Transcription

LESER UKBristolsales@leser.co.ukLESER GermanyHamburg andHohenwestedtsales@leser.comAndré Ramseyer AGFlamatt, Switzerlandinfo@ramseyer.chLESER ChinaTianjin, Beijing,Shanghai and Shenzhensales.china@leser.comLESER PolandPoznanleser@leser.plLESER FranceToulousecontact@leser.frLESER USACharlotte (NC)salesus@leser.comLESER BrazilRio de Janeirovendas@leser.com.brLESER BahrainAl Manamahsalesme@leser.comLESER SingaporeSingaporesales@leser.com.sgHigh PerformanceLESER worldwideHighPerformanceFlanged Safety Relief ValvesSeries 441Series 441 Full nozzleSeries XXLSeries 444Series 458LESER UAELESER IndiaDubaiMumbai and Paithansales.uae@leser.com sales@leser.co.inLESER representativesLESER stock and local assemblyCATALOGHigh Performance CatalogEdition July 2016 / 3.0000777.5465The-Safety-Valve.comLESER GmbH & Co. KGHigh Performance World format Umschlag.indd 120537 Hamburg, Wendenstr. 133-13520506 Hamburg, P.O. Box 26 16 51Fon 49 (40) 251 65-100Fax 49 (40) 251 65-500The-Safety-Valve.comE-Mail: sales@leser.comwww.leser.com14.07.2016 11:49:18

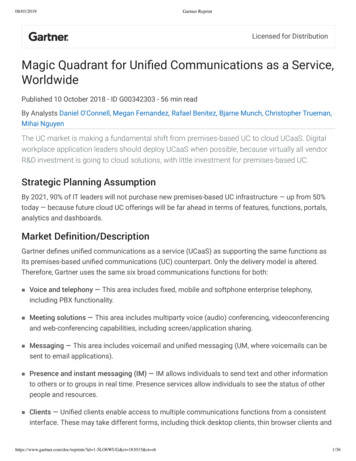

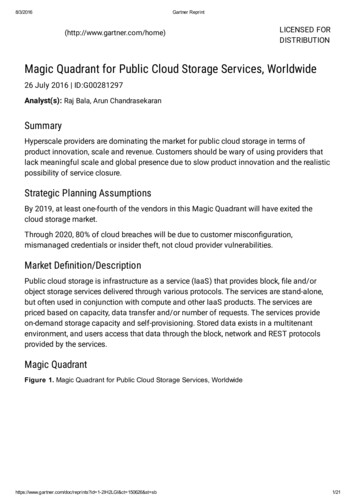

Valve finderHigh operating to setpressure ratio, high backpressureor low total ServiceMediumcontrolledHow to find the right Product GroupNoClean Serviceapplication?NoCritical Service / highly corrosiveapplication?YesAPINoSteam, gas and liquid applicationwith low capacity in relationto valve size?YesModulateActionSpring loadedAPI specifiedapplication?Safety ValvesNoNoOrifice FHighPerformanceRequiredOrifice letter?YesBestAvailabilityBurstingdiscAdditional componentsbeyond safety valvesChangeover valveOrifice FCompactPerformance2High Performance World format Umschlag.indd 214.07.2016 11:49:31

GeneralMaterials Conventional design Balanced bellows design810Article numbers56Dimensions and weights57Pressure temperature ratings59Flange drillings and facings61Approvals62Available options63Article numbers12Dimensions and weights13Pressure temperature ratings15Flange drillings19Type 444 DIN, ANSI64Flange facings / Change of nominal diameter20Materials Conventional design65Article numbers67Dimensions and weights68Pressure temperature ratings69Flange drillings and facings70Type 441, 442 ANSI21Materials Conventional design Balanced bellows design2224Article numbers26Approvals71Dimensions and weights27Available options72Pressure temperature ratings29Flange drillings and facings31Type 455, 45673Materials Conventional design Balanced bellows design7476Article numbers78Dimensions and weights79Pressure temperature ratings81Flange drillings83Flange facings84Approvals85Available options86Type 457, 45887Materials Conventional design Balanced bellows design8890Type 441, 442 Full nozzle DIN, Full nozzle ANSI33Materials Conventional design Balanced bellows design3436Article numbers38Dimensions and weightsType 441, 442 Full nozzle DINType 441, 442 Full nozzle ANSI3940Pressure temperature ratingsType 441, 442 Full nozzle DINType 441, 442 Full nozzle ANSI4244Flange drillings46Flange facings47Article numbers92Series 441, Series 441 Full nozzle48Dimensions and weights93Approvals48Pressure temperature ratings95Available options49Flange drillings97LESER Original Spare Parts Kits50Flange facings98Approvals99Available options100Type 441, 442ANSI7Type 441, 442Full nozzleType 441, 442 DIN5254Series 441,441 Full nozzle451Materials Conventional design Balanced bellows designType 441, 442XXLGeneral InformationType 441, 442 XXLType 4442Type 455, 456Valve finderType 457, 458GeneralType 441, 442DINContents3High Perf World format EN Print.indd 319.07.2016 13:05:07

