Transcription

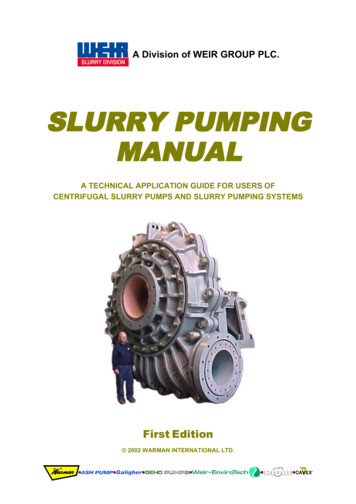

PUMPING SYSTEM CONTROLLERSTYPE FTASIMPLEX, DUPLEX, AND TRIPLEXPeerless Pump Company4851358Rev. 2/92

PUMPING SYSTEM CONTROLLERSTYPE FTASIMPLEX, DUPLEX, AND TRIPLEXA general Description of the FTA Controller is as follows:FTA610Simplex Motor ControllersFTA610-LF Peerless Standard Simplex ControllerA. NEMA 3R, single compartment, tions.B. One main disconnect with external handleand door interlock.C. Motor fuse block, fuses, motor starter, H-O-Aswitch and RUNNING pilot light for one motor.D. One 120 volt control circuit transformer withprimary and secondary fuses.E. Requires one incoming feeder circuit sized forthe motor horsepower and any other includedloads.FTA610-LG Peerless Simplex ControllerA. NEMA 3R, single compartment, tions.B. One main circuit breaker with externalhandle and door interlock.C. Motor starter, H-O-A switch and RUNNINGpilot light for one motor.D. One 120 volt control circuit transformer withprimary and secondary fuses.E. Requires one incoming feeder circuit sized forthe motor horsepower and any other includedloads.FTA620Duplex Motor ControllersFTA620-LF Peerless Standard Duplex ControllerA. NEMA 3R, single compartment, tions.B. One main disconnect with external handleand door interlock.C. Motor fuse block, fuses, motor starter, H-O-Aswitch and RUNNING pilot light for each oftwo motors.D. One 120 volt control circuit transformer withprimary and secondary fuses.E. Requires one incoming feeder circuit sized forthe motor horsepower and any other includedloads.FTA620-LA Peerless Duplex ControllerA. NEMA 3R, single compartment, tions.B. One main disconnect with external handleand door interlock.C. Motor circuit breakers (Std AIC), motorstarters, H-O-A switches and RUNNING pilotlight for each of two motors.4851358D. One 120 volt control circuit transformer withprimary and secondary fuses.E. Requires one incoming feeder circuit sized forthe motor horsepower and any other includedloads.2

FTA620-LG Peerless Standard Duplex ControllerA. NEMA 3R, single compartment, tion.B. Two motor circuit breakers (STD AIC) withexternal handles and door interlocks.C. Motor starters, H-O-A switches and RUNNINGpilot lights for each of two motors.D. One 120 volt control circuit transformer withfused primary and secondary.E. Requires two incoming feeder circuits, eachsized for its assigned motor horsepower andany other included loads.FTA620-LM Peerless Duplex Pump ControllerA. NEMA 3R, single compartment, tions.B. Two disconnect switches with externalhandle and door interlock.C. Motor fuse blocks, fuses, starters, H-O-Aswitches and RUNNING pilot lights for each oftwo motors.D. One 120 volt control circuit transformer withfused primary and secondary.E. Requires two incoming feeder circuits, eachsized for its assigned motor horsepower andany other included loads.FTA630Triplex Motor ControllersFTA630-LF Peerless Standard Triplex Pump ControllerA. NEMA 3R, single compartment, tions.B. One main disconnect with external handleand door interlock.C. Motor fuse blocks, fuses, motor starters, H-OA switch and RUNNING pilot light for each ofthree motors.D. One 120 volt control circuit transformer withfused primary and secondary.E. Requires one incoming feeder circuit sized forthe total motor horsepower and any otherincluded loads.FTA630-LA Peerless Triplex Pump ControllerA. NEMA 3R, single compartment, tions.B. One main disconnect with external handleand door interlock.C. Motor circuit breakers (Std AIC), motorstarters, H-O-A switches and RUNNING pilotlights for each of three motors.D. One 120 volt control circuit transformer withfused primary and secondary.E. Requires one incoming feeder circuit sized forthe total motor horsepower and any otherincluded loads.FTA630-LG Peerless Triplex Pump ControllerA. NEMA 3R, single compartment, tions.B. Three motor circuit breakers (STD AIC)with external handles and door interlocks.C. Motor starters, H-O-A switches and RUNNINGpilot light for each of three motors.FTA630-LM Peerless Triplex Pump ControllerA. NEMA 3R, single compartment, tions.B. Three disconnect switches with externalhandle and door interlock.C. Motor fuse blocks, fuses, motor starters, H-OA switches and RUNNING pilot light for eachof three motors.D. One 120 volt control circuit transformer withfused primary and secondary.E. Requires three incoming feeder circuits, eachsized for its assigned total motor horsepowerand any other included loads.D. One 120 volt control circuit transformer withfused primary and secondary.E. Requires three incoming feeder circuits, eachsized for its assigned total motor horsepowerand any other included loads.34851358

