW);24590-WTP-PH-50-0000300 I, Rev. 4, Standard Pipe Support Details, Cantilever-Cantilever (CC);24590-WTP-PH-50-00012001 , Rev . 7, Standard Pipe Support Details, Guide-U Bolts (GU);24590-WTP-PH-50-00012002, Rev. 6, Standard Pipe Support Details, Guide-U Strap (GU);24590-WTP-PH-50-00012003 , Rev. 4, Standard Pipe Support Details, Guide-U Strap (GU);24590-WTP-PH-50-0001400 I, Rev. I, Standard Pipe Support Details, Rods-Hangers (RH);24590-WTP-PH-50-00014002, Rev. I, Standard Pipe Support Details, Rods-Hangers (RH);24590-WTP-PH-50-00014003, Rev. I, Standard Pipe Support Details, Rods-Hangers (RH);24590-WTP-PH-50-00016001 , Rev. 4, Standard Pipe Support Details, Shoes-Clamped (SC);24590-WTP-PH-50-00019001, Rev. 4, Standard Pipe Support Details, Shoes-Welded (SW);24590-WTP-PH-50-00004001, Rev. 4, Standard Pipe Support Details, Frames- L Shape (FL).Page 4 of 17Orano Federal Services LLC

IA-3021153-000IQRPE Structural Integrity Assessment Report for DFLAW EMF DEPCritical Piping Ancillary Equipment-- MS Line Lists:"O 0c.i. ,,.,, MS LineQ,jc.i ListsQ,ji. Q,j 3/21/1824590-BOF-M6WX-DEP-00002001 ,24590-BOF-M6WX-DEP-00003001 003003 003006,Rev. I, MSRev. I, MSRev. I , MSRev. I , MSRev. I , MSRev. I , MSLine List forLine List forLine List forLine List forLine List forLine List forPage 5 of 1724590-BOF-M6-DEP-0000200 I;24590-BOF-M6-DEP-00003001 3006 .Orano Federal Services LLC

IQRPE Structural Integrity Assessment Report for DFLAW EMF DEPCritical Piping Ancillary EquipmentIA-3021153-000.Information AssessedSource of InformationDrawings listed above under References; " ii Ancillary equipmentdesign standards areappropriate andadequate for theequipment's intendeduse.3/21/1824590-WTP-DC-PS-01-001 , Rev. 9, Pipe Stress Design CriteriaIncluding " Pipe Stress Criteria" and "Span Method Criteria;"ASME B31.3 Code, Process Piping, American Society ofMechanical Engineers;24590-WTP-RPT-ST-01-001 , Rev. 2, RPP-WTP ComplianceWith Uniform Building Code Seismic Design Requirements.Page 6 of 17AssessmentThe Pipe Stress Design Criteria identifiesASME B3 1.3 as the design code for pipingsystems of the WTP. Drawings reviewed showthat the EMF ancillary equipment is ofcommercial quality level (CM) grade and isSeismic Category SC-IV. The Pipe StressDesign Criteria and RPP-WTP Compliancedocuments provide detailed requirements for theSC-IV ancillary equipment design perapplicable codes and standards. The codes andstandards used are acceptable and adequate forthe design of the ancillary equipment for theirintended service.Orano Federal Services LLC

