Transcription

StaticSealsYour Partner for Sealing Technology

Your Partner for Sealing TechnologyBusak Shamban is a major international sealing force,Facilities are certified to ISO 9001:2000 and ISO/TS 16949:2002,uniquely placed to offer dedicated design and developmentwith many manufacturing sites also working to QS9000 andfrom our market leading product and material portfolio; aVDA 6.1. Busak Shamban, as the global sales and marketingone-stop shop providing the best in elastomer, thermoplastic,organisation of Trelleborg Sealing Solutions, is backed by thePTFE and composite technologies for applications inexperiences and resources of one of the world's foremostaerospace, industrial, and automotive industries.experts in polymer technology, Trelleborg AB.With 50-years experience, Busak Shamban engineers supportcustomers with design, prototyping, production, test andinstallation using state-of-the-art design tools. Aninternational network of over 60 facilities worldwide includes32 manufacturing sites, strategically positioned research anddevelopment centres, including materials and developmentlaboratories and locations specialising in design andapplications.Developing and formulating materials in-house, we utilisethe resource of our material database, including over 2,000The information in this brochure is intended to be for general reference purposes only and isnot intended to be a specific recommendation for any individual application. The applicationlimits for pressure, temperature, speed and media given are maximum values determined inlaboratory conditions. In application, due to the interaction of operating parameters,maximum values may not be achieved. It is vital therefore, that customers satisfy themselves asto the suitability of product and material for each of their individual applications. Anyreliance on information is therefore at the user's own risk. In no event will Busak Shamban beliable for any loss, damage, claim or expense directly or indirectly arising or resulting from theuse of any information provided in this brochure. While every effort is made to ensure theaccuracy of information contained herewith, Busak Shamban cannot warrant the accuracy orcompleteness of information.proprietary compounds and a range of unique products.To obtain the best recommendation for a specific application,please contact your local Busak Shamban marketing company.Busak Shamban fulfil challenging service requirements,This edition supersedes all previous brochures.This brochure or any part of it may not be reproduced without permission.supplying standard parts in volume or a singlecustom-manufactured component, through our integrated All trademarks are the property of Busak Shamban and Trelleborg AB.logistical support, which effectively delivers over 40,000The turquoise colour is a registered trademark of Busak Shamban.sealing products to customers worldwide. Busak Shamban, 2005. All rights reserved.

ContentContentSelection Criteria for Static Seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2O-Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5Back-up Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9Kantseal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51Dualseal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63Bonded Seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69Seals for SAE J518 Flanges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89Fluid Connector Seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93Wills Rings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97Turcon Variseal HF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103Quality Criteria . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106Storage and shelf life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106Edition March 20051

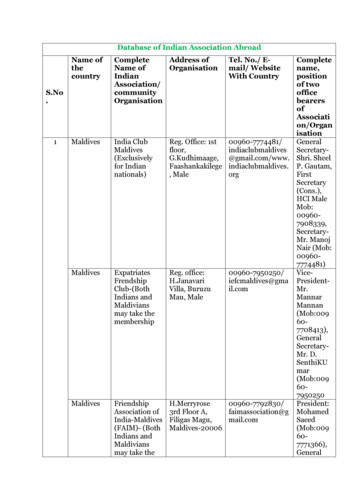

Selection criteria for static sealsSelection criteria for static sealsBack-up Ring,uncutBV/BU15Injection moulding staticTypeApplicationaxialSealradialTable IDDDDDDDDDDDSizerangeOperatingTemp.rangePressuremm CMPamax.MaterialSee further information catalogue O-RingMachine tools, presses,27Excavators, agriculturalmachinesValves for hydraulic circuitsBack-up Ring, cutBH/BG1527Back-up Ring,spiralBP-200/ISO 36016-500 260AS 568 A2-660 100250PTFE2335Back-up Ring,uncut concaveBA/BB193139-20/39NBR40-15/FKM 200Back-up Ring, cutconcaveBD/BC19ISO 36016-50031Kantseal51Flanges, valves, platesD-200/ 260250PTFE-30/DlocksNBR 1007-47050-18/FKM 200Edition March 20052