GeneralGeneral InformationLESER – High Performance SicherheitsventileThe High Performance product group represents High capacity related to the safety valve size High adaptability Excellent price / performance ratioLESERs High Performance Safety Valves Are designed to meet all industrial applications. Open rapidly with an overpressure of 5 % to the full designlift. Are used particularly for vapours and gases wherethe maximum mass flow has to be discharged rapidly. Have a maximum blowdown of minus 10 % for steam/gas service and minus 20 % for liquid service. Are one of the best selling spring loaded safety valveworldwide. Are developed in a close cooperation with plant engineersand service specialists. Serve for protection of processes and equipment. Are approved by all important approval organisations worldwide which ensures the worldwide applicability e.g.:European Community: CE-marking acc. to PressureEquipment Directive (PED) 97/23/EC resp. 2014/68/EU andEN ISO 4126-1 USA: UV-stamp acc. to ASME Section VIII Division 1,National Board certified capacities Germany: VdTÜV approval acc. to PED, EN ISO 4126-1,TÜV SV 100 and AD 2000-Merkblatt A2 Canada: Canadian Registration Number acc. to therequirements of particular provinces China: AQSIQ based on the approval acc. to ASMESection VIII Division 1 and AD 2000-Merkblatt A2 Eurasian Custom Union: Approval acc. to Eurasian CustomUnion (EAC - Eurasian Conformity) Furthermore, all LESER High Performance safety valvesare designed, marked, produced and approved acc. to therequirements of the following regulations (directives, codes,rules and standards).EN ISO 4126-7, EN 12266-1/-2, EN 1092 Teil I and II flanging,ASME PTC 25, ASME-Code Sec. II, ASME B16.34 and ASMEB16.5-flanging, API Std. 527, API RP 576,AD 2000-Merkblatt A4, AD 2000-Merkblatt HP0.UV4

GeneralGeneral InformationApplicationsGeneral Design FeaturesLESER – High Performance Safety ValvesLESERs High Performance Safety ValvesAre the ultimate solution for all industrialapplications for steam, gas and liquid.Offer a large variety of types, materials and optionsto suit any application:Typical applications forLESER High Performance Safety Valves are: 14 valve sizes from DN 20 to DN 400 – 3/4" to 16"provide a high connectivity to the application Inlet pressure ratings PN 16 to PN 400 / class 150 toclass 2500 to fit all required design pressures Orifice sizes from E to 3 x T cover all capacityrequirements Large variety of body materials; e.g.Series 441 Protection of chemical processes and equipment(e.g. distillation columns) Heat exchangers Low and medium pressure steam Blowers and turbo compressorsSeries XXL Low pressure steam at big power stations Capacities beyond the limits of API and Series 441Series 444 OEM in dying machines or filter constructions Stainless steel applications up to 16 bar / 232 psigSeries 441 Full Nozzle Same applications like Series 441 whenfull nozzle design is preferred. Special requirement for nozzle materialSeries 458 Power stations and industrial superheatedsteam generation Required flange classes PN 63 / CL600 Protection of high pressure Chemical processes,e.g. NH3 synthesis, CO2 extraction Desalination plants 0.6025 / grey iron 0.7043 / ductile iron 1.0619 / WCB 1.4408 / CF8M 1.7357 / WC6can be selected acc. to the application Set pressures from 0.1 to 300 bar / 1.5 to 4350 psigmake this product group suitable for all industrial processes Operating temperatures from -270 to 550 C / -454 to1022 F cover a wide range of applications LESER Nanotightness as standard for metal-to-metal sealings. The nanotightness exceeds the requirements for functional tightness of API 527 by 50% which means e.g. lesspollution when discharge to atmosphere, 50% reduction inmedium loss and increased plant efficiency One design and spring (single trim) for steam, gas andliquid applications reduces the number of spare parts andensure an easier maintenance High capacity compared to the API requirements to reduceinstallation costs Ringless design needs no trim adjustmentsfor easy maintenance One-piece spindle reduces friction which is leading tohigh operation accuracy Self-draining body design, avoids residues and reducescorrosionOptionsLESER – High Performance Safety Valves can be customizedwith a great variety of options, e.g. O-ring disc for superior tightness Stellited or hardened metal sealing for longer product life Stainless steel bellows for back pressure compensation Heating jacket for applications with high viscosity fluids Every part can be replaced by other material acc. tocustomer specification5High Perf World format EN Print.indd 519.07.2016 13:05:19

