Transcription

Standard Method of Test forThe California Bearing RatioAASHTO Designation: T 193-99 (2003)1.SCOPE1.1.This test method covers the determination of the California Bearing Ratio (CBR) of pavementsubgrade, subbase, and base/course materials from laboratory compacted specimens. The testmethod is primarily intended for but not limited to, evaluating the strength of cohesive materialshaving maximum particle sizes less than 19 mm (3/4 in.).1.2.When materials having maximum particle sizes greater than 19 mm (3/4 in.) are to be tested, thistest method provides for modifying the gradation of the material so that the material used for testsall passes the 19.0-mm (3/4-in.) sieve while the total gravel 4.75-mm (No. 4) to 75-mm (3-in.)fraction remains the same. While traditionally this method of specimen preparation has been usedto avoid the error inherent in testing materials containing large particles in the CBR test apparatus,the modified material may have significantly different strength properties than the originalmaterial. However, a large experience base has developed using this test method for materials forwhich the gradation has been modified, and satisfactory design methods are in use based on theresults of tests using this procedure.1.3.Past practice has shown that CBR results for those materials having substantial percentages ofparticles retained on the 4.75-mm (No. 4) sieve are more variable than for finer materials.Consequently, more trials may be required for these materials to establish a reliable CBR.1.4.This test method provides for the determination of the CBR of a material at optimum watercontent or a range of water content from a specified compaction test and a specified dry unit mass.The dry unit mass is usually given as a percentage of maximum dry unit mass from thecompaction tests of T 99 or T 180.1.5.The agency requesting the test shall specify the water content or range of water content and thedry unit mass for which the CBR is desired.1.6.Unless specified otherwise by the requesting agency, or unless it has been shown to have no effecton test results for the material being tested, all specimens shall be soaked prior to penetration.1.7.The values stated in SI units are to be regarded as the standard.2.REFERENCED DOCUMENTS2.1.AASHTO Standards:M 92, Wire-Cloth Sieves for Testing PurposesM 145, Classification of Soils and Soil-Aggregate Mixtures for Highway ConstructionPurposesT 2, Sampling of AggregatesT 87, Dry Preparation of Disturbed Soil and Soil Aggregate Samples for TestTS-1aT 193-1AASHTO

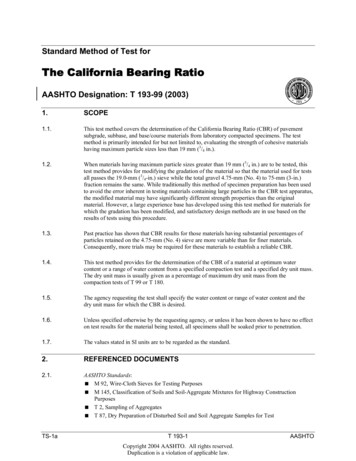

T 88, Particle Size Analysis of SoilsT 89, Determining the Liquid Limit of SoilsT 90, Determining the Plastic Limit and Plasticity Index of SoilsT 99, Moisture-Density Relations of Soils Using a 2.5-kg (5.5-lb) Rammer and a 305-mm(12-in.) DropT 180, Moisture-Density Relations of Soils Using a 4.54-kg (10-lb) Rammer and a 457-mm(18-in.) DropT 265, Laboratory Determination of Moisture Content of Soils3.SIGNIFICANCE AND USE3.1.This test method is used to evaluate the potential strength of subgrade, subbase, and base coursematerial, including recycled materials for use in road and airfield pavements. The CBR valueobtained in this test forms an integral part of several flexible pavement design methods.3.2.For applications where the effect of compaction water content on CBR is small, such ascohesionless, coarse-grained materials, or where an allowance is made for the effect of differingcompaction water contents in the design procedure, the CBR may be determined at the optimumwater content of a specified compaction effort. The dry unit mass specified is normally theminimum percent compaction allowed by using the agency’s field compaction specification.3.3.For applications where the effect of compaction water content on CBR is unknown or where it isdesired to account for its effect, the CBR is determined for a range of water content, usually therange of water content permitted for field compaction by using the agency’s field compactionspecification.3.4.The criteria for test specimen preparation of self-cementing (and other) materials, which gainstrength with time, must be based on a geotechnical engineering evaluation. As directed by theengineer, self-cementing materials shall be properly cured until bearing ratios representing longterm service conditions can be measured.4.APPARATUS4.1.Molds—The molds shall be cylindrical in shape, made of metal, with an internal diameter of152.40 0.66 mm (6.0 0.026 in.) and a height of 177.80 0.46 mm (7.0 0.018 in.) providedwith an extension collar approximately 50 mm (2.0 in.) in height and a perforated base plate thatcan be fitted to either end of the mold. (See Figure 1.) It is desirable to have at least three moldsfor each soil to be tested.TS-1aT 193-2AASHTO