IQRPE Structural Integrity Assessment Report for DFLAW EMF DEPCritical Piping Ancillary EquipmentIA-3021153-000.Information AssessedSource of InformationDrawings listed above under References·,If the ancillaryequipment to be used"0is not built to adesignstandard, the0CJ' - ' design calculationseJl·;;; demonstrate sound engineering principles ofconstruction.-. 3/21/1824590-WTP-DC-PS-01-001 , Rev. 9, Pipe Stress Design Criteriaincluding " Pipe Stress Criteria" and " Span Method Criteria;"ASME B3 1.3 Code, Process Piping, American Society ofMechanical Engineers;24590-WTP-3DP-G04T-00906, Rev. 10, Isometric Drawingsand Associated Calculations;24590-BOF-P6C-DEP-00022, Rev. B, Richland RPP-WTP BOFDFLA W DEP Stress Analysis;24590-BOF-P6C-DEP-00023 , Rev. A, BOF DFLA W DEPStress Analysis;24590-BOF-P6C-DEP-00024, Rev. A, Richland RPP-WTP BOFDFLA W DEP Stress Analysis;24590-BOF-P6C-DEP-00025 , Rev. A, Richland RPP-WTP BOFDFLA W DEP Stress Analysis;24590-WTP-3PS-PH0I-T0002, Rev. 7, EngineeringSpecification for Installation of Pipe Supports;24590-BOF-M6C-DEP-00009, Rev. B, Design Pressure andTemperature Calculations for the EMFDEP/DVP/ AFR/NLD/SHR/SNR Systems;CCN # 303955, EMF DWP Critical Isometrics and AssociatedDocuments to Support Permit Package BOF-010.Page 7 of 17AssessmentThe EMF ancillary equipment is built to designstandards established for the WTP project. ThePipe Stress Design Criteria specifies that pipingis to be designed in accordance with ASMEB3 1.3 Code. The Pipe Stress Design Criteriadocument lists criterion for critical and noncritical piping. All EMF pipelines representedby the isometrics listed in attachment to CCN #303955, are critical. The critical piping requirepipe stress analysis and pipe supportcalculations as stated in the Pipe Stress DesignCriteria and Isometric Drawings and AssociatedCalculations documents. The Stress Analysisdocuments identify the piping materialclassification and their routing between variousplant items in the EMF. The review of thedesign process and controls described in sampledocuments listed in the Source of Informationcolumn provide adequate assurance that DEPancillary equipment are properly designed,installed, and verified to meet the requirementsof the applicable design criteria established forthe project. The review of the aforementioneddocuments also demonstrates that sound designengineering principles are used for the designand construction of the ancillary equipment.Orano Federal Services LLC

IQRPE Structural Integrity Assessment Report for DFLA W EMF DEPCritical Piping Ancillary EquipmentInformation Assessed-- -- "C QCJefl Ancillary equipmenthas adequate strengthat the end of itsdesign life towithstand theoperating pressure,operatingtemperature, thermalexpansion, andseismic loads.Equipment isprotected againstphysical damage andexcessive stress dueto settlement,vibration, expansion,or contraction.3/21/18Source of Information24590-WTP-DC-PS-01-001, Rev. 9, Pipe Stress Design Criteriaincluding " Pipe Stress Criteria" and " Span Method Criteria;"ASME B31.3 Code, Process Piping, American Society ofMechanical Engineers;ASME Boiler and Pressure Vessel Code, Section Ill, Division I,Rules for Construction of Nuclear Power Plant Components,American Society of Mechanical Engineers;UBC 1997, Uniform Building Code;24590-WTP-PER-M-02-002, Rev. 4, Materials for AncillaryEquipment;24590-WTP-GPG-ENG-004, Rev. 3, Design Guide Pipe Stress,Pipe Layout and Support Spacing;24590-WTP-SE-ENS-03-704, Rev. 0, Seismic Evaluation forDesign (Seismic Design of Piping and Pipe Supports).Page 8 of 17IA-3021153-000AssessmentThe Pipe Stress Design Criteria requires the useof the ASME B3 \ .3 Code for process pipingdesign. ASME B3 l .3 requires explicitconsideration of operating pressure, operatingtemperature, thermal expansion/contraction,settlement, vibration, and corrosion allowancein the design of piping. For the seismic designof Seismic Category (SC-IV) ancillaryequipment, applicable sections of ASMESection Ill, Division 1, Appendix F, andsections of UBC 1997 are used to supplementthe requirements of ASME B3 \ .3. Details of theseismic design methods are discussed in thePipe Stress Design Criteria and SeismicEvaluation documents. The aforementioneddocuments, including the Design Guidedocument provide assurance that the ancillaryequipment has adequate strength at the end ofits design life to withstand all anticipated loads.Orano Federal Services LLC

