Transcription

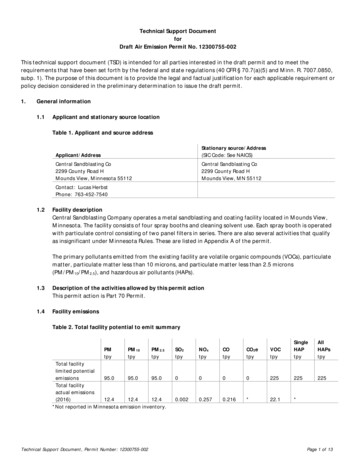

Technical Support DocumentForDraft Air Emission Permit No. 12300755-102This technical support document (TSD) is intended for all parties interested in the draft permit and to meet therequirements that have been set forth by the federal and state regulations (40 CFR § 70.7(a)(5) and Minn. R. 7007.0850,subp. 1). The purpose of this document is to provide the legal and factual justification for each applicable requirementor policy decision considered in the preliminary determination to issue the draft permit.1.General information1.1Applicant and stationary source location:Table 1. Applicant and source addressApplicant/Address1.2Stationary source/Address(SIC Code: 3479 - Coating, Engraving, and AlliedServices, Not Elsewhere Classified; See NAICS)Central Sandblasting Co2299 County Road HMounds View, Minnesota 55112-1517Central Sandblasting Company2299 County Road HMounds View, MN 55112-1517Contact: Lucas HerbstMetal Finishers IncorporatedPhone: 763-786-90402297 County Road HMounds View, MN 55112-1517Facility descriptionCentral Sandblasting Company operates a metal sandblasting and coating facility located in Mounds View,Minnesota, and also owns the nearby metal coating facility of Metal Finishers Incorporated. Under NewSource Review regulations, the two facilities are being permitted together as a single source because theyare both part of the same industrial grouping as defined by Standard Identification Classification (SIC code),they are adjacent next-door facilities, and they are under common ownership. The Central Sandblastingfacility consists of two spray booths each operating with two panel filters in series as particulate control,two air makeup units, and cleaning solvent use. The Metal Finishers facility consists of one spray boothoperating with a water curtain as particulate control, plus an air makeup unit. There are also severalactivities that qualify as insignificant under Minnesota Rules, listed in Appendix A of the permit.The primary pollutants emitted from the existing facility are volatile organic compounds (VOCs), particulatematter, particulate matter less than 10 microns, and particulate matter less than 2.5 microns(PM/PM10/PM2.5), and hazardous air pollutants (HAPs).1.3Description of the activities allowed by this permit actionThis permit action is Major Amendment. Construction is authorized for the spray booth (EQUI 9), panelfilters (TREAs 9, 10), and air makeup units (EQUIs 10, 11) being added to Central Sandblasting Co; however,the EQUI 9 spray booth and associated panel filters have already been constructed under a minoramendment application received in 2019 that was ultimately denied, and an enforcement action has beentaken which is being resolved in part through this major amendment. The spray booth (EQUI 12), watercurtain (TREA 11), and air makeup unit (EQUI 13) from Metal Finishers Inc were previously constructed andoperating under air permit # 123000774-001 so no construction is authorized at that facility.This major amendment adds a new spray booth (EQUI 9) with two associated panel filters (TREAs 9, 10) andtwo air makeup units (EQUIs 10, 11) to the permit. The units at Metal Finishers Inc are also being added toTechnical Support Document, Permit Number: 12300755-102 Page 1 of 11

