Transcription

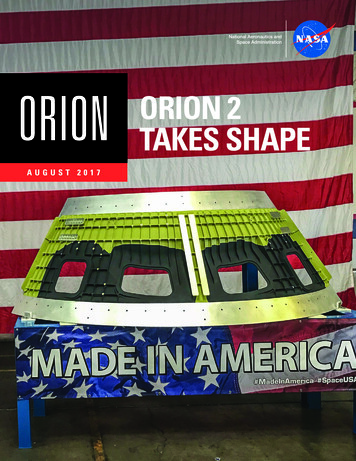

Slurry Pumpswww.metsominerals.comThe Orion Series ofHeavy & Mining Duty Horizontal Slurry Pumps8515 Orion Series102-04-09, 18.28

The Orion Series ofHeavy and Mining Duty Horizontal Slurry PumpsHorizontal PumpsThe Metso heavy (HM, HR) and mining (MR, MM) dutyhorizontal slurry pump range offers the newest and widestrange of world class rubber lined and hard metal slurrypumps for abrasive pumping applications. Use of fluid dynamic software to improve pump hydraulicefficiency 3-D computer design technology for development of hydraulicand mechanical componentsLong Wear LifeLowest Total CostOur focused product development combined with over 60years of experience from thousands of applications has led tocontinuous improvements in our products.The benefits to customers are numerous but the most significantis the life time cost saving that will be achieved by using Metsohorizontal slurry pumps.Low Power Consumption High efficiency hydraulic design ensures optimal powerutilization Range optimization ensures operation close to the bestefficiency point Wear parts of highest quality hard metal, rubber and corrosionresistant materials Robust design with extra thick sections at known pointsof wear Highest quality of wear resistant elastomers developedby Metso Interchangeability of hard metal and elastomer parts toprovide the best solution for each individual application Optional special materials available on request Careful application at best efficiency point and selection ofwear-resistant material give evenHR1508515 Orion Series202-04-09, 18.28

Features & BenefitsReliability in OperationTypical ApplicationsSpecially developed features in our pumps provide trouble-freeoperation and minimum downtime improving the cost effectiveness of the operation: Mining and mineral processing Oversized high strength alloy steel shaft is carried in heavyduty grease lubricated bearings in a self-contained cartridgeassembly Double seal arrangement provides positive seal of bearingsagainst contamination Proven and reliable gland seal options to meet individualrequirements, using expellers, flushed glands or mechanicalseals Modular design and full interchangeability of parts minimizes stock levels Back pull out feature allows ease of inspection and maintenance Compact and functional design Metso pumps and parts are manufactured under total qualitymanagement and all our production units are ISO certified Highly abrasive slurriesSAG and AG mill discharge recirculation dutiesCyclone feedMine refuse and tailingsIndustrial processingMill dischargeCoal and power plant ashSand and gravelMining duty abrasive slurriesIn-plant slurry transfer pumpsPulp & paperLime slurryAluminaFertilizerAcid NeutralizationHM1508515 Orion Series302-04-09, 18.29

Stuffing Box Sealing Options8515 Orion SeriesFull FlowLow FlowUse for suction conditions not suitable for centrifugal sealingwhen product dilution is not important. Full flow provides thelongest packing wearing life. The lantern ring is placed in thebottom of the stuffing box.Use for suction conditions not suitable for centrifugal sealingwhen product dilution needs to be minimized. One ring ofpacking is placed in front of the lantern ring.Standard Expeller Shaft SealMetso Slurry Mechanical SealUsed for no product dilution against positive suction head withoutleakage. The standard pump has a primary high performance dryhydrodynamic expeller which seals the shaft when the pump isrunning. A secondary, packed gland seal stops leakage when thepump is not running.Used for zero stuffing box leakage or product dilution. Availableas single slurry type mechanical seal or double mechanical sealwith external barrier fluid required. It is possible to use dead-endflush on the double seal.4The expeller is not used on flushed seal assemblies.02-04-09, 18.29

Technical DescriptionDouble Adjustment1The total impeller wear clearance adjustment is a patenteddesign feature. The procedure of closing the back and frontimpeller clearances permits constant perfomance of the pumpthroughout the normal wear life of all components. This simpleoperation is illustrated in the two steps shown below and canbe performed in minutes on site pump without disassemblingthe pump.Step 1. Adjust impeller back-side clearanceImpeller back clearance and centrifugal seal adjustment isachieved by adjusting the screw on the bearing cylinder housing.The bearing cylinder housing, shaft and impeller move back inorder to close the impeller back clearance.Back clearanceCentrifugal seal clearanceShimsStep 2. Adjust impeller front-side clearanceImpeller front clearance is made by removal of casing half-shimsand retightening casing bolts. This also acts as a visual wearindicator. The entire power frame moves forward to close theimpeller front-side clearance.Front clearanceBack and Front Pull-out DesignBack Pull-out DesignFor normal routine inspection or repair, the bearing frame androtating element can be removed as a unit. Impeller and glandseal component renewal can be carried out rapidly.Front Pull-out DesignFor casing only renewal, or if back pull-out is not convenient,the front pull-out feature can be used after pipework removal.8515 Orion Series502-04-09, 18.29

