Transcription

INTRODUCTION TOFIFTH EDITIONOPERATIONS ANDSUPPLY CHAINMANAGEMENTCecil C. BozarthNorth Carolina State UniversityRobert B. HandfieldNorth Carolina State UniversityNew York, NYA01 BOZA0607 05 SE FM.indd 117/11/17 4:47 PM

Vice President, Business, Economics, and UK Courseware:Donna BattistaDirector of Portfolio Management: Stephanie WallEditorial Assistant: Linda Siebert AlbelliVice President, Product Marketing: Roxanne McCarleySenior Product Marketer: Product Marketer: Kaylee CarlsonProduct Marketing Assistant: Marianela SilvestriManager of Field Marketing, Business Publishing:Adam GoldsteinExecutive Field Marketing Manager: Field MarketingManager: Nicole PriceVice President, Production and Digital Studio, Arts andBusiness: Etain O’DeaDirector of Production, Business: Jeff HolcombManaging Producer, Business: Melissa FeimerContent Producer: Yasmita HotaOperations Specialist: Carol MelvilleDesign Lead: Kathryn FootManager, Learning Tools: Brian SuretteContent Developer, Learning Tools: Lindsey SloanManaging Producer, Digital Studio and GLP, MediaProduction and Development: Ashley SantoraManaging Producer, Digital Studio: Diane LombardoDigital Studio Producer: Regina DaSilvaDigital Studio Producer: Alana ColesDigital Content Project Lead: Courtney KamaufProject Management: Thistle Hill Publishing ServicesInterior and Cover Design: Cenveo Publisher ServicesCover Art: Oscar Sanchez/EyeEm/Getty ImagesPrinter/Binder: LSC Communications, Inc./WillardCover Printer: Phoenix Color/HagerstownMicrosoft and/or its respective suppliers make no representations about the suitability of the information contained in the documentsand related graphics published as part of the services for any purpose. All such documents and related graphics are provided “as is”without warranty of any kind. Microsoft and/or its respective suppliers hereby disclaim all warranties and conditions with regardto this information, including all warranties and conditions of merchantability, whether express, implied or statutory, fitness for aparticular purpose, title and non-infringement. In no event shall Microsoft and/or its respective suppliers be liable for any special,indirect or consequential damages or any damages whatsoever resulting from loss of use, data or profits, whether in an action ofcontract, negligence or other tortious action, arising out of or in connection with the use or performance of information availablefrom the services.The documents and related graphics contained herein could include technical inaccuracies or typographical errors. Changes areperiodically added to the information herein. Microsoft and/or its respective suppliers may make improvements and/or changes in theproduct(s) and/or the program(s) described herein at any time. Partial screen shots may be viewed in full within the software versionspecified.Microsoft and Windows are registered trademarks of the Microsoft Corporation in the U.S.A. and other countries. This book is notsponsored or endorsed by or affiliated with the Microsoft Corporation.Copyright 2019, 2016, 2013 by Pearson Education, Inc. or its affiliates. All Rights Reserved. Manufactured in the United States ofAmerica. This publication is protected by copyright, and permission should be obtained from the publisher prior to any prohibitedreproduction, storage in a retrieval system, or transmission in any form or by any means, electronic, mechanical, photocopying,recording, or otherwise. For information regarding permissions, request forms, and the appropriate contacts within the PearsonEducation Global Rights and Permissions department, please visit www.pearsoned.com/permissions/.Acknowledgments of third-party content appear on the appropriate page within the text, which constitutes an extension of thiscopyright page.PEARSON, ALWAYS LEARNING, and MYLAB are exclusive trademarks owned by Pearson Education, Inc. or its affiliates in the U.S.and/or other countries.Unless otherwise indicated herein, any third-party trademarks, logos, or icons that may appear in this work are the property of theirrespective owners, and any references to third-party trademarks, logos, icons, or other trade dress are for demonstrative or descriptivepurposes only. Such references are not intended to imply any sponsorship, endorsement, authorization, or promotion of Pearson’sproducts by the owners of such marks, or any relationship between the owner and Pearson Education, Inc., or its affiliates, authors,licensees, or distributors.Library of Congress Cataloging-in-Publication DataNames: Bozarth, Cecil C., author. Handfield, Robert B., author.Title: Introduction to operations and supply chain management / Cecil C. Bozarth, North Carolina State University,Robert B. Handfield, North Carolina State University.Description: Fifth edition. New York, NY : Pearson, [2019] Includes bibliographical references and index.Identifiers: LCCN 2017050841 ISBN 9780134740607 (hardcover) ISBN 0134740602 (hardcover)Subjects: LCSH: Management. Production management. Business logistics.Classification: LCC HD31.2 .B69 2019 DDC 658.5—dc23LC record available at https://lccn.loc.gov/2017050841117ISBN 10: 0-13-474060-2ISBN 13: 978-0-13-474060-7A01 BOZA0607 05 SE FM.indd 217/11/17 4:47 PM