the permit (spray booth EQUI 12 with associated water curtain TREA 11, and one air makeup unit EQUI 13);however, these units were previously operating under air permit # 12300774-001 and are not being newlyconstructed. Three spray booths (EQUIs 4-6) and their associated panel filters (TREAs 1-3, 5-7) have beenpermanently removed from Central Sandblasting with the installation of the EQUI 9 spray booth.The MPCA has a combined operating and construction permitting program under Minn. R. ch. 7007. Underthat authority, this permit action authorizes construction.1.4Description of notifications and applications included in this actionTable 2. Notifications and applications included in this action1.5Date receivedApplication/notification type and description06/03/2020Major Amendment (IND20200001)Facility emissions:Table 3. Title I emissions summary (new units at Central Sandblasting Co) (IND20200001)PollutantUnlimited potentialemissions from themodification(tpy)Limited potentialemissions fromthe modification(tpy)NSR/112(g) thresholdfor new major source(tpy)NSR/112(g) 24250NoCO3.303.30250NoOzone 82408100,000NoMethyl IsobutylKetone235.90.0010No (already majorsource for HAPs)Toluene175.81.33E-510No (already majorsource for HAPs)Xylene254.30.0010No (already majorsource for HAPs)No (already majorTotal HAPs400.10.07425source for HAPs)*Carbon dioxide equivalents as defined in Minn. R. 7007.0100.Note that the existing COMG 2 Precap limits the potential particulate and VOC emissions increases due to the EQUI 9spray booth; additionally, 40 CFR pt. 63, subp. MMMM requirements incorporated at COMG 3 limits the potentialorganic HAP emissions increases due to the EQUI 9 spray booth. Unlimited potential HAP emissions reflect worst-casefor the specific individual HAP across all coating materials used.Table 4. Title I emissions summary (units operating at Metal Finishers Inc) (IND20200001)PollutantUnlimited potentialemissions from themodification(tpy)Limited potentialemissions fromthe modification(tpy)NSR/112(g) thresholdfor new major source(tpy)NSR/112(g) reviewrequired?(yes/no)PM161.70.073250NoTechnical Support Document, Permit Number: 12300755-102 Page 2 of 11

PollutantUnlimited potentialemissions from themodification(tpy)Limited potentialemissions fromthe modification(tpy)NSR/112(g) thresholdfor new major source(tpy)NSR/112(g) 0.810.81250NoOzone 801180100,000NoMethyl IsobutylKetone58.20.0010No (already majorsource for HAPs)Toluene43.43.26E-510No (already majorsource for HAPs)Xylene62.70.0010No (already majorsource for HAPs)No (already majorTotal HAPs98.70.01825source for HAPs)*Carbon dioxide equivalents as defined in Minn. R. 7007.0100.Note that the existing COMG 2 Precap limits the potential particulate and VOC emissions increases due to the EQUI 12spray booth; additionally, 40 CFR pt. 63, subp. MMMM requirements incorporated at COMG 3 limits the potentialorganic HAP emissions increases due to the EQUI 12 spray booth. Unlimited potential HAP emissions reflect worst-casefor the specific individual HAP across all coating materials used.Table 5. Total facility potential to emit summaryTotal l ions(2019)* Not reported in MN emission inventory.** Because of the various coatings which the facility could use, three different individual HAPs each have a limitedpotential to emit of 225 tpy. These are Methyl Isobutyl Ketone, Toluene, and Xylene.Table 6. Facility classificationClassificationMajorPSDSynthetic minor/areaXPart 70 Permit ProgramXPart 63 NESHAPXTechnical Support Document, Permit Number: 12300755-102 Page 3 of 11Minor/area