Total Impeller Wear Clearence AdjustmentClosing both back and front impeller running clearances permitsoptimum continuous performance of the pump. All adjustmentscan be made on installed pumps without disassembly.Back Pull-Out DesignDesigned for ease of maintenance.Taper Roller BearingsHeavy duty grease lubricatedbearings in a sealed cartridgedesigned for maximum bearinglife. Double bearing arrangements available.SealsDouble sealed with V-ring protected lip sealto ensure reliable operation.Heavy Duty ShaftDesigned for tough services. High power transmission designwith reduced impeller overhang for minimum shaft deflectionand a maximum pump life.Materials of Case linersImpellerNatural Rubber Natural urethanePolyurethaneMetachromeBack linerMetaChromeCD4MCu*BacklinerNatural RubberChloropreneEPDMButylPolyurethaneBearing frameExpellerDuctile Iron MetaChromeCD4MCu*Expeller Ring Shaft SleeveMetaChrome MetaChromeCD4MCu*CD4MCu*ShaftCarbon SteelSealsNitrileNeopreneVitonBearing FrameExpellerExpeller Ring Shaft SleeveDuctile Iron MetaChrome Natural Rubber ethaneShaftCarbon SteelSealsNitrileViton*Consult Factory8515 Orion Series602-04-09, 18.29

Technical DescriptionsCentrifugal Seal ArrangementThe expeller generates a high head and works in conjunctionwith expelling back vanes of the impeller to provide a highlyeffective seal against positive inlet heads without gland leakage.Performance improves with wear clearance adjustment at theback of the impeller. Abrasion resistant materials ensure wear lifeequivalent to the pump. Four rings of self-lubricating packing,seal the pump while stationary.Even Wear DesignCase and impeller are matched for minimum hydraulic turbulencefor longer and more equally distributed impeller and casewear life.Impeller DesignPartial mixed flow main vanes reduce hydraulic shock losses atthe suction eye. Large diameters and strategic mass distributionpermit high head and high performance at slow speeds withoutthe sacrifice of efficiency.ANSI / Metric Flanges as RequiredSuction and discharge flanges are split on all HM and MM pumpsfor optional flange configurations, ease of pipe connection andalignment. Rubber lined pumps have slotted flanges to allowmost metric or ANSI flanges.Wear Resistant CastingsStrict metallurgical control and casting integrity with extrametal at known areas of severe wear.Wet EndsHard metal and rubber lined wet ends available.8515 Orion Series7Front and Back Expeller VanesDouble adjustment feature permits the use of narrow expellingvanes greatly reducing internal recirculation with minimal energyconsumption.02-04-09, 18.30

8515 Orion Series802-04-09, 18.30

Technical SpecificationsSelection of Pump Size for the Heavy Duty Rubber Lined and Hard Metal Slurry Pumpsftm1003009080HM 75HM 50250HM 150HM 100HM 200HM 250HM3007020060m5015040HR 50100HR 100HR 75HR 150HR 200HR250 HR300302050101050401502006080 1003002005001000400600 800 10002000400020005000m 3/hr10000 USGPMPump 0HR50HR75HR100HR150HR200HR250HR300Inletmm inchOutletmm 551 0301 1424284635557139651 1251 14217,5172025344145171822283844576227328701 0251 2571 4601 6007077279031 1001 2961 5481 61 0003603604245456858161 3205501 2202 0402 8501802203306301 2502 1103 2803504407051 2122 6894 4186 2833964857271 3882 7554 6517 231* Bare shaft weight8515 Orion Series902-04-09, 18.30

8515 Orion Series1002-04-09, 18.31

Technical SpecificationsSelection of Pump Size for the Mining Duty Rubber Lined and Hard Metal Slurry M 0 50 60150 200300100200300 400 5001000400 500 750 1000 1500 2000 3000 4000 60002000300010000m /hUSPGMPump letmm 608951 0551 0801 2741,589210951293151215805045046226327548921 0951 2931 5121 5561 168161 ,527323239kg1601702604207401 5402 4502 98040501401502303706501 3502 1502 3003 000lb3533755739261 6313 3955 4016 570881103083305078151 4332 9764 7405 0706 614*Bare shaft weight8515 Orion Series1102-04-09, 18.31

Slurry PumpsOur Range:Horizontal. Rubber and MetalXR/XM, Extra Heavy Duty PumpsHR/HM, Heavy Duty PumpsMR/MM, Mining Duty PumpsDredge PumpsVertical. Rubber and MetalVF, Froth PumpsVS, Sump PumpsVT, Tank PumpsMetso MineralsSE-733 25 SalaSwedenPhone: 46 224 570 00Fax: 46 224 169 50Metso MineralsP.O. Box 340Colorado Springs, CO 80901USAPhone: 1 719 471 3443Fax: 1 719 471 4469Metso Minerals4050 B Sladeview CrescentMississauga, Ontario L5L 5Y5CanadaPhone: 1 905 607 3330Fax: 1 905 607 3339Metso Minerals7, Parker Centre, Mansfield RoadDerby, DE21 4SZUnited KingdomPhone: 44 1332 38 00 89Fax: 44 1332 20 70 81Metso MineralsPrivate Bag X2006Isando, Johannesburg,1600South AfricaPhone: 27 11 397 5090Fax: 27 11 397 5826Metso Minerals18 Lidco StreetArndell Park, NSW 2148Locker Bag 10Blacktown BC, NSW 2148AustraliaPhone: 61 2 8825 1600Fax: 61 2 8825 1799www.metsominerals.comE-mail: mineralsprocessing.info@metso.comSubject to alteration without prior notice.8515 Orion SeriesBrochure No: 1020-10-01-MP/Sala-English12Metso Minerals02-04-09, 18.31

The Metso heavy (HM, HR) and mining (MR, MM) duty h orizontal s lurry pump range off ers the newest and widest range of world class rubber lined and hard metal slurry pumps for abrasive pumping applications. Lowest Total Cost Our focused product development combined with over 60 years of experience from thousands of a pplications has led to continuous improvements in our products. The