Transcription

VARIABLE FREQUENCYDRIVEOPERATION AND APPLICATION OFVARIABLE FREQUENCY DRIVE (VFD)TECHNOLOGYCarrier CorporationSyracuse, New YorkOctober 2005

TABLE OF CONTENTSHARMONIC DISTORTION ANDINDUSTRY STANDARDS . 6Harmonic Definition . 6What Causes Harmonics? . 7Rocks and Ponds . 7Are Harmonics Harmful? . 7Understanding IEEE 519 . 7Introduction to Harmonic Terms . 8Mitigating Harmonics . 9INTRODUCTION . 2Common VFD TermsVFD OPERATION . 3BENEFITS OF VFD . 4VFD Capacity Control Saves Energy . 4Low Inrush Motor Starting. 5Easy Installation . 5High Power Factor . 5Low Full Load KVA . 6INTRODUCTIONVariable Frequency Drive (VFD)This device uses power electronics to vary thefrequency of input power to the motor, therebycontrolling motor speed.Variable frequency drive (VFD) usage has increaseddramatically in HVAC applications. The VFDs arenow commonly applied to air handlers, pumps,chillers and tower fans. A better understanding ofVFDs will lead to improved application andselection of both equipment and HVAC systems.This paper is intended to provide a basicunderstanding of common VFD terms, VFDoperation, and VFD benefits. In addition this paperwill discuss some basic application guidelinesregarding harmonic distortion with respect toindustry standards.Variable Speed Drive (VSD)This more generic term applies to devices thatcontrol the speed of either the motor or theequipment driven by the motor (fan, pump,compressor, etc.). This device can be eitherelectronic or mechanical.Adjustable Speed Drive (ASD)Again, a more generic term applying to bothmechanical and electrical means of controllingspeed.Common VFD TermsThere are several terms used to describe devices thatcontrol speed. While the acronyms are often usedinterchangeably, the terms have different meanings.This paper will discuss only VFDs.2

VFD OPERATIONUnderstanding the basic principles behind VFDoperation requires understanding the three basicsections of the VFD: the rectifier, dc bus, andinverter.The voltage on an alternating current (ac) powersupply rises and falls in the pattern of a sine wave(see Figure 1). When the voltage is positive,current flows in one direction; when the voltageis negative, the current flows in the oppositedirection. This type of power system enableslarge amounts of energy to be efficientlytransmitted over great distances.control when the power may begin to flow, making thistype of rectifier useful for solid-state starters as well.Transistors include a gate circuit that enables amicroprocessor to open or close at any time, making thetransistor the most useful device of the three. A VFDusing transistors in the rectifier section is said to have an“active front end.”Fig. 2. VFD basics: Existing technologyFig. 1. AC sine waveThe rectifier in a VFD is used to convertincoming ac power into direct current (dc)power. One rectifier will allow power to passthrough only when the voltage is positive. Asecond rectifier will allow power to passthrough only when the voltage is negative. Tworectifiers are required for each phase of power.Since most large power supplies are threephase, there will be a minimum of 6 rectifiersused (see Figure 2). Appropriately, the term “6pulse” is used to describe a drive with 6rectifiers. A VFD may have multiple rectifiersections, with 6 rectifiers per section, enablinga VFD to be “12 pulse,” “18 pulse,” or “24pulse.” The benefit of “multi-pulse” VFDs willbe described later in the harmonics section.Rectifiers may utilize diodes, silicon controlledrectifiers (SCR), or transistors to rectify power.Diodes are the simplest device and allow powerto flow any time voltage is of the properpolarity. Silicon controlled rectifiers include agate circuit that enables a microprocessor toAfter the power flows through the rectifiers it isstored on a dc bus. The dc bus contains capacitors toaccept power from the rectifier, store it, and later deliverthat power through the inverter section. The dc bus mayalso contain inductors, dc links, chokes, or similar itemsthat add inductance, thereby smoothing the incomingpower supply to the dc bus. The final section of theVFD is referred to as an “inverter.” The invertercontains transistors that deliver power to the motor.The “Insulated Gate Bipolar Transistor” (IGBT) is acommon choice in modern VFDs. The IGBT can switchon and off several thousand times per second andprecisely control the power delivered to the motor. TheIGBT uses a method named “pulse width modulation”(PWM) to simulate a current sine wave at the desiredfrequency to the motor.Motor speed (rpm) is dependent upon frequency.Varying the frequency output of the VFD controlsmotor speed:Speed (rpm) frequency (hertz) x 120 / no. of polesExample:2-pole motor at different frequencies3600 rpm 60 hertz x 120 / 2 3600 rpm3000 rpm 50 hertz x 120 / 2 3000 rpm2400 rpm 40 hertz x 120 / 2 2400 rpm3

