Transcription

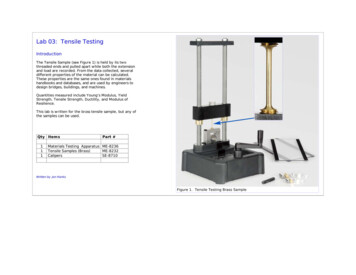

Figure 1. Tensile Testing Brass Sample

Figure 2. A typical stress-strain curve, with points of interest labeled.

Cross-Head Speedspeed (mm/Min)-50 No Data Selected mm/Min50Figure 4. Center Threads in Load CellFigure 3. Installing SampleFigure 5. Always use Saftey Shields!

0mm/Min50Tensile Test of Sample

600550500450400Stress g Slope0.12

750700650600550500Stress 08Strain0.100.120.14

SSABA0.000.020.040.060.08StrainGraph Regions0.100.120.14

QuestionsAnswers:1. Your data tells you how long your sample was just before it broke. Howlong would it be if, after the test, you put the two pieces back togetherand measured it. Would they be the same, within measurement errors, orbe different? Explain.1. The sample was still under tension (stretched) when it broke.Thus the two pieces would be shorter than the stretched length.2. As a mechanical engineer designing a component to be used in anautomobile, which would you use, the yield strength or tensile strength, inyour efforts to determine a safe working load? Explain.2. Yield strength In normal working conditions, the stressshould never exceed the yield strength because the part wouldthen be permanently deformed. However, if you wanted tostudy what would happen during catastrophic failure, you mightwant to look at tensile strength, along with ductility, resilienceand toughness.3. If you had tensile tested a specimen to about half way between where ityielded and when you expected the tensile stress to be reached, thenstopped the test, removed the sample, and later decided to test it again,what would the yield strength be during the second test?3. It would still be the same.4. During a forming operation a material may be bent or pulled to the newdimensions. If the material you just tested was to be as close to 10%longer as possible after this operation, how much longer than this does ithave to pulled during this operation?4. By the amount of Stain there was at the yield point. For thebrass sample used in this lab, that would only be about 1/4 %.5. In some designs a bolt may be declared one that you install once andtorque to specification, but only once. During a repair you must use a newbolt. Why?5. Bolts often have a torque specification very close to the yieldpoint. If there has been some permanent deformation, thatwould change the bolt.

want to look at tensile strength, along with ductility, resilience 3. It would still be the same. 4. By the amount of Stain there was at the yield point. For the brass sample used in this lab, that would only be about 1/4 %. 5. Bolts often have a torque specification very close to the yield point. If there has been some permanent deformation, that