Transcription

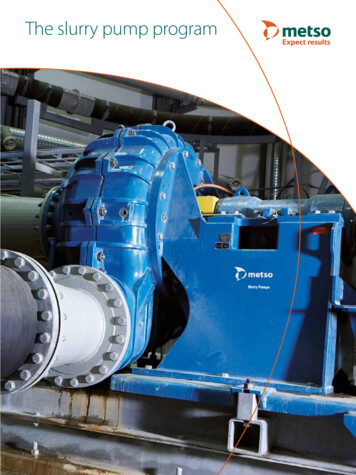

The slurry pump program

Metso slurry pump rangesBy acquiring Svedala Industri AB, Metso has added the well known pump manufacturers Sala, Denver, Orion, Thomas, Marathon, Titan and Amsco totheir manufacturing range. Several years ago Metso decided to streamlineand update its entire range of slurry pumps.A step was taken to better serve the market with state-of-the-art slurrypumps and a totally new range of horizontal and vertical slurry pumps hassince been launched.2Slurry pump program

– engineered for today’s operation.Slurry pump program3

XM 600 with MM25 in the middleThe Thomas and Sala series ofhorizontal slurry pumpsXM and XR pumps with slidebaseVASA HD pumps with slidebaseTypical applicationsForemost of the range is a group of e xtraheavy duty, large, slurry pumps known as theX range. These are available in an XM hardmetal version and an XR rubber lined version.Maintenace slide base options are availablefor inlet sizes up to 400 mm (16”).The traditional range of extra heavy dutypumps, VASA HD, are available in a smallersize range, but still at high efficiencies andspecifically designed with maintenance slidebases which reduces maintenance timemore than 50%! VASA HD pumps areavailable in both hard metal and rubberlined wear parts. Extra heavy duty highly abrasive slurries Flow rates from 50 to 2 500 m³/h– 220 to 11 000 USGPM In plant slurry transfer pumpsThe X range offers a large, heavy duty solidshandling pump with excellent performanceand low maintenance costs. The heavy dutydesign and robust construction combinedwith the highest quality of abrasion resistantwear materials is a guarantee for long life andtrouble free operation in the toughest heavyduty applications, such as SAG & AG mill recirculation duties.4 Flow rates from 1 000 to 10 000 m³/h– 4 400 to 44 000 usgpm Heads up to 75 m - 250 ftSlurry pump program Heads up to 50 m - 160 ft Mining and mineral processing Cyclone feed Mine refuse and tailings Industrial processing Mill discharge Sand and gravel Medium duty abrasive slurries

– lowest operating cost in industry.The Thomas series of heavyduty dredge pumpsThe Thomas dredge pump is designed specifically for dredging of large materials.Its design features allow maximum particle size passage while maintaining highefficiency. The Pumps are available in bothabrasion resistant and high impact materialsfor wear parts.Years of operation and many design improvements have resulted in a pump withthe lowest operating cost in the industrywhen dredging abrasive material.The improvements include the Armor-lok Seal, oversized bearings/shaft and extraheavy metal sections for longer wear. Thedesign and knock out ring features reducestime and maintenance costs. Flow rates from 500 to 10 000 m3/h– 2 200 to 44 000 USGPM Heads up to 75 m - 250 ft.Typical applications Dredging:– Sand and gravel– Contract dredging– Tailings Booster pump Sand waste pump Material transfer pumpThe Metso MD series of milldischarge pumpsThe Metso “MD” Mill Discharge pump isdesigned for efficient operation and longwear life in grinding mill circuits where highdensity slurries are often encountered.The rugged wet-end parts are designed tofeature extra heavy metal sections at pointsof extreme wear – the extra weight pays offin performance and low maintenance cost.The Metso Global power frame features anoversized shaft and bearing assembly andheavy fabricated frame and base offeringglobal commonality with the Metso PumpSolutions product line.Large diameter, high efficiency, high chromeiron impeller designs deliver predictable performance over the life of the parts and “DutyPoint Engineering” ensures operations in thebest efficiency range.Flow rates from 1000 to 10 000 m3/hr– 4 400 to 44 000 USGPMHeads up to 70 meters – 230 ft.Typical applications SAG/Ball mill discharge pumps Thickener under/overflow pumps Tailings pumpsSlurry pump program5

