Transcription

Caring LeadershipChanging a safety culture2014 PPSA Safety and Health ConferenceMike HignettWakefield, Ma. Corrugated Facility-RockTenn

Old school: 10 recordables was considered “good”From 2002 to 2008 Averaged one recordable per year All safety training, policies, programs in place Managed safety through my direct reports to the floor Life was good until I hit “the summer of 2009” .

‘Summer of 2009’4recordables in45 days !

Stop the madness !How do I do this ?Two avenues to choose from.One choice was

Begin a full court press Direct report meetings and a ‘personal note’ from me. Full scale safety reviews with all the tools available to me Safety awareness videos and action plans“Break the plane” and “ Hands Up !”Supervisory weekly audits became dailyThe “madness” stopped but something was missing.I knew I did NOT have a true safety culture.Was it luck all those years ?

Look at myself – Was I the problem ?Was I truly committed to running a safe plant ? Begin the change Did NOT go through direct reports to the get message to the floor– go myself – all 3 shifts. Started talking one on one with employees – all 3 shifts Began two safety teams in order to cover three shifts Sought out employee concerns and made them my ‘Daily Hot List’CommunicateCommunicateCommunicate

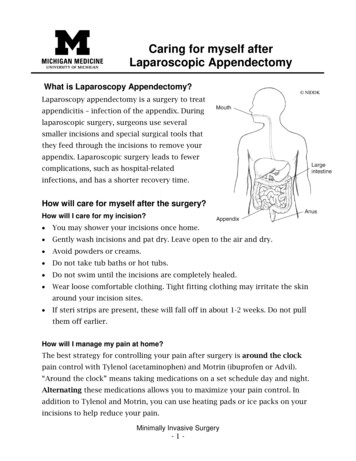

Big Visuals Big Impact Prove it Forktruckspeed

Big Visuals Big Impact Prove it Fork truck with lite bar and spot

Big Visuals Big Impact Prove it Pedestrian Safety

Big Visuals Big Impact Prove it

Safety CultureEMPLOYEE ENGAGEMENT ACTIVITIES262Safety team memberIncident investigation team - ONE YEAR3Machine Safety Audit28Safety Bingo - run it for one monthMSDS AUDIT - 5 chemicals at a timeEmergency lighting checks4Area Dept. Safety Audit29Emergency evacuation map audit - departmental5Machine Guarding Audit30Complete any one of the Safety Compliance Handbook audits6Plant wide Inspection31732339Conduct a Safety meeting or Toolbox meetingComplete PIT Checklist auditTell a Safe Start story in the safety meetingAssist with any Salcon audit finding correctionCheck Incident Investigation kit - up to date, everything thereCheck "Redbook" to see if up to date (Emergency Procedures)34Ladder Inspection10Electrical Safety Audit35Trailer audit - wheel chocks in place, glad locks, trailer jacks11121314Do a lockout audit and document it36373839Assist with or complete a HazRac audit18Review SWPs and suggest updatesHousekeeping TeamComplete a departmental combustible dust audit27Assist with or conduct a DuPont STOP audit16 Conduct 10 "Hands Up" audits401718424315Complete an Electrical Safety auditHome made tools search - departmental19 Secondary Container labeling audit - departmental20 Write safety slogans for the message light by time clock (5 MINIMUM)21 Eyewash inspections22Fire Extinguisher monthly checksOrganize safety poster contestAir hose / hose clamp / nozzle inspection - departmental25 Slip / trip hazard insepction - departmental23244144454647484950Write safety orientation for front lobby DVDConduct safety training - one topicConduct steam leak auditMaintenance employee to audit contractor safety: PPE, walkways, etcOrganize and run outside BBQReport NEAR MISSES & CLOSE CALLSDevelop employee recognition awardsCeiling leak check and record findings (when it is raining)Shipping dock check - docklocks, bumpers, lightsHand power tool inspectionHydraulic jack inspectionSlings, chains, straps, cable inspectionTwo man lift stickers on die boardsPre-shift machine center inspections

