Transcription

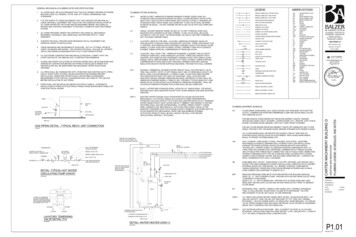

GENERAL MECHANICAL & PLUMBING NOTES AND SPECFICIATIONS:PLUMBING FIXTURE SCHEDULE:IT IS THE INTENT OF THESE DOCUMENTS THAT THE CONTRACTOR PROVIDE ALLLABOR, MATERIAL, EQUIPMENT AND TOOLS FOR THE COMPLETE INSTALLATION OFALL WORK SHOWN ON THE PLANS AND/OR DESCRIBED HEREIN, INCLUDING ALLDEVISES AND CONTROLS REQUIRED TO PROVIDE A COMPLETE AND FUNCTIONINGSYSTEM.BRANCH CONNECTION - TOP OF MAINPIPE DOWN OR PIPE FROM BELOWPIPE UP OR PIPE FROM ABOVEDIRECTION OF FLOWDOMESTIC COLD WATERDOMESTIC HOT WATERU-13.BRANCH CONNECTION - SIDE OF MAINWATER CLOSET: AMERICAN STANDARD MADERA FLOWISE, MODEL #3461.001,VITREOUS CHINA ELONGATED SIPHON JET BOWL, FLOOR MOUNTED, WHITE EXTRAHEAVY DUTY SOLID PLASTIC OPEN FRONT SEAT WITHOUT COVER, 2" MAXIMUM LIFT,STAINLESS STEEL CHECK HINGE, ADA COMPLIANT. FLUSH VALVE SHALL BE MOEN8310M128 OR EQUAL, 1.28 GPF CHROME PISTON FLUSH VALVE WITH ADA COMPLIANTHANDLE .ALL WORK PROVIDED UNDER THIS CONTRACT INCLUDING ALL MECHANICALEQUIPMENT, MATERIALS, AND LABOR SHALL BE PROVIDED WITH A 1 YEARWARRANTY.URINAL: KOHLER "BARDON" MODEL #K-4991-ET, 0.5 GPF VITREOUS CHINA WALLMOUNTED WITH HANGER PLATE AND CARRIER, FLUSH VALVE SHALL BE SLOANAUTOMATIC TYPE (3/4" INLET TOP SPUD) MODEL G2 8186-0.5, BATTERY POWERED, 0.5GPF, POLISHED CHROME FINISH.DOMESTIC HOT WATER RECIRCULATINGNATURAL GAS PIPINGGSANITARY SEWER, GREASE WASTE OR DRAINSANITARY VENT4.5.CONTRACTOR SHALL PROVIDE SHOP DRAWINGS FOR ALL EQUIPMENT FORAPPROVAL PRIOR TO INSTALLATION.L-1THESE DRAWINGS ARE DIAGRAMMATIC IN NATURE. NOT ALL FITTINGS, OFFSETS,VENTS, OR DRAINS ARE SHOWN. THE CONTRACTOR SHALL INCLUDE ALL OFFSETS,VENTS, AND DRAINS AS REQUIRED FOR A FULLY FUNCTIONING SYSTEM.ALL DUCTWORK CONSTRUCTION AND INSTALLATION SHALL COMPLY WITH THELATEST EDITION OF THE SMACNA DUCT CONSTRUCTION HANDBOOK.7.SLOPES AND INVERT ELEVATIONS OF EXISTING SEWER SHALL BE ESTABLISHED ANDVERIFIED BY CONTRACTOR BEFORE ANY PIPING IS INSTALLED IN ORDER THATPROPER SLOPE WILL BE MAINTAINED AND NECESSARY INVERT ELEVATIONSOBTAINED.9.ALL PIPES SHALL BE COORDINATED WITH OTHER NEW AND EXISTING DUCTS, PIPES,LIGHTS, STRUCTURAL SYSTEM, CEILING SUPPORTS AND FRAMING BEFOREINSTALLATION. MINOR PIPE OFFSETS SHALL BE PROVIDED AS REQUIRED.MEASUREMENTS FOR VERTICAL CLEARANCES SHALL BE TAKEN AT THE JOB SITEBEFORE INSTALLATION OF ANY PIPING.PIPING SHALL NOT BE INSTALLED ABOVE ELECTRICAL PANELS. COORDINATEINSTALLATION OF PIPES WITH ELECTRICAL PANELS WHEN SHOWN NEAR PANELS OROVER ELECTRICAL ROOMS.KS-1EWC-1UNIONROOFTOPUNITGAS COCKGAS PIPINGSUPPORTEDON ROOFUNIT CURBGOUTLET WITH P-TRAPWHWHALAVATORY, WALL HUNG TYPE. AMERICAN STANDARD "LUCERNE" 0355.012 WHITEVITREOUS CHINA WALL HUNG HANDICAP LAVATORY, THREE HOLE MOUNT FOR 4"CENTERS, WITH MOEN 8413F05 CENTERSET CHROME FAUCET WITH SINGLE LEVERHANDLE, METAL GRID STRAINER, OFFSET PVC P-TRAP, FLEXIBLE TUBING SUPPLIES,COMPRESSION FITTINGS AND STOPS. PROVIDE TRUEBRO #102W PRE- MOLDEDINSULATION ON BOTH WATER SUPPLIES AND DRAIN. PROVIDE WITH WALL CARRIER.WALL HYDRANTWATER HAMMER ARRESTERBALL VALVESHUTOFF VALVE IN VERTICALCHECK VALVET&P RELIEF VALVEROOF/GROUNDUNIONSHOWER, COMMERCIAL SHOWER SYSTEM TRIM KIT SHALL FEATURE METAL VALVETRIM, WALL SUPPLY (WITH 1/2" NPT FEMALE INLET AND 1/2" NPSM MALE OUTLET), 59"METAL HOSE, VACUUM BREAKER, 2.5 GPM/9.5 L/MIN. 3-FUNCTION HAND SHOWERWITH NON-POSITIVE SHUT-OFF AND A 36" SLIDE BAR. SHALL ALSO FEATUREONE-PIECE DOUBLE CERAMIC PRESSURE BALANCE CARTRIDGE. FITTING SHALL BEAMERICAN STANDARD MODEL # TU662.221.002. PROVIDE 2" FLOOR DRAIN (FD-1) ANDMIXING VALVE (FLASH ROUGH VALVE BODIES BY AMERICAN STANDARD). SHALL