Transcription

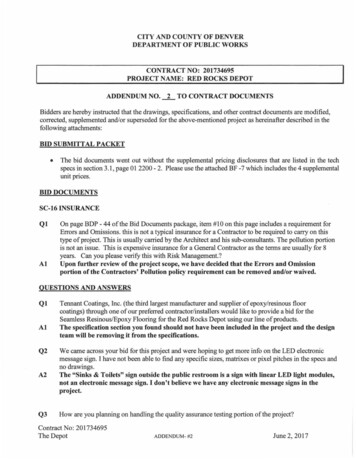

CITY AND COUNTY OF DENVERDEPARTMENT OF PUBLIC WORKSCONTRACT NO: 201734695PROJECT NAME: RED ROCKS DEPOTADDENDUM NO. 2 TO CONTRACT DOCUMENTSBidders are hereby instructed that the drawings, specifications, and other contract documents are modified,corrected, supplemented and/or superseded for the above-mentioned project as hereinafter described in thefollowing attachments:BID SUBMITTAL PACKET The bid documents went out without the supplemental pricing disclosures that are listed in the techspecs in section 3.1, page 01 2200 - 2. Please use the attached BF -7 which includes the 4 supplementalunit prices.BID DOCUMENTSSC-16 INSURANCEQlAlOn page BDP - 44 of the Bid Documents package, item #10 on this page includes a requirement forErrors and Omissions. this is not a typical insurance for a Contractor to be required to carry on thistype of project. This is usually carried by the Architect and his sub-consultants. The pollution portionis not an issue. This is expensive insurance for a General Contractor as the terms are usually for 8years. Can you please verify this with Risk Management.?Upon further review of the project scope, we have decided that the Errors and Omissionportion of the Contractors' Pollution policy requirement can be removed and/or waived.QUESTIONS AND ANSWERSQlAlQ2A2Q3Tennant Coatings, Inc. (the third largest manufacturer and supplier of epoxy/resinous floorcoatings) through one of our preferred contractor/installers would like to provide a bid for theSeamless Resinous/Epoxy Flooring for the Red Rocks Depot using our line of products.The specification section you found should not have been included in the project and the designteam will be removing it from the specifications.We came across your bid for this project and were hoping to get more info on the LED electronicmessage sign. I have not been able to find any specific sizes, matrixes or pixel pitches in the specs andno drawings.The "Sinks & Toilets" sign outside the public restroom is a sign with linear LED light modules,not an electronic message sign. I don't believe we have any electronic message signs in theproject.How are you planning on handling the quality assurance testing portion of the project?Contract No: 201734695The DepotADDENDUM- #2June 2, 2017

A3Facilities Capital Projects Management will be providing inspection/observation for the projectfrom our staff. For the QA testing our standard for this size project is to reach out to ourGeotechnical On-Calls directly.Q4A4The document lists the LED sign specs is on page 20.The design team informed us that it looks like the specification section was incorrect and theentire Daktronics section is to be removed. The correct specification section is attached to thisaddendum.QSASWill they need ADA signage?Yes, we do want ADA signage on the two ADA bathroom stalls, here is the requirement on thesignage: 9"x6" restroom sign on durable 1/8" substrate with tactile top layer featuring alarge International Symbol of Accessibility. 1" tall lettering and graphics shall be highcontrast, tactile and have grade-2 braille. Mounted per manufacturer's instructions withfoam tape. Basis of design: https://www.compliancesigns.com/RRE-35 l 93-White on Blue.shtmlSee attached signage specification.Q6The specifications call out a Daktronics EMC but I do not see it on the plans, can you point me in theright direction?Reference answer A4 as provided above.A6Q7A7Regarding Spec Section 10 14 00 Signage, specifically Section 1.24 and 1.26: Section 1.24 aboutadditional work - none of that makes any sense to me. Can you help me out there?Reference answer A4 as provided above.Q8A8What is the anticipated construction schedule?The anticipated NTP is September 4, 2017 with construction duration lasting 280 calendardays.Q9The spec mentions that "other" products besides the basis of design are allowed to bid. Do we need tosubmit a substitution request? If yes, to whom?Yes, please send in a substitution request directly to Diane. This will be the best way toconfirm that the proposed product meets/exceeds the requirements as specified.A9QlOAlODo you have a list of bidding GC' s?A list of GC's who attended the pre-bid meeting is provided on work4denver.QllAllIs there any signage we could bid on? I didn' t see much on the plans when looking on blue book.The signage includes but is not limited to the large "sinks and toilets" sign on the exterior ofthe bathrooms, ADA bathroom signage per the earlier response, gender neutral bathroomsignage and no trespassing signs per plans.Q12A12Please confirm that all work referenced in "red rocks depot utilities construction documentpackage" is by other.Confirmed, it is not included in this project scope.Q13A13Please confirm that all low voltage, security, and access control work is by Owner.Confirmed.Contract No: 201734695The DepotADDENDUM- #2June 2, 2017