Safety CultureOpen Employee Engagement Log as of 4/30/14 - Updated Status as of 5/8/14TotalTotalTotalTotalhazards reported through Employee Engagement activities: 62new hazards reported since 4/30/14: 0reported hazards open at 4/30/14: 35reported hazards open as of 5/8/14: 15AreaMachineReported By Audit DateDeviation Work Order # Issue DateStatusClosed DateCorrugatorCR1021BK, JF, AO, LS 3/13/2014Fix guard on drive1108410side at flute3/17/2014roll that hasClosedwire ties holdingCLOSEDitGuard fixedCR1021LS4/19/2014Floor grates falling1148963in at glue4/19/2014rolls (doublebacker)OpenNeed new concrete around edges of pit- HarnamCR1021BK, SD4/25/2014Roll movers too1153029weak - need4/25/2014new batteriesClosedCRBalerJB4/19/2014Red wire exposed1150097next to E-Stop4/19/2014button byOpenwallOil leak from gear1150101boxCLOSEDCommentsChange Batteries more frequentlyCRBalerJB4/19/2014CRPalletizerJG, RB3/6/2014Install missing Change gear boxCRPalletizerJG, RB3/6/2014Nothing missingReplace/install1096904missing guards3/6/2014ClosedCLOSEDCRStarchJF, BK4/19/2014Nothing found missingAreaMachineCV4561LV3/13/2014Electrical input1104692into main by3/13/2014bundle breakerClosedloose and5/8/2014not securedAddressed on scheduled PMCV4561EG, VS, JT3/14/2014Replace/install1105458missing roller3/14/2014at the feed conveyorClosednextCLOSEDto the loadMissingpusherrollers were replacedCV4561KN4/19/2014Missing roll after1145958the stacker4/19/2014on the conveyorClosed5/8/2014Addressed on scheduled PMCV4561KN4/19/2014Hoist belt is starting1145959to wear4/19/2014could use a newClosedone5/6/2014Strap was replacedCV4561KN4/19/2014Exposed wires 1145960below prefeeder4/19/2014control panelClosed5/8/2014Addressed on scheduled PMCV4562AG3/12/2014On main console1104713interrupt3/13/2014button and holeClosedare not working5/6/2014Machine center does not provide for themCV4562IR, LV3/13/2014Fix source of leak1105442detected3/13/2014on drive side ofClosedbundle breaker5/6/2014Tightened fittingCV4562CV4562SA4/18/2014Operator's side1145482shrink roll assembly4/18/2014insideClosedframe - the5/6/2014chain is wearingChain replacedaway a setCV4562SA4/18/2014Missing 2 rollers1145946after bundle4/19/2014breakerOpenCV4563MP, MR3/13/2014Cover exposed1105455wire (side of3/13/2014tech bar)Closed5/6/2014Nothing found exposedCV4563PR, AA, MJ4/16/2014Missing guard 1142317waste conveyor4/16/2014Closed5/6/2014Replaced guardCV4563IR, JR4/18/2014Conveyor and squaring1145546 section4/18/2014after bundleOpenbreaker boxes goingScheduledcrooked, forstoppingnext PMshrinkdue on 5/15/14CV4563HB4/25/2014Conveyor prefeeder1153347have to4/25/2014always push loadsOpen - could get hurt, Scheduledconveyor needfor nextto bePMfixeddue on 5/15/14CV4571TD, DW2/25/2014Replace frayed1086695wire on side2/26/2014scale's air jet OpenCV4571TD, DW2/25/2014Replace pinched1086697power cable2/26/2014on the hoistOpenunitCV4571TD, DW2/25/2014Install guard on1086698exit of shrink2/26/2014tunnel on bothCloseddrive and5/6/2014operatorAftersidesreview, guards were not installed -deemed it would create pinch pointCV4571IP, MP, LS3/14/2014Replace/install1105452missing roller3/14/2014line conveyorClosedby load former5/6/2014CV4571IP, MP, LS3/14/2014Permanently install1105454photo 3/14/2014eye in central deviceClosedas it is5/6/2014currently tapedCorrectedto positionon 5/6/14 scheudled PMCV4571AX4/16/2014One missing roller1142315- shrink 4/16/2014tunnel conveyorClosedCV4571AX4/16/2014Die cut pressure1142323assembly leaking4/16/2014oilCV4571TD, DW4/19/2014Missing 2 plexi-guard1145955covers4/19/2014after shrink Closedtunnel exiting5/6/2014beltsCV4571SS4/19/2014Signage for load1145997former needs4/19/2014replacementClosed(also a pinch5/6/2014point forReplacedfingers)missing rollersCV7999RG, AN3/13/2014Replace/install9953926 missing rollers#########(location notOpenspecified)CV7999MC, PK, AX4/19/2014Before strapper,11459944 rolls missing4/19/2014because unitsOpenare getting stuckCV7999DG4/24/2014Missing door handle1156635on door4/29/2014#3, replacementOpenneededCV7999CS4/18/2014Exposed or damaged1156639electrical4/29/2014wiring on doorOpen#9Storage tank 11148956- Exposed wires4/22/2014by missingOpenface plateConvertingReported By Audit DateJC, AP, AM, HD4/16/2014Deviation Work Order # Issue DateOil leak (drive side)1142310near the4/16/2014blowerStatusClosed DateCommentsOpen5/6/2014Nothing found missingCorrected on 5/6/14 scheudled PMOpenGuards were not replaced as previously existing guards created a pinch point