BELOCATED IN HANDICAP SHOWER STALLS AND SHALL BE ADA COMPLIANT.PRESSURE GAUGE AND GAUGE COCKTHERMOMETERSTRAINER, STRAINER WITH DRAINRELIEF VALVEELKAY, LUSTERTONE STAINLESS STEEL, 29"X22"X5-1/2", SINGLE BOWL, TOP MOUNT.PROVIDE ELKAY DECK MOUNTED FAUCET WITH LEVER HANDLES AND SIDE MOUNTEDSPRAYER.ELECTRIC WATER COOLER, ELKAY EZH2O BOTTLE FILLING STATION WITHMECHANICALLY ACTIVATED, SINGLE ADA COOLER FILTERED REFRIGERATEDSTAINLESS. CHILLING CAPACITY OF 8.0 GPH (GALLONS PER HOUR) OF 50 F DRINKINGWATER, BASED ON 80 F INLET WATER AND 90 F AMBIENT, PER ASHRAE 18 TESTING.FEATURES SHALL INCLUDE ANTIMICROBIAL, FILTERED, GREEN TICKER , HANDSFREE, LAMINAR FLOW, MECHANICALLY ACTIVATED, REAL DRAIN, VISUAL FILTERMONITOR. FURNISHED WITH FLEXI-GUARD SAFETY BUBBLER. ELECTRONIC BOTTLEFILLER SENSOR WITH MECHANICAL FRONT AND SIDE BUBBLER PUSHBARACTIVATION. PRODUCT SHALL BE WALL MOUNT (ON WALL), FOR INDOORAPPLICATIONS, SERVING 1 STATION(S).AIR ADMITTANCE VALVEVABOVEABOVE FINISHED FLOORBELOW FINISHED FLOORBRITISH THERMAL UNITBELOWCEILINGCLEANOUTCONNECT, CONNECTIONCOLD WATERCONTINUEDDOWNEACHELEVATIONELECTRIC WATER COOLERDEGREES FAHRENHEITFLOOR DRAINFINISHEDFLOORFROMFEETGALLONS PER HOURGALLONS PER MINUTEGREASE WASTEHOSE BIBBHANDICAPPED ACCESSIBLEHOT WATERHORSEPOWERINCH, INCHESINVERTMAXIMUMTHOUSAND BTU PER HOURMINIMUMSHEETTYPICALSANITARY VENTVENT THRU ROOFSANITARY WASTEWALL CLEANOUTWALL HYDRANTWATER HAMMER ARRESTERMEDICAL GAS ZONE VALVE BOXOMEDICAL GAS PIPING - OXYGENVMEDICAL GAS PIPING - VACUUMAMEDICAL GAS PIPING - MEDICAL AIRFDGAS PIPING DETAIL - TYPICAL MECH. UNIT CONNECTIONALL FLOOR DRAINS SHALL BE PROTECTED AGAINST LOSS OF TRAP SEAL BYEVAPORATION BY INSTALLATION OF ELASTOMERIC TRAP GUARD DRAIN INSERT,EQUAL TO PROSET SYSTEMS MODEL #TG.THERMOMETERHOT WATERRECIRC PUMPAQUASTAT, SET FOR 5 FDROP IN SUPPLY TEMPERATURENEEDLE VALVE (TYP)105 FSPRING LOADED CHECK VALVESTRAINERWHWALL HYDRANT, ZURN MODEL Z1320XL, ENCASED, ECOLOTROL, LEAD-FREE,NON-FREEZE AUTOMATIC DRAINING WALL HYDRANT FOR FLUSH INSTALLATION.HYDRANT FEATURES INTEGRAL BACKFLOW PREVENTER WITH ANTI-SIPHONTECHNOLOGY, COPPER CASING, ALL-BRONZE INTERIOR COMPONENTS WITH 1/2TURN LONG-LIFE CERAMIC DISC CARTRIDGE, COMBINATION 3/4" FEMALE SOLDERAND 3/4" MALE PIPE THREAD INLET CONNECTION, AND 3/4" MALE HOSE CONNECTION.HYDRANT FURNISHED WITH TYPE 304 STAINLESS STEEL HOUSING WITH LOCKINGHINGED COVER STAMPED “WATER” AND INCLUDES OPERATING KEY. CONTRACTORSHALL COORDINATE WITH WALL THICKNESS.HBHOSE BIBB/ WALL FAUCET. ZURN MODEL Z1341-BFP, EXPOSED, ANTI-SIPHON, WALLFAUCET FOR USE IN MODERATE CLIMATE INSTALLATION, COMPLETE WITH Z1399-BFPEXTERNAL BACKFLOW PREVENTER, ALL BRONZE INTERIOR COMPONENTS,VANDAL-RESISTANT OPERATING STEM, ROUGH BRONZE EXTERIOR AND 3/4 MALEHOSE CONNECTION (CONFORM TO ASME B1.20.7).BFPREDUCED PRESSURE ZONE BACK FLOW PREVENTER (FOR BUILDING SERVICE)SIZES 1/2" - 2": WATTS SERIES LFU009. PROVIDE WITH AIR GAP DRAIN OUTLET PIPEDTO NEAREST FLOOR DRAIN.SIZES 2-1/2" - 4": WATTS SERIES 909. PROVIDE WITH OUTSIDE STEM AND YOKERESILLIENT SEATED GATE VALVES AND AIR GAP DRAIN OUTLET PIPED TO NEARESTFLOOR DRAIN.HWCP-1SEE DETAIL THIS SHEETROOFBALL VALVE (TYP)GHOT WATER RECIRCCOLD WATER SUPPLYHOT WATER SUPPLYGAS SUPPLYFLOWFOR CONTINUATION ANDSIZE, SEE FLOOR PLANUNION (TYP)DETAIL- TYPICAL HOT WATERCIRCULATING PUMP (HWCP)EXP-1GAS COCKPROVIDE AIR INTAKE ANDGAS FLUE, SIZED AS PERMANUFACTURESREQUIREMENTS.THERMOMETER (TYP)NO SCALE6" DIRT TRAPINTAKE1208 Corporate CircleRoanoke, VA Project #2110111/23/2021FLOOR DRAIN, ZURN MODEL Z415, DURA-COATED CAST IRON BODY WITH BOTTOMOUTLET, COMBINATION INVERTIBLE MEMBRANE CLAMP AND ADJUSTABLE