1.6Changes to permitThe following changes were made with this permit action: Added a new spray booth (EQUI 9) with two associated panel filters (TREA 9, TREA 10). EQUI 9 issubject to COMG 2 limits and 40 CFR pt. 63, subp. MMMM requirements in COMG 3. TREAs 9 and10 are subject to COMG 4 and COMG 6 panel filter requirements Added two air makeup units (EQUI 10, EQUI 11). Removed three spray booths (EQUIs 4-6) and their associated panel filters (TREAs 1-3, 5-7). Incorporated operations at the nearby Metal Finishers Inc facility, specifically a spray booth (EQUI12) with associated water curtain (TREA 11) and one air makeup unit (EQUI 13). EQUI 12 is subjectto COMG 2 limits and 40 CFR pt. 63, subp. MMMM requirements in COMG 3. Corrected 40 CFR pt. 63, subp. MMMM applicability trigger date listed in COMG 3 from January 2,2007 to October 1, 2008.2.Regulatory and/or statutory basis2.1New source review (NSR)The permit carries forward limits on the facility such that it is a minor source under New Source Reviewregulations. This permit brings in the operations of Metal Finishers Inc, which is currently operating underan Option D registration permit (#12300774-001), under the permit for Central Sandblasting Company aspart of a single source; according to New Source Review regulations, the two facilities are both part of thesame industrial grouping as defined by Standard Identification Classification (SIC code), they are adjacentnext-door facilities, and they are under common ownership.2.2Part 70 permit programThe facility is a major source under the Part 70 permit program.2.3New source performance standards (NSPS)The Permittee has stated that no New Source Performance Standards apply to the operations at this facility.2.4National emission standards for hazardous air pollutants (NESHAP)The facility is an existing major source of HAPs and is subject to 40 CFR pt. 63, subp. MMMM (NationalEmission Standards for Hazardous Air Pollutants for Surface Coating of Miscellaneous Metal Parts andProducts). Note that EQUIs 9 and 12 are being added to facility but applicability under 40 CFR pt. 63, subp.MMMM does not change because per 40 CFR § 63.3882(b)(1), the entire collection at a source is consideredsubject to the standard and not subject by individual emission units.Additionally, the 40 CFR pt. 63, subp. MMMM applicability date listed in COMG 3 was corrected to October1, 2008. This is because the EQUI 7 spray booth was installed in October 2007 to trigger major source statusfor HAPs, and 40 CFR § 63.3881(c)(2) allows one year after the installation trigger (October 2008) to achievecompliance with the standard when it is later than the January 2, 2007 trigger date listed in the rule.2.5Compliance assurance monitoring (CAM)The table below lists the sources subject to CAM, the control equipment used, whether the source is a largeor other pollutant specific emission unit (PSEU), and the pollutants triggering CAM.Table 7. CAM summaryUnitControlCAM applicabilityTechnical Support Document, Permit Number: 12300755-102 Page 4 of 11PollutantEmission Limitation Basis

UnitControlCAM applicabilityPollutantEmission Limitation BasisPM 95.0 tpy.PM10 95.0 tpy.PM2.5 95.0 tpy.EQUI 9 (SprayBooth 5)TREA 9 Panel filterTREA 10 Panel filterOtherPM/PM10/PM2.5[Title I Condition: Avoid majorsource under 40 CFR52.21(b)(1)(i) and Minn. R.7007.3000]PM 95.0 tpy.PM10 95.0 tpy.PM2.5 95.0 tpy.EQUI 12(Spray BoothMFI)TREA 11 Water curtainOtherPM/PM10/PM2.5[Title I Condition: Avoid majorsource under 40 CFR52.21(b)(1)(i) and Minn. R.7007.3000]The controlled PM/PM10/PM2.5 PTE of each spray booth exceeds 100 tpy, but because both units are subjectto the COMG 2 PM/PM10/PM2.5 emission limits of 95.0 tons per year the spray booths are considered OtherPSEUs under CAM.CAM plans were not submitted for review with this major amendment because both EQUI 9 and EQUI 12spray booths are considered Other PSEUs under CAM. These CAM plans will need to be submitted forreview as part of permit reissuance.2.6Regulatory overviewTable 8. Regulatory overview of units affected by the modification/permit amendmentSubject item*Applicable regulationsRationaleCOMG 2 (VOCand ParticulateCoating Limits)40 CFR pt. 64 to avoid largePSEUCompliance Assurance Monitoring (CAM). Limits on PM, PM10, andPM2.5 emissions to avoid large PSEU classification under CAM.Title I Condition: Avoidmajor source under 40 CFR§ 52.21(b)(1)(i) and Minn.R. 7007.3000Prevention of Significant Deterioration (PSD). Limits on PM, PM10,PM2.5, and VOC emissions to avoid large PSEU classification underCAM.40 CFR pt. 63, subp.MMMMNational Emission Standards for Hazardous Air Pollutants for SurfaceCoating of Miscellaneous Metal Parts and Products. This is an existingaffected source under this standard. The Permittee is complying withthe emission rate without controls compliance option. If thePermittee’s coating operations include high performance or extremeperformance fluoropolymer coatings, the Permittee has the optionto either comply separately with each subcategory emission limit, orto comply with a facility-specific emission limit as described in 40 CFR§ 63.3890(c)(2). The Permittee has rejected the option to claim wastecredit in organic HAP emission calculations.40 CFR pt. 64Compliance Assurance Monitoring (CAM). The panel filters are usedto comply with the Industrial Process Equipment Rule particulatelimit, and each spray booth has an uncontrolled PTE greater than 100tpy.EQUI 9, EQUI 12spray boothsare subject tothis groupCOMG 3(NESHAPMMMM)EQUI 9, EQUI 12spray boothsare subject tothis groupCOMG 4(IndividualPanel FilterRequirements)Technical Support Document, Permit Number: 12300755-102 Page 5 of 11

