Transcription

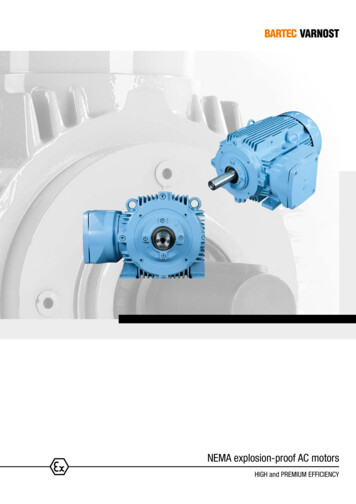

NEMA explosion-proof AC motorsHIGH and PREMIUM EFFICIENCY

The plant itself came into being in 1957 as one of the small working units ofthe Zagorje coal mine. Five years later, in 1962, it became a separate companycalled “TEVE VARNOST“. Numerous organizational restructurations took placeduring the following years and in 1997 the company was taken over by BARTECto become “BARTEC VARNOST“.MOTORS AND ELECTRICAL EQUIPMENTBARTEC develops and manufactures electric motors and electrical equipmentfor safe and reliable solutions in power, control and monitoring applications.Our production program includes: Electric motors Special motors and special solutions Control and connection equipment Mining motors and switch gearsAll products can be supplied for potentially explosive atmospheres, wet environments or tailored to our customers’ requirements.BARTEC VARNOST, Zagorje ob Savi, Slovenia

CONTENTS1 NORTH AMERICAN CERTIFICATION22 INTRODUCTION33 CONSTRUCTION3 - 28Basic design3Bearings4Shaft ends5Allowable radial force5Maximum axial loads6Terminal boxDegree of protection and paintingMountings form, Explosion protection and certificatesPower, voltage and service factor6-789 - 1010Windings11 - 12Duty cycles12 - 13Direct cable entries14Motors with brakes14Motors with encoders14Forced cooling14Electrical data for variable speed motors15Variable speed drive application15Electrical data for single speed motors HIGH EFFICIENCY16 - 17Electrical data for single speed motors PREMIUM EFFICIENCY18 - 19Motor dimensions20 - 27Special application28

NEMA Explosion-proof AC motors1 NORTH AMERICA CERTIFICATIONBARTEC VARNOST motor‘s type 4KTU are approved by CSA for use in divisionbased hazardous areas.Explosion-proof motors are labeled with the following:CSA Listing mark for use in Canada and the UnitedStates. The product is certified to the applicableAmerican and Canadian standards.Certificate: 70013549Marking and name plateThe name plate supplies information determining the motor’s construction andperformance characteristicsCUSHazardous area classificationsThe division defines how often the potentially explosive materials are presentduring normal operating conditionsDivision 1: ignitable concentrations are present all or most of the timeDivision 2: ignitable concentrations are not likely to be present during normaloperationHazard classGroups per NEC 500SubstanceClass IFlammable gases/vapors liquidsGroup CEthyleneGroup DPropaneGroup EMetal dustGroup FCoal dustGroup GGrain dustClass IICombustible dustClass IIIIgnitable fibersand flyingsNot divided into groups 165 C max. temperaturelimit for all Class III equipment not subject tooverloading 120 C max. temperature limit for allequipment subject to overloadingSurface temperatureThe T-Code identifies the maximum absolute motor surface temperature thatwill developed under any conditions of operation. Surface temperature ofBARTEC VARNOST motors will not exceed the following UL and CSA maximums under fault conditions.T-Code Maximum motorsurface temperature C FT1 450 842T2 300T2A FT3A 180 356 572T3B 165 329 280 536T3C 160 320T2B 260 500T4 135 275T2C 230 446T4A 120 248T2D 215 419T5 100 212T3 200 392T6 85 185BARTEC VARNOST14 Operating current15 Power factor16 Ambient temperature17 Service factor18 Motor weight19 Certification labels20 Service factor current21 NEMA code letters for locked-rotor kVA22 Current at 208 V23 Derating24 Degree of protection25 VFD SupplyT-Code Maximum motorsurface temperature C21 Serial no.2 Three phase3 Rated operating voltage4 Service duty5 Efficiency6 Frame size7 Enclosure8 Insulation class9 Temperature rise10 Design11 Frequency12 Rated power13 SpeedTechnical data subject to change without notice.