COLLARWITH SEEPAGE SLOTS.FOR ANY FLOOR DRAINS RECIEVING INDIRECT WASTE OR CONDESATE (NOT FLOORSINKS), PROVIDE TYPE I POLISHED NICKEL BRONZE STRAINER WITH RAISED FLANGE.NO SCALEDIAL TYPE PRESSUREGAUGE (0-100 PSIG)www.balzer.ccPLUMBING EQUIPMENT SCHEDULE:FOR MECHANICAL ROOM DRAINS NOT RECIEVING INDIRECT WASTE, FINISHEDSPACES INCLUDING TOILET, SHOWER, LOCKER ROOMS, ETC., PROVIDE WITH TYPE B,ROUND, POLISHED NICKEL BRONZE, LIGHT DUTY HEEL PROOF STRAINER.PROVIDE CPVC CONCENTRICVENT KIT FOR AIR INTAKE, GASFLUE AND THRU ROOF RAIN CAPRoanoke / RichmondNew River Valley / StauntonHarrisonburg / LynchburgBACKFLOW PREVENTER (BFP)DRIP LEGHW RECIRCCLEANOUT FLUSH WITH FLOORBALANCING COCKSH-18.COGATE VALVEL-26.LAVATORY, DROP-IN TYPE SINK. LAVATORY: AMERICAN STANDARD "AQUALYN"0478.028 WHITE VITREOUS CHINA COUNTERTOP LAVATORY, THREE HOLE MOUNT FOR4" CENTERS, WITH MOEN 8413F05 CENTERSET CHROME FAUCET WITH SINGLE LEVERHANDLE, 0.5 GPM, PUSH POP-UP DRAIN, OFFSET CHROME P-TRAP WITH CLEANOUT,FLEXIBLE TUBING SUPPLIES, COMPRESSION FITTINGS AND TRWWCOWHWHAZVBT&P RELIEFVALVEDRAWN BY-DESIGNED BY-CHECKED BY-DATEEXGWH-1EXPANSION TANK - AMTROL THERM-X-TROL MODEL #ST-5 THERMAL EXPANSIONTANK, 2.0 GALLONS MIN. ACCEPTANCE VOLUME WITH DIAPHRAGM. FACTORYPRE-CHARGED TO 40 PSI, SET EQUAL TO LINE PRESSURE.PLUMBING LEGEND, SCHEDULES, AND NOTESWC-1BRANCH CONNECTION - BOTTOM OF MAINADDITION AND RENOVATION2.ALL WORK SHALL BE IN ACCORDANCE WITH THE 2018 VIRGINIA UNIFORM STATEWIDEBUILDING CODE, ALL FEDERAL, STATE, AND CITY CODES, ORDINANCES, ANDSTANDARDS.ABBREVIATIONSCARTER MACHINERY BUILDING D1.LEGENDSCALE11/23/2021As indicatedREVISIONSLAVATORY1/2"ASSE 1070 TEMPERINGVALVE WITH UNION INLETS,INTEGRAL CHECKS & SCREENS,WITH LOCKING TEMPERATUREADJUSTMENT SET AT 109 FGWH-1A.O. SMITH GAS WATER HEATER, MODEL #BTH-150 MXI, 150,000 BTU/HR INPUT, 100GALLON CAPACITY TANK, 254 GAL./HR. RECOVERY AT 70 F. RISE, 95% THERMALEFFICIENCY, 120V/1PH POWER SUPPLY W/ DEDICATED 15AMP BREAKER; T & P RELIEFVALVE. PIPING CONNECTIONS INCLUDING T&P RELIEF VALVE ON SIDE OF EQUIPMENT.MOUNT ON 4" CONCRETE PAD WITH DRAIN PAN.HWCP-1HOT WATER RE-CIRCULATION PUMP. BELL & GOSSETT ECOCIRC XL 20-140 HIGHEFFICIENCY CIRCULATING PUMP WITH EMC MOTOR, 1/2 HP., 208-230V/1PH, 1.0 GPM AT12 FT. OF HEAD, STAINLESS STEEL CONSTRUCTION.FLUETO FDHW RISERHW STOPCW RISERCW STOPCONDENSATE NEUTRALIZATIONKIT ON DISCHARGE4" CONCRETE HOUSEKEEPING PADLAVATORY TEMPERINGVALVE DETAIL (TV)NO SCALECONDENSATE DRIP ELBOW TO FDDRAIN VALVEDETAIL- WATER HEATER (GWH-1)NO SCALEP1.01PROJECT NO

1.B.1.C.2.D. REVIEW OF SUBMITTALS AND SHOP DRAWINGS DOESNOT RELIEVE THE CONTRACTOR OF THERESPONSIBILITY FOR FITTING THE EQUIPMENT IN THESPACE ALLOTTED WITH SPACE FOR ALL CONNECTIONSAND SERVICING AND FOR THE COORDINATION OF THEWORK WITH WORK OF OTHER TRADES.THE PLANS ARE DIAGRAMMATIC IN NATURE AND BASEDON ONE MANUFACTURER'S EQUIPMENT. THEY ARE NOTINTENDED TO SHOW EVERY ITEM IN ITS EXACTLOCATION, THE EXACT DIMENSIONS, OR ALL THEDETAILS OF THE EQUIPMENT. VERIFY THE ACTUALDIMENSIONS OF THE EQUIPMENT PROPOSED TO BEUSED. INSTALLATION SHALL BE WITHIN THE LIMITATIONSIMPOSED BY THE ARCHITECTURAL, STRUCTURAL, HVAC,ELECTRICAL, AND PLUMBING REQUIREMENTS WITHADEQUATE SPACE FOR MAINTENANCE.2.E.GUARANTEE: ALL MATERIALS AND WORKMANSHIP SHALLBE GUARANTEED TO BE FREE FROM DEFECTS FOR APERIOD OF ONE (1) YEAR FROM DATE OF ACCEPTANCEAND CONTRACTOR SHALL MAKE GOOD, WITHOUTADDITIONAL COST TO THE OWNER, ANY DEFECTS WHICHMAY APPEAR WITHIN THAT PERIOD. MANUFACTURER'SWARRANTIES EXTENDING BEYOND ONE YEAR SHALL BEPROCESSED AND TURNED OVER TO THE OWNER.1.D.MAJOR ITEMS ARE SHOWN ON THE