Safety CultureMay Employee EngagementOpen Employee Engagement Log as of 4/30/14 - Updated Status as of 5/8/14Total hazards reported through Employee Engagement activities: 62Total new hazards reported since 4/30/14: 0Total reported hazards open at 4/30/14: 35Total reported hazards open as of 5/8/14: 15AreaCRCRCRCRMachineReported By Audit Date1021BK, JF, AO, LS 3/13/2014Deviation Work Order # Issue DateStatusClosed DateCorrugatorGuard fixedNeed new concrete around edges of pit- HarnamBK, SD4/25/2014Roll movers too1153029weak - need4/25/2014new batteriesClosedJB4/19/2014Red wire exposed1150097next to E-Stop4/19/2014button byOpenwallJB4/19/2014JG, RB3/6/2014CRPalletizerCRStarchAreaMachineJG, RB3/6/2014JF, BK4/19/2014CommentsFix guard on drive1108410side at flute3/17/2014roll that hasClosedwire ties holdingCLOSEDitLS1021BalerPalletizer4/19/2014Floor grates falling1148963in at glue4/19/2014rolls (doublebacker)Open1021BalerCRCROil leak from gear1150101boxInstall missing e/install1096904missing guards3/6/2014CLOSEDChange Batteries more frequentlyCLOSEDNothing missingCLOSEDNothing found missingChange gear boxClosedStorage tank 11148956- Exposed wires4/22/2014by missingOpenface plateConvertingReported By Audit DateDeviation Work Order # Issue DateStatusClosed DateCommentsCV4561LV3/13/2014Electrical input1104692into main by3/13/2014bundle breakerClosedloose and5/8/2014not securedAddressed on scheduled PMCV4561EG, VS, JT3/14/2014Replace/install1105458missing roller3/14/2014at the feed conveyorClosednextCLOSEDto the loadMissingpusherrollers were replacedCV4561KN4/19/2014Missing roll after1145958the stacker4/19/2014on the conveyorClosed5/8/2014Addressed on scheduled PMCV4561KN4/19/2014Hoist belt is starting1145959to wear4/19/2014could use a newClosedone5/6/2014Strap was replaced5/8/2014CV4561KN4/19/2014Exposed wires 1145960below prefeeder4/19/2014control panelClosedCV4562AG3/12/2014On main console1104713interrupt3/13/2014button and holeClosedare not working5/6/2014Machine center does not provide for themIR, LV3/13/2014Fix source of leak1105442detected3/13/2014on drive side ofClosedbundle breaker5/6/2014Tightened fittingCV4562CV4562CV4562CV4562JC, AP, AM, HD4/16/2014Oil leak (drive side)1142310near the4/16/2014blowerAddressed on scheduled PM4/18/2014Operator's side1145482shrink roll assembly4/18/2014insideClosedframe - the5/6/2014chain is wearingChain replacedaway a set4/18/2014Missing 2 rollers1145946after bundle4/19/2014breakerOpen4563MP, MR3/13/2014Cover exposed1105455wire (side of3/13/2014tech bar)Closed5/6/2014Nothing found exposed4563PR, AA, MJ4/16/2014Missing guard 1142317waste conveyor4/16/2014Closed5/6/2014Replaced guardCV4563CV4563CV4571CV4571CVCVIR, JR4/18/2014Conveyor and squaring1145546 section4/18/2014after bundleOpenbreaker boxes goingScheduledcrooked, forstoppingnext PMshrinkdue on 5/15/14HB4/25/2014Conveyor prefeeder1153347have to4/25/2014always push loadsOpen - could get hurt, Scheduledconveyor needfor nextto bePMfixeddue on 5/15/14TD, DW2/25/2014Replace frayed1086695wire on side2/26/2014scale's air jet OpenTD, DW2/25/2014Replace pinched1086697power cable2/26/2014on