Selection criteria for static sealsSelection criteria for static sealsFork lifts, mobile hydraulic,industrial hydraulic, toolingmachines, injection Table IDDSizerangeOperatingTemp.rangePressuremm CMPamax.6-280-30/50 80Hydraulic pressesBonded Seals69Flanges, Bolts, Plates, Valves,Engines, er headsO-Ring90FlangeDSAEDJ 5181/2”to-30/ 100100MaterialPolyurethaneNBR-18/ 200FKM-50/ 120EPDM-20/NBR 100212”SAE- SealType DRV291FlangeDSAEDJ 5181/2”to-20/ 100NBR422”SAE-SealType DRV392FlangeDSAEDJ 5181/2”to-20/ 8042Polyurethane2”Fluid ConnectorSeal DRV193Threaded parts, stud endsDDIN 3869ISO 9974ISO11926D12-51-25/ 100ISO 1179NBR63-18/FKM 200Wills Rings Turcon Variseal HF97103See further Informationcatalogue Wills Rings DSee further Informationcatalogue Turcon Variseal HFD83000DDDD-260/ 85010--200/2500 260Metal1000Turcon 80Edition March 20053

Selection criteria for static sealsEdition March 20054

O-RING- Elastomers and other materials -Edition March 2005Busak Shamban5

O-RingDescriptionAdvantagesO-Rings offer the designer an efficient and economicalsealing element for a wide range of static or dynamicapplications.Inexpensive production methods and its ease of use havemade the O-Ring the most widely used seal.A wide choice of elastomer materials for both standardand special applications allow the O-Ring to be used toseal practically all liquid and gaseous media.O-Rings are vulcanised in moulds and are characterisedby their circular form with annular cross section. Thedimensions of the O-Ring are defined by the insidediameter d1 and the cross section d2.Cross section diameters of approx. 0.35 to 40 mm andinside diameters up to 5,000 mm and more areavailable.Compared with other sealing elements, the O-Ring hasa wide range of advantages:- Inexpensive, allows low cost solutions- Simple, one piece groove design reduces hardwareand design costs- Compact design allows smaller hardware- Easy, foolproof installation reduces risk- Applicable to a wide range of sealing problems, static,dynamic, single or double acting- Wide compound choice for compatibility with mostfluids- Ex stock availability worldwide for easy maintenanceand repair.Standard size range for O–RingsStandard/DimensionrangePreferred metric dimensions1.0 1.5 2.0 2.5 3.03.5 4.0 4.5 5.0 5.56.0 7.0 8.0 10.0 12.0International standardISO 3601/1German standardDIN 3771/11.803.55Swedish standard SMS 15861.6 2.4 3.0 5.7 8.4French standard1.9 2.7 3.6 5.33 6.99Japanese standard JIS B 24011.9 2.4 3.1 3.5 5.7 8.4American standard AS 568 ABritish standard BS 18061.783.53American standardAS 568 A (Series 900)1.02 1.42 1.63 1.83 1.982.08 2.20 2.46 2.95 3.00Special versions for largediameters fromapprox. 1,000 mm to 5,000 mm5.0 5.4 7.0 7.79.2 10.0 12.0Ø d2Ø d1Figure 1O-Ring dimensioningO-Ring cross sectiond2 (mm)2.655.30 7.02.625.33 7.0Edition March 20056

O-RingMethod of operationO-Rings are double-acting sealing elements. The initialsqueeze acting in a radial or axial direction due to theinstallation gives the O-Ring its initial sealing capability.These forces are superimposed by the system pressure tocreate the total sealing force which increases withincreasing system pressure.Under pressure, the O-Ring behaves in a similar way toa fluid with high surface tension. The pressure istransmitted uniformly to all directions.ApplicationsO-Rings are used as sealing elements, as energisingelements for hydraulic slipper seals and wipers and thuscover a large number of fields of application. There areno fields of industry where the O-Ring is not used. Froman individual seal for repairs or maintenance to a qualityassured application in aerospace, automotive or generalengineering.The O-Ring is used predominantly for static sealingapplications:- As a radial static seal, e.g. for bushings, covers, pipes,cylinders- As an axial static seal, e.g. for flanges, plates, caps.- O-Rings in dynamic applications are recommendedonly for moderate service conditions. They are limitedby the speed and the pressure against which they areto seal:- For low duty sealing of reciprocating pistons, rods,plungers, etc.- For sealing of slowly pivoting, rotating or spiralmovements on shafts, spindles, rotary transmissionleadthroughs, etc.pFigure 2O-Ring sealing forces with and withoutsystem pressureEdition March 20057