PLANS. THECONTRACTOR SHALL BE RESPONSIBLE FOR ALLINCIDENTAL ITEMS REQUIRED TO PROVIDE A COMPLETEAND FUNCTIONAL SYSTEM.1.E.A TRADE NAMES AND CATALOG NUMBERS SHALL BEINTERPRETED AS ESTABLISHING A GENERAL DESIGNAND STANDARD OF QUALITY AND SHALL NOT BECONSTRUED AS LIMITING COMPETITION. UNLESSSTATED OTHERWISE, THE CONTRACTOR MAY USE ANYARTICLE WHICH, IN HIS JUDGEMENT, AND WITH WRITTENCOMMENT FROM THE ARCHITECT/ENGINEER INDICATINGNO OBJECTION, IS EQUAL OR SUPERIOR TO THATSPECIFIED. DRAWINGS SHOWING CHANGES ORREVISIONS REQUIRED BY THE SUBSTITUTION FORSPECIFIED ITEMS SHALL BE SUBMITTED WITH THE SHOPDRAWING DATA, AND THE COSTS OF ALL SUCHCHANGES SHALL BE BORNE BY THE CONTRACTOR.2.F.3.4.1.F.SIMILAR ITEMS SHALL BE PROVIDED BY A SINGLEMANUFACTURER.1.G.ALL REQUIRED WALL OR FLOOR OPENINGS SHALL BECOORDINATED WITH THE GENERAL CONTRACTORAND/OR OTHER RELEVANT TRADES.1.H.ALL PIPING SHALL BE INSTALLED ABOVE THE CEILINGUNLESS INDICATED OTHERWISE. ALL WATER PIPINGAND P-TRAPS SHALL BE INSTALLED WITHIN THEBUILDINGS INSULATION ENVELOPE OR BE PROVIDEDWITH A FREEZE PROTECTION SYSTEM.1.I.1.J.2.PROVIDE SUPPORTS TO RIGIDLY ATTACH ALLEQUIPMENT, APPURTENANCES AND PIPE AS REQUIREDFOR SUPPORT. PRIOR TO INSTALLATION OF HANGERSAND INSERTS, THE CONTRACTOR SHALL COORDINATELOCATIONS AND REQUIREMENTS TO MINIMIZECONFLICTS WITH OTHER BUILDING SYSTEMS.INSTALLATION OF PIPE HANGERS AND SUPPORTS SHALLBE IN STRICT ACCORDANCE WITH MANUFACTURERSSTANDARDIZATION SOCIETY (MSS) STANDARDS SP-58, 69AND 89.2.C.SUBMIT A DIGITAL PDF OF ALL NECESSARY DATA, CUTS,MANUFACTURER'S SELECTIONS, CATALOGS, BULLETINS,INSTALLATION INSTRUCTIONS, DRAWINGS, DIAGRAMS,CURVES, ETC. CLEARLY INDICATE ON THE SUBMITTEDDATA, THE MANUFACTURER'S NAME, PRODUCTNUMBER(S), OPTIONS, EQUIPMENT CAPACITY,DIMENSIONAL DATA, WEIGHTS, AND OTHER APPLICABLETECHNICAL DATA FOR THE PROJECT.TRADE NAMES, MANUFACTURERS, AND CATALOGUENUMBERS ARE MENTIONED HEREIN AND ON THEDRAWINGS SOLELY IN ORDER TO ESTABLISH ASTANDARD FOR THE TYPE, GENERAL DESIGN, ANDQUALITY OF PRODUCT REQUIRED. OTHER PRODUCTSSIMILAR IN DESIGN OF EQUIVALENT QUALITY CAPABLEOF FITTING WITHIN THE SPACES ALLOCATED ANDCOMPLYING WITH THE DRAWINGS AND SPECIFICATIONSWILL BE CONSIDERED AFTER THE CONTRACT IS LET6.B.CORRECTIONS OR COMMENTS MADE ON THESUBMITTALS AND DRAWINGS DURING THIS REVIEWDOES NOT RELIEVE THE CONTRACTOR FROMCOMPLIANCE WITH THE REQUIREMENTS OF THECONTRACT DOCUMENTS. THIS REVIEW IS FOR GENERALCONFORMANCE WITH THE DESIGN CONCEPT OF THEPROJECT AND GENERAL COMPLIANCE WITH THEINFORMATION GIVEN IN THE CONTRACT DOCUMENTS.THE CONTRACTOR IS RESPONSIBLE FOR CONFIRMINGAND CORRELATING ALL QUANTITIES AND DIMENSIONS,FABRICATION PROCESSES, TECHNIQUES OFCONSTRUCTION, COORDINATING THE WORK WITH THATOF ALL OTHER TRADES, AND PERFORMING WORK IN ASAFE AND SATISFACTORY MANNER. REVIEW OF THESUBMITTALS SHALL NOT PERMIT ANY DEVIATION FROMPLANS AND SPECIFICATIONS.6.C.B.6.C.C.PIPING SPECIALTIES:5.A. ACCESS DOORS: ACCESS DOORS SHALL BE PROVIDEDFOR ALL CONCEALED VALVES, CONTROLS, AND ANYOTHER EQUIPMENT OR MATERIALS REQUIRINGINSPECTION OR MAINTENANCE. ACCESS DOORS SHALLBE FURNISHED FOR FLOORS, WALLS AND CEILINGS, OFADEQUATE SIZE SO THAT CONCEALED ITEMS WILL BEREADILY ACCESSIBLE FOR SERVICING OR FOR REMOVALAND REPLACEMENT IF NECESSARY.PIPE ESCUTCHEONS: INSTALL PIPE ESCUTCHEONS ONEACH PIPE PENETRATION THRU FLOORS, WALLSPARTITIONS, AND CEILINGS WHERE PENETRATION ISEXPOSED TO VIEW AND ON EXTERIOR OF BUILDING.SECURE ESCUTCHEON TO PIPE OR INSULATION SOESCUTCHEON COVERS PENETRATION HOLE, AND ISFLUSH WITH ADJOINING SURFACE. PROVIDE SHEETSTEEL ESCUTCHEONS, SOLID OR SPLIT HINGED. FORAREAS WHERE WATER AND