The Orion series of horizontal slurry pumpsThe Orion series of heavy dutyslurry pumps HR, HM and HHThe Orion series of miningduty slurry pumps MR and MMTypical applicationsThe heavy duty, H-range slurry pumps areavailable in rubber lined HR, in hard metalHM and high head HH versions. They aredesigned for the most arduous industrialslurry pumping applications. The excellenthydraulic design guarantees maximum efficiency throughout the life of the generouslyproportioned wear parts.Metso’s mining duty slurry pumps is the Mrange. They are designed for medium abrasive solids, lower solids concentrations andmedium heads. They are available in bothhard metal MM and an elastomer version MR.The modular design and the optional backpull-out feature provides easy access forinspection and maintenance. The excellent hydraulic design ensures maximumefficiency, thereby reducing both the rate ofwear and the power consumed. Extra heavy duty highly abrasive slurriesThe M range pumps are the preferred choicefor abrasive duties such as general in-planttransfer pumps. Medium duty abrasive slurriesThe wear materials used are the very bestavailable providing both outstanding wearproperties and corrosion resistance forabrasive plant duty applications. The optionalback pull-out feature provides easy access forinspection and maintenance of the wet end. Flow rates to 2 800 m³/h – 10 000 usgpm Flow rates to 5 000 m/³h – 20 000 usgpm Heads up to 100 m – 330 ft Heads up to 60 m – 200 ftMaintenance slidebase available as an option.6Slurry pump program Mining and mineral processing SAG and AG mill discharge recirculationduties Cyclone feed Mine refuse and tailings Industrial processing Mill discharge Coal and power plant ash Sand and gravel In plant slurry transfer pumps

– for the most aggressive industrialslurry pumping applications.Orion series of heavy dutygravel pumps HGOrion series of high pressurepumps HPOrion series of heavy dutytunneling pumps HTGravel pumps are specifically designed topass large solids typically found in the sandand gravel industry. The suction side of thepump is also opened up to accommodatelarge solid transfer. These pumps are built onthe same heavy-duty frame as the HM pump.These pumps can be applied to any application that may encounter very large solids.High-pressure hard metal pumps are designed to operate at 40 bar (600 psi) with testpressure at 1.5 times the design pressure.These pumps incorporate extra thick ribbedcases to withstand the extreme pressures.The pump comes standard with double dryend bearings, high-pressure flanges andMetso's patented double adjust frame tomaintain high pump hydraulic efficiencies.The HP casing can also be incorporated intoapplications that require longer wear lifecasings.Tunneling pumps are typically used inconjunction with large boring equipment.These pumps are specifically designed totransfer newly cut material from the face ofthe tunnel. They can also be used in series totransfer material to the entrance of long tunnels. The pump is specifically designed witha special casing and frame for a low-profilesmall footprint to fit into the confined spacesof a tunnel. A 90 elbow is cast into thecasing to help achieve this small profile.Typical applications Sand and Gravel Coal processing WoodchipsTypical applications Tailing lines Series pumpingSlurry pump program7

The Sala series of vertical pumpsVertical sump pumps VSThe VS Sump Pumps are strong, tough andthe most reliable pumps on the market. Forthis reason this range is preferred throughoutthe world by most heavy industries.The VS pumps is used in floor cleaning andprocess applications. A number of differentimpeller and agitation options are available. Choose from closed, semi-open andinduced flow impellers. Agitation can beaccomplished with casing spray holes orextended shaft with a slurry agitator. The fullyinterchangeable wear parts are available inabrasion resistant rubber or hard metal. Therobust cantilever design without any submerged bearings or shaft seals, has alreadymade this range well known and establishedin the slurry pump market.8 Flow rates to 1 500m³/h – 6 600 usgpm Heads up to 45 m – 150 ftSlurry pump programVertical sump pumpsVSH and VSMTypical applicationsMetso has recently expanded its VS pumprange with the introduction of the VSH andVSM models: a perfect marriage of therugged Sala VS frame with our heavy-dutyhigh efficiency Orion series horizontal pumphydraulics. Mill scale pumpingThe VSH and VSM provide larger diameterimpellers designed for slower speeds (lowerwear rates) and higher head capability.Additionally, the customer now has thebenefit of commonality of wet end parts forboth its horizontal and vertical slurry pumps,reducing spare parts inventories while simplifying maintenance.A special fully recessed Vortex impeller designis also available on several pump sizes forlow slurry shear applications like gold carbontransfer. Floor sumps in process plants Pumping of machine tool cuttings Wood chips pumping