OPERATION DESCRIPTION OF THE FTACONTROLLER IS AS FOLLOWS:INSTALLATION: Before installation, check the controllerhorsepower, voltage and phase information to see that itagrees with the incoming power available and pumpingequipment supplied. Check system pressure to makesure it is compatible with the controller. See “SelectionData Sheet” for “options” and design parameters ofcontroller. If not compatible, contact the pump supplierand do not proceed with installation. The controllerelectrical specifications are located on a silver and blackidentification plate mounted inside the controller door.the specified line voltage and has two fuses located in itsprimary circuit. The 120 volt output of the transformer isalso fused and connected to terminals 2 and 3 of thecontrol circuit. 120 volt power is available to the controlcircuit whenever the disconnect switch is “ON”.CAUTION: Controllers may be supplied with automaticoperating devices such as pressure switches oftransducers, timers and alarms. These devices must be“SET” before attempting operation. No inspection,service or maintenance work should be attempted on thepumps, motors or controls without first turning thedisconnect switch “OFF”. The FTA Controller has thesystem pressure, delay on start and minimum runtimbers located in an electric sequencing control. Referto Instructions: Electronic Sequencing Control,bulletin FTA 461 for these adjustments which is includedin this manual.Check to see that the disconnect switch and Hand-OffAutomatic (H-O-A) switches are “OFF” prior toinstallation. Check inside the controller for bolts, nutsand electrical connections which may have loosened orbeen damaged during shipment.The controller was shipped with dual element fuses orcircuit breakers. Replacement fuses or circuit breakersshould be of the same type, current and voltage rating.Adequately sized wiring, based upon National ElectricCode requirements, is to be connected to the top of thedisconnect switch and between the overload relays andthe individual pump motors.After electronic sequencing control settings arecompleted, the FTA Controller may be placed inmanual or automatic position.MANUAL OPERATION: Controllers are furnished withan individual H-O-A switch for each pump motor. Eitherone or multiple pumps may be run manually by turningtheir individual selector switches to “HAND”. They maybe stopped by turning the switches to “OFF”. Controllersequipped with one of more alarms and shutdown optionsmay be prevented from operating due to the alarmactuation. Refer to the appropriate alarm option for theiroperation and adjustment.AUTOMATIC OPERATION: Automatic operation isaccomplished by turning both H-O-A switches to “AUTO:Equipment operation is determined by the type ofoptions included in the controller. Refer to options 4through 65.1 for description.OPTIONS, GENERAL: Controllers are supplied withoptions which meet pumping systems requirements.START-UP: Energize the incoming power to thecontroller by turning the disconnect switch “ON”.CAUTION: Measure the line voltage at the disconnectswitch and confirm that the voltage readings between allthree line phases are equal and agree with the controllernameplate rated voltage.Turn the disconnect switch “OFF”.Close and secure the enclosure door with the lockingdoor handle. Confirm the selectors switches are “OFF”then turn the disconnect switch handle “ON”.Refer to the pump instruction manual for the properprocedure for checking pump motor rotation. When thatprocedure is complete, motor rotation may be checkedby momentarily turning the individual H-O-A selectorswitches to “HAND”. Motor rotation may be reversed byfirst turning the disconnect switch “OFF”, opening theenclosure door, and reversing two of the three motorleads at the point where they connect to the overloadrelay. Confirm correct rotation by securing the enclosuredoor, turning the disconnect switch “ON” and energizingthe motors using the “HAND” position. When correctmotor rotation has been established, follow the pumpinstruction manual procedure for returning the pumps toan operable condition.REFER TO THE SELECTION DATA SHEET FOROPTIONS SUPPLIED WITH THIS CONTROLLER. Thefunctional description of each option is located by itsnumerical designation. The wiring diagrams furnished forthis controller will provide the proper instructions for fieldinstallation and trouble-shooting of the controller. Also,options supplied are stamped on inside of enclosuredoor.With the incoming power “ON” and pump rotationverified, the controller is ready for initial start-upoperation. Consult the pump installation instructionmanual to see that the pumps and system piping areready for proper operation.2. Motor overload device sizes supplied in magneticstarters are furnished in accordance with the fullload ampere ratings for motors as specified by thecorrect National Electric Code.The control circuit power for sequencing and alarmfunctions is provided by a 120 volt control circuittransformer connected between L1 and L2 on LOADside of disconnect switch. The transformer is sized for4851358NOTES FOR SIMPLEX, DUPLEX AND TRIPLEXCONTROLLERS:1. All controls are furnished in accordance with theNational Electric Code.43. For pump systems where the pump may be run atshutoff, it is recommended that a temperaturecontrolled purge valve be ordered for the pump.Failure to comply with this recommendation will voidequipment warranty.

