Transcription

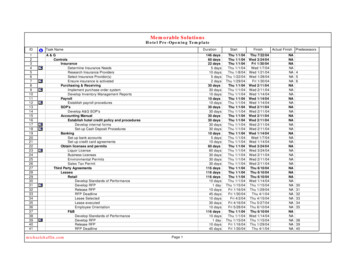

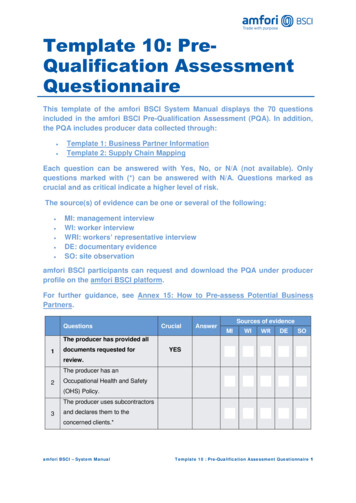

Template 10: PreQualification AssessmentQuestionnaireThis template of the amfori BSCI System Manual displays the 70 questionsincluded in the amfori BSCI Pre-Qualification Assessment (PQA). In addition,the PQA includes producer data collected through: Template 1: Business Partner InformationTemplate 2: Supply Chain MappingEach question can be answered with Yes, No, or N/A (not available). Onlyquestions marked with (*) can be answered with N/A. Questions marked ascrucial and as critical indicate a higher level of risk.The source(s) of evidence can be one or several of the following: MI: management interviewWI: worker interviewWRI: workers’ representative interviewDE: documentary evidenceSO: site observationamfori BSCI participants can request and download the PQA under producerprofile on the amfori BSCI platform.For further guidance, see Annex 15: How to Pre-assess Potential BusinessPartners.QuestionsCrucialAnswerSources of evidenceMIWIWRDESOThe producer has provided all1documents requested forYESreview.The producer has an2Occupational Health and Safety(OHS) Policy.The producer uses subcontractors3and declares them to theconcerned clients.*amfori BSCI – System ManualTemplate 10 : Pre-Qualification Assessment Questionnaire 1

The producer makes workers4aware of their rights andCRITICALresponsibilities.The producer respects the5workers’ right to bargainCRITICALcollectively.The producer does not interfere in6the workers’ representativeelection.The producer takes thenecessary measures to avoid or7eradicate discrimination in theYESworkplace.The producer takes the necessarymeasures to ensure workers are8not disciplined or discriminatedagainst for using a grievancemechanism.The producer takes the necessarymeasures to ensure female9workers are not discriminatedagainst, with special attention inthe case of pregnancy.*The producer complies with thegovernment’s minimum wage10legislation or the industryYESstandard approved throughcollective bargaining.The producer pays workers'wages in a timely manner,11regularly, and fully in legal tender.(Any in kind payment must bebeyond the minimum wage.)The producer pays apprentices,12trainers, and workers on probationin accordance with the law.*The producer provides workerswith an understandable wage slip.13(At the minimum, this includesregular and overtime hoursamfori BSCI – System ManualTemplate 10 : Pre-Qualification Assessment Questionnaire 2

worked regular and overtimepremium payments, and anypossible legal deductions.)The producer provides workers14with the social benefits that arelegally granted.*The producer pays overtime at a15premium rate no lower than 1.25of the regular rate.The producer pays public holidays16in accordance with the premiumrate defined by law.The producer pays workersadditional benefits as granted by17law (e.g. bonuses, incentives, andallowances).The producer ensures thatdeductions are only taken18under the conditions and to theCRITICALextent prescribed by the law.The producer grants workers19the right to resting breaks inYESevery working day.The producer grants workersthe right to at least one day offin every seven days. (Collective20bargaining may allow aYESdifferent combination of daysoff.)The producer observes applicable21OHS regulations for its activities.The producer conducts fire drillson a regular basis (if not defined22by the law, at least once a year) inall premises and floors and duringall shifts.amfori BSCI – System ManualTemplate 10 : Pre-Qualification Assessment Questionnaire 3

The producer regularly providesOHS trainings to ensure workersunderstand their personal23protection, including night shiftworkers (making sure that youngworkers and migrant workershave access to trainings).The producer documents thepurchases of necessary PPE to24provide continuous protection toworkers.The producer implementsengineering and administrativecontrol measures to avoid orminimise the release of hazardous25substances into the workenvironment, keeping the level ofexposure below internationallyestablished or recognised limits.The producer makes potentialhazards visible to the workers and26visitors through signs andwarnings.The producer has and properlyuses procedures and systems for27reporting and recordingoccupational accidents andinjuries.The producer confirms that the28equipment and buildings used forproduction are stable and safe.The producer respects theworkers’ right to remove29themselves from imminentCRITICALdanger without seekingpermission.The producer documents each fire30drill with, at the least, informationon the date, announcementamfori BSCI – System ManualTemplate 10 : Pre-Qualification Assessment Questionnaire 4