Subject item*Applicable regulationsRationaleTREA 9, TREA10 panel filtersare subject tothis groupTitle I Condition: Avoidmajor source under 40 CFR§ 52.21(b)(1)(i) and Minn.R. 7007.3000Prevention of Significant Deterioration (PSD). Control efficiency andother operating parameter requirements to limit PM/PM10/PM2.5PTE below major source classification thresholds under PSD.COMG 6 (PanelFilters w/HoodCapture)Minn. R. 7007.0800, subps.2 and 14Requirement to operate two panel filters in series at EQUI 9 in orderto demonstrate compliance with the Industrial Process EquipmentRule particulate limit.TREA 9, TREA10 panel filtersare subject tothis groupTitle I Condition: Avoidmajor source under 40 CFR§ 52.21(b)(1)(i) and Minn.R. 7007.3000Prevention of Significant Deterioration (PSD). Control efficiency andother operating parameter requirements to limit PM/PM10/PM2.5PTE below major source classification thresholds under PSD.EQUI 9 (SprayBooth 5)Minn. R. 7011.0715, subp.1Standards of Performance for post-1969 Industrial ProcessEquipment. Equipment for which there is no other promulgatedperformance standard is subject to the opacity and PM limits in thisrule. Construction of the unit was on or after July 9, 1969.EQUI 10 (AMU1)Minn. R. 7011.0610, subp.1Standards of Performance for Direct Heating Equipment. Construction of the unit was on or after July 9, 1969; The unit burns gaseous fuel; The facility is located in the Twin Cities; and The facility has less than or equal to 250 MMBtu/hr of indirect anddirect heating equipment.EQUI 11 (AMU2)Minn. R. 7011.0610, subp.1Standards of Performance for Direct Heating Equipment. Construction of the unit was on or after July 9, 1969; The unit burns gaseous fuel; The facility is located in the Twin Cities; and The facility has less than or equal to 250 MMBtu/hr of indirect anddirect heating equipment.EQUI 12 (SprayBooth MFI)Minn. R. 7011.0715, subp.1Standards of Performance for post-1969 Industrial ProcessEquipment. Equipment for which there is no other promulgatedperformance standard is subject to the opacity and PM limits in thisrule. Construction of the unit was on or after July 9, 1969.EQUI 13 (AMUMFI)Minn. R. 7011.0610, subp.1Standards of Performance for Direct Heating Equipment. Construction of the unit was on or after July 9, 1969; The unit burns gaseous fuel; The facility is located in the Twin Cities; and The facility has less than or equal to 250 MMBtu/hr of indirect anddirect heating equipment.TREA 11 (Watercurtain)Compliance Assurance Monitoring (CAM) applies because the watercurtain is used for the EQUI 12 spray booth to comply with theIndustrial Process Equipment rule particulate limit, and EQUI 12 hasan uncontrolled potential to emit greater than 100 tpy.*Location of the requirement in the permit (e.g., EQUI 1, STRU 2, etc.).3.40 CFR pt. 64Technical information3.1Calculations of potential to emit and emissions increase analysisAttachment 1 to this TSD contains a summary of the PTE of the Facility as well as detailed spreadsheets andsupporting information prepared by the MPCA and the Permittee.Technical Support Document, Permit Number: 12300755-102 Page 6 of 11