Q14A14Please confirm whether PVC roofing (075419) or hot fluid applied rubberized asphaltwaterproofing (071413) is to be used on the roof deck below the vegetated roof system.071413 as 1.2-B-1 lists vegetated roofs as a related section.QlSAlSPlease provide specifications for the geo-foam fill shown in several details on sheet A501 .The geo foam fill is a component of the vegetated roof assembly. The basis of design isindicated in 3295002.2-A-1-a as American Hydrotech Intensive Green Roof.Q16A16Please provide clarification on locations heat tape will be required (spec 220533).Refer to l/P102 & 1/EPlOO & Branch Panel LA schedule on E-950.Ql 7Al 7Please confirm that wall type "WT' is not used.W7 is the doug fir wall that the leader is pointing to on A701 that separates the common spacefrom the stalls. Unfortunately, it looks as though it is calling out the north wall of therestroom. The north wall of the restroom is actually W4 as called out on A401.Q18There is l " THK FIRE STOPPING shown on B l /S502 but there is no fire stopping shown onarchitectural drawings or a specification for fire stopping products. Please show locations where 1"THK FIRE STOPPING is required and provide specifications for acceptable products.A18Q19A19Q20A20Q21A21a. Also, the detail B l/S502 is not to scale and does not show dimensions for how far fire stoppingis to continue.Structural mistakenly assumed rated walls, the purpose of the 1" gap is to allow the beam tosettle without loading wall. A standard backer rod and flexible sealant to prevent drafts issufficient.The table of contents lists specifications sections 050513 - Shop Applied Metal Finishes and057300 - Decorative Metal Railings but there is no specification section in the project manual.Please provide specifications or can these be removed from table of contents.The shop applied metal finishes was meant to be removed. Decorative metal railings aremeant to cover a possible railing at the roof that could be added in the future. If the ownerdecides to add that railing in the future that section will be issued.Specification section 054000 - Cold Metal Framing is included in the project manual but there areno wall types on A601 that call for cold metal framing. Please confirm if there is no cold metalframing as a part of this project and if so can this specification section be deleted from the projectmanual.Metal framing can be deleted from the project manual.Per specification section 012200 - Unit Price, Unit Price #4: Miscellaneous and Structural Steel, isfor specifications sections 051200 - Structural Steel Framing and 055000 - Metal Fabrications.Specification Section 051200 - Structural Steel Framing is not part of the project specifications,please provide this specification section or can this specification section be deleted from unitpricing description.Spec section 051200 is not included in the project specifications. However, Structural SteelFraming is covered sufficiently for this project in Metal Fabrications spec section 055000, 235Miscellaneous Framing and Supports.Contract No: 201734695The DepotADDENDUM- #2June 2, 2017

Q22A22Q23A23Q24A24Q25A25Q26Per specification section 055000 - Metal Fabrications the bollards are to be Schedule 80 hot-dippedsteel pipe, but the plans call our Cor-Ten Bollards. Please confirm which bollards are to beprovided.Corten should be provided. Additionally Cl/G109 calls for precast, which is also incorrectand should be disregarded.Please confirm LEED Submittal for specification section 081113 - Hollow Metal Doors and Framesis required.There are no LEED requirements on this project. All references to LEED may bedisregarded.Per specification section 093013 - Ceramic Tiling requires either a five-star member of the NationalTile Contractors Association or a Trowel of Excellence member of the Tile Contractors'Association of North America. Please confirm this is requirement for the tile installer as there aretwo installers within 500 miles of the project with either of these certifications.Tile is consistently one of the most problematic trades besieged by poorly skilled labor. Someguarantee of quality is recommended. "Advanced Certifications for Tile Installers" (ACT)would be an acceptable alternate certification.Specification section 096723 - Resinous Flooring is part of the project manual but no locations areindicated on the plans. Please indicate locations on plans or can this specification section be deletedproject manual.Sealed polished concrete provides adequate protection against urine at the restroom, resinmay be deleted from the project.Per the finish schedule on A402 the North Wall of Room A-110 Restroom calls for the Material tobe concrete but has the Finish as W03 Sandstone Veneer and the East Wall calls for the Material tobe stone and has the Finish as W03. Please confirm which is correct.a.A26Q27A27Q28A28Also, is the W03 Sandstone Veneer to be the same material as the exterior DimensionalSawn Sandstone Veneer or per Specification Section 093033 - Stone Tiling?North and east wall are W4: Concrete with sand stone per the wall types.Per specification section 101400 - Signage calls out for a LED Digital Displays but there are noneindicated on the plans. Please provide locations for these displays or can this section of thespecification section be deleted?The spec incorrectly calls for a Daktronics Galaxy GS6 which not in project. Signage shouldbe fabricated per the drawing sheets. Keynote 4 of the signage drawings does call out a LEDsign lighter which should be selected and provided as part of sign design and fabrication.Specification Section 107315 - Metal Screen Awnings is provide as part of the project manual butthere are none indicated on the plans. Please provide locations for these awnings or can thespecification section be deleted?Metal awnings are called out in note #3 on Al02 and A201 and detailed on B3/A505. Specsection 107315 can be deleted.Contract No: 201734695The DepotADDENDUM- #2June 2, 2017