CONDENSATION CAN BEEXPECTED TO ACCUMULATE, PROVIDE CAST BRASS ORSHEET BRASS ESCUTCHEONS, SOLID OR SPLIT HINGED.5.C. PIPE SLEEVES: INSTALL PIPE SLEEVES WHERE PIPINGPASSES THROUGH WALLS, FLOORS, CEILINGS, ANDROOFS. DO NOT INSTALL SLEEVES THROUGHSTRUCTURAL MEMBERS OF WORK, EXCEPT AS DETAILEDON DRAWINGS, OR AS REVIEWED BYARCHITECT/ENGINEER. SIZE SLEEVES SO THAT PIPINGAND INSULATION (IF ANY) WILL HAVE FREE MOVEMENT INSLEEVE, INCLUDING ALLOWANCE FOR THERMALEXPANSION; BUT NOT LESS THAN 2 PIPE SIZES LARGERTHAN PIPING RUN. INSTALL LENGTH OF SLEEVE EQUALTO THICKNESS OF CONSTRUCTION PENETRATED, ANDFINISH FLUSH TO SURFACE; EXCEPT FLOOR SLEEVES.EXTEND FLOOR SLEEVES 1/4 INCH ABOVE LEVEL FLOORFINISH, AND 3/4 INCH ABOVE FLOOR FINISH SLOPED TODRAIN. PROVIDE TEMPORARY SUPPORT OF SLEEVESDURING PLACEMENT OF CONCRETE AND OTHER WORKAROUND SLEEVES, AND PROVIDE TEMPORARY CLOSURETO PREVENT CONCRETE AND OTHER MATERIALS FROMENTERING SLEEVES.5.D.WATER HAMMER ARRESTORS (WHA): PROVIDE AT ALLFAST OPENING WATER VALVES INCLUDING WATERCLOSETS, URNIALS, AND CLOTHES WASHERS. SHALL BEZURN MODEL 1260XL OR EQUIVALENT AND SHALL BESIZED AND PLACED WITHIN THE SYSTEM ASRECOMMENDED BY THE MANUFACTURER.INSTALLATION: INSULATION SHALL BE APPLIED INACCORDANCE WITH MANUFACTURER'SRECOMMENDATIONS USING ONLY ADHESIVES, MASTICSAND PLUMBING FASTENERS APPROVED BY THEINSULATION MANUFACTURER. INSULATION SHALL NOTBE APPLIED UNTIL AFTER THE EQUIPMENT HAS BEENTESTED WITH RESULTS ACCEPTABLE TO THEARCHITECT/ENGINEER. INSULATION WITH A VAPORBARRIER JACKET SHALL BE APPLIED WITH ACONTINUOUS, UNBROKEN VAPOR SEAL AND ALL JOINTSSHALL BE SEALED WITH A VAPOR BARRIER ADHESIVEUNLESS OTHERWISE INDICATED. STAPLES, STICK CLIPSAND HANGERS SHALL BE VAPOR SEALED WHERE THEYPUNCTURE VAPOR BARRIER JACKETS.6.C.A.OPERATION AND MAINTENANCE MANUALS:4.A. UPON COMPLETION OF THE PROJECT, SUBMIT ALLOPERATION AND MAINTENANCE MANUALS,WARRANTIES, SPARE PARTS LIST, AS-BUILT DRAWINGS,TEST AND BALANCE REPORTS, AND LETTER OFGUARANTEE ALL BOUND IN THREE RING BINDERS,CLEARLY SHOWING WHICH EQUIPMENT WAS SUPPLIEDTO THE JOB.5.B.SIZES LESS THAN 4 INCHES. SLOPE AT 1/8 INCH PERFOOT FOR SIZES 4 INCH AND LARGER.7.GLASS FIBER PIPE INSULATION: HEAVY DENSITYPREFORMED PIPE INSULATION WITH OPERATINGTEMPERATURE RANGE OF -60 DEGREES F TO 350DEGREES F, THERMAL CONDUCTIVITY "K" 0.24BTU-IN/HOUR-SF-DEG F AT 100 DEGREES F.FACTORY APPLIED JACKET (ASJ) SHALL CONSIST OFWHITE KRAFT PAPER BONDED TO ALUMINUM FOILAND REINFORCED WITH GLASS FIBER YARN. EQUALTO OWENS-CORNING ASJ.CELLULAR FOAM PIPE INSULATION: TUBULAR,FLEXIBLE, FIRE RESISTANT INSULATION WITHOPERATING TEMPERATURE RANGE OF -40 DEGREESF TO 220 DEGREES F, THERMAL CONDUCTIVITY"K" 0.27 BTU-IN/HOUR-SF-DEG F AT 75 DEGREES F.NO JACKET REQUIRED. EQUAL TO ARMSTRONGARMAFLEX AP.A POLYETHYLENE PIPE INSULATION: INSULATIONMATERIALS CORPORATION OF AMERICA (IMCOA),FLEXIBLE CLOSED CELL POLYETHYLENE TUBING,ASTM C534, "K" 0.24 AT 75 DEGREES F, SERVICETEMPERATURE -110F TO 210F. NO JACKETREQUIRED.6.D.OMIT INSULATION ON EXPOSED PLUMBING FIXTURERUNOUTS FROM FACES OF WALL OR FLOOR TO FIXTURE;ON UNIONS, FLANGES, STRAINERS, FLEXIBLECONNECTIONS, AND EXPANSION JOINTS.6.E.COVER VALVES, FITTINGS AND SIMILAR ITEMS IN EACHPIPING SYSTEM WITH EQUIVALENT THICKNESS ANDCOMPOSITION OF INSULATION AS APPLIED TOADJOINING PIPE RUN.6.F.ALL DOMESTIC WATER PIPING ABOVE GROUNDINCLUDING COLD, HOT, AND HOT WATERRE-CIRCULATING PIPING SHALL BE INSULATED WITH AMINIMUM 1/2" THICK INSULATION.PLUMBING PIPING:7.A. DOMESTIC WATER PIPING SHALL BE COPPER TUBE ANDFITTINGS IN ACCORDANCE WITH ASTM B88, TYPE L HARDDRAWN COPPER. JOINTS SHALL BE MADE WITH LEADFREE