IQRPE Structural Integrity Assessment Report for DFLA W EMF DEPCritical Piping Ancillary EquipmentInformation AssessedSource of InformationIA-3021153-000AssessmentDrawings listed above under References;"'I .0C.C. r,iAncillary equipmentsupports areadequately designed.3/21/1824590-WTP-DC-PS-01-001 , Rev. 9, Pipe Stress Design Criteria including" Pipe Stress Criteria" and " Span Method Criteria;"24590-WTP-PER-PS-02-001 , Rev. 6, Ancillary Equipment Pipe SupportDesign;.ASME 831.3 Code, Process Piping, American Society of MechanicalEngineers;.MSS-SP-58, Pipe Hangers and Supports-Materials, Design, and Manufacture,Manufacturers Standardization Society of the Valve and Fittings Industry, Inc.;AISC Manual of Steel Construction, ASD, 9th Ed ition, American Institute ofSteel Construction ;ASME Boiler and Pressure Vessel (B&PV) Code, Section III, Division I,Rules for Construction of Nuclear Power Plant Co mponents, American Societyof Mechanical Engineers;24590-WTP-VV-PS-01-002, Rev. 10, Verification and Validation TestPlan/Test Report for ME 150 Pipe Support Family of Programs (PCFAPPS);24590-WTP-VV-PS-01-001 , Rev. 6, Verification and Va lidation TestPlan/Test Report for ME IO I, Linear Elast ic Ana lys is o f Pipin g;.24590-WTP-GPG-ENG-005, Rev. 8, Engineering Design Gu ide for PipeSupports;. .24590-WTP-DC-PS-01-002, Rev. 8, Pipe Support Design Criteria;24590-BOF-PHC-DEP-00176, Rev. 0, RPP-WTP Engin eered SupportCalculation for BOF-DEP-H0 1439;24590-BOF-PHC-DEP-00195, Rev. 0, RPP-WTP Engineered SupportCalculation for BOF-DEP-H0l640;24590-BOF-PHC-DEP-00200, Rev. 0, RPP-WTP Engineered SupportCalculation for BOF-DEP-H01660, -H01661 , -H01682 &-H0l686;24590-BOF-PHC-DEP-00201 , Rev. 0, RPP-WTP Engineered SupportCalculation for BOF-DEP-H00187, -H00188, -H00198 & -H00199;24590-BOF-PHC-DEP-00202, Rev. 0, RPP-WTP Engineered SupportCalculation for BOF-DEP-H0l 146 and -H0l 147;24590-WTP-PHC-P50T-00002, Rev. I, Justification for the use of StandardSupports for RPP-WTP-Project;.24590-WTP-3DP-G04T-00906, Rev. 10, Isometric Drawings and AssociatedCalculations;24590-WTP-PHC-PS0-0000 1, Rev. I, RPP/WTP Support Standards.CCN # 303955, EMF DWP Critical Isometrics and Associated Documents toSupport Permit Package BOF-010.Page 9 of 17The Pipe Support Design Criteria document considers allloadings identified in ASME 831.3 including MSS-SP-58and AISC Manual and also utili zes ASME B&PV Code,Section Ill, Division I, and Appendix F, to supplement therequirements of ASME 831 .3 for design of Seismic .Category (SC-JV) pipe supports. The Pipe Stress Desi Criteria document li sts criterion for critical and non-criticalpiping. All EMF pipelines represented by the isometricslisted in attachment to CCN # 303955 are critical,therefore, formal analysis of pipe stress and pipe supportcalculations are required for them, as stated in the PipeStress Design Criteria and Isometric Drawings andAssociated Calculations documents. Supports spacing anddetails of the seismic design methodology are di sc ussed inthe Pipe Support Design Criteria document. Examples oftypical ancillary equipme nt supports are shown in theAncillary Equipment Pipe Support Design document.Design/Analysis is by manual calculation and/or approvedcomputer programs th at have been verified and validated.Ancillary equipment supports are to be designed to allow aminimum of heat to be transferred to the buildingstructures such th at the temperature of the buildingstructures does not exceed 150 F for concrete and steel,except for sleeve penetrations where th tempe ature ayrise up to 200 F. Review of the isometric drawings, pipestress analyses, standard pipe support drawings, engineeredpipe support calculations and drawings, and of the esignprocess and controls described in Pipe Support DesignCriteria and Isometric Drawings and AssociatedCalculations documents provides sufficient assurance thatDEP ancillary equipment; piping and supports areadequately designed, installed, and verified to meet therequirements of the applicable design criteria establishedfor the project.Orano Federal Services LLC