BENEFITS OF VFDAs VFD usage in HVAC applications has increased,fans, pumps, air handlers, and chillers can benefitfrom speed control. Variable frequency drives provide the following advantages: energy savings low motor starting current reduction of thermal and mechanicalstresses on motors and belts during starts simple installation high power factor lower KVAUnderstanding the basis for these benefits will allowengineers and operators to apply VFDs withconfidence and achieve the greatest operationalsavings.VFD Capacity Control Saves EnergyMost applications do not require a constant flow ofa fluid. Equipment is sized for a peak load that mayaccount for only 1% of the hours of operation. Theremaining hours of operation need only a fraction ofthe flow. Traditionally, devices that throttle outputhave been employed to reduce the flow. However,when compared with speed control, these methodsare significantly less efficient.Fig. 3. Mechanical capacity controlPump power flow x head / 39601Variable Speed Capacity ControlFor centrifugal pumps, fans and compressors, theideal fan (affinity) laws describe how speed affectsflow, head and power consumption (Table A).When using speed to reduce capacity, both the headand flow are reduced, maximizing the energysavings. A comparison of mechanical and speedcontrol for capacity reduction (Figure 4) shows thatvariable speed is the most efficient means ofcapacity control.EfficiencyThrottling valves, vanes, or dampers may beemployed to control capacity of a constant speedpump or fan. These devices increase the head, thereby forcing the fan or pump to ride the curve to apoint where it produces less flow (Figure 3). Powerconsumption is the product of head and flow.Throttling the output increases head, but reducesflow, and provides some energy savings.HorsepowerMechanical Capacity ControlFig. 4. Comparison of mechanical capacity control andspeed capacity controlTable A: Effects of Changes in Fan SpeedFlow changes linearly with speedHead varies as the speed squaredPower varies as the speed cubed1Flow Rate2 Flow Rate1 x (RPM2/RPM1)Lift2 Lift1 x (RPM2/RPM1)2Power2 Power1 x (RPM2/RPM1)3Assumes fluid is fresh water, (specific gravity 1).4

met. The current level of the motor never exceedsthe full load amp rating of the motor at any timeduring its start or operation. In addition to the benefitof low starting current, motor designs can now beoptimized for high efficiency.Low Inrush Motor StartingMotor manufacturers face difficult design choices.Designs optimized for low starting current oftensacrifice efficiency, power factor, size, and cost.With these considerations in mind, it is common forAC induction motors to draw 6 to 8 times their fullload amps when they are started across the line.When large amounts of current are drawn on thetransformers, a voltage drop can occur2, adverselyaffecting other equipment on the same electricalsystem. Some voltage sensitive applications mayeven trip off line. For this reason, many engineersspecify a means of reducing the starting current oflarge AC induction motors.Table BComparison of Starter Types Based on InrushStarter TypeVFDWye-Delta StarterSoft StartersStarting Current (% of FLA)100%200-275%Solid State Soft Starter200%Autotransformer Starter400-500%Part Winding Starter400-500%Across the Line Starter600-800%Easy InstallationWye-delta, part winding, autotransformer, and solidstate starters are often used to reduce inrush duringmotor starting. All of these starters deliver power tothe motor at a constant frequency and therefore mustlimit the current by controlling the voltage suppliedto the motor. Wye delta, part winding, and autotransformer starters use special electricalconnections to reduce the voltage. Solid-statestarters use SCRs to reduce the voltage. The amountof voltage reduction possible is limited because themotor needs enough voltage to generate torque toaccelerate. With maximum allowable voltagereduction, the motor will still draw two to four timesthe full load amps (FLA) during starting.Additionally, rapid acceleration associated withwye-delta starters can wear belts and other powertransmission components.Many pieces of equipment are factory shipped withunit mounted VFDs that arrive pre-programmed andfactory wired. Motor leads, control power forauxiliaries, and communication lines are all factorywired. The VFD cooling lines on unit-mountedchiller VFDs are also factory installed. Theinstalling contractor needs only to connect the linepower supply to the VFD.High Power FactorVFDs as StartersPower converted to motion, heat, sound, etc. iscalled real power and is measured in kilowatts (kW).Power that charges capacitors or builds magneticfields is called reactive power and is measured inKilovolts Amps Reactive (kVAR). The vector sumof the kW and the kVAR is the Total Power (energy)and is measured in Kilovolt Amperes (KVA)(Figure 5). Power factor is the ratio of kW/KVA.A VFD is the ideal soft starter since it provides thelowest inrush of any starter type as shown in TableB. Unlike all other types of starters, the VFD canuse frequency to limit the power and currentdelivered to the motor. The VFD will start the motorby delivering power at a low frequency. At this lowfrequency, the motor does not require a high level ofcurrent. The VFD incrementally increases thefrequency and motor speed until the desired speed isMotors draw reactive current to support theirmagnetic fields in order to cause rotation.Excessive reactive current is undesirable because itcreates additional resistance losses and can requirethe use of larger transformers and wires. In addition,utilities often penalize owners for low powerfactor. Decreasing reactive current will increasepower factor.2This is a significant consideration for "soft" systemssuch as backup generators.5