Q29A29Q30A30Q31A31Q32A32Specification Section 02810 - Irrigation System refers to Division 32 Section "Automatic IrrigationControllers" but this division section is not included in the project manual. Please provide thisdivision section or can the line be deleted from the specification section.See Irrigation Spec 328400, section 2.6. Automatic Control System.Per Note #2 on A201 there are Bi-Fold Overhead Doors with Cor-Ten Cladding. There is nospecification section for Bi-Fold Overhead doors, can one be provided.Renlita S-2000. Confirm the weight of the corten with mnfr, the S-3000 may be needed.Per specification section the Cor-Ten Steel is to be 22 Gage or 1/32", but detail Al/A507 calls for118" Corten Panel. Please confirm which is to be provided.Gutters should be 18 GA. Where corten is perforated or mounted via standoffs it needs to be3116" to have adequate thickness and rigidity.Please provide installation guidelines or instructions as Corten doesn' t provide installationinstructions for their Weathering Steel Siding products.Where Corten held off face of wall (such as B2/A503) the suggested method is Z-clip standoffs,but the "installation guides" section of http: I / www. metalsales. us. com offers avariety of installation methods. These 118" perforated panels are intended to be a customproduct, and the supplier should provide an appropriate attachment method that meets thisdesign intent. For attachment at the overhead bi-fold door the attachment method needs to becoordinated with the door manufacturer.Q33A33How long are the soil nails?The soil nail wall design shall be submitted by the contractor as described in the contractspecifications. See Section 315000, Part 1.4 and Part 1.5.Q34What diameter are the soil nails #6 #8 or different? It specifies epoxy or galvanized just not the barsize.The soil nail wall design shall be submitted by the contractor as described in the contractspecifications. See Section 315000, Part 1.4 and Part 1.5.A34Q35A35Last what diameter is the soil nail drill hole.The soil nail wall design shall be submitted by the contractor as described in the contractspecifications. See Section 315000, Part 1.4 and Part 1.5.Q36The Specification 084113 refers to provide Oldcastle Storefront HP-225 that no-longer exists andthe details show curtain-wall.HP-225 is still on their website. It appears to be interchangeable with HP-175 which is simplya narrower version, which is acceptable. Due to the thickness of the wall assembly we doneed the 1-3/4" x 6-3/4" version to be used.A36Q37A37The specifications 088000 states impact resistance for large missile for glazing located within 30feet of the grade, which all the windows do fall within this criteria.This requirement may be disregarded.Q38A38Do we know what system they want use?Please reference answer A36 above.Q39 Are the windows to be designed for large missile impact?Contract No: 201734695The DepotADDENDUM- #2June 2, 2017

