Transcription

TUBE BUNDLE SYSTEM DESIGNGas Monitoring

Table of Contents Company OverviewProduct OverviewProject DesignProject StructureComponentsCompetitive AdvantageTube Integrity TestingAdditional ProductsOperating Systems

Company Overview23yrsLTIFreeDelta Automation has been providing Gas Management Products and Services, On-site Electrical Labour andAutomation and Control Solutions to the coal mining industry since 1996. We have a strong commitment to safetyand to date are proud to be a 100% LTI free organisation.Delta Automation’s experience in gas management, engineering, electrical services and control products is enhancedby our development and manufacturing capabilities. This has allowed us to offer our clients complete solutions;turning concepts into reality and producing a wide range of products with a focus on four key areas:1.Improving mine safety through gas management innovation.2.Improving communications in the underground mining environment.3.Implementing professional methods to monitor and report on production performance.4.Continuous safety improvements through innovation and collaboration.

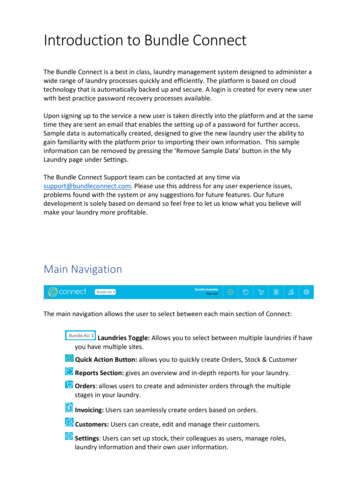

Tube Bundle Key Features Designed from the ground up to comply with AS 3000 & other relevant ASNZS Standards NSW Coal Mine Regulations Emerson analysers providing high accuracy, fast response and long term stability. All major components mounted on front panel for ease of viewing. Rotameters on all tubes to allow for flow balancing and monitoring of each individual tube. Low volume flow path to allow for low purge time between samples All electronic components suitably IP rated, are in an IP 65 enclosures or are installed in thecommunications hut. Supplied with high efficiency, high flow rate purge pumps to allow for high flow rates from the mine,leading to lower time delay from samples points.

Key Features Cont. The System is set to measure standard mine gases, but also can be configured with a GC to detect andrecord other gases such as Hydrogen, Ethylene, Ethane, AcetyleneStandby sample and purge pumps supplied connected and ready to operate to allow for rapid recoverytime in the event of a pump failure Ethernet connection to analyser to allow for remote access for high level remote diagnostics System can be supplied with IP cameras to allow remote monitoring Check valves fitted on each line to prevent air ingress back into the tubes System was designed in consultation with experienced ventilation officers as well as DII personnel tomaximise functionality while ensuring compliance with standards.

Tube Bundle DesignThe system is made up from two separatebuildings –A naturally ventilated building housingthe Emerson gas analyzer/s andinstrumentation.2. A demountable ‘communications shed’housing communication and controlequipment.Gas Analyzer Shed1.This ‘naturally ventilated’ design eliminatesseveral hazards associated withconventional Tube Bundle System designs.CommunicationShed

Tube Bundle Design Cont The standard gas building ismanufactured from galvanised mesh and colourbondsheeting to provide natural ventilation and security against unauthorized access,whilst still ensuring the compliance with Australian and NSW Mines Department requirements.

Tube Bundle Design Cont Emerson X-Stream process gas analyzer is used to deliver highaccuracy gas readings. The X-stream measures up to fourcomponents in various combinations, and its versatile designallows physical benches to be installed in their owncompartment, separate from the electronics. In addition to the X-Stream gas analyzer, an Emerson GasChromatograph can be installed to assist with monitoring oftrace gases in the mine. Typically the GC would be setup tomeasure trace levels of hydrocarbons.

Tube Bundle Design Cont All control and monitoring components aremounted on the front panel and include vacuum and samplepump pressure transmitters with displays as well as a flow controller to ensure a regulatedflow of gas independent of tube resistance.

Tube Bundle Design Cont The calibration gas connection facilitateseasy calibration of the analyzer by simply a click of a button.To monitor system stability test gas cylinders have been designed to be included within the samplegas sequence.