– strong, tough and reliable.Vertical tank pumps VTThe VT Vertical Tank Pumps are designed forabrasive slurry service and feature simplemaintenance and robust construction. Theingenious design of the pump with no shaftseal makes it exceptionally service friendlyand easy to install.Standard pumps are supplied with wetend parts in wear resistant rubber or hardmetal. Parts in different materials are fullyinterchangeable and can be combined foroptimum life. Flow rates to 1 000 m³/h – 4 400 usgpm Heads up to 30 m – 100 ftTypical applications VT Feed to dewatering cyclones in sandplants Screen underflow duties Sampling pumps in concentrators Permanent, mobile or semi-mobile installations in industrial applications Mixing/distribution units in applicationsfor flocculent or lime in sewage plants orcement grouting in tunnels or mines.Vertical froth pumps VFThe VF Froth Pump has been designed toincrease the pumpability of frothy slurries.The principle of operation is similar to thatof hydrocyclone s eparation. Air is separatedfrom the slurry in a vortex created by theimpeller rotation and the tangential inletto the pump’s conical tank. This results in amore efficient pumping and a smooth operation, free from pulsation caused by airblocking.Typical applications VF Ideal for all applications involving handling of air entrained slurries, such as flotation froth in base metal concentrators,phosphate and apatite washing plantsand calcium carbonate upgrading plants Used as a mixing and distribution unit,where dry powder has to be mixed (andwetted) with water Can also be used with cement in readymixed concrete and for groutingStandard wear materials are in natural rubberor hard metal. Other wear materials includesynthetic rubbers and polyurethane. Flow rates to 600 m³/h – 2 600 usgpmHeads up to 20 m – 65 ftSlurry pump program9

Wet end conversions– reduce your maintenance costs.Orion wet endsThomas wet endsFeaturesMetso can offer the Orion series pump hydraulics and shaft sealing options onto competitor’s pump frames and bearing assemblies. These conversions can help overcomestraditional slurry pump problems such as lowhydraulic efficiency, premature componentfailure, inconsistent performance, ineffectivecentrifugal seals and difficult maintenance.The Thomas series hydraulics and shaft sealing options are available for conversion ontolarger pumps. These conversions are typically installed into dredge and grinding milldischarge applications where wear rates arehigh and longer life is required. Metso hasmany standard hydraulic wet end designsthat can move the duty point closer to thebest efficiency line of the pump curve whichwill improve component wear life. Dutypoint engineering is also available for thehighest wear life potential improvement. Prolongs pump life significantly Reduces maintenance costs Simple two step impeller adjustment fortotal wear clearance without dismantling Maintains optimum operating efficiency Sizes range from 50 x 32 to 350 x 300 mmfor Orion and up to 700 x 600 mm forThomas.The wet ends are the same as those used inthe standard Orion series of pumps. Theyare 100% interchangeable with other Metsopumps that may be operating in the sameinstallation. The double adjustment featurepermits optimum impeller adjustment onboth gland and suction sides of the casing,with clearances that result in vastly improvedperformance and longer pump life.10Slurry pump program

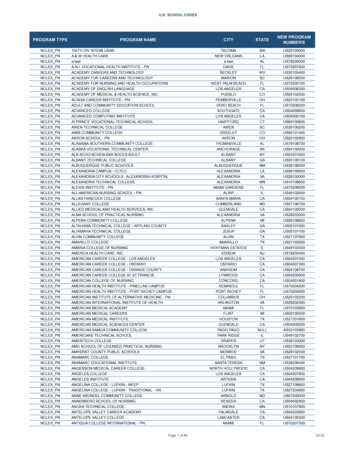

Metso slurry pumpsPump size – inlet flangeInlet size(mm)255075100150200250300 2Orion series MM - WFR MR HM HM - WFR HR MMHH and HMPHGHG - WFR HPHT Thomas seriesMM MR XM XR MD Thomas Dredge Marathon Dredge MA - Matrix XG Sala seriesVSMM VSMM - WFR VSHMVSHM - WFRVSHR VSHGVSHG - WFROutlet size (mm)(Inch) Pump size – outlet flange2540508011,52 1001502002503003503468101214 Sala series VF VSVTVASA HD Slurry pump program11

3xD bendsCouplingsMaterial handling hoseReducersBranch pipesGasketsMetso hose system for heavy-duty use.Metso Slurry Handling Solutions are based on easily exchangeablestandard components: hoses, couplings and gaskets of varying diameters.The Metso Trellex Hose system is the natural choice for handling materials in heavy-duty hydraulic or pneumatic conveying systems.The system is designed on the basis offirsthand experience of transporting highlyabrasive iron, copper and other metallic ornonmetallic ores in mineral processingplants.Rubber offers superior wear resistance whenhandling abrasive rocks and sands, as well asslag and other materials.The Trellex hose system is used in sand, lime,and glass plants, in quarries, in coalpreparation and power plants, as well as insteel and cement works.12Slurry pump programRubber absorbs energyAppropriate conditionsRubber is an elastomer. While steel and ceramics presen

Metso slurry pump ranges By acquiring Svedala Industri AB, Metso has added the well known pump manufacturers Sala, Denver, Orion, Thomas, Marathon, Titan and Amsco to their manufacturing range. Several years ago Metso decided to streamline and update its entire range of slurry pumps. A step was taken to better serve the market with state-of-the-art slurry pumps and a totally new range of .