Totalvolts xampstransmitted.Powerconsu medas heat,sound,worketc.Energyused tobuild /decaymagneticfield s inmotors,transformers etc. Fig. 5. Measuring powerTypical AC motors may have a full load power factorranging from 0.84 to 0.88. As the motor load isreduced, the power factor becomes lower. Utilitiesmay require site power factor values ranging from0.85 to 0.95 and impose penalties to enforce thisrequirement. Power factor correction capacitors canbe added to reduce the reactive current measuredupstream of the capacitors and increase themeasured power factor. To prevent damage to themotor, power factor correction capacitors should notexceed the motor manufacturer’s recommendations.In most cases, this results in maximum correctedvalues of 0.90 to 0.95.The VFDs include capacitors in the DC Bus that perform the same function and maintain high powerfactor on the line side of the VFD. This eliminatesthe need to add power factor correction equipment tothe motor or use expensive capacitor banks. Inaddition, VFDs often result in higher line side powerfactor values than constant speed motors equippedwith correction capacitors.Low Full Load KVATotal Power (KVA) is often the limiting factor in theamount of energy that can be transmitted through anelectrical device or system. If the KVA required byequipment can be reduced during periods of peakdemand, it will help alleviate voltage sags, brownouts, and power outages. The unit efficiency andpower factor are equally weighted when calculatingKVA. Therefore, equipment that may be equal orworse in efficiency, but higher in power factor hassignificantly lower KVA (Table C).In this example, equipment with a higher powerfactor uses 15% less KVA while performing thesame job. This can lower electrical system cost onnew projects and free up KVA capacity on existingsystems.Table CPower Factors and Energy nal 480417350.4.99426Nominal 480354NOTE: KVA Volts x Amps x 1.732Backup generators are typically sized to closelymatch the load. Lowering KVA can reduce the sizeof the generator required. When VFDs with activefront ends are used, the generator size can approachan ideal 1:1 ratio of kW/KVA because the powerfactor is near unity (1.0) and the harmonicsproduced by the VFD are extremely low.Lower KVA also benefits utilities. When the powerfactor is higher, more power (kW) can be deliveredthrough the same transmission equipment.HARMONIC DISTORTION AND INDUSTRYSTANDARDSA discussion of the benefits of VFDs often leads toa question regarding harmonics. When evaluatingVFDs, it is important to understand how harmonicsare provided and the circumstances under whichharmonics are harmful.Harmonic DefinitionIn the United States, three-phase AC power typicallyoperates at 60 hertz (60 cycles in one second). Thisis called the fundamental frequency.6

