Transcription

Laura BucklesActivity 2.3.2 Tensile Testing – SIMIntroductionTensile testing provides engineerswith the ability to verify andestablish material propertiesrelated to a specific material. Thisverification process is critical inensuring that the selected materialwill meet design specifications. Inthis activity you will interpret andmake sample specific calculationsrelated to the material propertiesof a dog bone test sample.Equipment Computer with access to Virtual Tensometer and Adobe FlashMaterial Testing Formula SheetProcedureYou will use a tensile test simulation to observe how the test is performed and howthe force displacement graph is created during the test. You will perform calculationsusing the graph to better understand the graph and important data.1. Go to the Virtual Tensometer.2. Click Enter to begin the simulation. 2012 Project Lead The Way, Inc.POE Activity 2.3.2 Tensile Testing SIM – Page 1

3. Choose Want to try?4. Click on the image of the VirtualTensometer.5. This should bring you to the VirtualTensometer for testing.6. Four materials are available to test.All but cast iron will create usabledata for this activity. Check with yourinstructor to determine whichmaterial you will test. A sampling ofeach material should be testedamong the class.7. Test the material by dragging it into the clamps and pressing Start.8. Upon completion of the test, enlarge your browser window by using Ctrl sothat the graph is large. 2012 Project Lead The Way, Inc.POE Activity 2.3.2 Tensile Testing SIM – Page 2

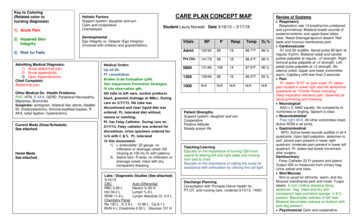

9. Take a screen shot of the browser, paste it into the Proportional Limit tablebelow, and then crop out all but the graph. Copy the cropped image andpaste it into the remainder of the tables.The original diameter of the specimen is 5mm or 0.20 in. and the originallength is 75mm or 2.95 in.Test Sample Calculations1. Proportional Limit StressThe greatest stress that a material is capable of withstanding without deviation fromstraight line proportionality between the stress and strain. If the force applied to amaterial is released, the material will return to its original size and shape.Tensile test results graph (Insert test graph)Locate the proportional limit on the test graph.Solve for the proportional limit stress: F/A 5.133 kN/mm 2012 Project Lead The Way, Inc.POE Activity 2.3.2 Tensile Testing SIM – Page 3

2. Yield Point StressThe point at which a sudden elongation takes place while the load on the sampleremains the same or actually drops. If the force applied to the material is released,the material will not return to its original shape.Tensile test results graph (Insert test graph)Locate the Yield Point on the test graph.Solve for the Yield Point stress: F/A 6kN/mm 2012 Project Lead The Way, Inc.POE Activity 2.3.2 Tensile Testing SIM – Page 4

3. Ultimate/Tensile StressThe point at which a maximum load for a sample is achieved. Beyond this pointelongation of the sample continues, but the force exerted decreases.Tensile test results graph (Insert test graph)Locate the maximum load location on the test graph.Solve for the Ultimate/Tensile stress: F/A 8 kN/mm 2012 Project Lead The Way, Inc.POE Activity 2.3.2 Tensile Testing SIM – Page 5

4. Breaking/Rupture PointThe maximum amount of stress that can be applied before rupture occurs. Thespecimen fractures in the necking region where the material reduces in diameter asit elongates.Tensile test results graph (Insert test graph)Locate the Breaking/Rupture Point on the test graph.Solve for the Breaking/Rupture Point stress: F/A 6.13 kN/mm 2012 Project Lead The Way, Inc.POE Activity 2.3.2 Tensile Testing SIM – Page 6

5. Modulus of ElasticityA measure of a material’s ability to regain its original dimensions after the removal ofa load or force. The modulus is the slope of the straight line portion of the stressstrain diagram up to the proportional limit.Tensile test results graph (Insert test graph)Solve for the Modulus of Elasticity: E (F2 -F1)L0(δ2 -δ1)AE 45 psi 2012 Project Lead The Way, Inc.POE Activity 2.3.2 Tensile Testing SIM – Page 7

6. Modulus of ResilienceA measure of a material’s ability to absorb energy up to the yield point. This modulusis represented by the area under the stress vs. strain curve from 0-force to the yieldpoint.Tensile test results graph (Insert test graph)Solve for the Modulus of Resilience: Ur ½( yp yp)Ur 9.99 2012 Project Lead The Way, Inc.POE Activity 2.3.2 Tensile Testing SIM – Page 8

7. Modulus of ToughnessA measure of a material’s ability to plastically deform without fracturing. Work isperformed by the material absorbing energy from the blow or deformation. Thismeasurement is equal to the area under the stress vs. strain curve from its originthrough the rupture point.Tensile test results graph (Insert test graph)Solve for the Modulus of Toughness: Ut 1/3 ( br)( yp 2 ult)Square: 25.75*10.666 274.66610.66*.6666 7.111.166666*.666666 .1111115/3*6 105/3*4 6.66666666Total area: 298.555 mm 2Conclusion Questions 2012 Project Lead The Way, Inc.POE Activity 2.3.2 Tensile Testing SIM – Page 9

1. Test and observe the graph created when testing cast iron. What does thegraph tell you about the hardness of cast iron? Describe an application wherethe hardness of cast iron would be an advantage.It shows it is very hard and brittle. This could be useful in something that just needs tobe sturdy and doesn’t need to put up with lots of force.2. Compare the difference in the size and shape of the material if the test isstopped before or after the yield point.Before the yield point it looks about the same, but after it begins necking. 2012 Project Lead The Way, Inc.POE Activity 2.3.2 Tensile Testing SIM – Page 10

POE Activity 2.3.2 Tensile Testing SIM – Page 2 3. Choose Want to try? 4. Click on the image of the Virtual Tensometer. 5. This should bring you to the Virtual Tensometer for testing. 6. Four materials are available to test. All but cast iron will create usable data for this activity. Check with your instructor to determine which material you will test. A sampling of each material should be .File Size: 374KBPage Count: 10