To Andrea, James, and PhilipC.B.To Sandi, Simone, and LucR.H.A01 BOZA0607 05 SE FM.indd 317/11/17 4:47 PM

ABOUT THE AUTHORSCecil Bozarth is Professor of Operations and Supply Chain Management at thePoole College of Management at N.C. State University, where he has received awardsfor teaching excellence at both the undergraduate and graduate levels. He is a former chair of the Operations Management Division of the Academy of Management,and in 1999 was recognized by APICS as a subject matter expert (SME) in the area ofsupply chain management. His particular areas of interest are operations and supply chain strategy and supply chain information systems. Cecil’s consulting experience cuts across a wide range of industries, including such companies as BlueCrossBlueShield of North Carolina, Daimler-Benz, John Deere, Duke Energy, Eisai, FordMotor Company, GKN, IBM, GlaxoSmithKline, Milliken, Patheon, Sonoco, and others. For thirteen years, Cecil was an associate editor for the Journal of Operations Management; he now serves on the journal’s editorial advisory board. Cecil has also servedas a guest editor for the Academy of Management Journal, as well as the Journal of Operations Management.Robert Handfield is the Bank of America Professor and a Distinguished UniversityProfessor at N.C. State University. Handfield has consulted with over 25 Fortune 500companies, including Biogen Idec, Caterpillar, John Deere, GlaxoSmithKline, BostonScientific, Delphi, Chevron, British Petroleum, Chevron Phillips, Bank of America,Sensata, Honda of America, KPMG, Conoco Phillips, Federal Express, SAP, and others, and is a world-renowned expert in the areas of purchasing and logistics. Rob isthe former editor-in-chief of the Journal of Operations Management and has written several books on SCM topics, including Introduction to Supply Chain Management (PrenticeHall, with Ernest L. Nichols; translated into Japanese, Korean, Chinese, and Indonesian), Supply Chain Redesign (Prentice Hall Financial Times), and Purchasing and SupplyChain Management, 5th edition (South-Western College Publishing, with Robert M.Monczka, Larry C. Giunipero, and James L. Patterson).ivA01 BOZA0607 05 SE FM.indd 417/11/17 4:47 PM

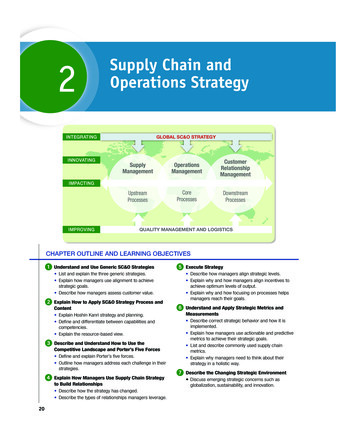

BRIEF CONTENTSPrefacexiCREATING VALUE THROUGH OPERATIONSAND SUPPLY CHAINS 1PART I12Introduction to Operations and Supply Chain ManagementOperations and Supply Chain Strategies 20ESTABLISHING THE OPERATIONS ENVIRONMENTPART II34566SESTABLISHING SUPPLY CHAIN LINKAGESSupply ManagementLogistics 221189Forecasting 254Sales and Operations Planning (Aggregate Planning) 299Managing Inventory throughout the Supply Chain 331Managing Production across the Supply Chain 364Supply Chain Information Systems 399JIT/Lean Production 408PROJECT MANAGEMENT AND PRODUCT/SERVICEDEVELOPMENT 429PART V1415189PLANNING AND CONTROLLING OPERATIONSAND SUPPLY CHAINS 254PART IV910111212S1340Process Choice and Layout Decisions in Manufacturing and Services 40Business Processes 74Managing Quality 108Managing Capacity 142Advanced Waiting Line Theory and Simulation Modeling 175PART III781Managing Projects 429Developing Products and ServicesAppendicesGlossaryIndex451469475487vA01 BOZA0607 05 SE FM.indd 517/11/17 4:47 PM