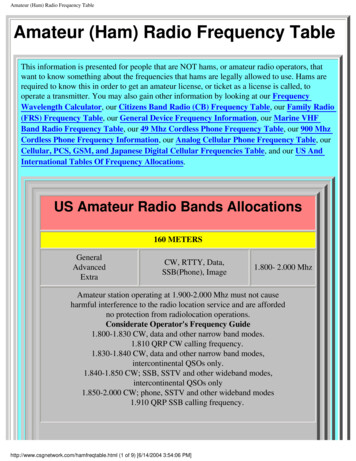

A harmonic is any current form at an integralmultiple of the fundamental frequency. For example,for 60-hertz power supplies, harmonics would be at120 hertz (2 x fundamental), 180 hertz, 240 hertz,300 hertz, etc.What Causes Harmonics?VFDs draw current from the line only when the linevoltage is greater than the DC Bus voltage inside thedrive. This occurs only near the peaks of the sinewave. As a result, all of the current is drawn in shortintervals (i.e., at higher frequencies). Variation inVFD design affects the harmonics produced. Forexample, VFDs equipped with DC link inductorsproduce different levels of harmonics than similarVFDs without DC link inductors. The VFDs withactive front ends utilizing transistors in the rectifiersection have much lower harmonic levels thanVFDs using diodes or silicon controlled rectifiers(SCRs).Electronic lighting ballasts, uninterruptible powersupplies, computers, office equipment, ozonegenerators, and other high intensity lighting are alsosources of harmonics.Rocks and PondsObviously, the magnitude of the contributing waveforms has an effect on the shape of the resultantwave form. If the fundamental wave form (60 Hz)has a very large magnitude (5,000 amps) and theharmonic wave forms are very low (10 amps), thenthe resultant wave form will not be very distortedand total harmonic distortion will be low. If theharmonic wave form current value is high relativeto the fundamental, the effect will be more dramatic.In nature, we see this effect with waves in water. Ifyou continually throw baseball size rocks into theocean, you would not expect to change the shape ofthe waves crashing onto the beach. However, if youthrew those same size rocks into a bathtub, youwould definitely observe the effects. It is similarwith electrical waves and harmonics.3When you calculate harmonics you are calculatingthe effect of the harmonics on the fundamental current wave form in a particular distribution system.There are several programs that can performestimated calculations. All of them take into accountthe amount of linear loads (loads drawing powerthroughout the entire sine wave) relative to nonlinear loads (loads drawing power during only afraction of the sine wave). The higher the ratio oflinear loads to non-linear loads, the less effect thenon-linear loads will have on the current wave form.Are Harmonics Harmful?Harmonics that are multiples of 2 are not harmfulbecause they cancel out. The same is true for 3rdorder harmonics (3rd, 6th, 9th etc.). Because the powersupply is 3 phase, the third order harmonics canceleach other out in each phase 3. This leaves only the5th, 7th, 11th, 13th etc. to discuss. The magnitude of theharmonics produced by a VFD is greatest for thelower order harmonics (5th, 7th and 11th) and dropsquickly as you move into the higher orderharmonics (13th and greater).Harmonics can cause some disturbances in electricalsystems. Higher order harmonics can interfere withsensitive electronics and communications systems,while lower order harmonics can cause overheatingof motors, transformers, and conductors. Theopportunity for harmonics to be harmful, however,is dependent upon the electrical system in whichthey are present and whether or not any harmonicsensitive equipment is located on that sameelectrical system.Understanding IEEE 519IEEE (Institute of Electrical and ElectronicsEngineers) created a recommendation for evaluatingharmonics. The IEEE-519 standard providesrecommended limits for harmonic distortionmeasured at the point of common coupling. Thepoint of common coupling is the point at which thecustomer’s electrical system is connected to theutility.The neutral wire sizing should account for 3rd orderharmonic current.7