SOLDER.7.B.7.C.7.D.STORM, SOIL, WASTE, AND VENT PIPING BELOW GRADESHALL BE SCHEDULE 40 PVC PIPE AND FITTINGS. PVCSCHEDULE 40 PIPE SHALL BE IRON PIPE SIZE (IPS)CONFORMING TO ASTM D 1785. INJECTION MOLDED PVCSCHEDULE 40 FITTINGS SHALL CONFORM TO ASTM D2466. PIPE AND FITTINGS SHALL BE MANUFACTURED ASA SYSTEM AND BE THE PRODUCT OF ONEMANUFACTURER. PIPE AND FITTINGS SHALL CONFORMTO NSF INTERNATIONAL STANDARD 61 AND THEHEALTH-EFFECTS PORTION OF NSF STANDARD 14.STORM, SOIL, WASTE, AND VENT PIPING ABOVE GRADESHALL BE HUBLESS CAST IRON TYPE DESIGNED FORSAID APPLICATION. HUBLESS CAST IRON PIPE ANDFITTINGS SHALL BE MANUFACTURED FROM GRAY CASTIRON AND SHALL CONFORM TO ASTM A 888 AND CISPISTANDARD 301. ALL PIPE AND FITTINGS SHALL BEMARKED WITH THE COLLECTIVE TRADEMARK OF THECAST IRON SOIL PIPE INSTITUTE AND LISTED BY NSF INTERNATIONAL. HUBLESS COUPLINGS SHALL CONFORMTO CISPI STANDARD 310, SHALL BE MANUFACTURED INTHE UNITED STATES, AND BE CERTIFIED BY NSF INTERNATIONAL.CONDENSATE DRAINS SHALL BE TYPE L HARD DRAWNCOPPER. JOINTS SHALL BE MADE WITH LEAD FREESOLDER.7.F.SOIL, WASTE, AND VENT PIPING BELOW GRADE SHALL BEA MINIMUM OF 2 INCH AND SHALL BE PROVIDED WITHMETALLIC TRACING/DETECTION WIRE.7.G.VENTS SHALL EXTEND A MINIMUM OF 12 INCHES ABOVETHE ROOF. ROOF FLASHING SHALL BE PROVIDED ANDCOORDINATED WITH THE GENERAL AND ROOFINGCONTRACTORS.7.H.TRENCHING AS REQUIRED FOR UNDERGROUND PIPINGSHALL BE GRADED TO UNIFORM PITCH AND SHALL BE NOWIDER THAN NECESSARY FOR PIPING INSTALLATION.CLEAN BACKFILL SHALL BE USED AND THOROUGHLYTAMPED IN LAYERS NOT EXCEEDING 6 INCHES TO AMINIMUM DEPTH OF 1 FOOT ABOVE PIPE. COMPACTEDBACKFILL SHALL BE USED FOR THE ENTIRE DEPTH OFEXCAVATION UNDER SLAB ON GRADE CONSTRUCTION.7.I.6.C. MATERIALS:AS-BUILT DRAWINGS:3.A. MAINTAIN DAILY UPDATED DRAWINGS SHOWINGDEVIATIONS FROM CONSTRUCTION DOCUMENTS. ATTHE END OF THE PROJECT, PROFESSIONALLY PREPAREAS-BUILT DRAWINGS AND SUBMIT DRAWINGS TO THEARCHITECT/ENGINEER.THE CONTRACTOR SHALL MAKE FINAL CONNECTIONS TOALL EQUIPMENT INDICATED TO BE FURNISHED BYOTHERS.SUBMITTAL AND SHOP DRAWINGS:2.A. SUBMIT MANUFACTURER'S CERTIFIED DATA RELATIVETO ALL EQUIPMENT, PIPING, CONTROLS, ETC. REQUIREDFOR THE INSTALLATION OF THE PLUMBING AND FIREPROTECTION SYSTEMS. SUBMIT FOR REVIEW ALLNECESSARY ENGINEERING, PRODUCT ANDINSTALLATION DATA, SHOP DRAWINGS, SAMPLES ETC.FOR ALL EQUIPMENT, MATERIAL, AND SYSTEMS TOASCERTAIN COMPLIANCE WITH THE TECHNICALREQUIREMENTS OF THE CONTRACT DOCUMENTS.2.B.5.THE CONTRACTOR SHALL REVIEW ALL SUBMITTALS ANDSHOP DRAWINGS AND INDICATE BY STAMP OR LETTERTHAT HE HAS REVIEWED THEM, BEFORE FORWARDINGTHEM TO THE ARCHITECT AND/OR ENGINEER.SUBMITTALS AND DRAWINGS WILL BE RETURNED AFTERREVIEW INDICATING WHETHER EXCEPTIONS ARE TAKEN,THE SUBMITTAL RETURNED WITH CORRECTIONS, OR ISCOMPLETELY REJECTED. RESUBMISSION OF REVISEDSUBMITTALS AND SHOP DRAWINGS, IF REQUIRED, SHALLBE DONE BEFORE INSTALLATION AND CONSTRUCTION ISBEGUN.INSULATION:6.A. FLAME/SMOKE RATINGS: PROVIDE COMPOSITEPLUMBING INSULATION (INSULATION, JACKETS,COVERINGS, SEALERS, MASTICS AND ADHESIVES) WITHFLAME-SPREAD RATING OF 25 OR LESS, ANDSMOKE-DEVELOPED RATING OF 50 OR LESS, AS TESTEDBY ASTM E84 METHOD. INSULATION SHALL BE LABELEDBY THE MANUFACTURER. THE LABEL SHALL INDICATETHE INSULATING VALUE, FLAME SPREAD ANDSMOKE-DEVELOPED RATING.8.NATURAL GAS SYSTEMS: PIPING SHALL BE SCHEDULE40 BLACK STEEL PIPE, ASTM A120/A53-CW OR ASTM/A53GRADE B (WELDED OR SEAMLESS); WROUGHT STEELBUTTWELDING FITTINGS. GAS COCKS 2 INCHES ANDSMALLER SHALL BE RATED FOR 150 PSI, NON SHOCKWOG, BRONZE STRAIGHTWAY COCK, FLAT OR SQUAREHEAD, WITH THREADED ENDS. ALL GAS PIPINGCONNECTIONS