OPTIONS: PUMPING SYSTEM CONTROLLERSPEERLESS PUMP TYPE FTAOPTIONNO.OPTION NAMEDESCRITPTION4NEMA 4 water-tightType 4 enclosures are intended for indoor or outdoor use primarily to provide a degreeof protection against windblown dust and rain, splashing water and hose directedwater. They are not intended to protect against internal icing. Enclosures are paintedsteel.12NEMA 12 outlightenclosureType 12 enclosures are intended for indoor use primarily to provide a degree ofprotection against dust, falling dirt, and dripping noncorrosive liquids. They areintended to provide protection against internal icing.13Thermostat andanti-condensationspace heaterSpace heater, thermostat and line circuit breaker mounted in controller and wired toterminal strip for connection to external power source. Specify 120 or 240V, 1 phasepower.14Humidistat andanti-condensationspace heaterSpace heater, humidistat and line circuit breaker mounted in controller and wired toterminal strip for connection to external power source. 120 or 240V, 1 phase power.15External overloadreset pushbuttonReset pushbutton mounted through controller door for external operation of motoroverload relays.18Floor mountingfeetExternal mounting feet, factory installed on standard wall mount type enclosure. Feetadd 18 inch additional height to controller. Feet are painted steel.OPTIONNO.DESCRIPTIONSEQUENCING OPERATIONSOPTION NAME20Manual alternation(Duplex)Pump lead-lag status is determined by manual selector switch mounted on thecontroller.20.1Manual alternation(Triplex)Pumps 1 and 2 lead-lag status is determined by a 2-position manual selector switchmounted on the controller.20.2Manual alternation(Triplex)Pumps 2 and 3 lead-lag status is determined by a 2-position manual selector switchmounted on the controller.20.3Manual sequencealternation(Triplex)Pumps lead-lag status is determined by 3-position selector switch mounted oncontroller for alternating pumps as follows: 1-2-3, 2-3-1, 3-1-2.24 hour clockalternation(Duplex)Clock motor driven alternator switches pump lead-lag status once each 24 hours.23.124 hour clockalternation (Triplex)Clock motor driven alternator switches pump lead-lag status of pumps 1 and 2 onceeach 24 hours.23.224 hour clockalternation (Triplex)Clock motor driven alternator switches pump lead-lag status of pumps 2 and 3 onceeach 24 hours.2348513585

OPTIONS: PUMPING SYSTEM CONTROLLERSPEERLESS PUMP TYPE FTAOPTIONNO.DESCRIPTIONSEQUENCING OPERATIONSOPTION NAME23.324 hour clockalternation (Triplex)Pumps lead-lag status changes every 24 hours by clock motor driven alternator asfollows: 1-2-3, 2-3-1, 3-1-2. Changes once every 24 hours.247 day clock (sametime, any day)alternation (Duplex)Clock motor driven alternator switches pump lead-lag status at one specified time onany of 7 days.24.17 day clock (sametime, any day)alternation(Triplex)Clock motor driven alternator switches pump lead-lag status of pumps 1 and 2 at onespecified time on any of 7 days.24.27 day clock (sametime, and day)Alternation (Triplex)Clock motor driven alternator switches pump lead-lag status of pumps 2 and 3 at onespecified time on any of 7 days.24.37 day clock (sametime, any day)alternation (Triplex)Pump lead-lag status changes due to 7-day clock motor alternator. Alternates pumpsas follows: 1-2-3, 2-3-1, 3-1-2. Changes are specified time on any of 7 days.257 day programmedClock (any time, anyday) alternation(Duplex)Clock motor driven alternator

FTA630-LM Peerless Triplex Pump Controller A. NEMA 3R, single compartment, raintight enclosure suitable for indoor/outdoor applications. B. Three disconnect switches with external handle and door interlock. Motor fuse blocks, fuses, motor starters, H-O-A switches and RUNNING pilot light for each of three motors. D. One 120 volt control circuit transformer with fused primary and secondary. E .