IQRPE Structural Integrity Assessment Report for DFLAW EMF DEPCritical Piping Ancillary EquipmentInformation Assessed"'- The system willwithstand the effects of frost heave.-Source of InformationDrawings listed above under References·'1:11"O0 "'- Seams andconnections are adequately designed.( ,I 0u3/21/1824590-WTP-DC-ST-01-001 , Rev. 13, Structural DesignCriteria. 4590 W:.P DC-PS-01-001, Rev. 9, Pipe Stress Design Criteriamcludmg Pipe Stress Criteria" and " Span Method Criteria;"ASME B3 1.3 Code, Process Piping, American Society ofMechanical Engineers;AS E B 16.5, Piping Flanges and Flanged Fittings, AmericanSociety of Mechanical Engineers;ASM Boiler and Pressure Vessel Code (B&PV), Section IX,Welding and Brazmg Qualifications, American Society ofMechanical Engineers.Page 10 of 17IA-3021153-000AssessmentThe Structural Design Criteria requires that alloutdoor equipment structural foundations shallextend into the surrounding soil below the 30"frost line to preclude frost heave. The DEPancillary equipment system considered in thisassessment are located inside the DFLA Wfacility rooms, at above ground floor slabelevation, as shown on the drawings therefore''they are not subjected to any frost heave effects.The Pipe Stress Design Criteria specifies theASME B31.3 Process Piping design code forthe piping systems. Welding is to be performedin accordance with the requirements of ASMEB31.3 and the ASME B&PV Code, Section IX.ASME B 16.5 is specified for flange designs.These are appropriate and adequate codes andstandards for design and fabrication including,connections and seams of the DEP systemancillary equipment.Orano Federal Services LLC

IQRPE Structural Integrity Assessment Report for DFLAW EMF DEPCritical Piping Ancillary EquipmentInformation Assessed- -"'Characteristics of the·c:" ' waste to be stored ortreated have been(Jco:identified (ignitable,I.co:reactive,toxic,u- specific gravity, "'co: vapor pressure, flash point, temperature).-3/21/18Source of Information24590-BOF-3ZD-25-0000I , Rev. I, WTP Direct Low ActivityWaste (DFLA W) Facility and System Design Descriptions;24590-WTP-PER-PR-03-001 , Rev. 2, Prevention of HydrogenAccumulation in WTP Tank Systems and MiscellaneousTreatment Unit Systems;DE 16NWP-003, US DOE Non-Radioactive Air Emi ssionsNotice of Construction Approval Order, Conditions andRestrictions.Page 11 of 17IA-3021153-000AssessmentThe DFLA W Facility System DesignDescriptions, Prevention of HydrogenAccumulation in WTP Tank Systemsdocuments, indicate that flammable or explosiveconcentrations of hydrogen are not expected inthe DFLA W facility systems ancillaryequipment. Similarly, the USDOE ApprovalOrder No. DE I 6NWP-003 addressescompliance to conditions and restrictions set forthe non-radioactive toxic air pollutantsemissions from the EMF. The above mentioneddocuments appropriately identify thecharacteristic of the waste to be handled by theDEP system.Orano Federal Services LLC

IQRPE Structural Integrity Assessment Report for DFLA W EMF DEPCritical Piping Ancillary EquipmentIA-3021153-000-Information Assessed-. "OQ '-',,., Ancillary equipment ,,., is designed to handle -·t:the wastes with thecharacteristicscsI.cs defined above and- u any treatment ,,., reagents. cs 3/21/18Source of InformationAssessment24590-WTP-PER-M-02-002, Rev. 4, Materials for AncillaryEquipment.24590-BOF-P6C-DEP-00022, Rev. B, Richland RPP-WTP BOFDFLA W DEP Stress Analysis;24590-BOF-P6C-DEP-00023, Rev. A, BOF DFLA W DEPStress Analysis;24590-BOF-P6C-DEP-00024, Rev. A, Richland RPP-WTP BOFDFLA W DEP Stress Analysis;24590-BOF-P6C-DEP-00025 , Rev. A, Richland RPP-WTP BOFDFLA W DEP Stress Analysis;24950-WTP-PER-PL-02-00 I, Rev. 8, Piping Material ClassDescription;24590-CM-POA-MEVV-00003-05-00001, Rev. 00C, DEPEvaporator Primary Condenser;24590-CM-POA-MEVV-00003-05-00002, Rev. 00D, DEPEvaporator Separator;24590-CM-POA-MEVV-00003-05-00003 , Rev. 00E, DEPEvaporator Reboiler;24590-CM-POA-ME00-00003-04-00001 , Rev. 00C, DEPEvaporator After-Condenser;24590-CM-POA-ME00-00003-04-00004, Rev. 00C, DEPEvaporator Inter-Condenser.The Materials for Ancillary Equipmentdocument specifies that ancillary equipmentmaterials that contact the waste are to be equalto or better than those of the upstream sourcevessels or units. Review of documents listed inthe Source of Information column reveals thatthe materials of the source plant items and thatof the downstream ancillary equipment meet therequirements stated in the Materials forAncillary Equipment document. Therefore,selection of proper material for the DEP pipingand equipment ensures that the ancillaryequipment is appropriately designed to handlethe waste without addition of any treatmentreagents.Page 12 of 17Orano Federal Services LLC

