Transcription

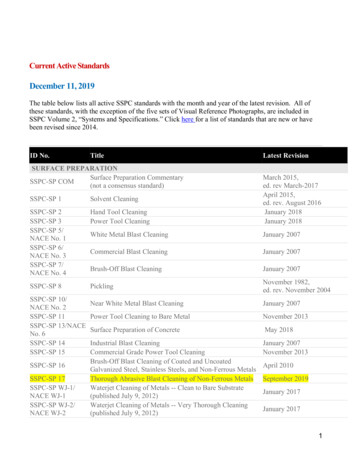

SSPC Painting Manual, Volume 1GOOD PAINTING PRACTICESSPC Painting Manual, Volume 1, 4th EditionSSPC’S Leading Best sellers!“Good Painting Practice,” SSPCPainting Manual, Volume 1 is anencyclopedic overview of procedures,equipment and materials used forsurface preparation and coatingwork on industrial steel and concretestructures.The 4th edition of SSPC’s “Good Painting Practice”provides a detailed overview of the procedures,equipment and materials used for surfacepreparation and coating work on industrial steel andconcrete structures. In it you’ll find information on awide range of relevant topics-from the fundamentalsof surface preparation and coating applicationto recent advances in alternate coating removaltechnologies-to the complexities of painting specificfacilities and structures, regulations affecting thecoatings industry, strategies for the developmentof maintenance coating programs, and much more.The most complete, up-to-date book on industrialcoating practices around! Available in a 581page hardcover and on a multi-platform CD-ROMdesigned to run on Macintosh , Windows , andUNIX operating systems.“Systems and Specifications,”SSPC Painting Manual, Volume 2 is acomplete collection of SSPC standards,guides, specifications, and otherconsensus documents. Together theyform the essential works for anyoneconcerned with the safe and effectiveuse of protective coatings and linings!(see page 3-4)HARDCOVERItem #02-14SSPC Member Price: 136.50Non-Member Price: 195.00BUY BOTH AND SAVE!Purchase the latest editions of “GoodPainting Practice” and “Systems andSpecifications” together as a set forone special price!SSPC PAINTING MANUALHardcover/Binder SetItem #PMBSETSSPC Member Price: 310.00Non-Member Price: 430.00Counts as two (2) SSPC OrganizationalMember free publication selections.FOUR CONVENIENT WAYS TO ORDER!PHONE: Call 1-877-281-7772 (toll-freewithin the USA) or 1-412-281-2331 (fromoutside the USA). Phone orders areaccepted Monday through Friday, 8:30AM to 5:00 PM, Eastern Standard Time.FAX: Complete the catalog order formand send it to 1-412-281-9995 along withyour credit card information. Fax ordersaccepted 24 hours a day, 7 days a week.MAIL: Complete the catalog order formand return it to SSPC along with yourcheck or credit card information.BUY IT Contact the SSPC Publication SalesOffice at the phone and fax numbersabove, or by email at books@sspc.org.www.sspc.orgCD-ROMItem #CD07SSPC Member Price: 136.50Non-Member Price: 195.00Here’s what you will find inside the 4th edition ofGood Painting Practice, SSPC Painting Manual, Volume 1 Introduction Corrosion of Metals Designing Steel Structures for Good PaintingPerformance Mechanisms of Corrosion Control byCoatings Properties of Generic Coating Types Organic Coatings: Composition and FilmFormation Cathodic Protection of Coated Structures Coating Galvanized Steel Overview of Steel Surface Preparation Hand and Power Tool Cleaning Nonmetallic Abrasives Metallic Abrasives Abrasive Air Blast Cleaning Centrifugal Blast Cleaning Wet Abrasive Blast and PressurizedWater Cleaning (Water jetting) Other Methods of Surface Preparation– Pickling– Chemical Stripping– Sodium Bicarbonate (Baking Soda)Blast Cleaning– Pliant Media Blasting– Carbon Dioxide (Dry-Ice) Blasting– Electrochemical Stripping Solvent and Chemical Pre-Cleaning Dehumidification During Coating Operations Concrete Surface Preparation Surface Preparation of NonferrousSurfaces Coatings for Industrial Steel Structures Coatings for Concrete