For the spray booths (EQUI 9, EQUI 12), unrestricted PTE for the spray booths was calculated by multiplyingthe highest possible material content for each pollutant, as applied (lb/gal), by the maximum applicationrate. The Permittee applies coatings either with or without reducers, following the material manufacturer’srecommendations on the type and quantity of reducers used. The Permittee identified the highest materialcontents under both scenarios (either when adding reducers, or when applying the coatings withoutreducers), and used the maximum value in calculating the unrestricted PTE. Note that any individual coatingmaterial could have different HAP contents, however unrestricted total HAP emissions are limited to theHAP contents of any particular coating being sprayed at a given moment. The COMG 2 VOC emission limit of225 tons per year also effectively limits the total facility HAP emissions to 225 tons per year, because eachHAP used in the coating materials is also a VOC.Regarding particulate emissions from the spray booths, a transfer efficiency of 45% was assumed for theairless spray guns. Spray booth 5 (EQUI 9) operates under a certified hood and is controlled by two panelfilters in series; this results in a capture efficiency of 80%, a control efficiency for PM, PM10, and PM2.5 of 85% by each panel filter from the captured portion of the particulate emissions, and an overall controlefficiency of 97.8%. The spray booth at Metal Finishers Inc (EQUI 12) operates under a certified hood and iscontrolled by a water curtain; this results in a capture efficiency of 80%, a control efficiency for PM, PM10,and PM2.5 of 85% from the captured portion of particulate emissions, and an overall control efficiency of68%. Standard control efficiencies were taken from the control equipment rule at Minn. R. 7011.0070 whenused with certified hoods. The EQUI 12 spray booth is capable of applying coating either as a liquid at 45%transfer efficiency, or as a powder with an assumed 95% transfer efficiency, but is not capable of applyingcoating with both methods simultaneously. Under worst-case assumptions, EQUI 12 has the greatestpotential to emit when applying liquid coating through airless spray guns.For the air makeup units (EQUIs 10, 11, 13), PTE was calculated based on the maximum rated heat input foreach burner multiplied by criteria and HAP pollutant emission factors from AP-42 Section 1.4 andgreenhouse gas emission factors from 40 CFR pt. 98. A heat value of 1,050 BTU/scf was used to determinethe natural gas fuel consumption rate at maximum burner capacity for each unit. The insignificant activitiesat Metal Finishers Inc all operate using natural gas combustion as well, and PTE for these activities was alsocalculated using the maximum rated heat input, along with emission factors from AP-42 Section 1.4 and 40CFR pt. 98.3.2MonitoringIn accordance with the Clean Air Act, it is the responsibility of the owner or operator of a facility to havesufficient knowledge of the facility to certify that the facility is in compliance with all applicablerequirements.In evaluating the monitoring included in the permit, the MPCA considered the following: The likelihood of the facility violating the applicable requirements. Whether add-on controls are necessary to meet the emission limits. The variability of emissions over time. The type of monitoring, process, maintenance, or control equipment data already available for theemission unit. The technical and economic feasibility of possible periodic monitoring methods. The kind of monitoring found on similar units elsewhere.The table below summarizes the monitoring requirements associated with this amendment.Technical Support Document, Permit Number: 12300755-1

MMMM (National Emission Standards for Hazardous Air Pollutants for Surface Coating of Miscellaneous Metal Parts and Products). Note that EQUIs 9 and 12 are being added to facility but applicability under40 CFR pt. 63, subp. MMMM does not change because per 40 CFR § 63.38