TS-1aT 193-3AASHTOFigure 1—California Bearing Ratio Apparatus

TS-1aT 193-4AASHTOFG*Oe*0.012.416f3 129 38238.1U***Figure 1—ContinuedTOLERANCE, in.TOLERANCE, mmENGLISH, 2313275.4kADJUSTABLE STEM AND PLATE6 7 32158.0T*hd0.018788.9Q5.60.026661.370.25PMETRIC, mm116177.800.46V*W3 34X4n*3YL*18p*254.0ZM*m3419.08 38212.7151623.811828.61 51633.3389.5250.8146.3r116A149.2N*1325 15160.8150.8146.3414107.9s2 3469.8RSTEEL**23K19.0STEEL**1J95.2PISTON7I76.21165 PSPACER DISCSTEEL **MOLD WITH EXTENSION ENSION49.5E24 34F1.6MATERIALTOLERANCE, in.16.3METRIC, mmTOLERANCE, mmENGLISH, in.A4DIMENSIONMATERIALTOLERANCE, in.1E9.51.62D120.65 781C63.5SURCHARGEENGLISH, in.1B12.7TRIPOD FOR DETERMINING EXPANSIONSTEEL **TOLERANCE, mmA6.3DIMENSIONMETRIC, mmMATERIALTable of Measurements

4.2.Spacer Disk—A circular spacer disk made of metal 150.8 0.8 mm (515/16 1/32 in.) in diameterand 61.37 0.25 mm (2.416 0.01 in.) in height. (See Figure 1.)Note 1—When using molds having a height of 177.80 mm (7.0 in.) (Figure 1), a spacer diskheight of 61.37 mm (2.416 in.) is needed to obtain a thickness of compacted specimen thatconforms to the thickness: 116.43 mm (4.584 in.) of specimens in T 99 and T 180.4.3.Rammer—A rammer as specified in either T 99 or T 180.4.4.Apparatus for Measuring Expansion—This consists of a swell plate with adjustable stem(Figure 1) and a tripod support for a dial indicator (Figure 1). The swell plate is made of metal,149.2 1.6 mm (57/8 1/16 in.) in diameter and is perforated with 1.6-mm (1/16-in.) diameter holes.The tripod used to support the dial indicator is arranged to fit the mold extension collar.4.5.Indicators—Two dial indicators: each indicator shall have a 25-mm (1-in.) throw and read to0.02 mm (0.001 in.).4.6.Surcharge Weights—One annular metal weight with a center hole approximately 54.0 mm(21/8 in.) in diameter and several slotted or split metal weights, all 149.2 1.6 mm (57/8 1/16 in.)in diameter and each having a mass of 2.27 0.04 kg (5 0.10 lb) (Figure 1) (Note 2).Note 2—When using split weights, the mass of the pair shall be 2.27 0.04 kg (5 0.10 lb).4.7.Penetration Piston—A metal piston of circular cross-section having a diameter of 49.63 0.13 mm (1.954 0.005 in.) area 1935 mm2 (3 in.2) and not less than 102 mm (4 in.) long.(See Figure 1.)4.8.Loading Device—A compression-type apparatus capable of applying a uniformly increasing loadup to a capacity sufficient for the material being tested at a rate of 1.3 mm/min. (0.05 in./min.),used to force the penetration piston into the specimen.4.9.Soaking Tank—A soaking tank suitable for maintaining the water level 25 mm (1 in.) above thetop of the specimens.4.10.Drying Oven—A thermostatically controlled drying oven capable of maintaining a temperature of110 5ºC (230 9ºF) for drying moisture samples.4.11.Moisture Content Containers—As specified in T 265.4.12.Miscellaneous—Miscellaneous tools such as mixing pans, spoons, straightedge, filter paper,balances, etc.5.SAMPLE5.1.The sample shall be handled and specimen(s) for compaction shall be prepared in accordancewith the procedures given in T 99 or T 180 for compaction in a 152.4-mm (6-in.) mold exceptas follows:5.1.1.If all material passes a 19.0-mm (3/4-in.) sieve, the entire gradation shall be used for preparingspecimens for compaction without modification. If there is material retained on the 19.0-mmsieve, the material retained on the 19.0-mm sieve shall be removed and replaced by an equalTS-1aT 193-5AASHTO