6High Perf World format EN Print.indd 619.07.2016 13:05:19

Type 441, 442DINType 441, 442 DINFlanged Safety Relief ValvesContentsType 442 DINPlain lever H3Open bonnetConventional designPageMaterials Conventional design Balanced bellows design810Article numbers12Dimensions and weights Metric Units US Units1314Pressure temperature ratings Metric Units US Units1517Flange drillingsFlange facingsChange of nominal diameter192020Series 441, Series 441 Full nozzleApprovalsAvailable optionsLESER Original Spare Parts Kits484950Type 441 DINPacked lever H4Closed bonnetConventional design7High Perf World format EN Print.indd 719.07.2016 13:05:19

Type 441, 442DINType 441, 442 DINConventional design40Cap H218Adjusting screw19Lock nut16Upper spring plate9Bonnet12Spindle54Spring17Lower spring plate55Stud56Nut14Split ring60Gasket8Guide with bushing57Pin61Ball7Disc5Seat1Body8High Perf World format EN Print.indd 819.07.2016 13:05:25

ItemComponent1Body5Seat7DiscGuide8with bushing9Bonnet12Spindle14Split ring16/17Spring plate18Adjusting screwwith bushing19Lock nut40Cap H2Spring standard54Spring optional55Stud56Nut57Pin60Gasket61BallType 441, 442DINType 441, 442 DINConventional designMaterialsType 4411 / 4421 DINType 4415 / 4425 DINType 4412 / 4422 DINType 4414 DIN0.6025Cast iron1.4404316L1.4122Hardened stainless steel1.4104, 1.0501, 0.7040Chrome or carbon steel1.4104 teniferChrome steel tenifer0.7040, 0.7043, 1.0619Ductile Gr. 60-40-18,SA 216 WCB0.7043Ductile Gr. 60-40-181.4404316L1.0619SA 216 WCB1.4404316L1.4408SA 351 CF8M1.4404316L1.4122Hardened stainless steel1.4104, 1.0501, 0.7040Chrome or carbon steel1.4104 teniferChrome steel tenifer0.7040, 0.7043, 1.0619Ductile Gr. 60-40-18,SA 216 WCB1.4122Hardened stainless steel1.4104, 1.0501, 0.7040Chrome or carbon steel1.4104 teniferChrome steel tenifer0.7040, 0.7043, 1.0619Ductile Gr. 60-40-18,SA 216 WCB1.4404316L1.4404316L––1.4408, 1.4404, 1.4571SA 351 CF8M,SA 479 316L, SA 479 316Ti1.40214201.4104Chrome steel1.0718Steel1.4104 PTFEChrome steel PTFE1.0718Steel1.0460 or 0.7043SA 105 or Gr. 60-40-181.1200, 1.8159, 1.7102Carbon steel1.4310Stainless steel1.1181Steel1.05012H1.4310Stainless steelGraphite / 1.4401Graphite / 3161.3541Hardened stainless steel1.40214201.4104Chrome steel1.0718Steel1.4104 PTFEChrome steel PTFE1.0718Steel1.0460 or 0.7043SA 105 or Gr. 60-40-181.1200, 1.8159, 1.7102Carbon steel1.4310Stainless steel1.1181Steel1.05012H1.4310Stainless steelGraphite / 1.4401Graphite / 3161.3541Hardened stainless steel1.40214201.4104Chrome steel1.0718Steel1.4104 PTFEChrome steel PTFE1.0718Steel1.0460 or 0.7043SA 105 or Gr. 60-40-181.1200, 1.8159, 1.7102Carbon steel1.4310Stainless steel1.1181Steel1.05012H1.4310Stainless steelGraphite / 1.4401Graphite / 3161.3541Hardened stainless steel1.4404316L1.4404316L1.4404316L1.4404 PTFE316L PTFE1.4404316L1.4404316L1.4310Stainless steel––1.4401B8M1.44018M1.4310Stainless steelGraphite / 1.4401Graphite / 3161.4401316Please notice:- Modifications reserved by LESER- If several materials are specified LESER defines the material.- LESER can upgrade materials without notice.- Every part can be replaced by other material acc. to customer specification.9High Perf World format EN Print.indd 919.07.2016 13:05:26