SHALL BE PROVIDED WITH A 6 INCH DIRTTRAP, UNION, AND GAS COCK SHUT OFF VALVE. ALLJOINTS SHALL BE SEALED WITH CHEMICALLY RESISTANTSEALER APPLIED TO MALE THREADS OF PIPECONNECTION. GAS PIPING SHALL BE INSTALLED WITH A1/64 INCH PER FOOT DOWNWARD SLOPE IN THEDIRECTION OF FLOW. A ROLLER BEARING TYPE PIPESUPPORT SHALL BE USED TO SUPPORT ALL GAS PIPINGLOCATED ON THE ROOF. SUPPORTS SHALL HAVE APOLYCARBONATE BASE, WITH PIPE RESTING ON A SELFLUBRICATING POLYCARBONATE RESIN AXLE ANDROLLER AND BE SIZED FOR THE PIPE BEINGSUPPORTED. MAXIMUM SPACING SHALL NOT EXCEED10FT.SLOPE ALL DRAIN LINES AT 1/4 INCH PER FOOT FORwww.balzer.cc1208 Corporate CircleRoanoke, VA Project #2110111/23/2021PLUMBING FIXTURES, PUMPS, AND WATER HEATERS SHALL BEPROVIDED AND INSTALLED AS PER THE PLUMBING FIXTURESCHEDULE. ALL EXPOSED FIXTURE SUPPLIES AND WASTELINES SHALL BE CHROME PLATED. NO EXPOSED COPPER, PVC,AND/OR CAST IRON IS ALLOWED.9.CLEANOUTS SHALL BE THE SAME SIZE AS LINE SERVED, BUTNOT LARGER THAN 4 INCHES, AND SHALL BE PROVIDED AT THEBASE OF EACH SOIL AND WASTE STACK, AT ALL POINTS WHEREDIRECTION CHANGE IS MORE THAN 45 DEGREES, AT MINIMUMINTERVALS OF 50 FEET FOR 4 INCH AND SMALLER PIPING, ATMINIMUM INTERVALS OF 100 FEET FOR PIPING LARGER THAN 4INCHES, AS REQUIRED BY CODE AND AS INDICATED ON THEDRAWINGS. COVERS SHALL BE SET FLUSH WITH FLOOR ORWALL.10. PLUMBING VALVES10.A. PROVIDE SHUT-OFF VALVE AND UNION OR EQUIVALENTAT EACH HOT AND COLD WATER EQUIPMENTCONNECTION. PROVIDE SHUTOFF VALVE ON EACHBRANCH OR RISER THAT SERVES TWO OR MOREPLUMBING FIXTURES.10.B. GATE VALVES 2-1/2 INCHES AND SMALLER: ALL BRONZE,RISING STEM, SOLID WEDGE DISC. STOCKHAM B-100 ORB-108.10.C. GLOBE VALVES: ALL BRONZE, RENEWABLECOMPOSITION DISC. STOCKHAM B-16 OR B-14-T.10.D. CHECK VALVES IN HORIZONTAL PIPES: 2 INCHES ANDSMALLER: ALL BRONZE, REGRINDING BRONZE DISC,HORIZONTAL SWING, Y-PATTERN. STOCKHAM B-319ORB-309.10.E. CHECK VALVES IN VERTICAL PIPES AND PUMPDISCHARGE: SILENT CHECK VALVE WITH SEMI-STEELBODY, BRONZE TRIM AND STAINLESS STEEL SPRING.METRAFLEX 700 SERIES.10.F. BALL VALVES MAY BE USED IN LIEU OF GATE VALVES 2INCHES AND SMALLER. BALL VALVES SHALL HAVEBRONZE BODY, BRONZE BALL AND TFE SEATS ANDSEALS. STOCKHAM S-216BRRT OR S-216BRRS.DRAWN BY-DESIGNED BY-CHECKED BY-DATESCALE11/23/2021As indicatedREVISIONS11. CLEANING AND TESTING11.A. ALL WATER PIPING, VALVES, ETC. SHALL BETHOROUGHLY FLUSHED OF FOREIGN MATTER ANDTESTED FOR LEAKS IN ACCORDANCE WITH THEPLUMBING AND BUILDING CODE, LATEST EDITION. ANYLEAKAGE SHALL BE REPAIRED. DISINFECT DOMESTICWATER PIPING INCLUDING WATER SERVICE PIPING INACCORDANCE WITH AWWA C601.11.B. ALL DRAIN, WASTE AND VENT PIPING SHALL BE TESTEDFOR LEAKS IN ACCORDANCE WITH THE PLUMBING ANDBUILDING CODE CODE, LATEST EDITION. NO VISIBLEDROP IN WATER LEVEL WILL BE ACCEPTABLE.END OF SPECIFICATIONS.7.E.Roanoke / RichmondNew River Valley / StauntonHarrisonburg / LynchburgPLUMBING SPECIFICATIONSGENERAL PROVISIONS:1.A. ALL WORK SHALL BE IN ACCORDANCE WITH THE 2018VIRGINIA UNIFORM STATEWIDE BUILDING CODE, ALLFEDERAL, STATE, AND CITY CODES, ORDINANCES, ANDSTANDARDS.6.ADDITION AND RENOVATION1.UNLESS “PRIOR APPROVAL” REQUIREMENTS ARE SETFORTH IN THESE DOCUMENTS.CARTER MACHINERY BUILDING DPLUMBING SPECIFICATIONS:P1.02PROJECT NO

