Transcription

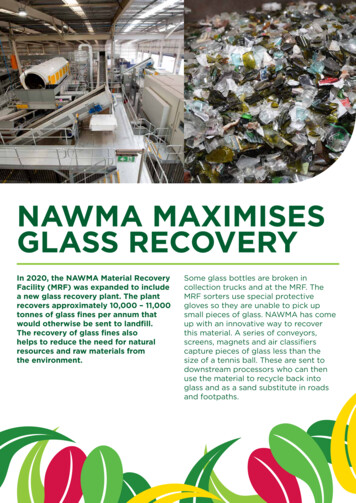

NAWMA MAXIMISESGLASS RECOVERYIn 2020, the NAWMA Material RecoveryFacility (MRF) was expanded to includea new glass recovery plant. The plantrecovers approximately 10,000 – 11,000tonnes of glass fines per annum thatwould otherwise be sent to landfill.The recovery of glass fines alsohelps to reduce the need for naturalresources and raw materials fromthe environment.Some glass bottles are broken incollection trucks and at the MRF. TheMRF sorters use special protectivegloves so they are unable to pick upsmall pieces of glass. NAWMA has comeup with an innovative way to recoverthis material. A series of conveyors,screens, magnets and air classifierscapture pieces of glass less than thesize of a tennis ball. These are sent todownstream processors who can thenuse the material to recycle back intoglass and as a sand substitute in roadsand footpaths.

NAWMA MINIMISESGLASS WASTEIn 2020, the NAWMA Material RecoveryFacility (MRF) expanded to include anew glass recovery plant. The plantrecovers approximately 10 000 – 11 000tonnes of glass fines per annum thatwould otherwise be sent to landfill.The recovery of glass fines alsohelps to reduce the need of naturalresources and raw materials fromthe environment.Some glass bottles are broken incollection trucks and at the MRF. TheMRF sorters use special protectivegloves so they are unable to pick uptiny pieces of glass. NAWMA has comeup with an innovative way to recoverthis material. A series of conveyors,screens, magnets and air classifierscapture pieces of glass less than asize of a tennis ball. These are sent todownstream processors who then usethe material to recycle back into glassand as a sand substitute in roads andfootpaths.

POWERING THE MRFThe NAWMA Material Recovery Facility(MRF) processes around 53,000 tonnesof household recyclables collectedfrom the kerbside each year. This isa large operation requiring 50 staffto work 18 hours over two shifts/day.A lot of specialised equipment is alsoused. To offset some of the electricityuse and associated greenhouse gasemissions, we have installed a 100kWSolarcare solar system on the MRF roofwhich is combined with a 250kVArpower factor correction system(to enhance and improve the efficiencyof the motorised equipment).Our aim is to generate more than140,000 kWh of electricity and reduceour carbon footprint by around 73tonnes of CO2e each year. We’re alsolooking forward to the ongoing financialsavings – predicted to be approximately 1.9 million over the next twentyfive years.Environmental benefitsof installation after firstthree monthsCO2 Emission Saved15,902.61 kgEquivalent Trees Planted53.14

INNOVATIVE BALEFILLMANAGEMENTEach year around 86,000 tonnes ofhousehold and commercial waste isbaled at NAWMA’s Edinburgh NorthWaste Processing Facility. The bales,which each weigh around 1.5 tonnes,are then transported to the UleyburyBalefill and Renewable Energy Park,also owned and operated by NAWMA.In 2019 this best-practice balefilloperation was awarded a nationalexcellence award for its innovation andadherence to protecting the surroundingenvironment. For at least 30 years afterclosure of the site, NAWMA will continueto monitor and/or manage: Landfill gas Ground water Surface water Revegetatedareas LeachateIn an Australia-first, a combined solar/landfill gas renewable energy facilityhas also been developed at the site.Operational since October 2017,the facility pumps more than 11,000MWh/year into the local power grid –enough to supply the power needs ofaround 1,900 homes.11,000 MWh/yearto local power gridPowers1,900 homes

MAX-AI AQCTECHNOLOGYHEADING OUR WAYIn February 2019, NAWMA secured 1.5 million through Green IndustriesSA’s Infrastructure Investment grantsto implement a series of exciting newprojects. One of these is the purchaseof a paper and plastic detectingMax-Ai AQC (Autonomous QualityControl) robot.Using artificially intelligent roboticsorting will help NAWMA identify andrecover more recyclables on the MRFsort lines. Importantly, the robot won’treplace any MRF staff, it will workalongside them, enhancing the recoveryof reusable material in readiness forsecondary reprocessing. The robotis scheduled to be operational inFebruary 2020.Through deep learning technology,the Max-AI robot employs bothmulti-layered neural networks and avision system to see and identify objectssimilarly to the way a person does.It has the capability to pick 60 unitsper minute.

SOLAR AND POWER FACTORCORRECTION SYSTEM ROOFINSTALLATIONThe NAWMA Material Recovery Facility(MRF) processes around 53,000 tonnes ofhousehold recyclables collected from thekerbside each year. This is a large operationrequiring 50 staff to work 18 hours over twoshifts/day. A lot of specialised equipment isalso used. To offset some of the electricity useand associated greenhouse gas emissions, wehave installed a 100kW Solarcare solar systemon the MRF roof which is combined witha 250kVAr power factor correction system(to enhance and improve the efficiency ofthe motorised equipment).Our aim is to generate more than 140,000kWh of electricity and reduce our carbonfootprint by around 73 tonnes of CO2e eachyear. We’re also looking forward to theongoing financial savings – predicted tobe approximately 1.9 million over the nexttwenty-five years.ENVIRONMENTAL BENEFITSOF INSTALLATION AFTERFIRST THREE MONTHSCO2 Emission Saved15,902.61 kgEquivalent Trees Planted53.14

SOLAR AND POWER FACTORCORRECTION SYSTEM ROOFINSTALLATIONThe NAWMA Material Recovery Facility(MRF) processes around 53,000 tonnes ofhousehold recyclables collected from thekerbside each year. This is a large operationrequiring 50 staff to work 18 hours over twoshifts/day. A lot of specialised equipment isalso used. To offset some of the electricity useand associated greenhouse gas emissions, wehave installed a 100kW Solarcare solar systemon the MRF roof which is combined witha 250kVAr power factor correction system(to enhance and improve the efficiency ofthe motorised equipment).Our aim is to generate more than 140,000kWh of electricity and reduce our carbonfootprint by around 73 tonnes of CO2e eachyear. We’re also looking forward to theongoing financial savings – predicted tobe approximately 1.9 million over the nexttwenty-five years.ENVIRONMENTAL BENEFITSOF INSTALLATION AFTERFIRST THREE MONTHSCO2 Emission Saved15,902.61 kgEquivalent Trees Planted53.14

tiny pieces of glass. NAWMA has come up with an innovative way to recover this material. A series of conveyors, screens, magnets and air classifiers capture pieces of glass less than a size of a tennis ball. These are sent to downstream processors who then use the material to recycle back in