amount of material passing the 19.0-mm sieve and retained on the 4.75-mm (No. 4) sieve obtainedby separation from portions of the sample not otherwise used for testing.5.1.2.Bearing Ratio at Optimum Water Content—From a sample having a mass of 35 kg (75 lb) ormore, select a representative portion having a mass of approximately 11 kg (25 lb) for a moisturedensity test and divide the remainder of the sample to obtain three representative portions having amass of approximately 6.8 kg (15 lb) each.5.1.3.Bearing Ratio for a Range of Water Content—From a sample having a mass of 113 kg (250 lb) ormore, select at least five representative portions having a mass of approximately 6.8 kg (15 lb)each for use in developing each compaction curve.6.MOISTURE-DENSITY RELATION6.1.Bearing Ratio at Optimum Water Content—Using the 11-kg (25-lb) portion prepared as describedin Section 5.1, determine the optimum moisture content and maximum dry density in accordancewith the compaction method specified, either T 99 or T 180. A previously performed compactiontest on the same material may be substituted for the compaction test just described, provided that ifthe sample contains material retained on the 19.0-mm (3/4-in.) sieve, soil prepared as described inSection 5.1 is used (Note 3).Note 3—Maximum dry unit mass obtained from a compaction test performed in a 101.6-mm(4-in.) diameter mold may be slightly greater than the maximum dry unit weight obtained fromcompaction in the 152.4-mm (6-in.) compaction mold or CBR mold.6.2.Bearing Ratio for a Range of Water Content—Using the 6.8-kg (15-lb) specimens prepared asdescribed in Section 5.1, determine the optimum moisture content and maximum dry density inaccordance with the compaction method specified, either T 99 (Method D) or T 180 (Method D)except that the CBR molds shall be used and each specimen shall be penetrated for CBRdetermination. In addition, the complete moisture-density relationship for 25-blow and 10-blowper layer compactions shall be developed and each test specimen compacted shall be penetrated.Perform all compaction in CBR molds. In cases where the specified unit mass is at or near 100percent maximum dry unit mass, it will be necessary to include a compactive effort greater than56 blows per layer (Note 4).Note 4—A semilog plot of dry unit mass versus compactive effort usually gives a straight-linerelation when compactive effort in J/m3 (ft-lb/ft3) is plotted on the log scale. This type of plot isuseful in establishing the compactive effort and number of blows per layer needed to bracket thespecified dry unit mass and water content range.6.2.1.TS-1aIf the soaked CBR is to be determined, take a representative sample of the material, for thedetermination of moisture, at the beginning of compaction of each specimen and another sampleof the remaining material after compaction of each specimen. Use T 265 to determine the moisturecontent. If the unsoaked CBR is to be determined, take a moisture content sample in accordancewith T 99 or T 180 if the average moisture content is desired.T 193-6AASHTO

7.PROCEDURE7.1.Bearing Ratio at Optimum Water Content:7.1.1.Normally, three specimens must be compacted so that their compacted densities range from95 percent (or lower) to 100 percent (or higher) of the maximum dry density determined inSection 6.1.Note 5—Generally about 10, 30, and 65 blows per layer are suitable for compacting specimens 1,2, and 3, respectively. More than 56 blows per layer are generally required to mold a CBRspecimen to 100 percent of the maximum dry density determined by T 99 (Method D); this is dueto the sample for the moisture-density test being reused, while the sample for the CBR specimen ismixed and compacted only once.Note 6—Some laboratories may prefer to test only one specimen which would be compacted tomaximum dry density at optimum moisture content as determined by either T 99 or T 180.7.1.2.Clamp the mold to the base plate, attach the extension collar and weigh to the nearest 5 g (0.01 lb).Insert the spacer disk into the mold and place a coarse filter paper on top of the disk.7.1.3.Mix each of the three 6.8-kg (15-lb) portions prepared in Section 5.1.2 with sufficient water toobtain the optimum moisture content determined in Section 6.1.7.1.4.Compact the first of the three portions of soil-water mixture into the mold, using three equal layersand appropriate rammer if maximum density was determined by T 99 or five equal layers ifmaximum density was determined by T 180, to give a total compacted depth of about 125 mm,compacting each layer with the lowest selected number of blows in order to give a compacteddensity of 95 percent or less of the maximum density.7.1.5.Determine the moisture content of the material being compacted at the beginning and end of thecompaction procedure (two samples). Each moisture sample shall have a mass of at least 100 g forfine-grained soils and 500 g for coarse-grained soils. Determination of moisture content shall bedone in accordance with T 265, Laboratory Determination of Moisture Content of Soils.7.1.6.Remove the extension collar, and using a straightedge, trim the compacted soil even with the topof the mold. Surface irregularities should be patched with small-sized material. Remove the spacerdisk, place a coarse filter paper on the perforated base plate, invert the mold and compacted soiland place on the filter paper so the compacted soil is in contact with the filter paper. Clamp theperforated base plate to the mold and attach the collar. Determine the mass o

with the procedures given in T 99 or T 180 for compaction in a 152.4-mm (6-in.) mold except as follows: 5.1.1. If all material passes a 19.0-mm (3/ 4-in.) sieve, the entire gradation shall be used for preparing specimens for compaction without modification. If there is material retained on the 19.0-mmFile Size: 1MBPage Count: 11