method, number of participants,and time used for evacuation.The producer ensures thatelectrical panels, wires, and31outlets are protected andinspected regularly by certifiedstaff.The producer has installed anadequate amount of properly32working firefightingYESequipment.*The producer ensures thatfirefighting equipment is33inspected in a timely manner byYESan external party with theappropriate knowledge.*The producer has installed afire alarm that works and is34heard and recognised from allYESworkplaces.*The producer ensures that, if amanual fire alarm is used, there35is a clear designation ofYESresponsibilities and proceduresto trigger the alarm.*The producer ensures thatthere are functioning fire36extinguishers along emergencyYESexit paths.*The producer ensures that allfire extinguishers are37functioning, clearly visible, andYESaccessible.*The producer ensures that fire38extinguishers are in complianceYESwith the legal requirements.*The producer ensures that fire39extinguishers are inspectedYESmonthly by the responsibleamfori BSCI – System ManualTemplate 10 : Pre-Qualification Assessment Questionnaire 5

staff and once a year by aspecialised external party.*The producer ensures thatsmoke detectors present in the40workplace and related facilitiesYESare inspected monthly by aspecialised external party. *The producer ensures thatescape routes, aisles, andemergency exits in theproduction site are41unobstructed, easilyYESaccessible, and clearly markedand that they lead to anunobstructed and safeassembly point.*The producer ensuresemergency exits are located ina way that facilitates smooth42evacuation (including two setsYESof stairs if the facility is locatedabove the ground floor).*The producer ensures thatemergency lightening is43connected to a secondary powersource.*The producer ensures qualifiedfirst-aid is available at all times,including in the housing44provided, with trained staff toYESadminister first aid and writtenprocedures to deal with workaccidents.The producer ensures that there45is a room for providing first-aid toits workers.The producer ensures washing46and toilet areas are equipped withsoap.amfori BSCI – System ManualTemplate 10 : Pre-Qualification Assessment Questionnaire 6

The producer provides workerswith potable water at all times,47including at the housingCRITICALprovided. (Access to potablewater is a human right.)The producer provides workerswith access to an appropriate,48clean area for storing food,YESeating, and/or cooking.The producer ensures that firedrills are regularly conducted at49the housing provided anddocumentation on the dates andmethod is maintained.The producer ensures that thehousing units are located in a safeenvironment, outside the50production area and the storageareas (with particular vigilance toavoid contact with hazardous orinflammable substances).The producer ensures that theevacuation plot plan is posted in avisible place at several locations51in the housing zone to ensureworkers can evacuate dormitoriesin safe conditions.*The producer does not engage52in illegal child labour directly orCRITICALindirectly.The producer requests and keepsoriginal legal documentation toverify workers' ages at the hiring53time, even if hiring is doneindirectly (e.g. via brokers orrecruiting agencies).The producer ensures that youngworkers are protected against54work conditions that are harmfulto their health, safety, morals, andamfori BSCI – System ManualTemplate 10 : Pre-Qualification Assessment Questionnaire 7

development and do not worknight shifts.The producer ensures thatyoung workers’ working hoursdo not affect their attendance atschool, their participation in55vocational orientationsYESapproved by the competentauthority, or their capacity tobenefit from training orinstruction programmes.*The producer keeps accuraterecords and relevantdocumentation concerning young56workers (e.g. copy of identity,working time, parental permissionto work, course schedules, andvacation periods).*The producer provides workerswith understandable informationconcerning their rights and57obligations before they enter intoemployment, even if hiredindirectly.The producer does not useemployment arrangements in a58way that deliberately conflictsYESwith the genuine purpose of thelaw.The producer does not engagein any form of servitude, or59forced, bonded, indentured,CRITICALtrafficked or non-voluntarylabour.The producer takes additionalprecautions to avoid forced labour60when engaging and recruitingmigrant workers both directly andindirectly.amfori BSCI – System ManualTemplate 10 : Pre-Qualification Assessment Questionnaire 8

The producer ensures that61workers don’t cover any of thecosts related to accessing the job.The producer maintains anoverview of the way recruitment62agencies or brokers paysubcontracted workers.*The producer does not subjectworkers to inhumane or63degrading treatment or verbalYESabuse.The producer does not subjectworkers to corporal64punishment or mental orYESphysical coercion.The producer has establishedall applicable disciplinaryprocedures in writing and has65explained them verbally toYESworkers in clear andunderstandable terms.The producer has the required66environmental permits andlicences.The producer manages itsgenerated waste in a way that67does not lead to the pollution ofthe environment.The producer actively opposesany act of corruption, extortion, or68embezzlement, or any form ofbribery, in its activities as abusiness enterprise.The producer keeps accurateinformation regarding its ownactivities, structure, and69performance in a way thatYESavoids the risk of falsifieddocuments oramfori BSCI – System ManualTemplate 10 : Pre-Qualification Assessment Questionnaire 9

misrepresentation in the supplychain.The reviewed documents are70found to be free of anymanipulation or falsification.amfori BSCI – System ManualTemplate 10 : Pre-Qualification Assessment Questionnaire 10

amfori BSCI – System Manual Template 10 : Pre-Qualification Assessment Questionnaire 1 QuestionsFile Size: 361KBPage Count: 10