Powder Coating Thermal-Spray (Metallized) Coatings for Steel2 Application of Industrial Coatings Contractor Equipment: An Overview Shop Painting of Steel Painting Highway Bridges and Structures Corrosion Protection of Water and FuelTanks Linings for Vessels and Tanks Painting Chemical Plants Painting Waste Treatment Plants Painting Petroleum Refineries Painting Power Generation Facilities Painting Steel Structures in Pulp andPaper Mills Painting Hydraulic Structures Coatings for Buried and Immersed MetalPipelines Painting Ships Inspection Safety and Health in the ProtectiveCoatings Industry Air Quality Regulations Waste Handling and Disposal Other Regulations Affecting ProtectiveCoatings Total Protective Coatings Programs Comparative Painting Costs Using Plant Surveys to Maintain CoatingProtectionof Structures Preparing a Specification for a CoatingProject Maintenance Painting Programs Quality Control for Protective CoatingsProjects Coating Failures IndexSSPC PRODUCTS CATALOG

SSPC Painting Manual, Volume 2SYSTEMS AND SPECIFICATIONSSSPC Painting Manual, Volume 2A complete, up-to-date collection of SSPC standards, guides, specifications, and other consensus documents.Contains SSPC standards for the cleaning and preparation of steel and concrete surfaces, the selection andapplication of protective coating systems, the basic composition requirements and performance capabilitiesof paints and coatings, qualification procedures, and other materials, processes, and technologies.HARDCOVERItem #08-02SSPC Member Price: 205.00Non-Member Price: 280.00Here’s what you will find inside theSystems And Specifications, SSPC Painting Manual, Volume 2HOW TO USE SSPC STANDARDS, SPECIFICATIONS, ANDGUIDES SSPC-AB 4 – Recyclable Encapsulated Abrasive Media (in acompressible cellular matrix)SURFACE PREPARATION STANDARDS, GUIDES, ANDSPECIFICATIONS SSPC-SP COM – Surface Preparation Commentary for Steeland Concrete Substrates SSPC-SP 1 – Solvent Cleaning SSPC-SP 2 – Hand Tool Cleaning SSPC-SP 3 – Power Tool Cleaning SSPC-SP 5/NACE No. 1 – White Metal Blast Cleaning SSPC-SP 6/NACE No. 3 – Commercial Blast Cleaning SSPC-SP 7/NACE No. 4 – Brush-Off Blast Cleaning SSPC-SP 8 – Pickling SSPC-SP 10/NACE No. 2 – Near-White Blast Cleaning SSPC-SP 11 – Power Tool Cleaning to Bare Metal SSPC-SP WJ-1/NACE WJ-1 – Waterjet Cleaning of Metals Clean to Bare Substrate SSPC-SP WJ-2/NACE WJ-2 – Waterjet Cleaning of Metals Very Thorough Cleaning SSPC-SP WJ-3/NACE WJ-3 – Waterjet Cleaning of Metals Thorough Cleaning SSPC-SP WJ-4/NACE WJ-4 – Waterjet Cleaning of Metals Light Cleaning SSPC-SP 13/NACE No. 6 – Surface Preparation of Concrete SSPC-SP 14/NACE No. 8 – Industrial Blast Cleaning SSPC-SP 15 – Commercial Power Tool Cleaning SSPC-SP 16 – Brush-Off Blast Cleaning of Coated andUncoated Galvanized Steel, Stainless Steels, and NonFerrous Metals Guide to SSPC-VIS 1 – Guide and Reference Photographs forSteel Surfaces Prepared by Dry Abrasive Blast Cleaning Guide to SSPC-VIS 2 – Standard Method of Evaluating Degreeof Rusting on Painted Steel Surfaces Guide to SSPC-VIS 3 – Guide and Reference Photographs forSteel Surfaces Prepared by Power- and Hand-Tool Cleaning Guide to SSPC-VIS 4/NACE VIS 7 – Guide and ReferencePhotographs for Steel Surfaces Prepared by Waterjetting Guide to SSPC-VIS 5/NACE VIS 9 – Guide and ReferencePhotographs for Steel Surfaces Prepared by Wet AbrasiveBlast CleaningPAINTING AND COATING SYSTEMS GUIDES ANDSPECIFICATIONS SSPC-PS Guide 7.00 – Guide for Selecting One-Coat ShopPainting Systems SSPC-PS Guide 12.00 – Guide