Although the IEEE standard recommends limits forboth voltage distortion and current distortion,specifications that reference a 5% harmoniclimitation are generally referring to currentdistortion. In most cases, if the current distortionfalls within IEEE-519 requirements, the voltagedistortion will also be acceptable.Determining compliance with IEEE-519 requires anactual measurement of the system during operation.Predicting compliance in advance often requires asystem study that accounts for all electricalequipment (transformers, wires, motors, VFDs,etc.) in the system.Introduction To Harmonic TermsTotal Harmonic Voltage Distortion - THD (V)As harmonic currents flow through devices withreactance or resistance, a voltage drop is developed.These harmonic voltages cause voltage distortion ofthe fundamental voltage wave form. The totalmagnitude of the voltage distortion is the THD (V).The IEEE-519 standard recommends less than 5%THD (V) at the point of common coupling forgeneral systems 69 kV and under.Total Harmonic Current Distortion - THD (I)This value (sometimes written as THID) representsthe total harmonic current distortion of the waveform at the particular moment when themeasurement is taken. It is the ratio of the harmoniccurrent to the fundamental (non-harmonic) currentmeasured for that load point. Note that thedenominator used in this ratio changes with load.Total Demand Distortion - TDDTotal Demand Distortion (TDD) is the ratio of themeasured harmonic current to the full loadfundamental current. The full load fundamentalcurrent is the total amount of non-harmonic currentconsumed by all of the loads on the system when thesystem is at peak demand. The denominator used inthis ratio does not change with load. Although TDDcan be measured at any operating point (full or partload), the worst case TDD will occur at full load. Ifthe full load TDD is acceptable, then the TDDmeasured at part load values will also be acceptable.To use our rock analogy, the full load fundamentalcurrent is the size of our pond and the harmoniccurrent is the size of our rock. (See Table D.)Table DComparison of TDD and THD(I)FundamentalCurrent (rms)HarmonicCurrent (rms 40029.77.4%3.0%20020.010%2%10013.413.4%1.3%TDD - Total Demand DistortionTHD(I) - Total Harmonic Current DistortionShort Circuit RatioShort circuit ratio is the short circuit current value ofthe electrical system divided by its maximum loadcurrent. Standard IEEE-519 Table 2 definesdifferent acceptance levels of TDD depending onthe short circuit ratio in the system. Systems withsmall short circuit ratios have lower TDDrequirements than systems with larger short circuitratios. This difference accounts for the fact thatelectrical systems with low short circuit ratios tendto have high impedances, creating larger voltagedistortion for equivalent harmonic current levels.(See Table E.)Mitigating HarmonicsSome utilities now impose penalties for introducingharmonics onto their grid, providing incentives forowners to reduce harmonics. In addition, reducingharmonic levels can prevent potential damage tosensitive equipment residing on the same system.There are many approaches to mitigating harmonics.Several commonly used methods are discussed here.Line ReactorsLine reactors add reactance and impedance to thecircuit. Reactance and impedance act to lower thecurrent magnitude of harmonics in the system andthereby lower the TDD. Line reactors also protectdevices from large current spikes with short rise8

Table ETable 2 - Current distortion limits for systems rated 120 V through 69 kVMaximum harmonic current distortion in percent of ILIndividual harmonic order (odd harmonics)a,bIsc/IL3 h 1111 h 1717 h 2323 h 3535 h 50TDD 20c4.02.01.50.60.35.020 507.03.52.51.00.58.050 10010.04.54.01.50.712.0100 100012.05.55.02.01.015.0 100015.07.06.02.51.420.0a Evenharmonics are limited to 25% of the odd harmonic limits above.distortions that result in a dc offset, e.g., half-wave converters, are not allowed.c All power generation equipment is limited to these values of current distortion, regardless of actual I /I wheresc LIsc maximum short-circuit current at PCCIL maximum demand load current (fundamental frequency component) at the PCC under normal load operating conditions.b Currenttimes. A line reactor placed between the VFD andthe motor would help protect the motor from currentspikes. A line reactor placed between the supply andVFD would help protect the supply from currentspikes. Line reactors are typically only usedbetween the VFD and the motor when afreestanding VFD is mounted more than fifty feetfrom the motor. This is done to protect the motorwindings from voltage peaks with extremely quickrise times.Passive FiltersTrap Filters are devices that include an electricalcircuit consisting of inductors, reactors, andcapacitors designed to provide a low impedance pathto ground at the targeted frequency. Since currentwill travel through the lowest impedance path, thisprevents the harmonic current at the targetedfrequency from propagating through the system.Filters can be mounted inside the drive cabinet or asfree standing devices. Trap filters are typicallyquoted to meet a THD(I) value that would result incompliance with IEEE-519 requirements if thesystem were otherwise already in compliance.Active FiltersSome devices measure harmonic currents andquickly create opposite current harmonic waveforms. The two wave forms then cancel out,preventing harmonic currents from being observed9upstream of the filter. These types of filters generallyhave excellent harmonic mitigation characteristics.Active filters may reduce generator sizerequirements.VFDs Using Active Front End Technology (AFE)Some VFDs are manufactured with IGBT rectifiers.The unique attributes of IGBTs allow the VFD toactively control the power input, thereby loweringharmonics, increasing power factor and making theVFD far more tolerant of supply side disturbances.The AFE VFDs have ultra low harmonics capable ofmeeting IEEE-519 standards without any externalfilters or line reactors. This significantly reducesinstallation cost and generator size requirements.An AFE drive provides the best way to takeadvantage of VFD benefits and minimize harmonics.Multi-Pulse VFDs (Cancellation)There are a minimum of six rectifiers for a threephase AC VFD. There can be more, however.Manufacturers offer 12, 18, 24, and 30 pulse drives.A standard six-pulse drive has six rectifiers, a 12pulse drive has two sets of six rectifiers, an 18-pulsedrive has three sets of six rectifiers and so on. If thepower connected to each set of rectifiers is phaseshifted, then some of the harmonics produced by oneset of rectifiers will be opposite in polarity from theharmonics produced by the other set of rectifiers.