Roanoke / RichmondNew River Valley / StauntonHarrisonburg / Lynchburgwww.balzer.cc1208 Corporate CircleRoanoke, VA Project #211011311/23/202131531. EXISTING WATER CLOSET TO BE REMOVED IN ITSENTIRETY.2. EXISTING URINAL TO BE REMOVED IN ITSENTIRETY.3. EXISTING LAVATORY/SINK TO BE REMOVED IN ITSENTIRETY.4. EXISTING SHOWER TO BE REMOVED IN ITSENTIRETY.5. EXISTING GAS WATER HEATER TO BE REMOVED INITS ENTIRETY. REMOVE FLUE UP THROUGH ROOFAND GAS PIPING BACK TO MAIN AND CAP.6. EXISTING 1" DOMESTIC WATER SERVICE PIPINGBELOW GRADE TO BE REMOVED BACK TO MAIN.7. EXISTING 4"SANITARY MAIN BELOW GRADE TO BEREMOVED FOR NEW ADDITION. CONTRACTOR TOCONFIRM ROUTING AND INVERT ELEVATIONS.8. EXISTING FLOOR DRAIN TO BE REMOVED.78633122PLUMBING DEMOLITION PLANSDEMOLITION KEYED NOTES:ADDITION AND RENOVATION1. CONTRACTOR SHALL COORDINATE/VERIFYEXISTING CONDITIONS PRIOR TO BIDDING.2. ALL EXISTING BRANCH PLUMBING PIPINGSERVING THE FIXTURES WITHIN THE AREA OFWORK SHALL BE REMOVED.CARTER MACHINERY BUILDING DGENERAL NOTES:64DRAWN BY-DESIGNED BY-CHECKED BY-DATESCALE11/23/2021As indicatedREVISIONS1P2.01PLUMBING DEMOLITION PLAN - FIRST FLOORSCALE 1/4" 1'-0"2P2.01PLUMBING DEMOLITION PLAN - MEZZANINESCALE 1/4" 1'-0"P2.01PROJECT NO

EXISTING STORAGE110EXISTING STORAGEGWH-11102" CW1GWH-1212" WWOMEN'S LOCKERROOM1084" WCO4" W12"FD4WOMEN'S LOCKERROOM1082" WL-2WC-1WC-1SH-12" V1" CW1" HW1/2" HWRL-2WC-1WC-1SH-1WOMEN'S SHOWER1097GENERAL NOTES:MEN'S SHOWER106MEN'S SHOWER1064" W51/2" CW1/2" HWWOMEN'S SHOWER1094" WHWCP-11. CONTRACTOR SHALL COORDINATE/VERIFYEXISTING CONDITIONS PRIOR TO BIDDING.1. 2" VENT DOWN2. 2" WASTE AND VENT DOWN.3. NEW 2"DOMESTIC WATER SERVICE TO BUILDINGBELOW GRADE.4. 1/2" CW AND HW DOWN TO SINK/LAV.5. 1" CW DOWN TO WATER CLOSET. PROVIDEWATER HAMMER ARRESTOR.6. 3/4" CW DOWN TO URINAL. PROVIDE WATERHAMMER ARRESTOR.7. 1/2" CW AND HW DOWN TO SHOWER.8. SEE SITE UTILITY PLAN FOR CONTINUATION.9. 3/4" CW AND HW DOWN, CONNECT 1/2" CWAND HW TO EACH LAV.10. 1-1/2" VENT AND 2" WASTE DOWN FROMWATER COOLER.SH-19151L-1L-13"VTR2" W3/4" CW3/4" HWWC-11L-123" V2" VL-11/2" CW1/2" HW3L-11U-12" VWC-12" CW1/2" HW1/2" HWRU-1L-12" Project #21101611/23/2021U-12" BFP3" W1208 Corporate CircleKEYED NOTES:3" V4" Wwww.balzer.ccRoanoke, VA 2401872" WRoanoke / RichmondNew River Valley / StauntonHarrisonburg / LynchburgU-1112" WHALL1072" CWMEN'S LOCKERROOM105102" VEWC-1HALL107MEN'S LOCKERROOM1051/2" CW1/2" HW1/2" HWR1/2" CWCHECKVALVE42EWC-12" WS-1S-13OFFICE1028OFFICE102DRAWN BY-DESIGNED BY-CHECKED BY-DATESCALE4" WPLUMBING NEW WORK PLANSHALL103ADDITION AND RENOVATIONHALL103BREAK ROOMCO104BREAK ROOM104CARTER MACHINERY BUILDING D4" W11/23/2021As indicatedREVISIONSRECEPTION101RECEPTION101CO4" W BELOW GRADE TOEXISITNG SANITARYMAIN.81P3.01PLUMBING NEW WORK PLAN - WASTE & VENTSCALE 1/4" 1'-0"2P3.01PLUMBING NEW WORK PLAN - WATERSCALE 1/4" 1'-0"P3.01PROJECT NO

Roanoke / RichmondNew River Valley / StauntonHarrisonburg / Lynchburgwww.balzer.cc1208 Corporate CircleRoanoke, VA 24018540.772.95801-1/2" GAS FROM METERENLARGE GAS DISCHARGE FROMMETER/REGULATOR TO 4" OR ASREQUIRED TO MEET DEMAND.CONTRACTOR TO VERIFY ject #21101EXISTING STORAGE110GWH-1150 MBH1-1/4" GASTO GWH-111/23/2021WOMEN'S LOCKERROOM108WOMEN'S SHOWER109MEN'S SHOWER1061-1/2" GAS1" GAS1-1/2" GAS(100 MBH)GENERAL NOTES:1. CONTRACTOR SHALL COORDINATE/VERIFY EXISTINGCONDITIONS PRIOR TO BIDDING INCLUDING BUT NOTLIMITED TO THE CAPACITY OFF THE EXISTING GASMETER AND MAIN CURRENTLY SERVING THE FACILITY.GAS METER SHALL BE REPLACED IF NECESSARY.RECEPTION101PLUMBING NEW WORK PLAN - GASOFFICE102ADDITION AND RENOVATIONHALL103BREAK ROOM104CARTER MACHINERY BUILDING DHALL107MEN'S LOCKERROOM105DRAWN BY-DESIGNED BY-CHECKED BY-DATESCALE11/23/2021As indicatedREVISIONS1P3.02PLUMBING NEW WORK PLAN - GASSCALE 1/8" 1'-0"P3.02PROJECT NO

all floor drains shall be protected against loss of trap seal by evaporation by installation of elastomeric trap guard drain insert, equal to proset systems model #tg. whwall hydrant, zurn m