to Zinc-Rich Coating Systems SSPC-PS 12.01 – One-Coat Zinc Rich Painting System SSPC-CS 23.00/ AWS C2.23M/ NACE No. 12 – Specificationfor the Application of Thermal Spray Coatings (Metallizing)of Aluminum,Zinc, and Their Alloys and Composites for theCorrosion Protection of Steel SSPC-PS 28.01 – Two-Coat Zinc-Rich Polyurethane Primer/Aliphatic Polyurea Topcoat System, Performance-Based SSPC-PS 28.02 – Three-Coat Moisture-Cured PolyurethaneCoating System, Performance-BasedSSPC/NACE JOINT TECHNOLOGY REPORTS SSPC-TR 1/NACE 6G194 – Thermal Pre-Cleaning SSPC-TR 2/NACE 6G198 – Wet Abrasive Blast Cleaning SSPC-TR 3/NACE 6A192 – Dehumidification and TemperatureControl During Surface Preparation, Application, and Curingfor Coatings/Linings of Steel Tanks, Vessels, and OtherEnclosed Spaces SSPC-TR 4/NACE 80200 – Preparation of Protective CoatingSpecifications for Atmospheric Service SSPC-TR 5/ ICRI Technical Guideline 03741/ NACE 02203 –Design, Installation, and Maintenance of Protective PolymerFlooring Systems for ConcreteABRASIVE SPECIFICATIONS SSPC-AB 1 – Mineral and Slag Abrasives SSPC-AB 2 – Cleanliness of Recycled Ferrous MetallicAbrasives SSPC-AB 3 – Ferrous Metallic AbrasiveSSPC PRODUCTS CATALOGPAINT AND COATING STANDARDS AND SPECIFICATIONS SSPC-Paint 15 – Steel Joist Primer/Metal Building Primer SSPC-Paint 16 – Coal Tar Epoxy Polyamide Black (or DarkRed) Coating SSPC-Paint 20 – Zinc-Rich Coating (Type I – Inorganic, andType II – Organic) SSPC-Paint 23 – Latex Primer for Steel Surfaces SSPC-Paint 24 – Latex Semigloss Exterior Topcoat SSPC-Paint 27 – Basic Zinc Chromate—Vinyl Butyral WashPrimer SSPC-Paint 29 – Zinc Dust Sacrificial Primer, PerformanceBased SSPC-Paint 30 – Weld-Through Inorganic Zinc Primer SSPC-Paint 32 – Coal Tar Emulsion Coating SSPC-Paint 33 – Coal Tar Mastic, Cold Applied SSPC-Paint 36 – Two-Component Weatherable AliphaticPolyurethane Topcoat, Performance-Based SSPC-Paint 38 – Single-Component Moisture-CureWeatherable Aliphatic Polyurethane Topcoat, PerformanceBased – (Revised March 2012) SSPC-Paint 39 – Two-Component Aliphatic Polyurea TopcoatFast or Moderate Drying, Performance-Based SSPC-Paint 40 – Zinc-Rich Moisture-Cure PolyurethanePrimer, Performance-Based SSPC-Paint 41 – Moisture-Cured Polyurethane Primeror Intermediate Coat, Micaceous Iron Oxide Reinforced,Performance-Based SSPC-Paint 42 – Epoxy Polyamide/Polyamidoamine Primer,Performance-Based SSPC-Paint 43 – Direct-to-Metal Aliphatic Polyurea Coating,Performance-BasedSTANDARDS, GUIDES, AND METHODS RELATED TO COATINGAPPLICATION SSPC-PA COM – Commentary on Paint ApplicationMonitoring and Controlling Ambient Conditions DuringCoating Operations SSPC-PA 1 – Shop, Field, and Maintenance Painting of Steel SSPC-PA 2 – Procedure for Determining Compliance to DryCoating Thickness Requirements SSPC-PA Guide 4 – Guide to Maintenance Repainting with OilBase or Alkyd Painting Systems3 SSPC-PA Guide 5 – Guide to Maintenance Coating of SteelStructures in Atmospheric Service SSPC-PA 6/NACE No. 10 – Fiberglass-Reinforced Plastic (FRP)Linings Applied to Bottoms of Carbon Steel AbovegroundStorage Tanks SSPC-PA 7 – Applying Thin Film Coatings to Concrete SSPC-PA 8/NACE No. 11 – Thin-Film Organic Linings Appliedin New Carbon Steel Process Vessels SSPC-PA 9 – Measurement of Dry Organic Coating Thicknesson Cementitious Substrates Using Ultrasonic Gages SSPC-PA Guide 10 – Guide to Safety and Health Requirementsfor Industrial Painting Projects SSPC-PA Guide 11 – Guide to Methods for Protection ofEdges, Crevices, and Irregular Steel Surfaces