NEMA Explosion-proof AC motors2 INTRODUCTIONBasic designFlame proof AC electric motors are used in hazardous locations or potentiallyhazardous environments where concentrations of combustible gases, vaporsand or dust are present or present some of the time. Motors type 4KTU canbe manufactured to NEMA frame size 143 to 365 as well as IEC frame size71 to 255.Frame size IEC 714KTU motors are three-phase, asynchronous electric motors with short circuitrotors explosion-protected according to the: “Flame-proof enclosure” for the motor housing and “Increased safety”for terminal box according to UL 60079-1/CSA C22.2 60079-1,UL 60079-7/CSA C22.2 60079-7 and CSA C22.2 No. 30 (Class I, Zone I) “Flame-proof enclosure” for the motor housing and“Flame-proof enclosure”for terminal box according to UL 60079-1/CSA C22.2 60079-1 andCSA C22.2 No. 30 (Class I, Zone I) Dust Ignition Proof “DIP” (Class II, Division 1) according to CSA C22.2 No. 25Frame size IEC 80-132; NEMA 143/5 – 213/5 Dust protected “NI” (Class II, Division 2) according to CSA C22.2 No. 25 Protection by Enclosure “Ex tb” (Class II, Zone 21) according toUL 60079-31/CSA C22.2 No. 60079-31The standard electric motor is suitable for T4 to T6 temperature classes orthe maximum 257 F to 185 F/ 125 C to 85 C surface temperaturesof equipment.Type 4KTU motors are available in a high efficiency class.3 CONSTRUCTIONThe type 4KTU motors are totally enclosed and fan-cooled (TEFC), as per NEMAMG-1 Part 6. Non-ventilated versions (TENV), air over (TEAO) and with forcedventilation (TEFV) are available.Frame size IEC 160-225; NEMA 254/6 – 364/5MaterialsFramesizeStatorShieldFrame FeetMaterialTerminal Flange Fanboxcover chnical data subject to change without notice.Ultramid, Polyamid or Aluminium286TSSteel sheet extruded284TSCast iron screw on256TCast iron254TCast iron215TCast iron213TCast iron screw on feet184TAluBARTEC VARNOST3

NEMA Explosion-proof AC motorsBearingsThe following table lists the bearings used in different motors. Only the latestand most innovative bearings of well-renowned producers are used in ourmotors. Upon customer request, we equipped the motors with other bearings(depending on the respective construction).On both sides drive and non-drive, a Pt100 probe can be installed that monitorsthe temperature of the bearings.Lubricants and seals used in bearings are suitable to operate at the maximumtemperatures of the bearings.The effectiveness of motor lubrication should bechecked by measuring thesurface temperature of the bearing end shield during normal operating conditions. If the measured temperature is 176 F/ 80 C or above, the intervalsbetween re-lubrications must be shortened. The re-lubrication interval shouldbe halved for every 15 K increase in bearing temperature. If this is not possiblethen use lubricants that are suitable for high operating temperature conditions.Ball bearings: lubrication intervals in duty hoursFramesizeAmount Speed of the motor [rpm]of greaseFramesizePolesDE bearingNDE bearingBearingdishes143T2, 4, 6, 86205620525 x 52 x 15145T2, 4, 6, 8182T2, 4, 6, 86206620630 x 62 x 16184T2, 4, 6, 8213T2, 4, 6, 86208620840 x 80 x 18215T2, 4, 6, 8254T2, 4, 6, 86309630945 x 100 x 25256T2, 4, 6, 8284TS2, 4, 6, 86310631050 x 110 x 27At the ambient temperature of 77 F/ 25 C, the grease lifespan can beexpected to double, however, 33000 hours is the maximum.286TS2, 4, 6, 8324TS2, 4, 6, 86312631260 x 130 x 31326TS2, 4, 6, 8In case of frequency inverters and in continuous operation at very low speed,as well as at low temperature, the lubrication capabilities of standard greasesmay not be sufficient and special greases with additives are needed.364/5TS2, 4, 6, 86313631365 x 140 x 33If motors are equipped with sealed bearings (i.e. bearings greased for life), anydeviation in the operating temperature from the design temperature will resultin change in the lifespan of the bearings.Frame size 254/6 – 364/5IEC 160-225The use of conductive greases to eliminate bearing currents is not recommended due to their poor lubrication characteristics and low conductivity.Bearing assembliesFrame size 143 – 213/5IEC 90-132[Lb]3600300018000.067000950014000 17000 21000 240000.076000800013500 16000 20000 230000.094000600011000 13000 17000 21000364/5T 0.123000500010000 12500 16500 g or replacing the grease is only allowed using a grease of equalquality (same saponification component or consistency).Drive endNon-drive endBearing lubricationMotors are normally fitted with permanently greased bearings type 2Z. Thisbearings are greased for life.Motors fitted with grease nipplesMotors from frame size 254T and above can be fitted with re-greasable bearings. Lubricate the motor during its operation. If the motor is fitted with alubrication plate, use the value given, or use the values listed in the accordingtable.4BARTEC VARNOSTTechnical data subject to change without notice.