Hazardous Area ClassificationPrior to manufacture, the systemdesign was assessed for hazardouszoning to determine the types ofcomponents which were to be usedin the final design and theirpermitted locations .

Hazardous Area Classification

Tube Bundle Component nsducerFlameArrestorsRotometer

Tube Bundle StructureSTEEL MESHCORRUGATED IRONGAS CYLINDERS

Tube Bundle StructureFLEX IOENCLOSURESLIGHTINGINCOMING TUBEBULKHEAD FITTINGSANALYZERVENTURI SOLENOIDENCLOSUREPUMPSVENTURICOMPRESSORSAMPLEPUMPS

Tube Bundle StructureFLEX IO ENCLOSURESVENTURI SOLENOIDENCLOSUREINCOMING TUBE BULKHEAD FITTINGSCALIBRATION GASSOLENOID ENCLOSUREANALYSERSAMPLE PUMPSPURGE PUMPSVENTURI COMPRESSORLIGHTINGGAS CYLINDERS

Tube Bundle OW CONTROLLERWATER SENSORSSAMPLE PUMPS

Human Machine Interface (HMI)SoftwareSafegasSCADA / CitectThe tube bundle system comes complete with SCADA/CITECT screens and is Safegascompatible.18

Bundled Emerson Software19

Competitive Advantage The Delta Automation TBH system is designed from the ground up with compliance in mind. Hazard elimination through design ingenuity. Explosion protection components meet Australian Standards and Department of Industry andInvestment (DII NSW) requirements using IECEx, ANZEx and ISO certification schemes. Local support including engineering and technical training. Delta Automation are the only company able to offer a complete life of mine packageincluding automated integrity testing.

Additional TBH SupportMobile Tube Integrity Testing Unit The Delta Automation mobile integrity testing unit isdesigned to comply with Australian Standards AS2290.3relating to monthly leak testing and sample tube integrity.The systems eliminates safety hazards and labour intensivetesting associated with traditional coal mine testingpractices. Safe – Scheduled testing & reporting to comply with AS2290.3 regulations.Fast – Methodical step by step approach much faster than current manualmethodsEfficient – Portable & all testing completed from the surface at aconvenient time.Convenient – No disruption to sampling. Failure point location mapped to /- 50mtrs. All data logged on SQL database.Cost Effective – Eliminates mine site manual labour, u/g transportrequirements, reduces troubleshooting & repair times

Additional TBH SupportMobile Tube Integrity Testing Unit BenefitsTaskMine compliance with AS2290.3Mine site staff requiredScheduling with U/G staff requiredU/G transport requiredTime consuming & labour intensiveSafety hazards encounteredReal time reportingAccurate leak detectionsConvenientTesting of tubes where end point access is difficult orimpossible (ie buried in goaf)Mobile Integrity TestingUnitTraditional Mine TestingMethodsEasy 0 No No No No Yes Yes Yes Difficult X2 XYes XYes XYes XYes XNo XNo XNo XYes No X

Additional TBH ProductsLDPE Tubing Deltamation supplies single and bundled LDPE tubing in a range of colours. Anti-static tubing suitable for underground environments with reflective tape,colour coding and numbered label easy identification.

Additional TBH Products End of line filters Gas Chromatograph Self-draining water filter panels Water trap panels Flame arrestors 3, 6 and 12mth maintenance schedules

Operating Tube Bundle Systems Ashton Mine Gas Drainage Plant – Yancoal Australia Abel Mine – Yancoal Australia Mandalong Mine - Centennial Coal Wambo Mine – Peabody Energy Chain Valley Colliery – LDO Integra Colliery – Glencore

Delta Automation Pty LtdPhone: 61 (02) 4932 4700E-mail: sales@delta-automation.com.au12/37 Shipley Drive,Rutherford NSW 2320.www.delta-automation.com.au

System can be supplied with IP cameras to allow remote monitoring Check valves fitted on each line to prevent air ingress back into the tubes System was designed in consultation with experienced ventilation officers as well as DII personnel to maximise functionality