SSPC-PA 12 – Method for Preparation of UncontaminatedRusted Steel Test Panels (formerly SSPC-ME 1) SSPC-PA Guide 13 – Guide Specification for Application ofCoating Systems With Zinc-Rich Primers to Steel Bridges SSPC-PA 14 – Field Application of Plural Component Polyureaand Polyurethane Thick Film Coatings to Concrete and Steel SSPC-PA 15 – Material and Preparation Requirements forSteel Test Panels Used to Evaluate the Performance ofindustrial Coatings SSPC-PA 16 – Method for Evaluating Scribe Undercutting onCoated Steel Test Panels Following Corrosion Testing SSPC-PA 17 – Procedure for Determining Conformance toSteel Profile/Surface Roughness/Peak Count RequirementsQUALIFICATION PROCEDURES SSPC-QP COM – Commentary on Qualification Procedures SSPC-QP 1 – Standard Procedure for Evaluating theQualifications of Industrial/Marine Painting Contractors (FieldApplication to Complex Industrial and Marine Structures) Revised June 2012 SSPC-QP 2 – Standard Procedure for the Qualification ofPainting Contractors (Field Removal of Hazardous Coatingsfrom Industrial and Marine Steel Structures) AISC-420-10/SSPC-QP 3 – Certification Standard for ShopApplication of Complex Protective Coating Systems SSPC-QP 4 – Standard Procedure for Evaluating theQualifications of Contractors Disturbing Hazardous CoatingsDuring Demolition and Repair Work SSPC-QP 5 – Standard Procedure for Evaluating theQualifications of Coating and Lining Inspection Companies(Revised May 2012) SSPC-QP 6 – Standard Procedure for Evaluating theQualifications of Contractors Who Apply Thermal Spray(Metallizing) for Corrosion Protection of Steel and ConcreteStructures SSPC-QP 7 – Procedure for Evaluating Painting Contractorswith Limited Industrial Work Experience SSPC-QP 8 – Standard Procedure for Evaluating theQualifications of Contracting Firms That Install PolymerCoatings and Surfacings on Concrete and Other CementitiousSubstrates SSPC-QP 9 – Standard Procedure for EvaluatingQualifications of Painting Contractors Who ApplyArchitectural Paints and Coatingswww.sspc.org

SSPC Painting Manual, Volume 2 – (cont.) SSPC-QS 1 – Standard Procedure for Evaluating aContractor’s Advanced Quality Management SystemTECHNOLOGY GUIDES SSPC-Guide 6 – Guide for Containing Debris GeneratedDuring Paint Removal Operations (editorial revisions March1, 2012) SSPC-Guide 7 – Guide to the Disposal of Lead-ContaminatedSurface Preparation Debris SSPC-Guide 9 – Guide for Atmospheric Testing of Coatingsin the Field SSPC-Guide 10 – Guide to Specifying and Testing CoatingsConforming to Volatile Organic Compound (VOC) ContentRequirements SSPC-Guide 12 – Guide for Illumination of Industrial PaintingProjects SSPC-Guide 13 – Guide for the Identification and Use ofIndustrial Coating Materials in Computerized ProductDatabases SSPC-Guide 14 – Guide for the Repair of Imperfections inGalvanized, Organic, or Inorganic Zinc-Coated Steel UsingOrganic Zinc-Rich Coatings SSPC-Guide 15 – Field Methods for Retrieval and Analysis ofSoluble Salts on Steel and Other Nonporous Substrates SSPC-Guide 16 – Guide to Specifying and Selecting DustCollectors SSPC-Guide 17 – Guide to Developing a Corporate SafetyProgram for Indust

SSPC-PA 14 – Field Application of Plural Component Polyurea and Polyurethane Thick Film Coatings to Concrete and Steel SSPC-PA 15 – Material and Preparation Requirements for Steel Test Panels Used to Evaluate the Performance of industrial Coatings SSPC-PA 16 – Method for Evaluating Scribe Undercutting on Coated Steel Test Panels Following Corrosion Testing SSPC-PA 17 .