A39This requirement may be disregarded.Q40If storefront and impact can EFCO' s S-526 impact storefront framing system for 1-5/16" glazing beused in bid?Please reference answer A36 ere is also a note on the drawings for seismic loads which is not mentioned in the specifications084113 or 088000, so do these frames also need to meet this seismic in the General Notes on thedrawing sheet SOO 1?We (the structural engineer) are required to include the seismic design information in ourgeneral notes, but seismic design is not required for the storefront system. Wind will suffice.Are the use of threaded ends/form savers be used at locations where the perpendicular concretewalls come off of the single sided walls for the continuation of rebar? As rebar projecting from thesingle sided walls will not work with the large single sided wall gang forms?Form savers are acceptable for this type of installation to preserve forming systems.Does the concrete beam along gridline 1 at ceiling height (Al/S302) follow the sloping of the roofpitch, or does it run flat on the bottom? If the beam slopes this will cause major issues with thesingle sided form work systems and rebar installation. If the beam is flat on the bottom, additionalconcrete will need to be placed in the beam and additional shoring accounted for unless this beamsteps in multiple locations.The intent is for the beam to slope with the roof slab. If this is not feasible with the proposedforming systems, it is acceptable to form the bottom of this beam flat. To limit the amount ofadditional concrete, step beam at intersecting beams/walls at grids B, C, D, and E. Locatesteps on roof high side of intersecting beams at these locations. Include step locations andassociated rebar layout in shop drawings for review.Will the final concrete roof decking structurally support the use of a single sided wall form systemalong gridline 1 or will the roof decking need to be temporarily shored for the parapet wallconstruction?Temporarily shored.Per details Al /S302, A3/S302, B2/S302, A2/S303, A4/S303, Bl /S303, A3/S304, Cl /S304 requires#4 x 3'-0" @ 12' O.C. where the SOG is keyed into the foundation walls. Will the use of threadedends/form savers be allowed as this detail will damage any type of gang form system?Yes, this is acceptable.Has the shoring wall design accounted for concrete pump trucks and crane surcharging behind thetop of the wall prior to the foundation walls being placed?The shoring wall design must be done by the contractor or subcontractor per contractspecifications. See Section 315000, Part 1.4 and Part 1.5. Section 315000 Part 2.1 identifies theperformance requirements for design of the wall and prequalification by thecontractor/subcontractor. Construction loads are part of the design load requirements.When aligning the exact location of the shoring wall, how much horizontal wall movement can thecontractor expect to see? If the wall moves too much and encroaches on the permanent foundationwall and rebar, is there going to be an acceptable variance in foundation wall thickness? Likewise,if the temporary soil nail wall doesn't move as much as expected, who is to carry the overrun onshotcrete or concrete, or will this be carried as an alternate?Contract No: 201734695The DepotADDENDUM- #2June 2, 2017

A47The shoring wall design must be done by the contractor or subcontractor per contractspecifications. See Section 31SOOO, Part 1.4 and Part 1.S. DOR can't assign responsibility foroverrun.Q48Will temporary rebar supports be allowed to penetrate the waterproofing systems along the singlesided wall to support the massive rebar mats that will reinforce the permanent foundation wall?No.A48Q49A49Will a natural gas service be provided for temp. heat for gas heaters over the winter? And if so, isthe consumption the responsibility of the contractor.No, temporary gas is not available at the site.QSOASOOn large wall pours, what is the longest pour length that will be acceptable?7S feet per concrete notes on SOOl.QSlPlease confirm if all vertical construction joints in the single-sided walls and walls that getbackfilled require water stop?Yes all below grade walls, and exterior walls (exposed to weather) require waterstops inconstruction joints.A51Q52AS2Per Spec. Section 033000-1.6 E. 2. All exposed faces of concrete are to be board formed includingparapets. Please confirm if this is only intended for exterior exposed concrete?Exterior: All exterior exposed faces of concrete are board formed. Top and back sideof parapets do not need to be board formed.Interior: Only the walls of Parking Bay 108 and exposed concrete walls in the restroomneed to be board formed.QS3A53Would it be acceptable to use the hot-applied roofing that we are using on the majority of theproject on the PVC roof to avoid using separate crews?Hydrotech hot-applied is not designed to be exposed, however their rock ballasted IRMAassembly would be an acceptable substitution provided all components of the assembly areper Hydrotech spec.Q54AS4Should we bid to expect Rock Drilling?Review soils report to determine.Q55ASSCan you provide a copy of the soils report that is referenced in the drawings?See attachmentQS6AS6Can we use the existing lot for lay down/staging area?The concert season ends on October 31, 2017, before the end of season the laydown/stagingarea will be minimal to maintain parking and aisles. After the concert season, the stagingspace can be expanded if needed. See Glll-G113 for anticipated staging space. All workerscan park in the lot, although it will remain open to the public throughout construction. Also,see note 19 sheet GllO and sheet G112.QS7The project manual lists Division 9 - 096723 " Resinous Flooring", but on drawing A402 "FinishPlan" it indicates "Sealed Concrete" or "Polished Concrete" for all rooms I Finish Legend FloorFinishes FOl & F02. Please state what room(s) are to receive the 096723 Resinous Flooring.Contract No: 201734695ADDENDUM- #2June 2, 2017The Depot

A57Sealed polished concrete provides adequate protection against urine at the restroom, resinmay be deleted from the project.Q58I

A27 The spec incorrectly calls for a Daktronics Galaxy GS6 which not in project. Signage should be fabricated per the drawing sheets. Keynote 4 of the signage drawings does call out a LED sign lighter which should be sele