O-RingTechnical informationThe following Table provides a summary of the variouselastomer material groups. B S can offer a largenumber of compounds within each group.Table IIElastomer materialsDesignationTrade Name*AbbreviationISO 1629ASTM 1418B SEuroprene Krynac Nipol N NBRNBRNHydrogenated Acrylonitrile-Butadiene RubberTherban Zetpol HNBRHNBRHPolyacrylate RubberNoxtite Hytemp Nipol AR ACMACMAChloroprene RubberBaypren Neoprene CRCRWCEthylene-Propylene-Diene RubberDutral Keltan Vistalon Buna EP EPDMEPDMESilicone RubberElastoseal Rhodorsil Silastic Silopren VMQVMQSFluorosilicone RubberSilastic FVMQFVMQFTetrafluorethylene-Propylene CopolymerElastomerAflas FEPMTFE / P**WTButyl RubberEsso Butyl IIRIIRWISBRSBRWBAcrylonitrile-Butadiene RubberNitrile RubberPerbunan NTBreon Styrene-Butadiene RubberS BunaEuroprene Polysar S Natural RubberNRWRWRDai-El Fluorel FKMFKMVPerfluoro RubberIsolast Kalrez FFKMFFKMJPolyester UrethanePolyether UrethaneAdiprene Pellethan Vulcollan Desmopan AUEUAUEUWUWUChlorosulphonated Polyethylene RubberHypalon CSMCSMWMPolysulphide ElastomerThiocol -TWTWYEpichlorohydrin ElastomerHydrin --WOFluorocarbon RubberTecnoflon Viton * Selection of registered trade names** Abbreviation not yet standardisedASTM American Society for Testing and MaterialsISO International Organization for StandardizationFor further details on O-Rings please refer to our catalogue ”O-Ring”.Edition March 20058

BACK-UP RING- Protective and supporting element - PTFE compounds, elastomers and other materials -Edition March 2005Busak Shamban9

Back-up RingDescriptionExternal sealing (Bore)Back-up Rings have no intended sealing function.Instead, as their name indicates, they are protective andsupporting elements made from extrusion-resistantmaterials which generally have a rectangular crosssection. They are installed in a groove together with anelastomeric sealing element preferably with acorresponding O-Ring in static applications.Due to the tight fit of the Back-up Ring in the housing, theyprevent extrusion of the pressurised elastomeric sealingelement into the sealing gap.Advantages- Use of O-Rings in high pressure applications-Use of O-Ring materials with a low hardnessCompensation of radial sealing gapsUse for internal and external sealing applicationsReciprocating and rotating movements possibleCompensation for large temperature fluctuationsStatic and dynamic applicationsBack-up Ring types, uncutH Type BV-Rectangular cross sectionMaterial PTFEStatic and dynamic useReciprocating and rotating movements possibleH Type BB- Concave cross section- Materials: NBR, FKM- The large contact surface protects the O-Ring againstdeformation in case of high pulsating pressure- Dimensional stability of the O-Ring improves thesealing force and increases the service life- Preferably for static use- Reciprocating movements possibleH Type BASealing gapSp- Concave cross section- Material: PTFE- The large contact surface protects the O-Ring againstdeformation in case of high pulsating pressure- Dimensional stability of the O-Ring improves thesealing force and increases the service life- Static and dynamic use- Reciprocating and rotating movements possibleH Snap-back Back-up Ring, special TypeSealing gapSpFigure 3- Easy installation in closed grooves due to thesnap-back effect of the material- The dimensions are different compared to thestandard Back-up Rings. Production only on requestaccording to drawingO-Ring installation with and withoutBack-up RingEdition March 200510

Back-up RingBack-up Ring types, cutInternal sealing (Rod)H Type BH-Rectangular cross sectionMaterial PTFECut angle

ISO 3601/1 German standard DIN 3771/1 1.80 2.65 3.55 5.30 7.0 Swedish standard SMS 1586 1.6 2.4 3.0 5.7 8.4 French standard 1.92.73.65.336.99 Japanese standard JIS B 2401 1.9 2.4 3.1 3.5 5.7 8.4 American standard AS 568 A British standard BS 1806 1.78 2.62 3.53 5.33 7.0 American standard AS 568 A (Series 900) 1.02 1.42 1.63 1.83 1.98 2.08 2.20 2.46 2.95 3.00 Special versions for large .