the hoistOpenunit4571TD, DW2/25/2014Install guard on1086698exit of shrink2/26/2014tunnel on bothCloseddrive and5/6/2014operatorAftersidesreview, guards were not installed -deemed it would create pinch point4571IP, MP, LS3/14/2014Replace/install1105452missing roller3/14/2014line conveyorClosedby load former5/6/2014CV4571IP, MP, LS3/14/2014Permanently install1105454photo 3/14/2014eye in central deviceClosedas it is5/6/2014currently tapedCorrectedto positionon 5/6/14 scheudled PMCV4571AX4/16/2014One missing roller1142315- shrink 4/16/2014tunnel conveyorClosed5/6/2014CV4571AX4/16/2014Die cut pressure1142323assembly leaking4/16/2014oilCV4571TD, DW4/19/2014Missing 2 plexi-guard1145955covers4/19/2014after shrink Closedtunnel exiting5/6/2014beltsNothing found missingCorrected on 5/6/14 scheudled PMOpenGuards were not replaced as previously existing guards created a pinch pointCV4571SS4/19/2014Signage for load1145997former needs4/19/2014replacementClosed(also a pinch5/6/2014point forReplacedfingers)missing rollersCV7999RG, AN3/13/2014Replace/install9953926 missing rollers#########(location notOpenspecified)CV7999MC, PK, AX4/19/2014Before strapper,11459944 rolls missing4/19/2014because unitsOpenare getting stuckCV7999DG4/24/2014Missing door handle1156635on door4/29/2014#3, replacementOpenneededCV7999CS4/18/2014Exposed or damaged1156639electrical4/29/2014wiring on doorOpen#9EMPLOYEE ENGAGEMENT ACTIVITIESSafety team memberIncident investigation team - ONE YEAR2623Machine Safety Audit28Safety Bingo - run it for one monthMSDS AUDIT - 5 chemicals at a timeEmergency lighting checks4Area Dept. Safety Audit29Emergency evacuation map audit - departmental5Machine Guarding Audit30Complete any one of the Safety Compliance Handbook audits6Plant wide Inspection317Conduct a Safety meeting or Toolbox meetingComplete PIT Checklist auditTell a Safe Start story in the safety meeting32Assist with any Salcon audit finding correctionCheck Incident Investigation kit - up to date, everything thereCheck "Redbook" to see if up to date (Emergency Procedures)189273334Ladder Inspection10 Electrical Safety Audit35Trailer audit - wheel chocks in place, glad locks, trailer jacks1112131436373839Assist with or complete a HazRac auditDo a lockout audit and document itReview SWPs and suggest updatesHousekeeping TeamComplete a departmental combustible dust audit100 %OpenSASACVCV15 Assist with or conduct a DuPont STOP audit4016 Conduct 10 "Hands Up" audits4117 Complete an Electrical Safety audit18 Home made tools search - departmental424319 Secondary Container labeling audit - departmental4420 Write safety slogans for the message light by time clock (5 MINIMUM)4521 Eyewash inspections4622 Fire Extinguisher monthly

17 Complete an Electrical Safety audit 42 Report NEAR MISSES & CLOSE CALLS 18 Home made tools search - departmental 43 Develop employee recognition awards 19 Secondary Container labeling audit - departmental 44 Ceiling leak check and record findings (when it is raining) 20 Write safety slogans for the message light by time clock (5 MINIMUM) 45 Shipping dock check - docklocks, bumpers, lights .