CONTENTSPrefacexiPART ICreating Value through Operationsand Supply Chains 11 Introduction to Operations andSupply Chain Management 1Introduction 21.1 Why Study Operations and Supply ChainManagement? 3Operations Management 4Supply Chain Management 61.2 Important Trends 9Agility 10Information Technologies 10People 101.3 Operations and Supply Chain Management andYou 11Professional Organizations 12Cross-Functional and Interorganizational Linkages 131.4 Employability Skills 14Critical Thinking 14Collaboration 15Knowledge Application and Analysis 15Information Technology Application and ComputingSkills 151.5 Purpose and Organization of This Book 15Chapter Summary 17Key Terms 17Discussion Questions 17Problems 17Case Study 18References 192 Operations and Supply ChainStrategies 20viIntroduction 222.1 Elements of the Business 222.2 Strategy 222.3 Operations and Supply Chain Strategies 25Customer Value 26Four Performance Dimensions 27Trade-Offs among Performance Dimensions 29Order Winners and Order Qualifiers 29Stages of Alignment with the Business Strategy 30Core Competencies in Operations and SupplyChains 32Chapter Summary 33Key Formula 34Key Terms 34Solved Problem 34A01 BOZA0607 05 SE FM.indd 6Discussion QuestionsProblems 36Case Study 38References 3936PART IIEstablishing the OperationsEnvironment 403 Process Choice and Layout Decisionsin Manufacturing and Services 40Introduction 413.1 Manufacturing Processes 42Production Lines and Continuous FlowManufacturing 43Job Shops 44Batch Manufacturing 45Fixed-Position Layout 45Hybrid Manufacturing Processes 453D Printing 46Linking Manufacturing Processes across the SupplyChain 47Selecting a Manufacturing Process 47The Product-Process Matrix 473.2 Product Customization within the Supply Chain 48Four Levels of Customization 48The Customization Point 483.3 Service Processes 51Service Packages 52Service Customization 52Customer Contact 53Service Positioning 56Services within the Supply Chain 573.4 Layout Decision Models 58Line Balancing 59Assigning Department Locations in FunctionalLayouts 62Chapter Summary 66Key Formulas 66Key Terms 67Solved Problem 67Discussion Questions 69Problems 70Case Study 72References 734 Business Processes 74Introduction 754.1 Business Processes 76Improving Business Processes 764.2 Mapping Business Processes 79Process Maps 79Swim Lane Process Maps 8217/11/17 4:47 PM

CONTENTS4.3 Managing and Improving Business Processes 84Measuring Business Process Performance 84Productivity 84Efficiency 86Cycle Time 87Benchmarking 88The Six Sigma Methodology 89Continuous Improvement Tools 914.4 Business Process Challenges and the SCOR Model 98How Standardized Should Processes Be? 98Business Process Reengineering (BPR) 99Coordinating Process Management Efforts across theSupply Chain 99The SCOR Model 99Chapter Summary 101Key Formulas 101Key Terms 102Solved Problem 102Discussion Questions 104Problems 104Case Study 106References 1075 Managing Quality108Introduction 1105.1 Quality Defined 1105.2 Total Cost of Quality 1135.3 Total Quality Management 114TQM and the Six Sigma Methodology 1175.4 Statistical Quality Control 117Process Capability 117Six Sigma Quality 120Control Charts 121Acceptance Sampling 127Taguchi’s Quality Loss Function 1295.5 Managing Quality across the Supply Chain 130ISO 9000 Family 130External Failures in the Supply Chain 131Chapter Summary 131Key Formulas 131Key Terms 133Using Excel in Quality Management 134Solved Problem 134Discussion Questions 135Problems 136Case Study 140References 1416 Managing Capacity142Introduction 1436.1 Capacity 144Measures of Capacity 144Factors That Affect Capacity 145Supply Chain Considerations 1456.2 Three Common Capacity Strategies 1456.3 Methods of Evaluating Capacity AlternativesCost 146Demand Considerations 149Expected Value 149Decision Trees 150A01 BOZA0607 05 SE FM.indd 7146Break-Even Analysis 152Learning Curves 153Other Considerations 1566.4 Understanding and Analyzing Process CapacityThe Theory of Constraints 157Waiting Line Theory 160Little’s Law 164Chapter Summary 166Key Formulas 166Key Terms 168Using Excel in Capacity Management 168Solved Problem 169Discussion Questions 170Problems 170Case Study 174References 174vii1576S Advanced Waiting Line Theory andSimulation Modeling 175Introduction 1766S.1 Alternative Waiting Lines 176Assumptions behind Waiting Line Theory 177Waiting Line Formulas for Three DifferentEnvironments 1776S.2 Simulation Modeling 181Monte Carlo Simulation 182Building and Evaluating Simulation Models withSimQuick 184Supplement Summary 187Discussion Questions 188Problems 188References 188PART IIIEstablishing Supply Chain Linkages7 Supply Management189189Introduction 1907.1 Why Supply Management Is Critical 191Global Sourcing 191Financial Impact 192Performance Impact 1947.2 The Strategic Sourcing Process 195Step 1: Assess Opportunities 195Step 2: Profile Internally and Externally 197Step 3: Develop the Sourcing Strategy 200Step 4: Screen Suppliers and Create SelectionCriteria 207Step 5: Conduct Supplier Selection 208Step 6: Negotiate and ImplementAgreements 2107.3 The Procure-to-Pay Cycle 212Ordering 212Follow-Up and Expediting 212Receipt and Inspection 212Settlement and Payment 213Records Maintenance 21317/11/17 4:47 PM

viii CONTENTS7.4 Trends in Supply Management 213Sustainable Supply 213Supply Chain Disruptions 214Chapter Summary 215Key Formulas 215Key Terms 215Solved Problem 216Discussion Questions 217Problems 217Case Study 219References 2208 Logistics 221Introduction 2238.1 Why Logistics Is C

Cecil Bozarth is Professor of Operations and Supply Chain Management at the Poole College of Management at N.C. State University, where he has received awards for teaching excellence at both the undergraduate and graduate levels. He is a for-mer chair of the Operations Management Division of the Academy of Management, and in 1999 was recognized by APICS as a subject matter expert (SME) in