IQRPE Structural Integrity Assessment Report for DFLAW EMF DEPCritical Piping Ancillary EquipmentInformation AssessedThe pH range of thewaste, wastetemperature, and thecorrosion behavior ofthe structuralmaterials areadequately addressed .Anci llary equipmentmaterial andprotective coatingsensure the ancillary:.6-.::: equipment structure Q.,is adequatelyprotectedfrom the0u corrosive effects ofthe waste stream andexternalenvironments. Theprotection issufficient to ensurethe equipment willnot leak or fail for thedesign life of thesystem.i 3/21/18Source of Information24590-WTP-DB-ENG-01-001 , Rev. 6, Basis of Design;24590-WTP-PER-M-02-002, Rev. 4, Materials for AncillaryEquipment.Page 13 of 17IA-3021153-000AssessmentThe Basis of Design document identifies aservice design life of 40 years for the anc illaryequipment. Detailed materials selection withcorrosion evaluations are conducted for eachvesse l in the EMF faci lity during process designto assure a 40-year service life. The Materialsfor Ancillary Equipment document requires thatthe material selection and corrosion/erosional lowances for ancillary equipment in contactwith the waste will be equal to or better than thematerial and corrosion allowance of the wastesource vessel. The evaluation in the WasteCharacteristics section above discusses thereview of the sources plant units materials andthat of the downstream piping equipment with aconclusion that the EMF anc illary equipmentwill provide the expected design service lifesame as provided by the associated vessels.Orano Federal Services LLC

IQRPE Structural Integrity Assessment Report for DFLAW EMF DEPCritical Piping Ancillary EquipmentIA-3021153-000·,Information AssessedSource of InformationDrawings listed above under References; C,I Corrosion allowance . Q·;;Q''-is adequate for theintended service lifeof the ancillaryequipment.Qu3/21/18ASME B31.3 Code, Process Piping, American Society ofMechanical Engineers;24590-WTP-DC-PS-01-001, Rev. 9, Pipe Stress Design Criteriaincluding " Pipe Stress Criteria" and "Span Method Criteria;"24590-WTP-DB-ENG-01-001 , Rev. 6, Basis of Design;24590-WTP-PER-M-02-002, Rev. 4, Materials for AncillaryEquipment;24950-WTP-PER-PL-02-00 I, Rev. 8, Piping Material ClassDescription.24590-CM-POA-MEVV-00003 -05-0000 I, Rev. 00C, DEPEvaporator Primary Condenser;24590-CM-POA-M EVV-00003-05-00002, Rev. 00D, DEPEvaporator Separator;24590-CM-POA-MEVV-00003-05-00003, Rev. 00E, DEPEvaporator Reboiler;24590-CM-POA-M E00-00003-04-0000 I, Rev. 00C, DEPEvaporator After-Condenser;24590-CM-POA-ME00-00003-04-00004, Rev. 00C, DEPEvaporator Inter-Condenser.Page 14 of 17AssessmentASME B31 .3 is the design code for the WTPpiping. Consideration of corrosion, includingcorrosion allowance, is a mandatoryrequirement of ASME B31.3 and isappropriately supplemented in the Pipe StressDesign Criteria document. A required servicelife of 40 years is identified in the Basis ofDesign for ancillary equipment. Detailedmaterials selection (corrosion) evaluations areconducted for each vesse l in the EMF facilityduring process design to ensure a 40-yearservice life. The Materials for Anci llaryEquipment document states that the ancillaryequipment downstream of a source vessel is tobe constructed of the same (or better) materialas the vessel and with the same or greatercorrosion allowance. However, if down streamancillary equipment warrants a differentmaterial or corrosion allowance, approval fromthe Material Engineering Technology (MET)group is required. Corrosion/Erosion allowancesare listed for the ancillary equipment (eachpiping class and associated valves, fittings, etc.)in the Piping Material Class Descriptiondocument. Review of the documents listed inthe " Source of Information" column, revealsthat the ancillary equipment materials withappropriate corrosion allowance are adequatefor their intended service life.Orano Federal Services LLC

IQRPE Structural Integrity Assessment Report for DFLA W EMF DEP Critical Piping Ancillary Equipment IA-3021153-000 Plant Drawings (cont'd): 24590-BOF-P3-DEP-GV00005001, Rev. 0, Balance of Facilities Isometric (Line No. DEP-GV-00005-S l lX-1 );