The two wave forms effectively cancel eachother out. In order to use phase shifting, aspecial transformer with multiple secondarywindings must be used. For example, with a12-pulse VFD, a Delta/Delta-Wye transformerwith each of the secondary phases shifted by30 degrees would be used.REFERENCESCONCLUSIONJohn F. Hibbard, Michael Z. Lowenstein.“Meeting IEEE 519-1992 HarmonicLimits Using Harmonic Guard PassiveFilters”(TRANS-COIL, INC) VFDs provide the most energy efficientmeans of capacity control. VFDs have the lowest starting current ofany starter type. VFDs reduce thermal and mechanicalstresses on motors and belts. VFD installation is as simple as connectingthe power supply to the VFD. VFDs with AFE technology can meet eventhe most stringent harmonic standards andreduce backup generator sizing. VFDs provide high power factor,eliminating the need for external powerfactor correction capacitors. VFDs provide lower KVA, helpingalleviate voltage sags and poweroutages.NOTE: It is the responsibility of the user toevaluate the accuracy, completeness orusefulness of any content in this paper. NeitherCarrier nor its affiliatesmakeanyrepresentations or warranties regarding thecontent contained in this paper. Neither Carriernor its affiliates will be liable to any user oranyone else for any inaccuracy, error or omission,regardless of cause, or for any damages resultingfrom any use, reliance or reference to the contentin this paper.Copyright 2005 Carrier Corporationwww.carrier.comIEEE Standard 519-2014. “IEEE RecommendedPractices and Requirements of HarmonicControl in Electrical Power Systems.”Rockwell Automation. “Dealing with lineharmonics from PWM variable frequencydrives.”Tony Hoevenaars, P. Eng, Kurt LeDoux, P.E.,Matt Colosina. 2003. “InterpretingIEEE Std 519 and Meeting itsHarmonic Limits in VFDApplications.”(IEEE paper No. PCIC-2003-XX).Gary Rockis, Glen Mazur, American TechnicalPublishers, Inc. 1997. “Electrical MotorControls.”Richard H. Smith, P.E., Pure Power. 1999.“Power Quality Vista Looks GoodThanks to IGBTs.”FURTHER READING FROM CARRIERCarrier. 1993. Harmonics: A Brief Introduction.Carrier. 1999. 19XRV Marketing Guide.Carrier. 2005. Carrier Introduces RotaryChillers with Liquiflo2 Variable Speed Drive.Carrier. 2005. Carrier Variable Speed ScrewWhite PaperPrinted in U.S.A.Rev 7-18Replaces: New

Variable frequency drive (VFD) usage has increased dramatically in HVAC applications. The VFDs are now commonly applied to air handlers, pumps, chillers and tower fans. A better understanding of VFDs will lead to improved application and selection of both equipment and HVAC systems. This paper is intended to provide a basic