NEMA Explosion-proof AC motorsShaft endsAllowable radial forceThe standard electric motor is equipped with one free shaft extension. Onrequest we can also supply versions with free shaft extensions on both sides.Permissible loads are in according with NEMA MG-1 (table 14-1A)Type 4KTU motors can be supplied with stainless steel shafts (AISI 316 andAISI 420) for highly corrosive environments.Frame sizeNumber of polesThe dimensions of shaft ends correspond to the NEMA MG-1 standard. Tolerances for shaft end-diameters are in accordance with NEMA MG-1, Part 4, Point 4/5TS2468820108012401390 up to a diameter of 1.5000 in ( 0.000/-0.005 in) more than 1.5000 in ( 0.000/-0.001 in)Free shaft extensions are equipped with keyways. Keyways and keys correspondto NEMA MG-1, Part 4The shafts have a threaded central hole for the drawing in, drawing out andfixing connections.Shaft diameter0.875 in1.125 in1.375 inA4Technical data subject to change without notice.1.625 in1.875 in2.125 inA4/UNC¾"-10Maximum radial force in poundsCenter of N-WBARTEC VARNOST5

NEMA Explosion-proof AC motorsMaximum axial loadsTerminal boxMaximum permissible axial loads in poundsThe terminal box of type 4KTU motors are made of cast iron which is the samematerial used to produce the frame.FramesizeNumber Horizontalof 062081098011701050128015301690364/5TVerticalWeight of rotor in load directionThe load rating of bearings has been calculated for at least 20000 operatinghours at a frequency of 60 Hz. Only the axial loads have been taken intoaccount. If the load is made of axial and radial loads, the working lifespan ofbearings is shorter.6BARTEC VARNOSTThe standard terminal box is made in assembly F-1, but it can be producedalso in F-2 and F-3.F-1F-2F-3The terminal box can be repositioned in steps of 90 to 180 to suit theapplication.Electric motors are designed with the terminal box in equipment protection: Increased safety “Ex e”, according to UL 60079-7 and CSA C22.2No. 60079-7. (for IEC frames only) Flame-proof enclosures “Ex d”, according to UL 60079-0, CSA C22.2No. 60079-0, UL 60079-1 and CSA C22.2 No. 60079-1.There is a direct cable entry available for all motors.Technical data subject to change without notice.

NEMA Explosion-proof AC motorsEx d terminal boxMotors can also be connected with rigid metal conduit, of which the size andlengths are in accordance with this table:Terminal boxes can have either metric or NPT threaded entries:Rigid conduit sizes and lengthsTerminal box entriesIEC frameNEMA 80284/6200324/6225364/5MetricNPTIEC frameNEMA frame Thread sizeLengthMetric2 x M25 1 x M203/4"2 x M25 1 x M201"2 x M50 2 x 80284/6200324/6225364/5NPT2 x M25 1 x M203/4"2ft3 x M321"2 x M50 2 x M20 2"18"The Ex d terminal box has a threaded entry to accept Ex d cable glands or rigid metal conduit. In a terminal box, there can be 6 or 12 main connection terminalsand 6 additional terminals for PTC sensors, heaters, etc. Each terminal box has one earth connection terminal.Ex d terminal boxIEC: 71IEC: 160-225/NEMA: 254/6 - 364/5Ex e terminal box (IEC frames only)IEC: 80-132/NEMA: 143/5 - 213/5Frame size 71Frame size 80 - 132Frame size 160 - 225In the terminal box with increased safety and cable glands according to UL 60079-0, CSA C22.2 No. 60079-0, UL 60079-7 and CSA C22.2 No. 60079-7 areused. Cable glands are fitted for this purpose and are separately certified.Technical data subject to change without notice.BARTEC VARNOST7

NEMA Explosion-proof AC motorsDegree of protection and paintingIP protectionType 4KTU motors are supplied with a rating of the degree of protection in conformance with NEMA MG-1 Part 5.The standard degree of protection for type 4KTU motors is IP 55 for Class I and IP 64 for Class II.Protection against environmental influences IP protectionProtection Protection against harmful contact and ingress ofclasssolids (1st Numeral)Protection Protection against ingress of water (2nd Numeral)classIP 44IP 44/IP 54Water particles spraying from any direction do not have anyharmful effects on the machine (i. e. rain).IP 55/IP 65*A jet of water spraying from any direction does not have anyharmful effects on the machine.IP 56During rough seas water must not penetrate into the interiorof the motor to such an extend as to cause damage to themachine (deck-mounted motors).Protection against direct contact with electrically live androtating inner parts using tools, wire or similar objects with adiameter exceeding 1 mm. Protection against ingress ofsolids (diameter 1 mm). Fan air outlets and waterexhausts may have a second-degree level of pr

to NEMA MG-1, Part 4 The shafts have a threaded central hole for the drawing in, drawing out and fixing connections. Shaft ends NEMA Explosion-proof AC motors 0.875 in 1.125 in 1.375 in 1.625 in 1.875 in 2.125 in A4 A4/UNC ¾"-10 Shaft diameter