Type 441, 442DINType 441, 442 DINBalanced bellows design40Cap H218Adjusting screw19Lock nut16Upper spring plate9Bonnet12Spindle54Spring14Split ring17Lower spring plate55Stud56Nut8Guide with bushing11Bonnet spacer60Gasket22Lift stopper15Bellows57Pin61Ball7Disc5Seat1Body10High Perf World format EN Print.indd 1019.07.2016 13:05:26

ItemComponent1Body5Seat7DiscGuide8with bushing9Bonnet11Bonnet spacer12Spindle14Split ring15Bellows16/17Spring plate18Adjusting screwwith bushing19Lock nut22Lift stopper40Cap H2Spring standard54Spring optional55Stud56Nut57Pin60Gasket61BallType 441, 442DINType 441, 442 DINBalanced bellows designMaterialsType 4411 / 4421 DINType 4415 / 4425 DINType 4412 / 4422 DINType 4414 DIN0.6025Cast iron1.4404316L1.4122Hardened stainless steel1.4104, 1.0501, 0.7040Chrome or carbon steel1.4104 teniferChrome steel tenifer0.7040, 0.7043, 1.0619Ductile Gr. 60-40-18,SA 216 WCB0.7043Ductile Gr. 60-40-181.4404316L1.0619SA 216 WCB1.4404316L1.4408SA 351 CF8M1.4404316L1.4122Hardened stainless steel1.4104, 1.0501, 0.7040Chrome or carbon steel1.4104 teniferChrome steel tenifer0.7040, 0.7043, 1.0619Ductile Gr. 60-40-18,SA 216 WCB1.4122Hardened stainless steel1.4104, 1.0501, 0.7040Chrome or carbon steel1.4104 teniferChrome steel tenifer0.7040, 0.7043, 1.0619Ductile Gr. 60-40-18,SA 216 WCB1.4404316L1.4404316L––1.4408, 1.4404, 1.4571SA 351 CF8M,SA 479 316L, SA 479 316Ti1.0460Carbon steel1.4404316L1.4104Chrome steel1.4571316Ti1.0718Steel1.4104 PTFEChrome steel PTFE1.0718Steel1.4404316L1.0460 or 0.7043SA 105 or Gr. 60-40-181.1200, 1.8159, 1.7102Carbon steel1.4310Stainless steel1.4401B8M1.44018M1.4310Stainless steelGraphite / 1.4401Graphite / 3161.3541Hardened stainless steel1.0460Carbon steel1.4404316L1.4104Chrome steel1.4571316Ti1.0718Steel1.4104 PTFEChrome steel PTFE1.0718Steel1.4404316L1.0460 or 0.7043SA 105 or Gr. 60-40-181.1200, 1.8159, 1.7102Carbon steel1.4310Stainless steel1.4401B8M1.44018M1.4310Stainless steelGraphite / 1.4401Graphite / 3161.3541Hardened stainless steel1.0460Carbon steel1.4404316L1.4104Chrome steel1.4571316Ti1.0718Steel1.4104 PTFEChrome steel PTFE1.0718Steel1.4404316L1.0460 or 0.7043SA 105 or Gr. 60-40-181.1200, 1.8159, 1.7102Carbon steel1.4310Stainless steel1.4401B8M1.44018M1.4310Stainless steelGraphite / 1.4401Graphite / 3161.3541Hardened stainless 04316L1.4404 PTFE316L PTFE1.4404316L1.4404316L1.4404316L1.4310Stainless steel––1.4401B8M1.4401

B16.5-flanging, API Std. 527, API RP 576, AD 2000-Merkblatt A4, AD 2000-Merkblatt HP0. UV General. 5 General Information Applications LESER – High Performance Safety Valves Are the ultimate solution for all industrial applications for steam, gas and liquid. Typical applications for LESER High Performance Safety Valves are: Series 441 Protection of chemical processes and equipment (e.g .